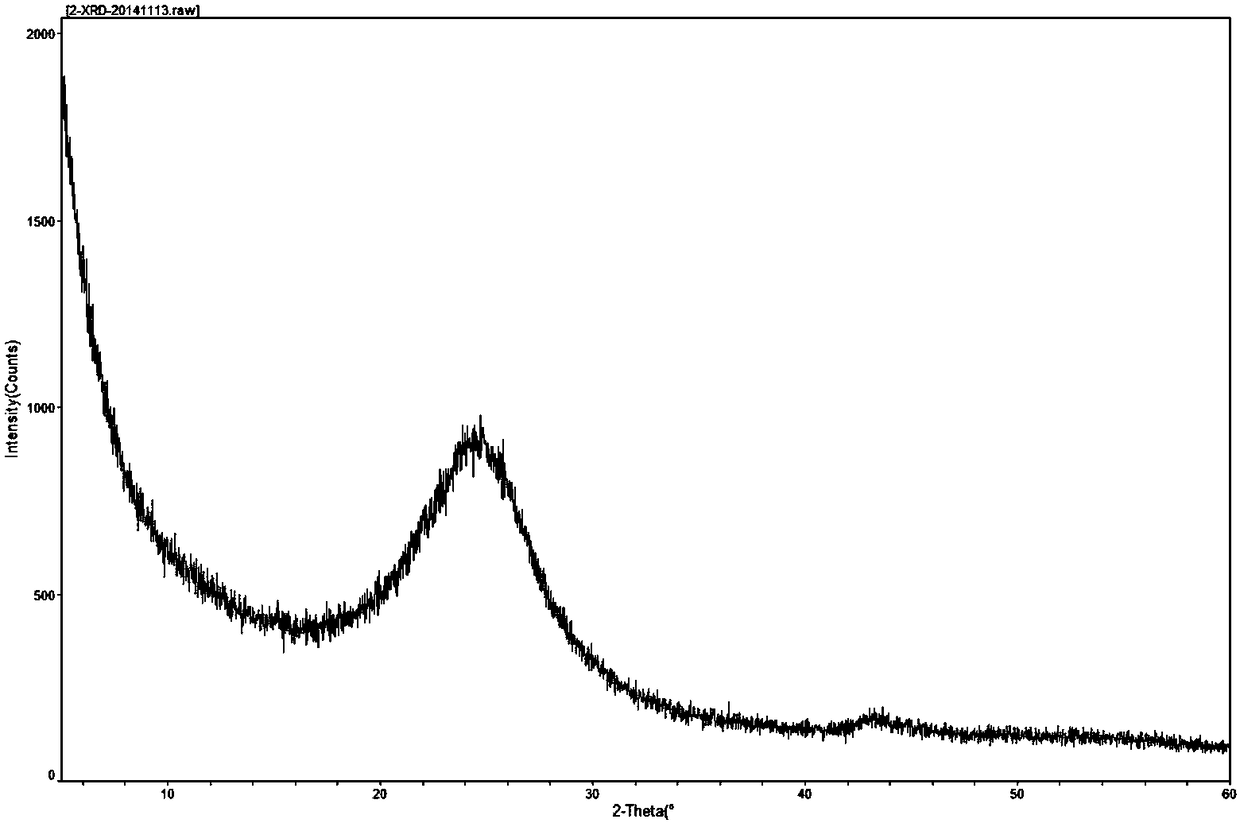

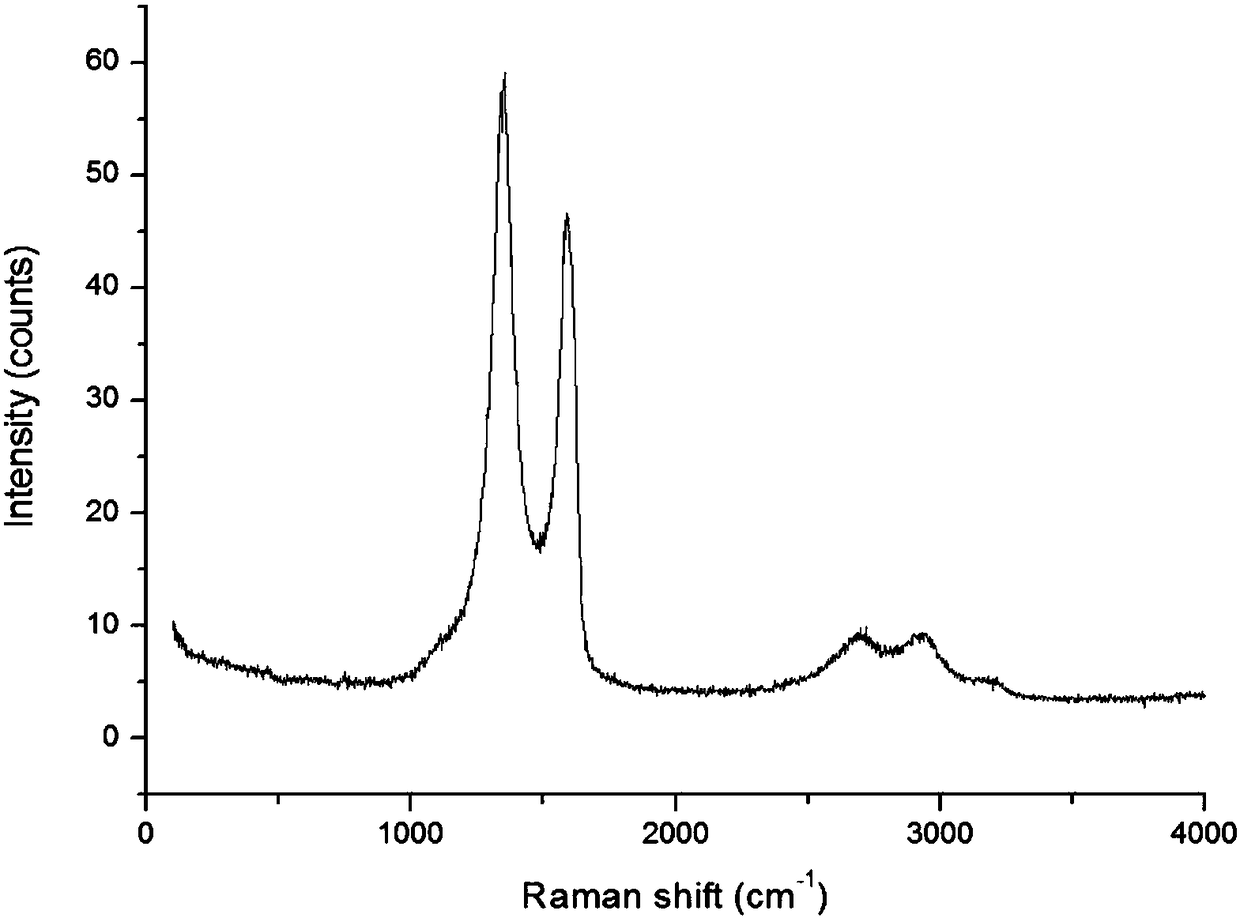

A kind of high saturation magnetization nano ferroferric oxide/graphene composite material with electromagnetic shielding function and preparation method thereof

A technology of ferroferric oxide and composite materials, which is applied in the field of high saturation magnetization nanometer ferroferric oxide/graphene composite materials and its preparation, can solve the problem of unfavorable broadband electromagnetic shielding materials, narrow electromagnetic shielding peak frequency range, material Problems such as particle size dispersion, to achieve good electromagnetic shielding performance, narrow particle size distribution, and stable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A kind of preparation method of nano ferroferric oxide / graphene composite material: comprise the following steps:

[0038] 1) Dissolve ferric salt, ferrous salt and urea in water to obtain mixed solution 1;

[0039] 2) Add reduced graphene oxide into water, ultrasonically disperse and stir to obtain a uniformly dispersed graphene suspension 2;

[0040] 3) Mix the above mixed solution 1 and suspension 2 evenly to obtain mixed solution 3, react mixed solution 3 at 120~180°C for 3~5h,

[0041] 4) Cool the product after the reaction in the previous step, wash it with ethanol solution, and dry it to a constant weight to obtain a nano-ferric oxide / reduced graphene oxide composite material.

[0042] Preferably, the molar ratio of ferric iron to ferrous iron in step 1) is 1-3:1.

[0043] Preferably, the mass ratio of urea to total iron salts in step 1) is 0.1-0.4:1.

[0044]Preferably, the concentration of iron ions in the mixed solution 1 in step 1) is 1-2.5 mmol / mL.

[00...

Embodiment 1

[0063] A method for preparing a nano-ferric oxide / graphene composite material with high saturation magnetization, comprising the steps of:

[0064] 1) Weigh 3g of ferrous chloride, 4.9g of ferric chloride and 2g of urea into a conical flask, add 30ml of deionized water, stir well, and obtain mixed solution 1.

[0065] 2) Weigh 0.1027g of reduced graphene oxide into a beaker, add 20ml of deionized water, ultrasonically disperse and vigorously stir for 0.5h at a stirring speed of 1500-1600rpm to obtain a uniformly dispersed graphene suspension 2.

[0066] 3) Mix solution 1 and suspension 2 evenly to obtain mixed solution 3.

[0067] 4) The mixed solution 3 was transferred to a hydrothermal reaction kettle, heated in an oven at 140° C. for 3 hours, the reaction kettle was taken out, and cooled to room temperature naturally. The product in the reaction kettle was taken out and washed by centrifugation with 50% ethanol solution for 2 to 3 times, and then dried in a vacuum oven at ...

Embodiment 2

[0069] A method for preparing a nano-ferric oxide / graphene composite material with high saturated chemical strength, comprising the steps of:

[0070] 1) Weigh 3g of ferrous chloride, 5.7g of ferric chloride and 2g of urea into a conical flask, add 30ml of deionized water, stir well, and obtain mixed solution 1.

[0071] 2) Weigh 0.1027g of reduced graphene oxide into a beaker, add 20ml of deionized water, ultrasonically disperse and vigorously stir for 0.5h at a stirring speed of 1200rpm, to obtain a uniformly dispersed graphene suspension 2.

[0072] 3) Mix solution 1 and suspension 2 evenly to obtain mixed solution 3.

[0073] 4) The mixed solution 3 was transferred to a hydrothermal reaction kettle, heated in an oven at 140° C. for 3 hours, the reaction kettle was taken out, and cooled to room temperature naturally. The product in the reaction kettle was taken out and washed by centrifugation with 50% ethanol solution for 2 to 3 times, and then dried in a vacuum oven at 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com