Lithium-sulfur battery negative electrode and lithium-sulfur battery comprising same

A lithium-sulfur battery and negative electrode technology, applied in the field of chemical power sources, can solve the problems of loss of active material and limited effect, and achieve the effects of improving sulfur utilization rate, improving cycle performance and service life, and suppressing shuttle effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

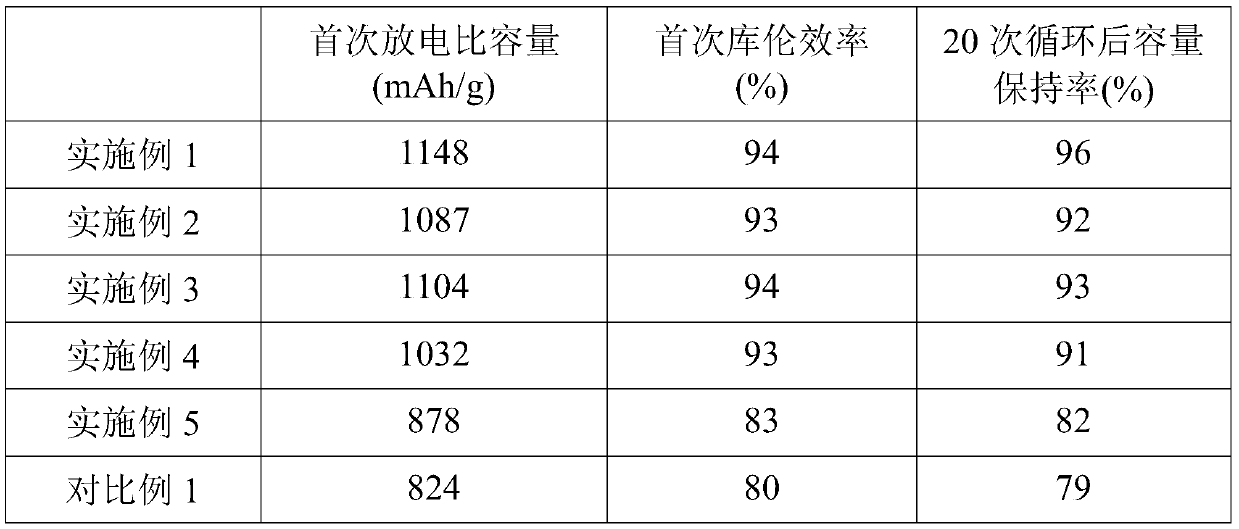

Examples

Embodiment 1

[0018] Add 6g of trichlorosilane, 15g of methanol and 20g of solvent benzene into the stirred reactor, heat and dissolve under stirring for reaction. After the reaction, heat distillation is carried out, the solvent is distilled off and recovered for recycling, and the remaining product is cooled to obtain trimethoxysilane. In a 250ml four-necked bottle, take 15g of trimethoxysilane, 15g of 1,1,2-trifluoro-1-butene and 1g of initiator, under the protection of dry nitrogen, keep stirring, and heat up to 40°C , kept for 2h, and then cooled to room temperature to obtain the addition reactant. In a 2L three-necked flask equipped with a condenser, a stirrer and a thermometer, add 20 g of the obtained addition reactant and 10 g of thiourea for reaction, reflux at 110 °C for 10 h, and when cooled to 60 °C, feed ammonia gas, when When the reaction is no longer exothermic, the ammonia gas is stopped. Then filter, distill the filtrate under reduced pressure, and take the 85°C / 0.80kPa ...

Embodiment 2

[0022] Add 4.5g of trichlorosilane, 10g of methanol and 15g of solvent benzene into the stirred reactor, heat and dissolve under stirring for reaction. After the reaction, heat distillation is carried out, the solvent is distilled off and recovered for recycling, and the remaining product is cooled to obtain trimethoxysilane. In a 250ml four-neck bottle, take 12.5g trimethoxysilane, 12.5g 1,1,2-trifluoro-1-butene and 0.75g initiator, under the protection of dry nitrogen, keep stirring, and heat up Heat at 40°C for 2 hours, then cool to room temperature to obtain the addition reactant. In a 2L three-necked flask equipped with a condenser, a stirrer and a thermometer, add 17.5 g of the obtained addition reactant and 8 g of thiourea to react, reflux at 105 ° C for 9 h, and when cooled to 60 ° C, feed ammonia gas, When the reaction is no longer exothermic, the ammonia gas is stopped. Then filter, distill the filtrate under reduced pressure, and take the 83.5°C / 0.75kPa fraction. ...

Embodiment 3

[0026] Add 3g of trichlorosilane, 5g of methanol and 10g of solvent benzene into the stirring reaction kettle, heat and dissolve under stirring for reaction. After the reaction, heat distillation is carried out, the solvent is distilled off and recovered for recycling, and the remaining product is cooled to obtain trimethoxysilane. In a 250 ml four-neck bottle, take 10 g of trimethoxysilane, 10 g of 1,1,2-trifluoro-1-butene and 0.5 g of initiator, under the protection of dry nitrogen, keep stirring, and heat up to 30 ℃, keep warm for 1h, and then cool to room temperature to obtain the addition reactant. In a 2L three-necked flask equipped with a condenser, a stirrer and a thermometer, add 15 g of the obtained addition reactant and 6 g of thiourea for reaction, reflux at 100 ° C for 8 h, and when cooled to 60 ° C, feed ammonia gas. When the reaction is no longer exothermic, the ammonia gas is stopped. Then filter, distill the filtrate under reduced pressure, and take the 82°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com