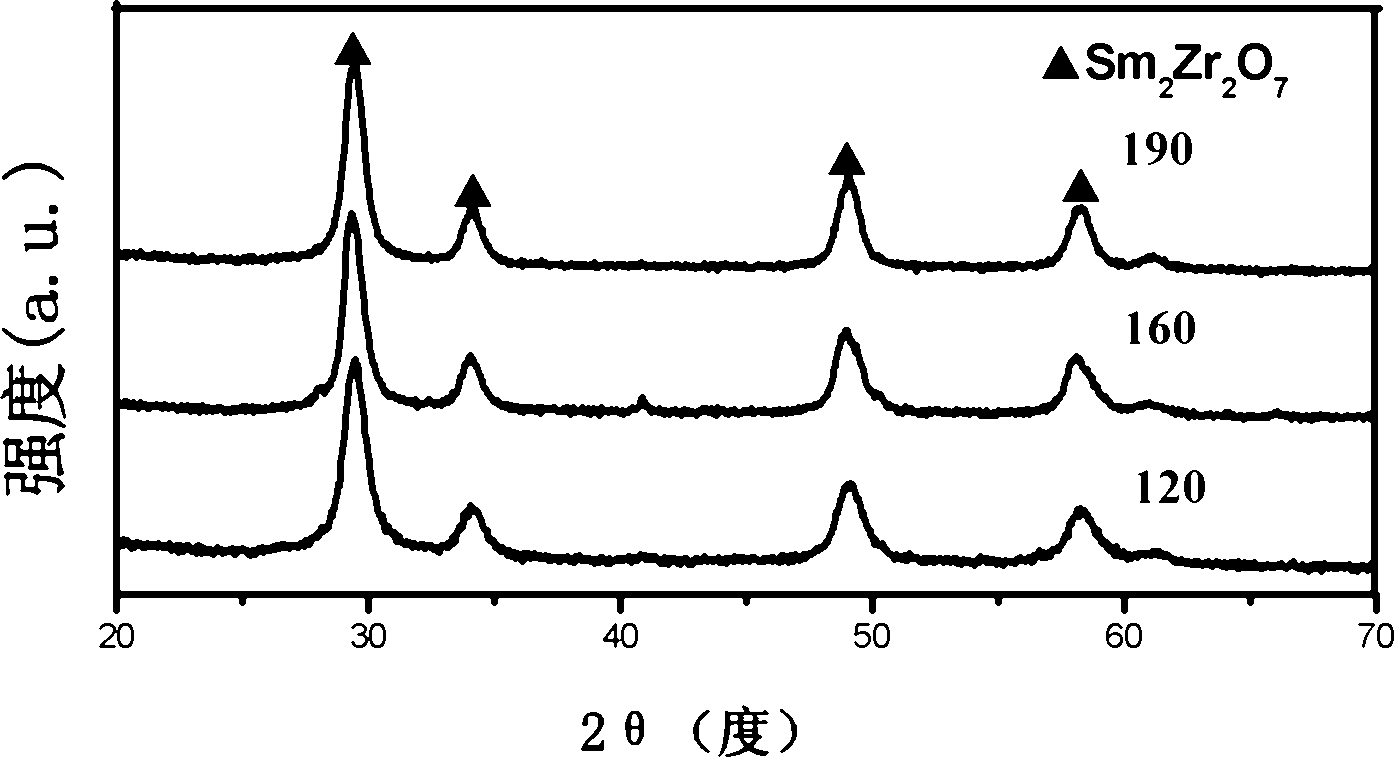

A rare earth samarium zirconate nanomaterial and its hydrothermal preparation method

A technology of samarium zirconate and rare earth, which is applied in the chemical industry, can solve the problems of serious agglomeration, difficulty in filtering and washing, etc., and achieve the effects of easy control of the reaction process, simple and easy preparation method, and easy popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1) Dissolve 30g of zirconium oxychloride in 200ml of water to obtain an aqueous solution, dissolve 10g of samarium oxide in 30ml of concentrated nitric acid to obtain a samarium nitrate solution, and mix the zirconium oxychloride solution and the samarium nitrate solution evenly.

[0063] 2) Under the action of magnetic stirring, add ammonia water dropwise to the mixed solution to adjust to PH = 4.0, and then continue to stir for 10 minutes to obtain a gel-like emulsion, centrifuge the gel-like emulsion to obtain a solid precipitate, add water to make a slurry (The purpose is to disperse the precipitate with water first) and then add KOH solution to pH=9 to obtain a white slurry.

[0064] 3) Put the above slurry into the reaction kettle, raise the temperature to 120°C at a rate of 5°C / min and react at a constant temperature for 24 hours, cool to room temperature, wash the product 7 times in a centrifuge with a rotating speed of 4000r / min, and then use Centrifuge and was...

Embodiment 2

[0066] 1) zirconium oxychloride that 30g particle size is 5 μm, pH value is 2.0 is dissolved in 200ml water and obtains aqueous solution, and 10g particle size is that samarium oxide of 3 μm is dissolved in the concentrated nitric acid that 30ml concentration is 8mol / L and makes samarium nitrate solution, will The zirconium oxychloride solution and the samarium nitrate solution are mixed evenly.

[0067] 2) Under the action of magnetic stirring, add ammonia water with a concentration of 10mol / L dropwise to the mixed solution to adjust the pH to 4.0, and then continue to stir for 10 minutes to obtain a gel-like emulsion, which is centrifuged to separate the gel-like emulsion Obtain a solid precipitate, add water to make a slurry (the purpose is to disperse the precipitate with water first), and then add a KOH solution with a concentration of 6 mol / L to PH=13 to obtain a white slurry.

[0068] 3) Put the above slurry into the reaction kettle, raise the temperature to 120°C at a ...

Embodiment 3

[0074] 1) 45g of zirconyl sulfate was dissolved in 200ml water to obtain an aqueous solution, 13g of samarium chloride was dissolved in 40ml of water to obtain an aqueous solution, and the zirconyl sulfate solution and the samarium chloride solution were mixed evenly.

[0075] 2) Under the action of magnetic stirring, add ammonia water dropwise to the mixed solution to adjust to PH = 4.0, and then continue to stir for 10 minutes to obtain a gel-like emulsion, centrifuge the gel-like emulsion to obtain a solid precipitate, add water to make a slurry (The purpose is to disperse the precipitate with water first) and then add KOH solution to pH=9 to obtain a white slurry.

[0076] 3) Put the above slurry into the reaction kettle, raise the temperature to 160°C at a rate of 5°C / min and react at a constant temperature for 24 hours, cool to room temperature, and wash the product 7 times in a centrifuge with a speed of 4000r / min, and then use Centrifuge and wash twice with water and e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com