A synthesis method of petal-shaped magnesia-aluminum spinel nanohollow spheres with high specific surface area

A technology of magnesium-aluminum spinel and high specific surface, which is applied in the field of nano-powder synthesis, can solve problems such as environmental pollution, complex process, and small specific surface area, and achieve good dispersion, simple process, and high particle purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

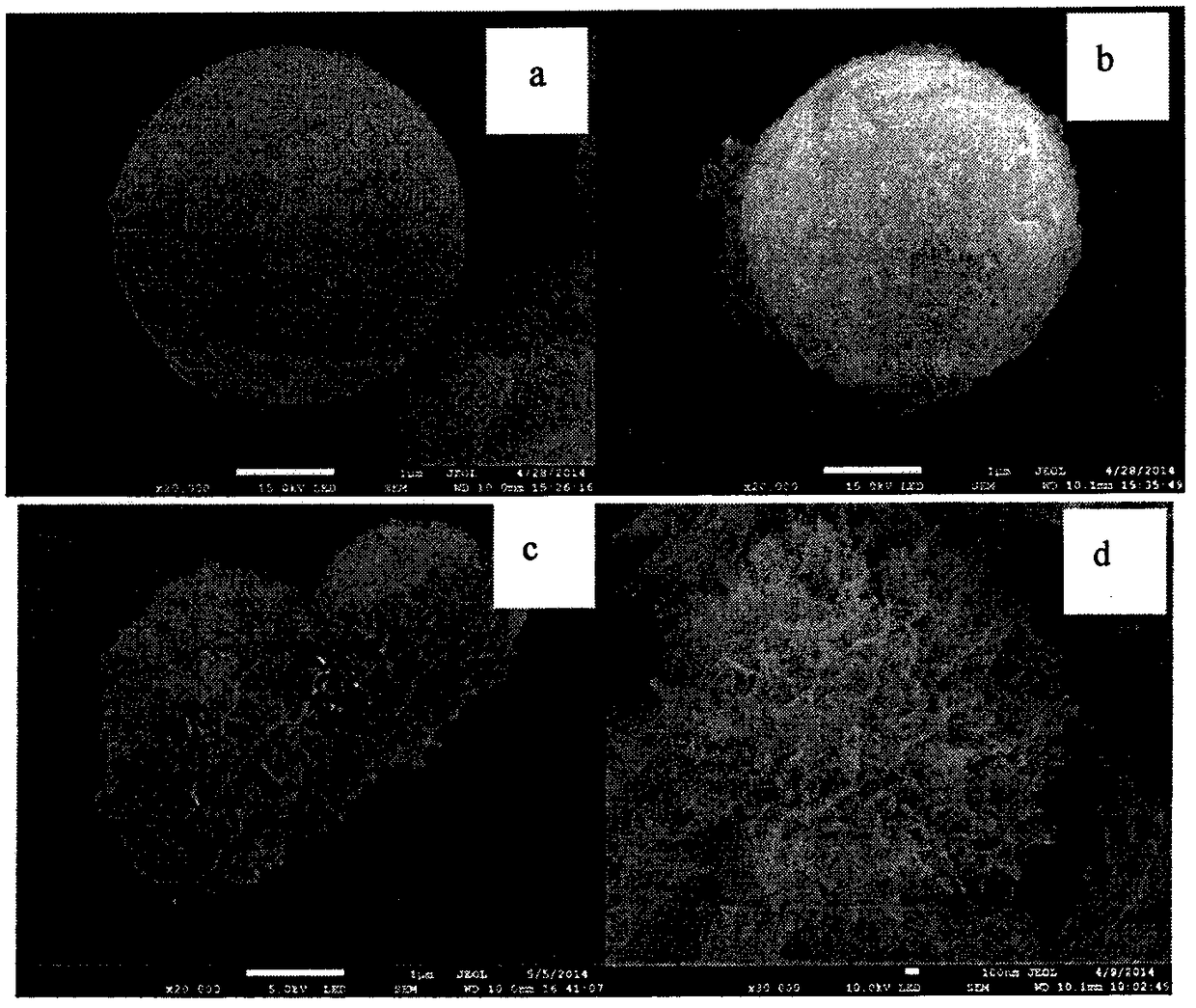

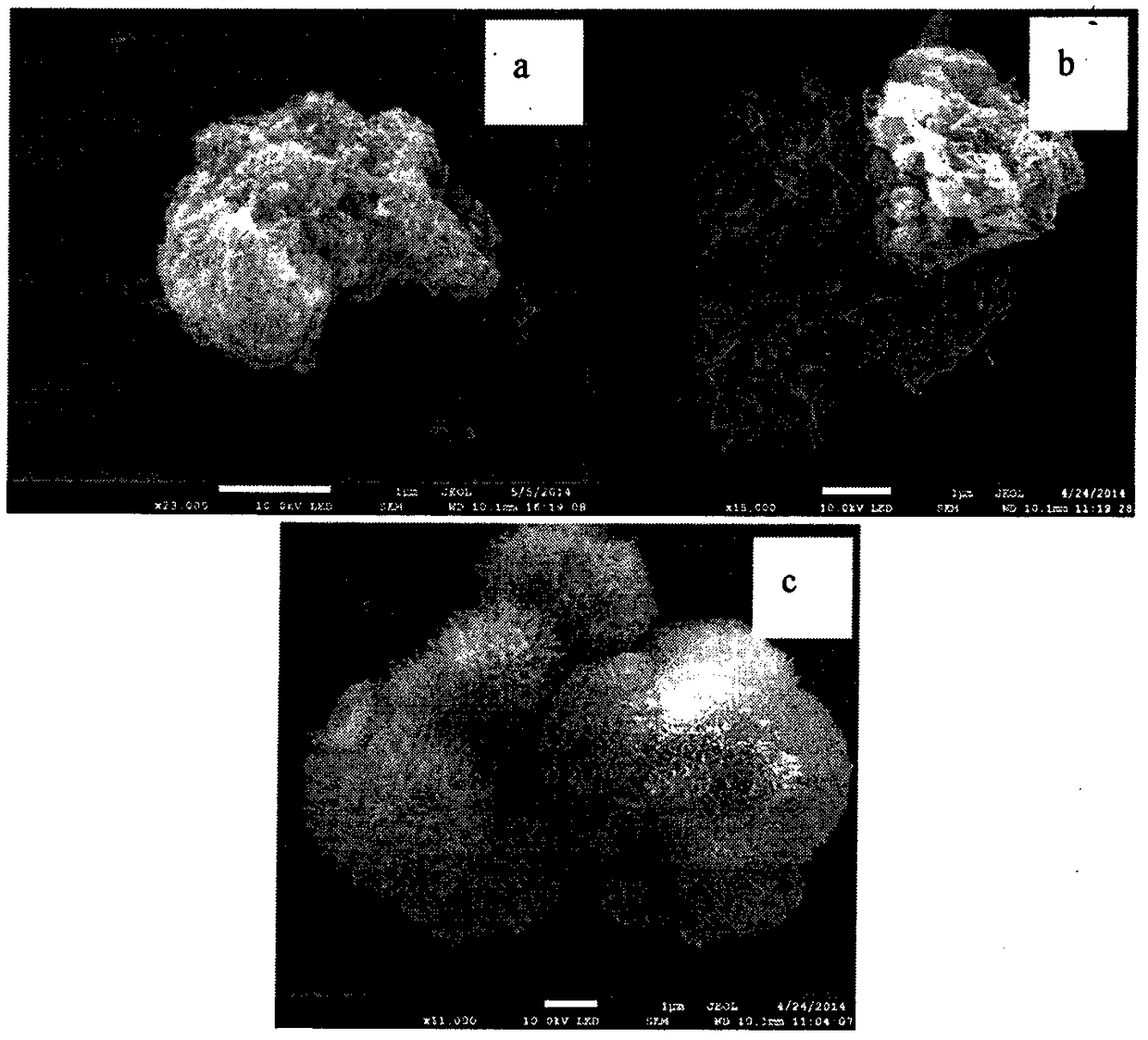

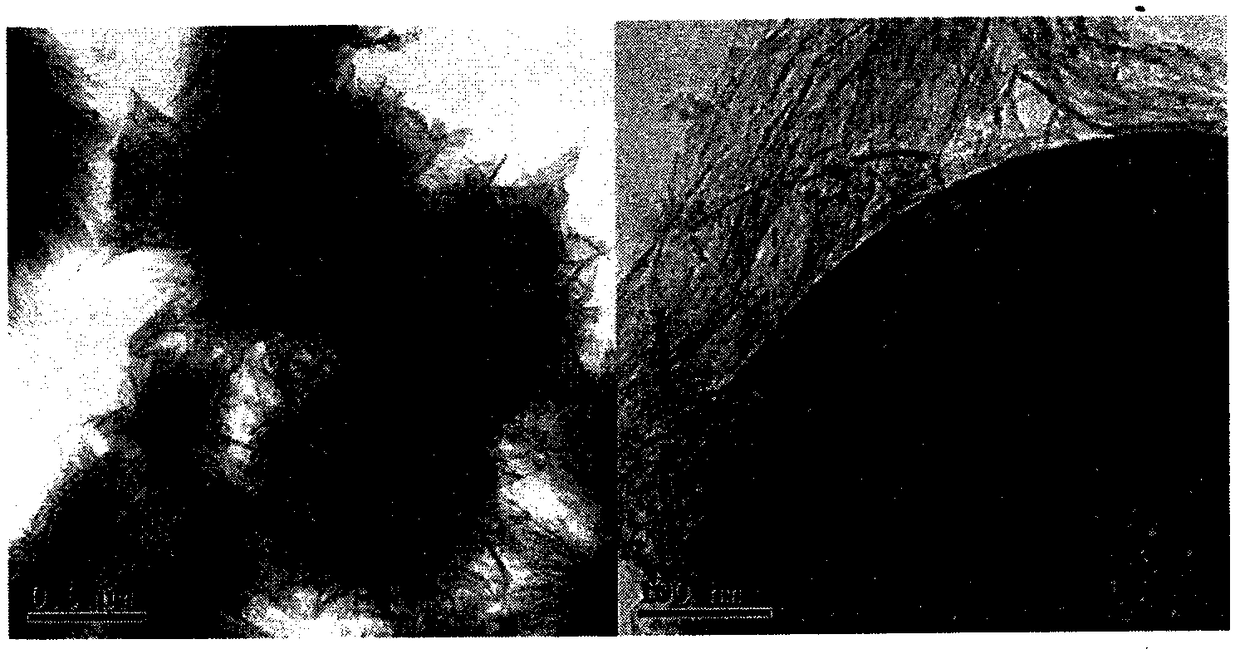

Image

Examples

Embodiment 1

[0028] 1) Preparation of carbon spheres

[0029] 1.1) Using glucose as raw material, according to the concentration of 2g glucose / 10mL water, dissolve 8g glucose in 40mL deionized water to form a clear solution A;

[0030] 1.2) Transfer the solution A obtained in step 1.1) to a hydrothermal kettle and react at 170°C for 24 hours; naturally cool the hydrothermal kettle to room temperature to obtain a black or dark brown suspension B;

[0031] 1.3) Wash the suspension B obtained in step 1.2) with deionized water and ethanol, centrifuge, and disperse to obtain a black or dark brown precipitate;

[0032] 1.4) The precipitate obtained in step 1.3) was dried at 60° C. for 12 hours to obtain carbon sphere particles.

[0033] 2) Dissolve 0.4g of carbon spheres in 72mL of deionized water, and ultrasonicate for 30 minutes at room temperature to obtain carbon sphere suspension solution C;

[0034] 3) Weighing the metal salt, the mass ratio of the carbon spheres in step 2) to the metal ...

Embodiment 2

[0050] 1) Preparation of carbon spheres

[0051] 1.1) Using glucose as raw material, according to the concentration of 2g glucose / 10ml water, dissolve 8g glucose in 40ml deionized water to form a clear solution A;

[0052] 1.2) Transfer the solution A obtained in step 1.1) to a hydrothermal kettle and react at 170°C for 24 hours; naturally cool the hydrothermal kettle to room temperature to obtain a black or dark brown suspension B;

[0053] 1.3) Wash the suspension B obtained in step 1.2) with deionized water and ethanol, centrifuge, and disperse to obtain a black or dark brown precipitate;

[0054] 1.4) The precipitate obtained in step 1.3) was dried at 60° C. for 12 hours to obtain carbon sphere particles.

[0055] 2) Weigh 0.4g of carbon spheres and dissolve them in a mixed solution of 36ml of deionized water and 36ml of ethylene glycol, and ultrasonicate for 30min at room temperature to obtain carbon sphere suspension solution C;

[0056] 3) Weighing the metal salt, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com