The preparation method of binary rus2 heterogeneous catalyst

A technology of heterogeneous catalysts and preparation steps, applied in the direction of molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of harsh reaction conditions, high energy consumption, unsuitable for industrial production, etc., and achieve mild reaction conditions , high purity, simple and feasible method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

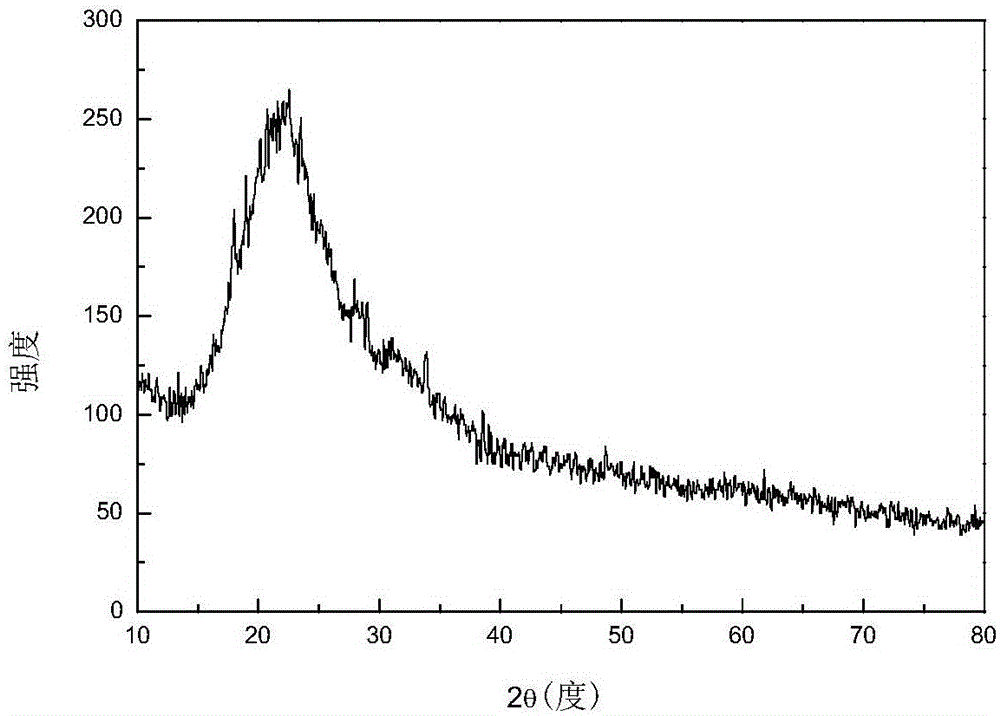

[0017] Example 1: Binary RuS 2 / ZSM-5 catalyst preparation and its hydrodesulfurization activity. Accurately weigh 15mg of RuCl 3 ·3H 2 O and 485mg of ZSM-5 were placed in a 25mL single-necked round bottom flask (Ru (wt%) was 1.16%), 10mL of ethanol was added, stirred at room temperature for 24h and then vacuum-dried. In a stirred autoclave, add the above-mentioned catalyst that has been dried, then add 17mL cyclohexane and 3mL carbon disulfide (wherein cyclohexane is the solvent, and carbon disulfide is the sulfur source in the pre-sulfurization), close the reactor, and use nitrogen Replace the air in the reactor for at least three times, then replace the nitrogen in the reactor with hydrogen for at least three times, then adjust the hydrogen pressure in the reactor to 2MPa, perform rapid stirring, heat to 200°C (programmed temperature rise 3°C / min) and maintain for 4h . After the reaction, the autoclave was cooled to room temperature, washed several times with ethanol, a...

Embodiment 2

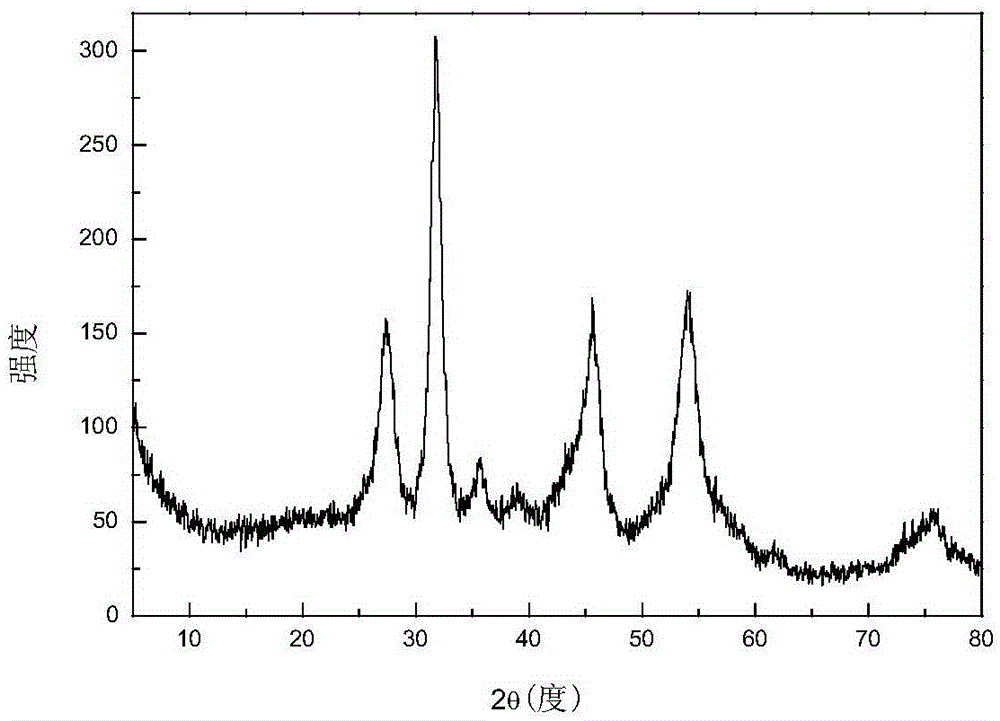

[0020] Example 2: Binary RuS 2 / SBA-15 catalyst preparation and its hydrodesulfurization activity. Accurately weigh 15mg of RuCl 3 ·3H 2 O and 485mg of SBA-15 were placed in a 25mL single-necked round bottom flask, 10mL of ethanol was added, then stirred at room temperature for 24h, and dried in a vacuum oven. Other conditions and method are with embodiment 1. The conversion rate of the prepared catalyst to thiophene is shown in Table 1.

Embodiment 3

[0021] Example 3: Binary RuS 2 / γ-Al 2 o 3 Catalyst preparation and its hydrodesulfurization activity. Accurately weigh 15mg of RuCl 3 ·3H 2 O and 485mg of γ-Al 2 o 3 Place in a 25mL single-necked round bottom flask, add 10mL of ethanol, then stir at room temperature for 24h, and dry in a vacuum oven. Other conditions and method are with embodiment 1. The conversion rate of the prepared catalyst to thiophene is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com