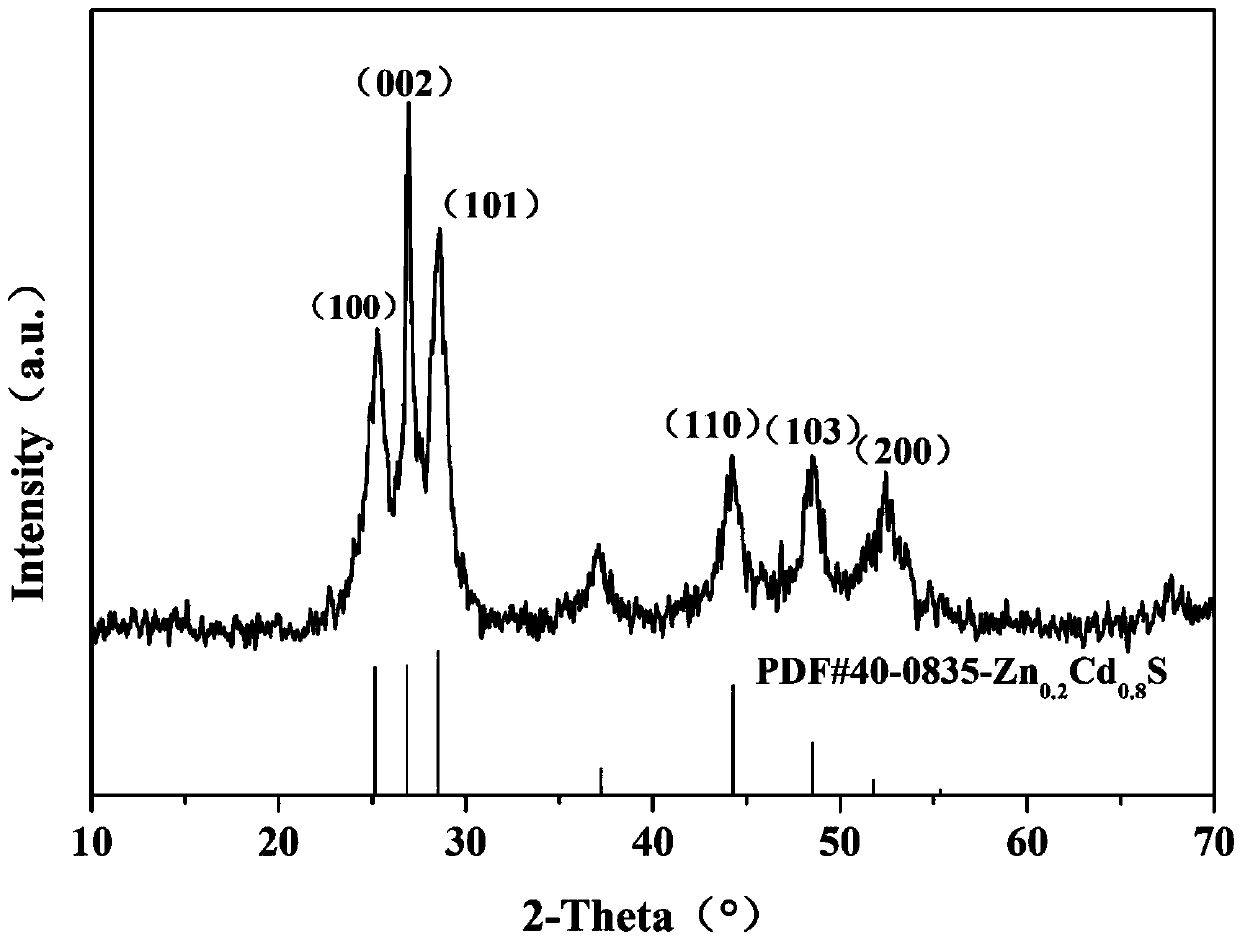

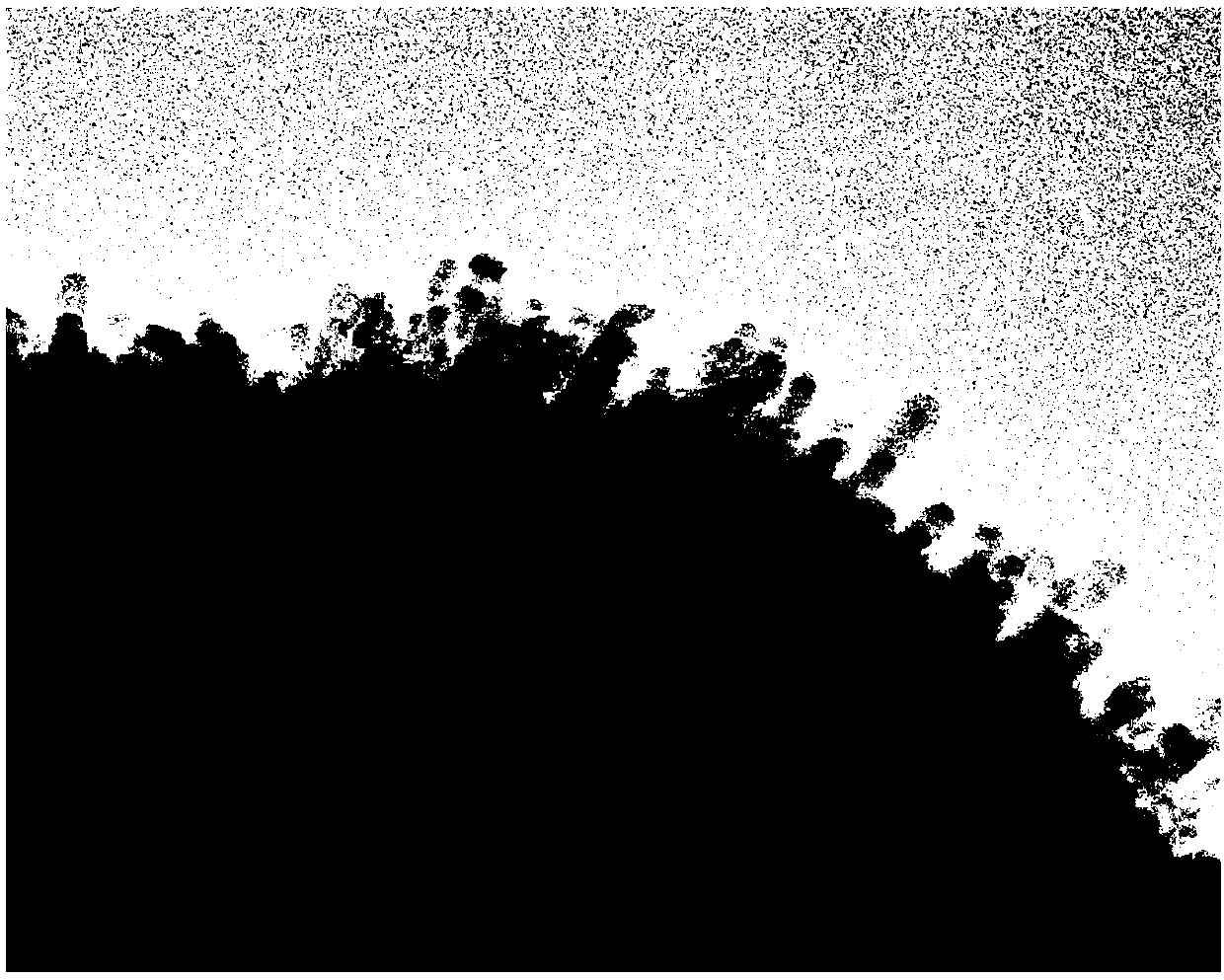

Preparation method of rod-shaped self-assembled spherical zinc-cadmium-sulfur solid solution material

A self-assembly and spherical technology, applied in the preparation of cadmium compounds, chemical instruments and methods, cadmium compounds, etc., can solve the problem of high energy and cost requirements for production, easy sintering or melting of products, and difficult control of reaction rate and other problems, to achieve the effects of shortening the electron transmission distance, overcoming uneven heating, and good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] A method for preparing a rod-shaped self-assembled spherical zinc-cadmium-sulfur solid solution material, comprising the following steps:

[0028] Step 1: Add ethylenediamine to the water, stir it magnetically for 0.5-1 hour, and then perform ultrasonic treatment for 5-30 minutes at a power of 360W to form a mixed solution A; the volume ratio of water and ethylenediamine is (20-40): (5~10);

[0029]Step 2: Weigh zinc acetate dihydrate and cadmium nitrate tetrahydrate and add them to mixed solution A, and after magnetically stirring for 45 minutes, perform ultrasonic treatment at a power of 360W for 5-30 minutes to form mixed solution B; Add 0.1 ~ 0.5mmol zinc acetate dihydrate and 0.4 ~ 1.2mmol cadmium nitrate tetrahydrate, and n Zn :n Cd =1:4;

[0030] Step 3: Weigh L-cysteine as a sulfur source and add it to the mixed solution B. After magnetically stirring for 15-30 minutes, perform ultrasonic treatment at a power of 360W for 5-30 minutes to form a mixed solutio...

Embodiment 1

[0035] 1) Measure 20mL H with a graduated cylinder 2 O, 5mL EN (ethylenediamine) was added thereinto to form a solution, and after magnetic stirring for 0.5h, ultrasound was carried out for 5min at a power of 360W to form a mixed solution A.

[0036] 2) Using zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and cadmium nitrate tetrahydrate (Zn(NO 3 ) 2 4H 2 O) is raw material (n Zn :n Cd =1:4), weighed 0.1mmol and 0.4mmol respectively, added to mixed solution A, stirred magnetically for 45min, and ultrasonicated at 360W for 5min to form mixed solution B.

[0037] 3) Using L-cysteine as the sulfur source, weigh 1 mmol, add it into the mixed solution B, perform magnetic stirring for 15 minutes, and perform ultrasonication at a power of 360W for 5 minutes to form a mixed solution C.

[0038] 4) Add the mixed solution C into the polytetrafluoroethylene lining, control the filling ratio at 30%, control the reaction temperature at 140°C, and control the reaction time at 0.5h.

[0...

Embodiment 2

[0041] 1) Measure 30mL H with a graduated cylinder 2 O, 8mL EN (ethylenediamine) was added thereinto to form a solution, and after magnetic stirring for 0.8h, ultrasound was carried out for 15min at a power of 360W to form a mixed solution A.

[0042] 2) Using zinc acetate dihydrate (Zn(Ac) 2 2H 2 O) and cadmium nitrate tetrahydrate (Zn(NO 3 ) 2 4H 2 O) is raw material (n Zn :n Cd =1:4), weighed 0.2mmol and 0.8mmol respectively, added to mixed solution A, carried out magnetic stirring for 45min, and ultrasonicated at 360W power for 15min to form mixed solution B.

[0043] 3) Use L-cysteine as the sulfur source, weigh 2 mmol, add it to the mixed solution B, perform magnetic stirring for 20 minutes, and perform ultrasonication at a power of 360W for 15 minutes to form a mixed solution C.

[0044] 4) The mixed solution C is added to the polytetrafluoroethylene lining, the filling ratio is controlled at 38%, the reaction temperature is controlled at 160° C., and the react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com