Magnesium hydride nano particle and preparation method and application thereof

A nanoparticle, magnesium hydride technology, applied in the direction of alkali metal/alkaline earth metal/beryllium/magnesium hydride, etc., to achieve excellent hydrogen absorption and desorption kinetic properties, improve hydrogen absorption and desorption kinetic properties, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

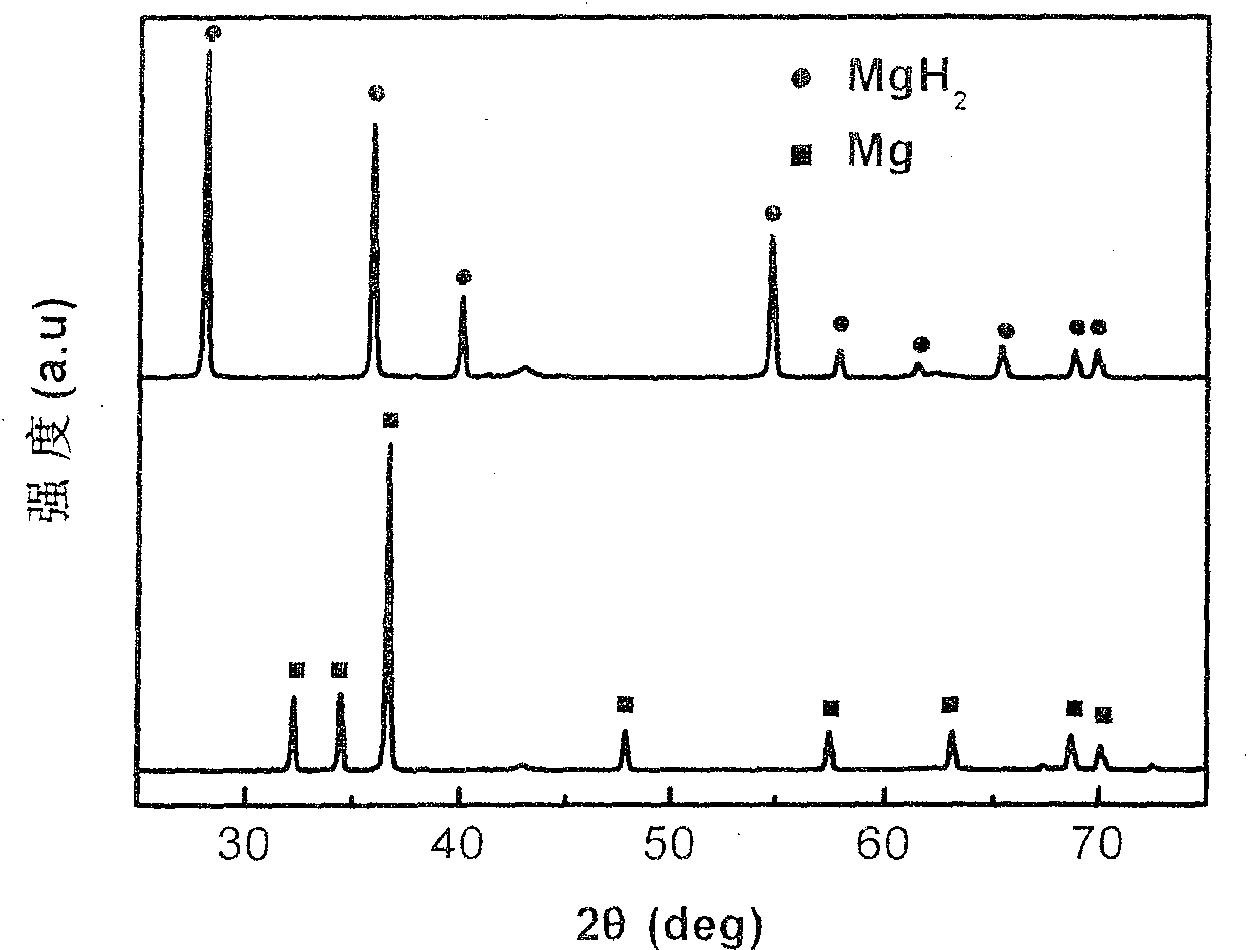

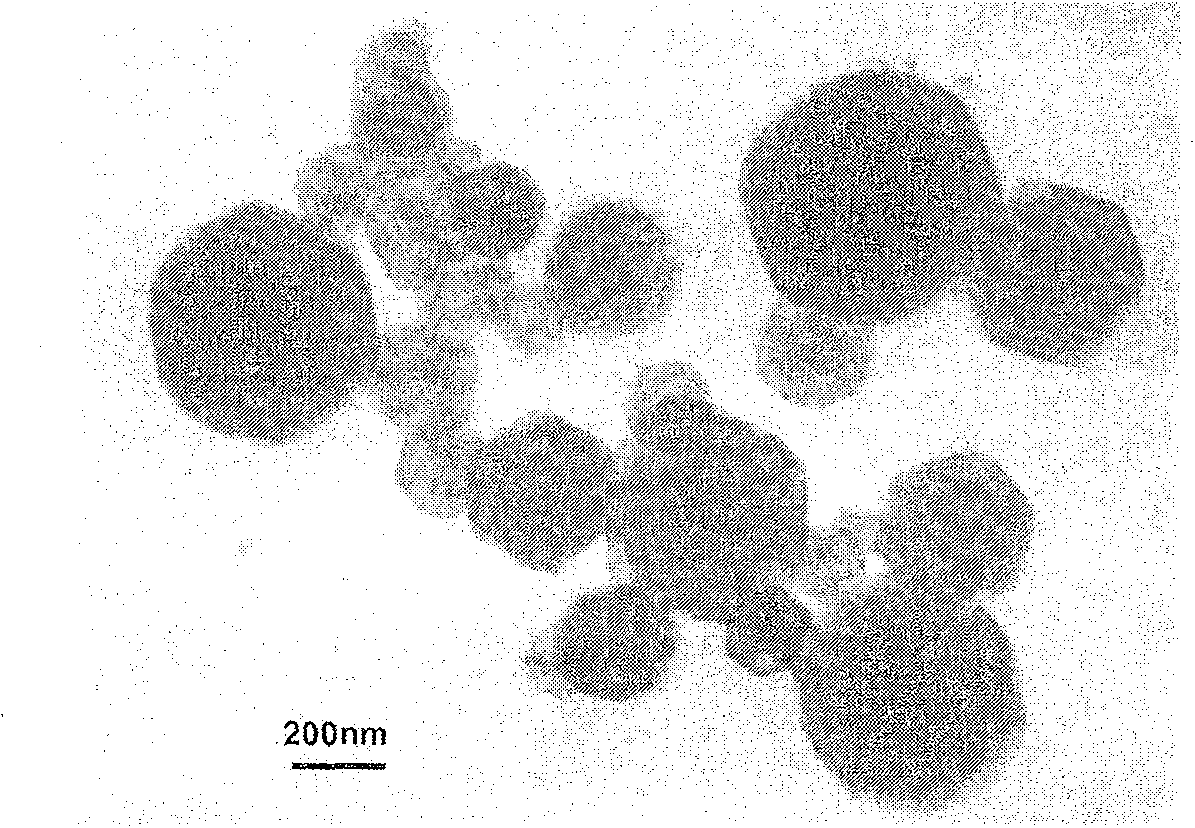

[0017] Embodiment 1, synthetic MgH 2 nanoparticles

[0018] (1) The magnesium block is placed in a hydrogen plasma arc heating furnace, and after vacuuming, under an Ar atmosphere with a total pressure of 0.8 bar, a DC arc plasma is applied to evaporate the magnesium by heating and condense to nanoparticles.

[0019] (2) Stop heating and vacuumize. After the system cools down, slowly pass air into the furnace for passivation, and take out the sample after 48 hours of passivation.

[0020] (3) Put the prepared Mg particles into a hydrogen reaction furnace. After the system is evacuated, heat to 400°C, activate for 1 hour, pass in 40bar hydrogen for 4 hours, and cool to room temperature to obtain a particle size of nanometer. magnesium hydride particles. Embodiment 2, synthetic MgH 2 nanoparticles

Embodiment 2

[0020] (3) Put the prepared Mg particles into a hydrogen reaction furnace. After the system is evacuated, heat to 400°C, activate for 1 hour, pass in 40bar hydrogen for 4 hours, and cool to room temperature to obtain a particle size of nanometer. magnesium hydride particles. Embodiment 2, synthetic MgH 2 nanoparticles

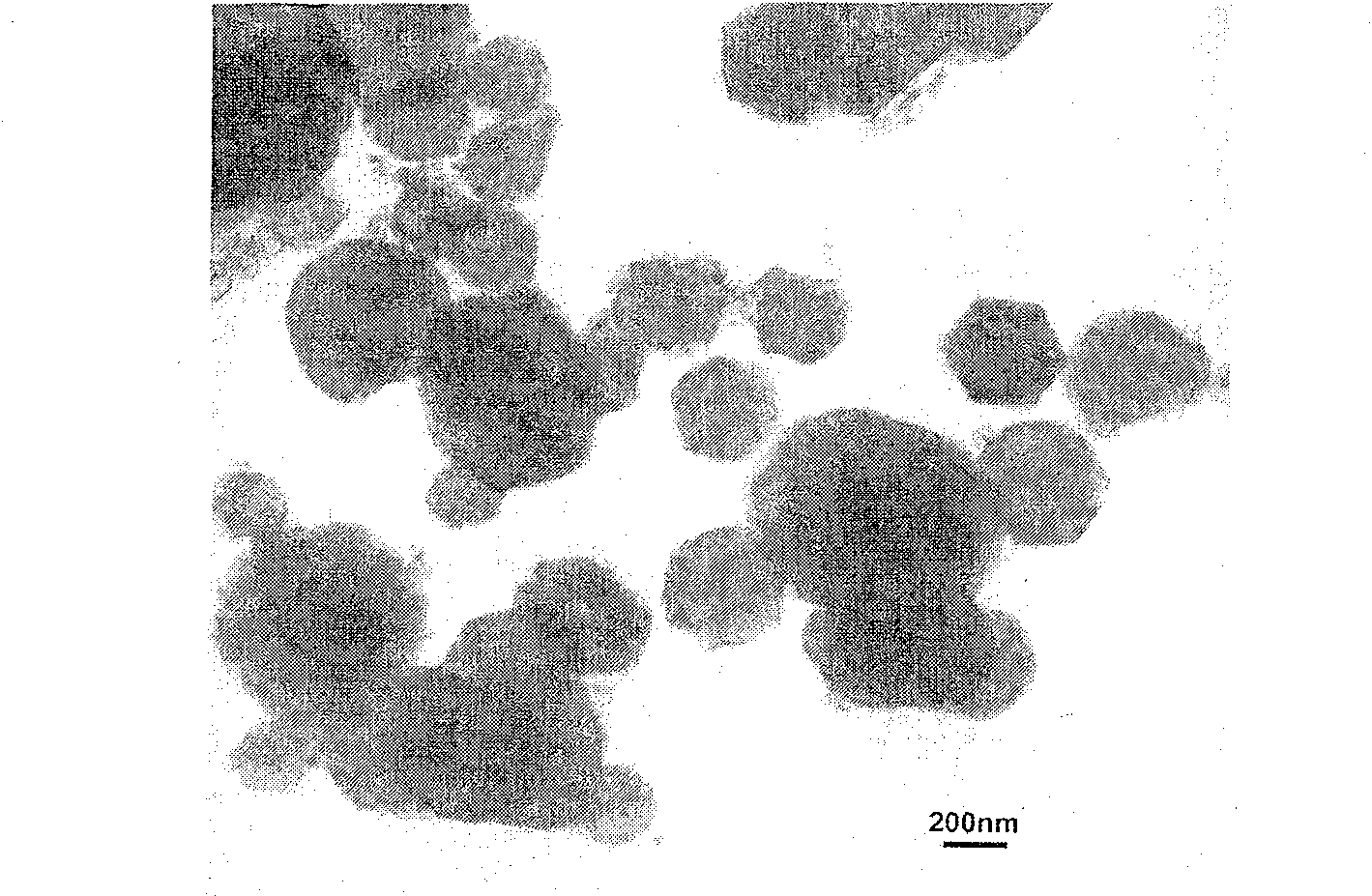

[0021] (1) Put the magnesium block in the hydrogen plasma arc heating furnace, and after vacuuming, the total pressure is 0.9bar in 40% N 2 Under a mixed atmosphere of Ar / Ar, DC arc plasma was applied to vaporize magnesium and condense it into nanoparticles.

[0022] (2) Stop heating and vacuumize. After the system cools down, slowly pass air into the furnace for passivation, and take out the sample after 48 hours of passivation.

[0023] (3) Put the prepared Mg particles into a hydrogen reaction furnace. After the system is evacuated, heat it to 350°C, activate it for 2 hours, pass in 10 bar hydrogen gas for 12 hours, and cool it to room temperature to obta...

Embodiment 3

[0023] (3) Put the prepared Mg particles into a hydrogen reaction furnace. After the system is evacuated, heat it to 350°C, activate it for 2 hours, pass in 10 bar hydrogen gas for 12 hours, and cool it to room temperature to obtain a particle size of nanometer. magnesium hydride particles. Embodiment 3, synthetic MgH 2 nanoparticles

[0024] (1) The magnesium block is placed in a hydrogen plasma arc heating furnace, and after vacuuming, the total pressure is 0.5bar in 40%H 2 Under a mixed atmosphere of Ar / Ar, DC arc plasma was applied to vaporize magnesium and condense it into nanoparticles.

[0025] (2) Stop heating and vacuumize. After the system cools down, slowly pass air into the furnace for passivation, and take out the sample after 48 hours of passivation.

[0026] (3) Put the prepared Mg particles into a hydrogen reaction furnace. After the system is vacuumed, heat it to 450°C, activate it for 1 hour, pass in 40bar hydrogen gas for 2 hours, and cool it to room temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com