Modified iron-copper bimetallic nanoparticles and preparation method thereof

A bimetallic nano, iron-copper technology, applied in chemical instruments and methods, water/sludge/sewage treatment, polluted groundwater/leachate treatment, etc. Affect the reactivity and processing efficiency of the material, and fail to obtain a better repair effect, etc., to achieve the effect of strong reducibility, avoiding contact with oxygen, and increasing reducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

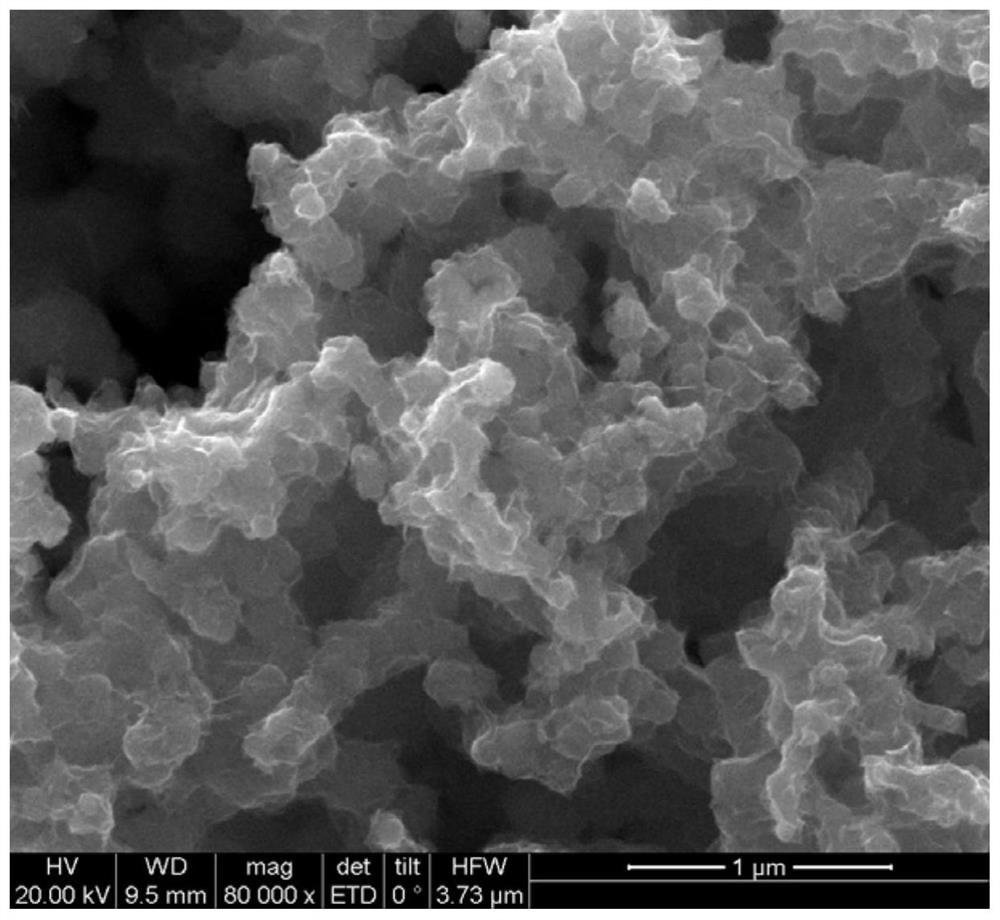

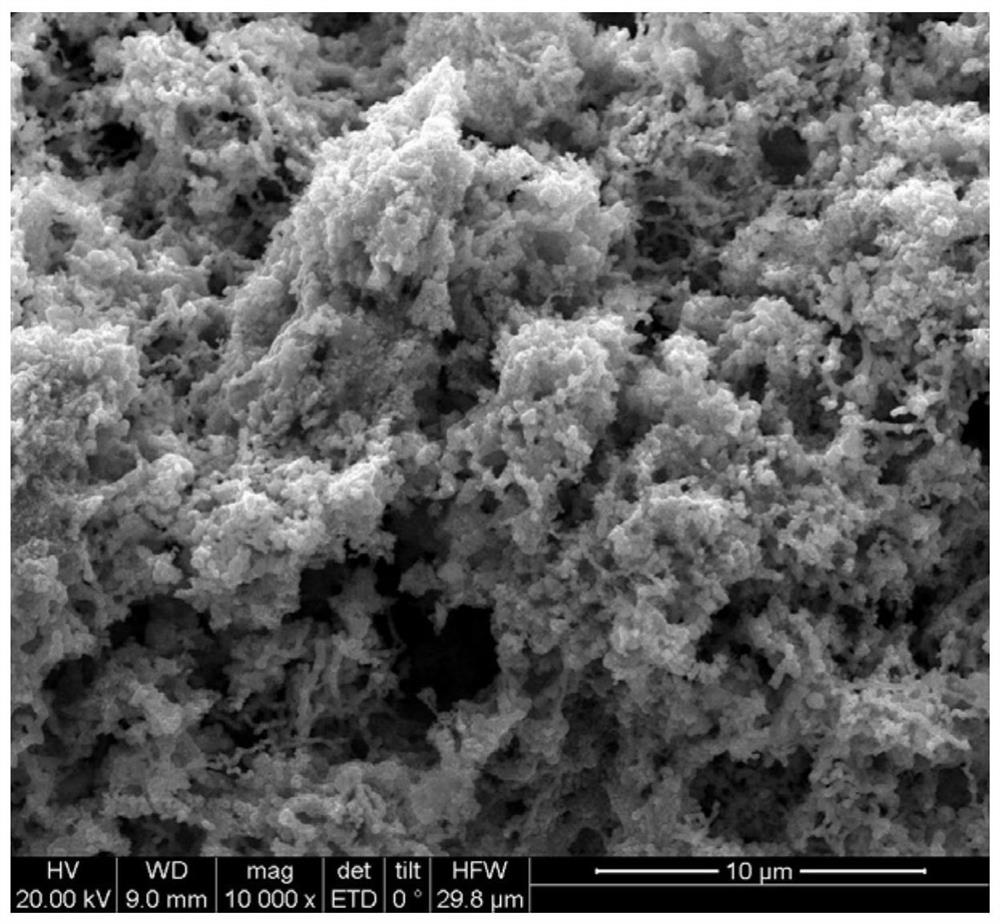

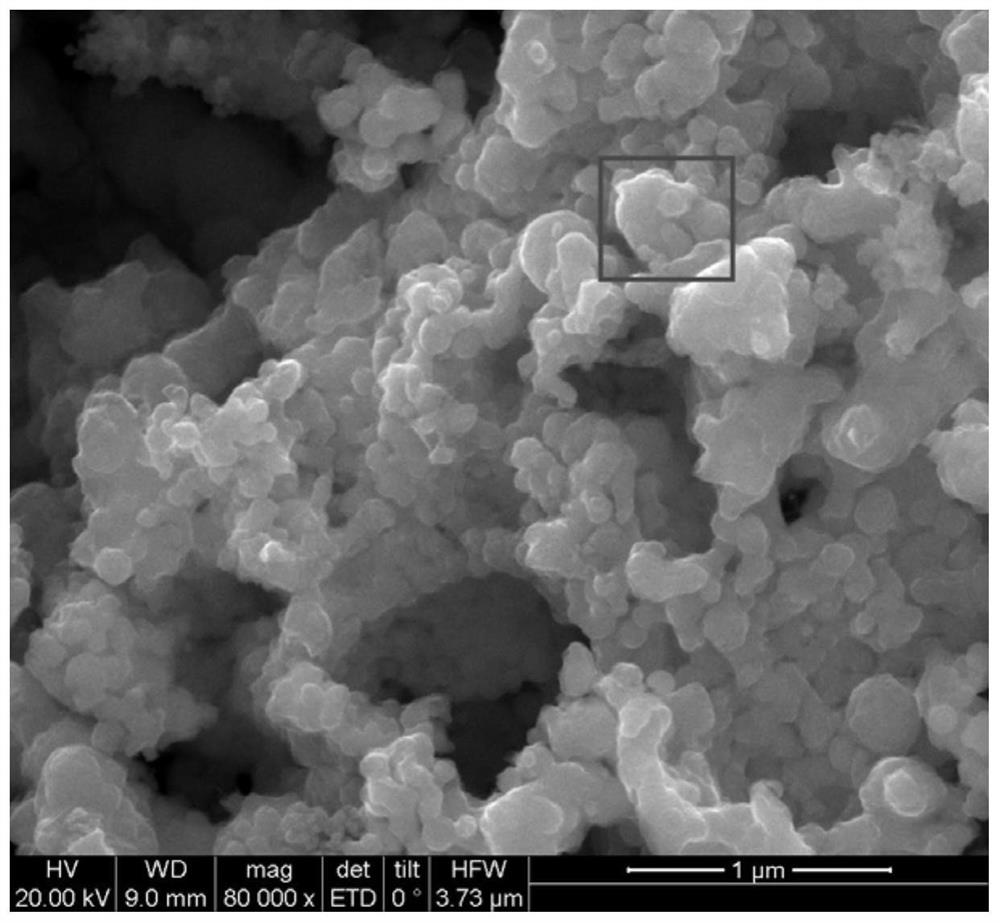

[0038] A modified iron-copper bimetallic nanoparticle comprises chitosan and iron-copper bimetallic nanoparticle, and the chitosan is coated on the surface of the iron-copper bimetallic nanoparticle.

[0039] In this embodiment, the mass ratio of chitosan to iron-copper bimetallic nanoparticles is 1%.

[0040] In this embodiment, the particle size of the modified iron-copper bimetallic nanoparticles is 5 nm to 20 nm.

[0041] A preparation method of the modified iron-copper bimetallic nanoparticles in the above-mentioned present embodiment, comprising the following steps:

[0042] (1) Preparation of solution:

[0043] Preparation of ferrous sulfate solution: weigh 5.6g FeSO 4 ·7H 2 O was dissolved in 100 mL of deoxygenated distilled water (the deoxygenated distilled water refers to the distilled water after nitrogen gas was introduced for 30 min to remove dissolved oxygen), and a light green ferrous sulfate solution with a concentration of 0.2 M was prepared.

[0044] Prep...

Embodiment 2

[0051] A modified iron-copper bimetallic nanoparticle is basically the same as the modified iron-copper bimetallic nanoparticle of Example 1, except that in the modified iron-copper bimetallic nanoparticle of Example 2, chitosan and iron The mass ratio of copper bimetallic nanoparticles is 2%.

[0052] The above-mentioned preparation method of the modified iron-copper bimetallic nanoparticles of the present embodiment is basically the same as the preparation method of the modified iron-copper bimetallic nanoparticles of The concentration of chitosan solution was 2g / L.

[0053] The modified iron-copper bimetallic nanoparticles prepared in Example 2 were named CS-Fe / Cu-2.

Embodiment 3

[0055] A modified iron-copper bimetallic nanoparticle is basically the same as the modified iron-copper bimetallic nanoparticle of Example 1, except that in the modified iron-copper bimetallic nanoparticle of Example 3, chitosan and iron The mass ratio of copper bimetallic nanoparticles is 3%.

[0056] The above-mentioned preparation method of the modified iron-copper bimetallic nanoparticles in the present embodiment is basically the same as the preparation method of the modified iron-copper bimetallic nanoparticles in The concentration of the chitosan solution was 3 g / L.

[0057] The modified iron-copper bimetallic nanoparticles prepared in Example 3 were named CS-Fe / Cu-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com