Preparation of high-purity nanometer silicon dioxide

A high-purity silica and nanotechnology, applied in the direction of silica, etc., to achieve the effect of continuous process, good particle dispersion and easy scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

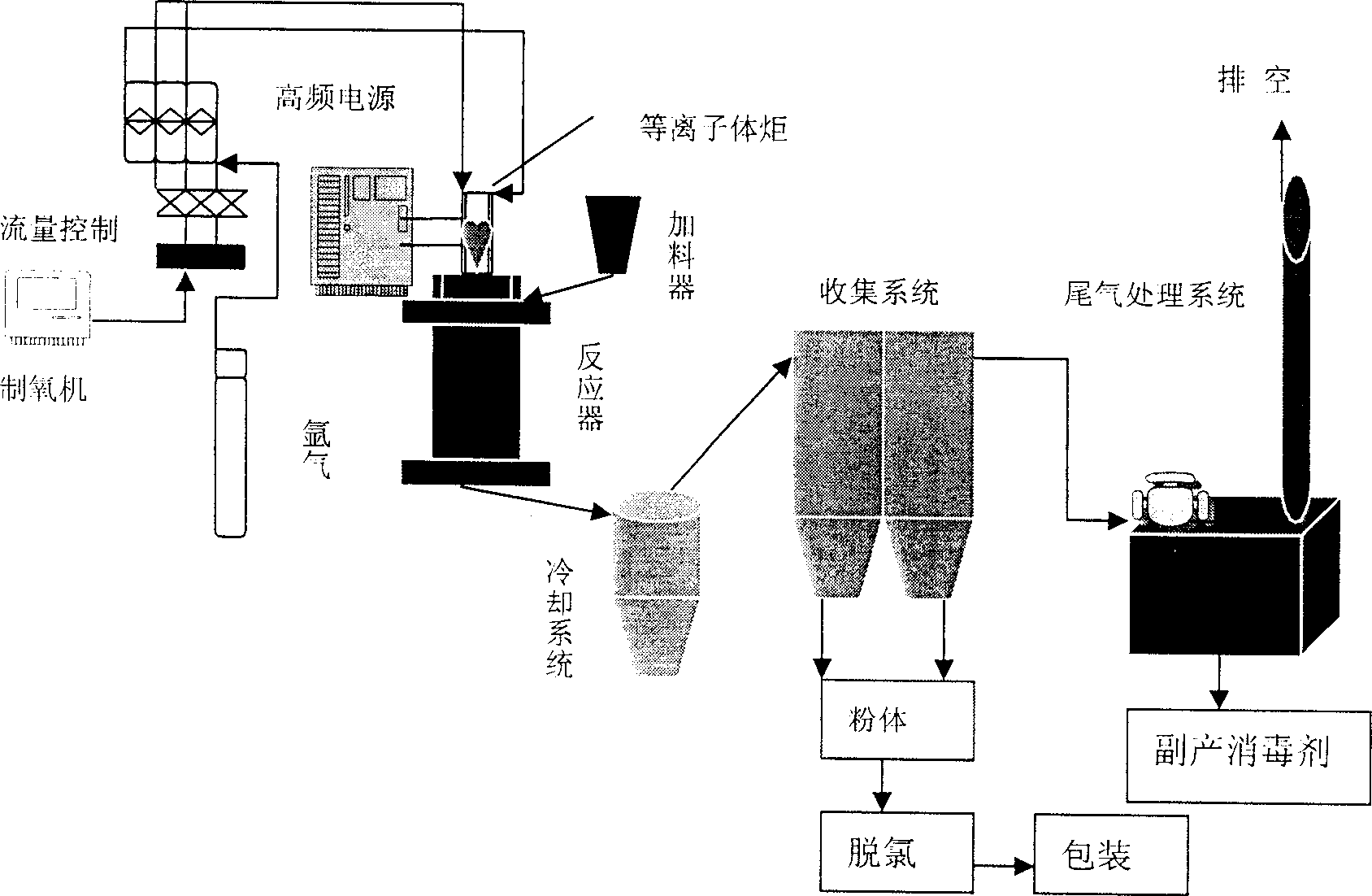

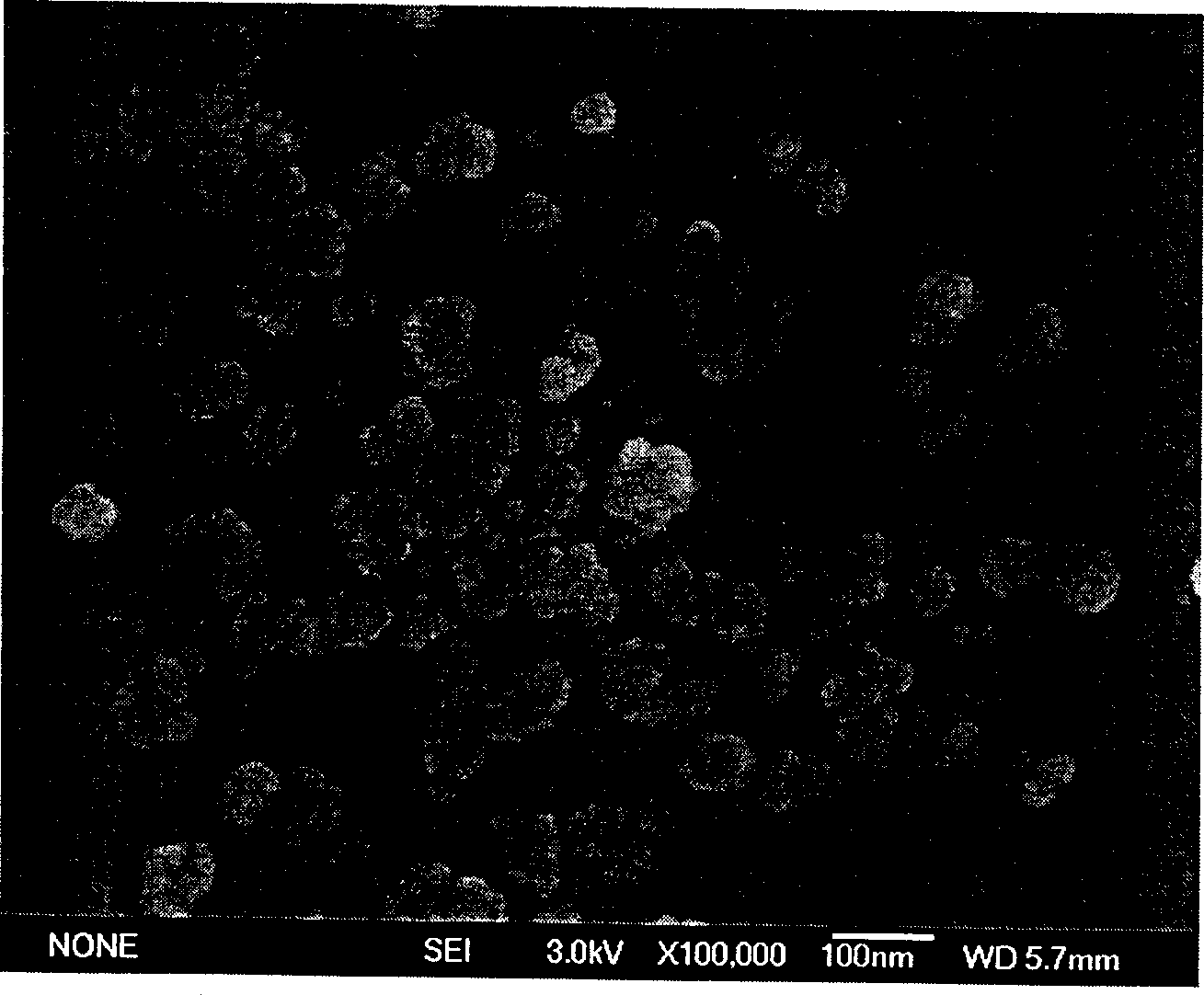

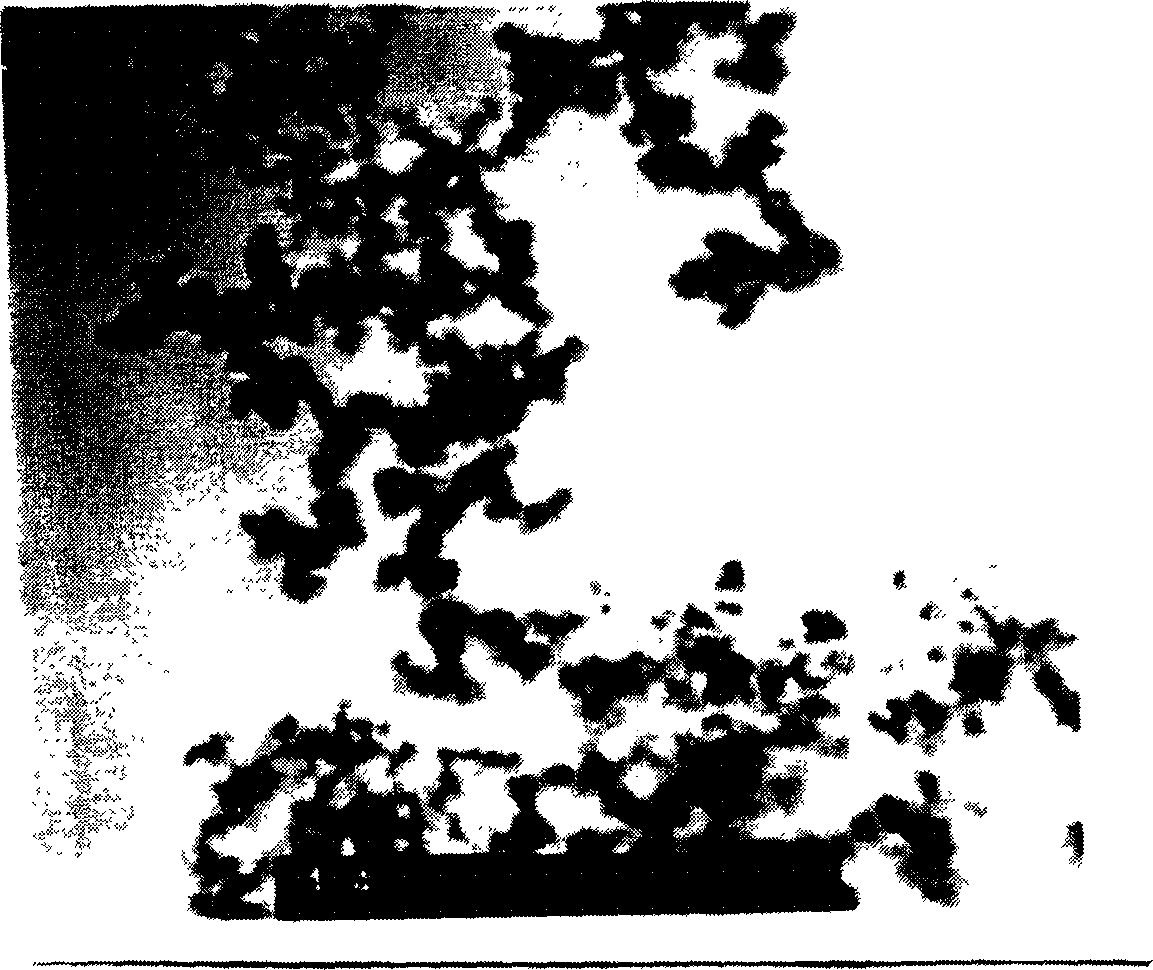

[0061] Such as figure 1 As shown in the process flow chart, in the plasma gas phase including plasma generator (high-frequency plasma power supply and plasma torch), plasma chemical reactor, scar removal device, cooling system, collection system and powder processing system, etc. The nanometer high-purity silicon dioxide of the present invention is prepared in an oxidation reaction device. Among them, the high-frequency plasma power supply has a power of 30KW and a frequency of 4MHz. The diameter of the plasma torch is Φ60, the diameter of the central tube is Φ50, and the length of the torch is 300mm. Furnace tube, high-pressure air blowing plate (scar removal device), quenching air blowing plate, the total length of the reactor (composed of three sections, each 250mm long) is 750mm, the inner diameter of the reactor is Φ111, and the high-pressure air blowing plate is in each section The reactors are connected (air hole diameter 2mm, air pressure ≥ 5Kg, tangential injection),...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com