Nanometer tungsten oxide photocatalyst paper-base bamboo curtain manufacturing method and product thereof

A technology of nano-tungsten oxide and photocatalyst, which is applied in the direction of chemical instruments and methods, wood layered products, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of photocatalyst light conditions, large bandgap width of TiO2, etc. , the joint effect is not clear, etc., to achieve the effect of easy control of the crystal form, uniform distribution, and small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

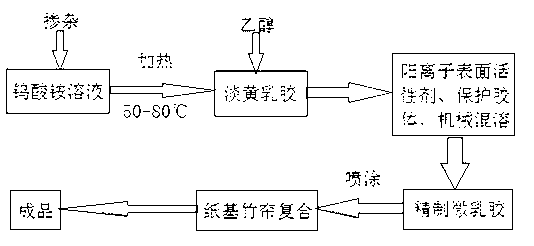

[0037] Preparation of nano-tungsten oxide photocatalyst water-based emulsion: heat 40% ammonium tungstate solution at 50°C and cool it down, then add ethanol to form the first emulsion; then add cationic surfactant to protect the colloid, and obtain it through mechanical miscible refining the second emulsion;

[0038] Preparation of paper-based bamboo curtains: composite paper-based fibers with bamboo curtains to obtain paper-based bamboo curtains;

[0039] Photocatalyst paper-based bamboo curtain: Spray the second latex liquid onto the paper-based bamboo curtain at a pressure of 0.2 MPa to form a film to obtain nano-tungsten oxide photocatalyst paper-based bamboo curtain.

[0040] The specific process can refer to figure 1 .

[0041] The parameters of the product are: the length of the bamboo curtain is 1.95m, the allowable error is plus or minus 20mm; the width is 1.5, the allowable error is plus or minus 10mm; squareness: diagonal difference <25mm; average gap <0.35mm;

...

Embodiment 2

[0047] Preparation of nano-tungsten oxide photocatalyst water-based emulsion: heat 80% ammonium tungstate solution at 80°C and cool it down, then add ethanol to form the first emulsion; then add cationic surfactant to protect the colloid, and obtain it through mechanical miscible refining the second emulsion;

[0048] Preparation of paper-based bamboo curtains: composite paper-based fibers with bamboo curtains to obtain paper-based bamboo curtains;

[0049] Photocatalyst paper-based bamboo curtain: Spray the second latex solution on the paper-based bamboo curtain under a pressure of 0.3 MPa to form a film to obtain nano-tungsten oxide photocatalyst paper-based bamboo curtain.

Embodiment 3

[0051] Preparation of nano-tungsten oxide photocatalyst water-based emulsion: heat 60% ammonium tungstate solution at 70°C and cool it down, then add ethanol to form the first emulsion; then add cationic surfactant to protect the colloid, and obtain it through mechanical miscible refining the second emulsion;

[0052] Preparation of paper-based bamboo curtains: composite paper-based fibers with bamboo curtains to obtain paper-based bamboo curtains;

[0053] Photocatalyst paper-based bamboo curtain: Spray the second latex liquid onto the paper-based bamboo curtain under a pressure of 0.25 MPa to form a film to obtain nano-tungsten oxide photocatalyst paper-based bamboo curtain.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com