Insulator anti-icing coating and preparation method thereof

A technology for insulators and waterproof coatings, which can be applied to radiation-absorbing coatings, coatings, etc., and can solve the problems of poor hydrophobicity, high cost of insulator structure, and poor effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

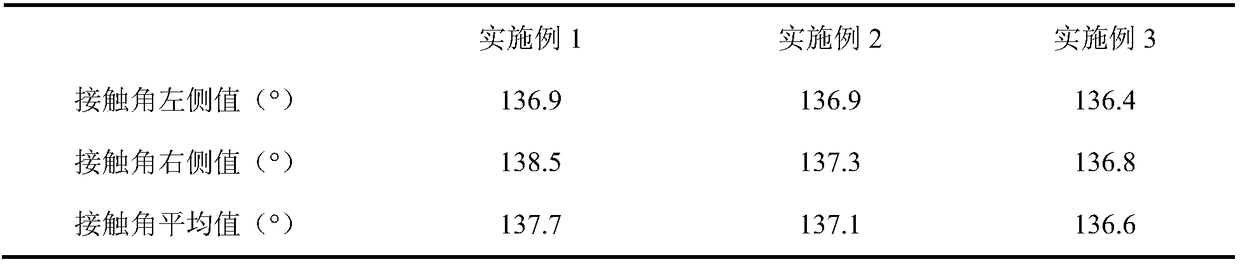

Examples

Embodiment 1-3

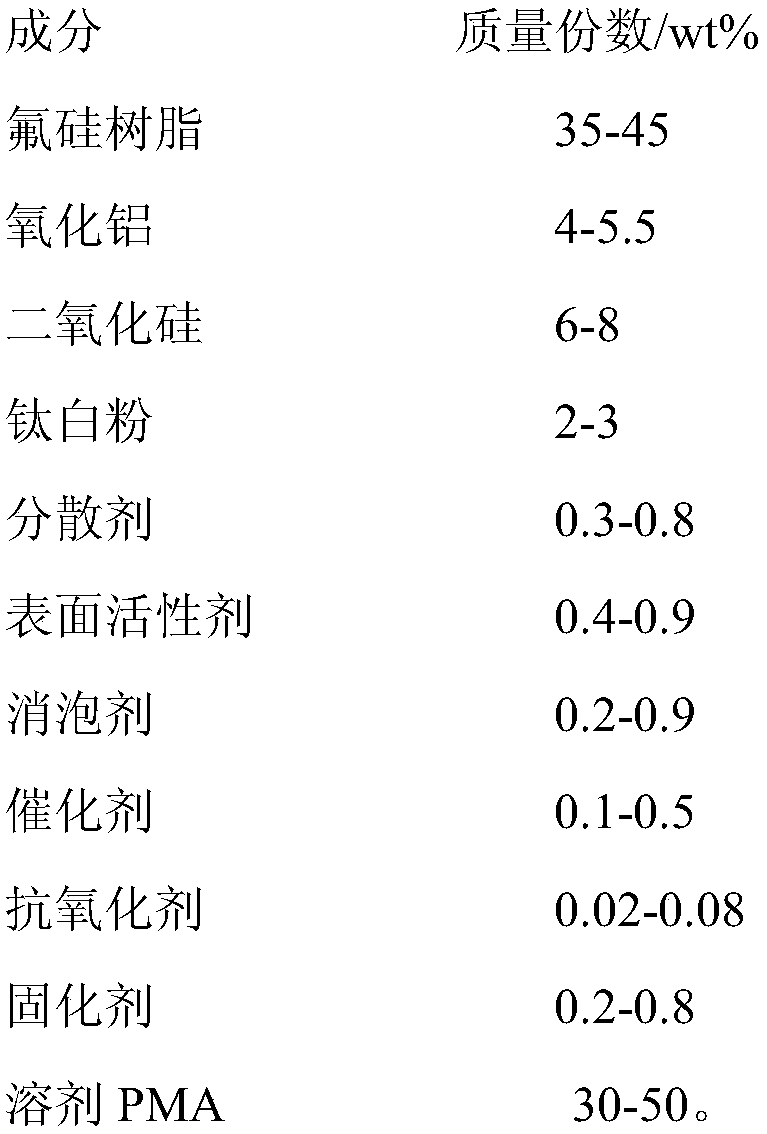

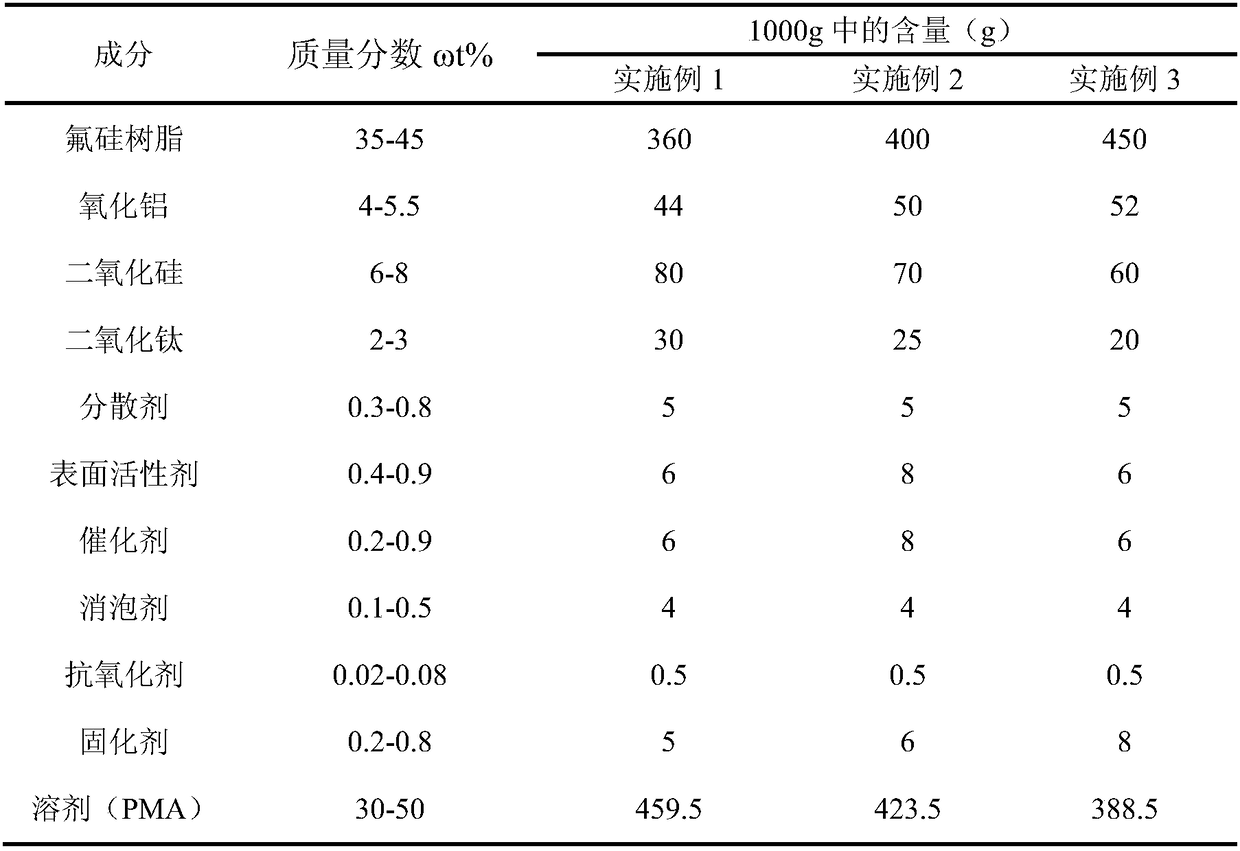

[0026] Each component mass fraction of embodiment 1-3 is shown in table 1 below, is prepared by 1000g:

[0027] Table 1

[0028]

[0029] The titanium dioxide is rutile nano-titanium dioxide, the aluminum oxide and the silicon dioxide are nanoscale, the dispersant is EFKA5010, the surfactant is sodium laurate, and the catalyst is dilaurate Butyl tin, described antioxidant is tert-butylhydroquinone, described curing agent is polyurethane, and solvent PMA refers to propylene glycol methyl ether acetate, and described defoamer selects Dow Corning defoamer for use.

[0030] The anti-icing coatings for insulators in Examples 1-3 are all prepared as follows:

[0031] Step 1. Weigh alumina, silicon dioxide and titanium dioxide respectively and place them in their respective beakers, place them in a blast drying oven, set a constant temperature of 105° to dry for 48 hours, add an appropriate amount of surfactants, and add anhydrous Add ethanol while stirring until it is completel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com