Preparation method for sodium ion battery positive electrode material doped with modified sodium vanadium phosphate

A sodium ion battery, sodium vanadium phosphate technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex process requirements, complex processes, increased processes, etc., and achieve simple processes, abundant raw material sources, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A preparation method of a sodium ion battery positive electrode material doped with modified sodium vanadium phosphate, comprising the following steps:

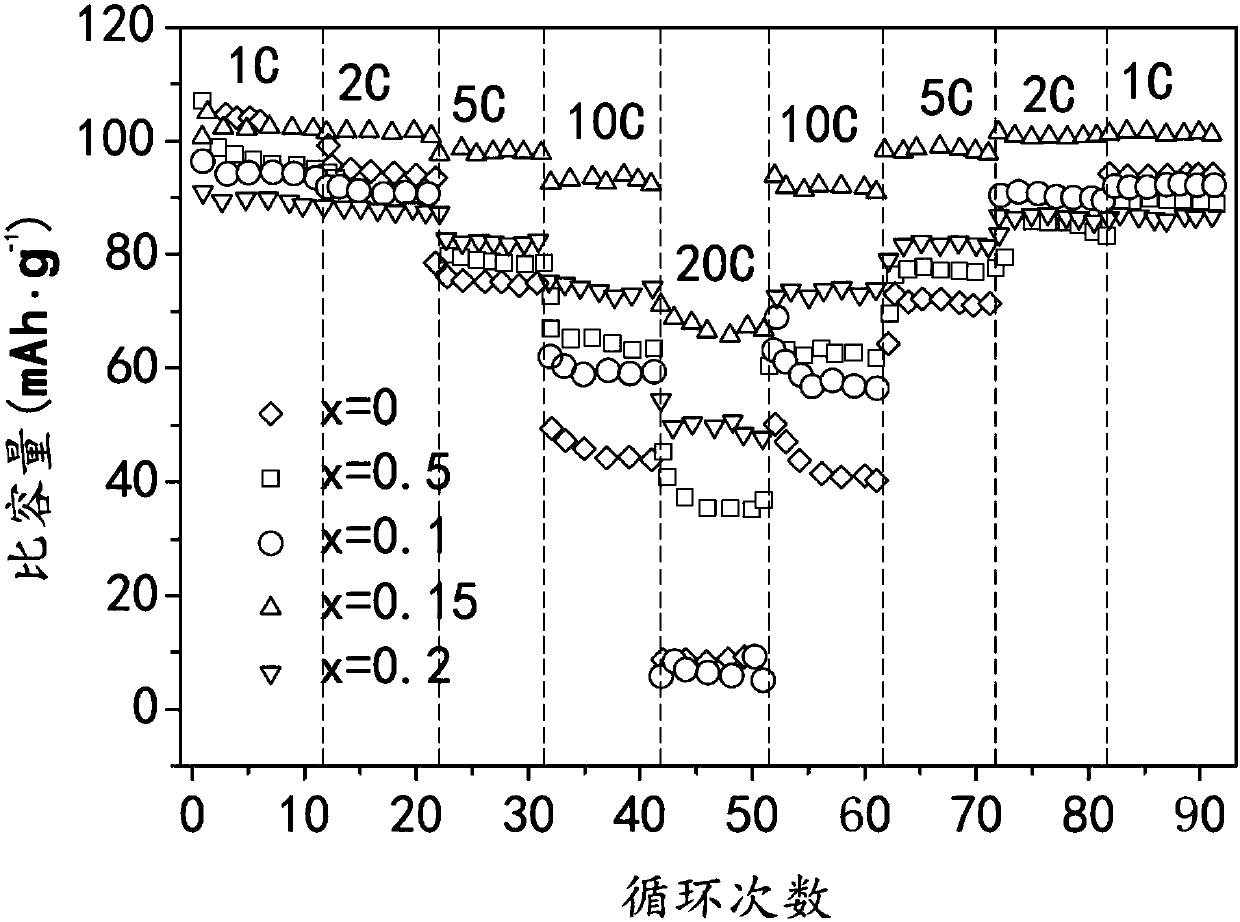

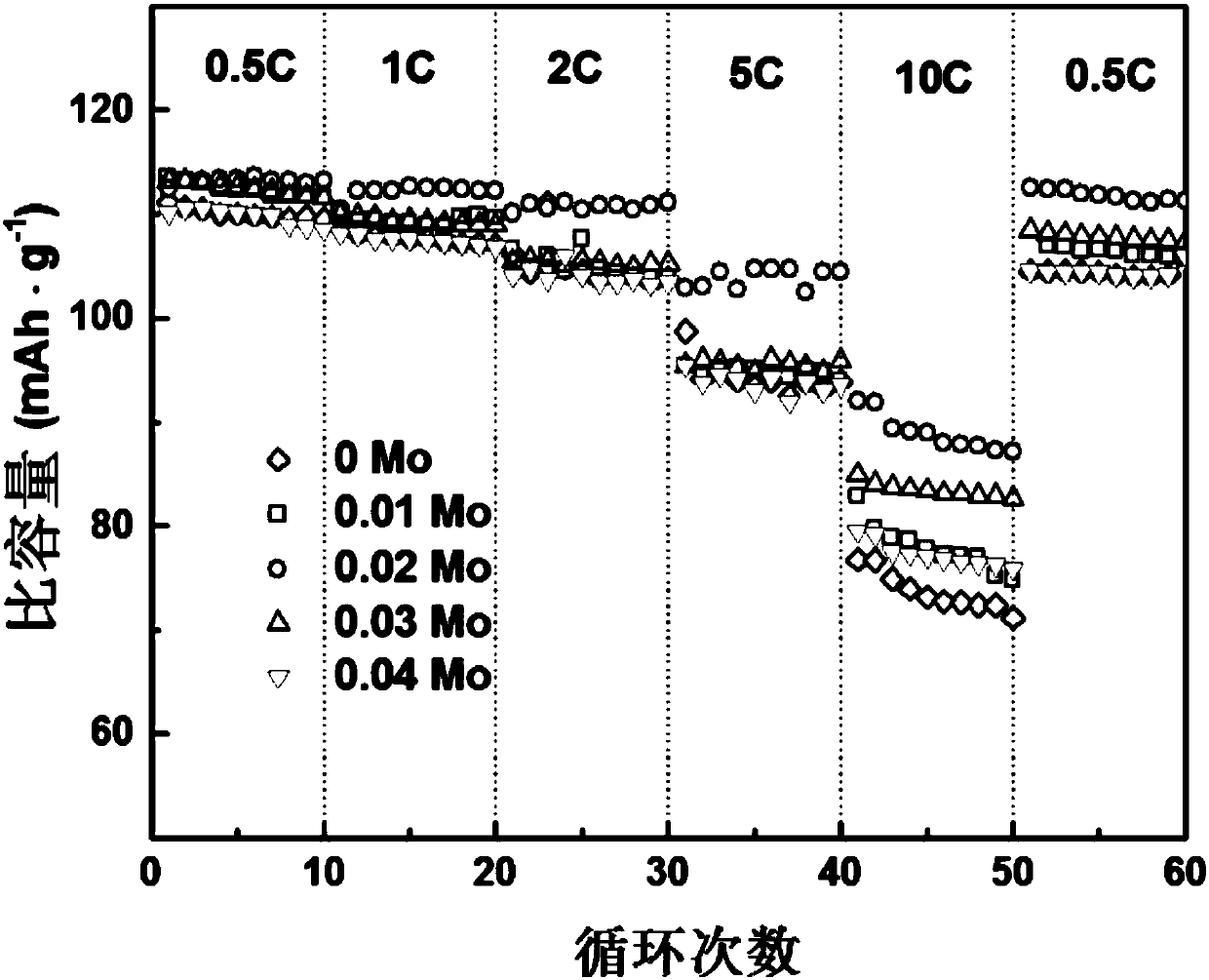

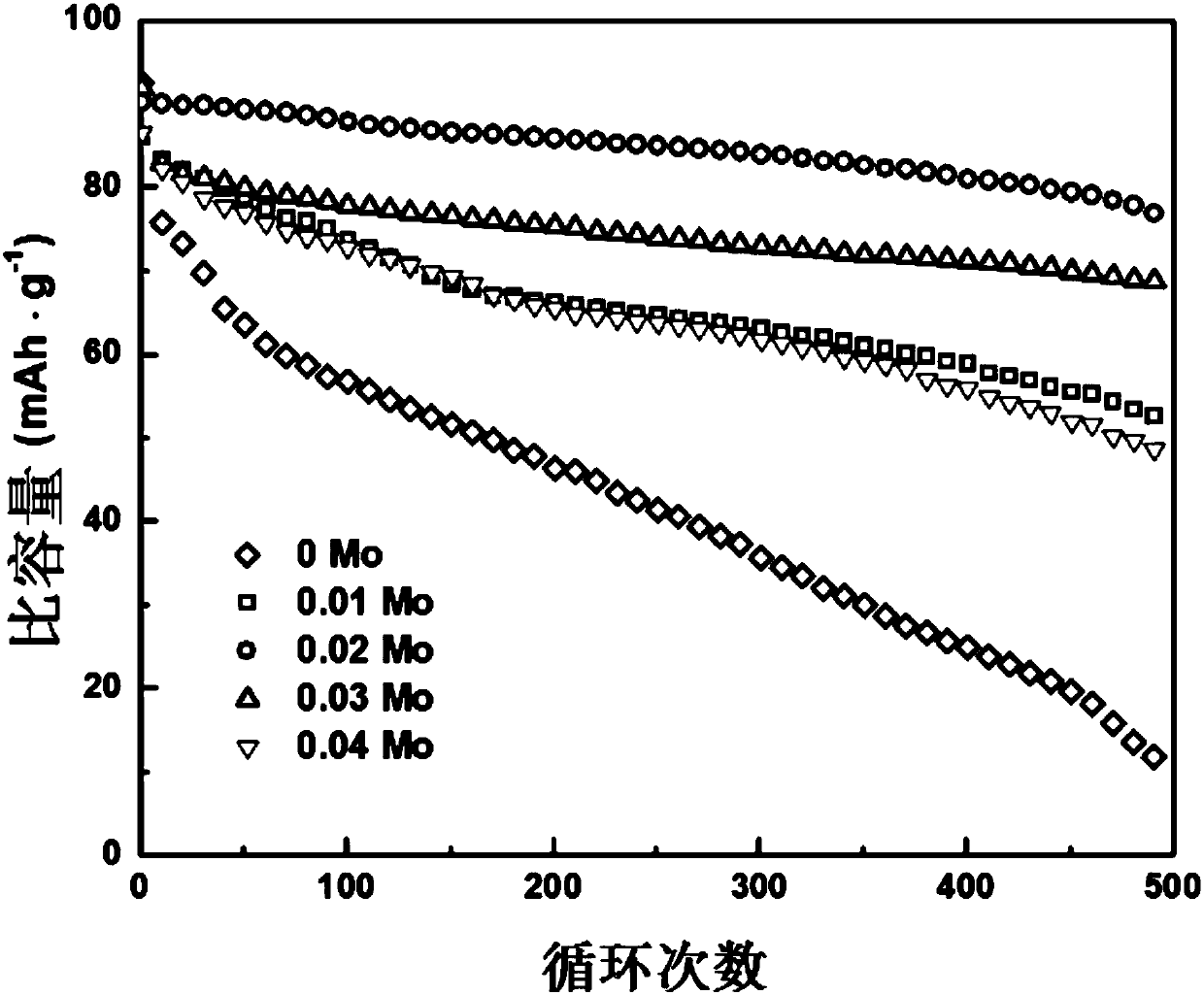

[0032] Step S1: Preparation of precursors: mixing sodium-containing raw materials, vanadium-containing raw materials, phosphoric acid-containing raw materials, M doping element compounds, organic carbon materials and solvents to form a slurry, and drying the slurry to obtain Precursor; Wherein, the doping element M is Ti or Mo;

[0033] Step S2: Sintering preparation of the product: placing the precursor at a temperature of 750° C. to 900° C. for heat treatment to obtain a sodium ion battery cathode material doped with modified sodium vanadium phosphate. In the present embodiment, the valence of Na is +1 valence, the valence of V is +3 valence, PO 4 The valence is -3.

[0034] The present invention prepares the doped modified sodium vanadium phosphate through the overall coordination of the precursor preparation step...

Embodiment 1

[0064] Embodiment one, a kind of preparation method of the positive electrode material of the sodium ion battery of doping modified sodium vanadium phosphate, comprises the following steps:

[0065] Step S1: Preparation of the precursor: Add 0.8189g of sodium carbonate, 0.91g of vanadium pentoxide and 1.7255g of ammonium dihydrogen phosphate into a nylon tube, add 0.2g of glucose and a small amount of absolute ethanol to form a slurry, and wet grind the slurry Dry it into powder after 30 minutes to obtain the precursor;

[0066] Step S2: Sintering of the product: put the precursor in the ark and transfer it to a tube furnace, and in an argon-hydrogen mixed gas reducing atmosphere, raise the temperature to 600°C at 3°C / min, keep it warm for 6h, and raise the temperature to 800°C at 3°C / min °C, keep warm for 10 hours to obtain the anode material of sodium ion battery without modified heterovanadium sodium phosphate.

Embodiment 2

[0067] Embodiment two, a kind of preparation method of the positive electrode material of the sodium ion battery of doping modified sodium vanadium phosphate, comprises the following steps:

[0068] Step S1: Preparation of the precursor: Add 0.8189g sodium carbonate, 0.91g vanadium pentoxide, 0.02g titanium dioxide and 1.7255g ammonium dihydrogen phosphate into the nylon tube, add 0.2g glucose and a small amount of absolute ethanol to form a slurry, Wet grind the slurry for 30 minutes and then dry it into powder to obtain the precursor;

[0069] Step S2: Sintering of the product: put the precursor in the ark and transfer it to a tube furnace, and in an argon-hydrogen mixed gas reducing atmosphere, raise the temperature to 600°C at 3°C / min, keep it warm for 6h, and raise the temperature to 800°C at 3°C / min ℃, heat preservation for 10h, to obtain a titanium-doped sodium vanadium phosphate positive electrode material for a sodium ion battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com