Method for preparing medium pore molecular sieve of titanium dioxide

A technology of mesoporous molecular sieve and titanium dioxide, which is applied in the direction of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problems of complex preparation process, increased reaction conditions, and increased difficulty of synthesis process, so as to reduce costs , improved photocatalytic activity and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

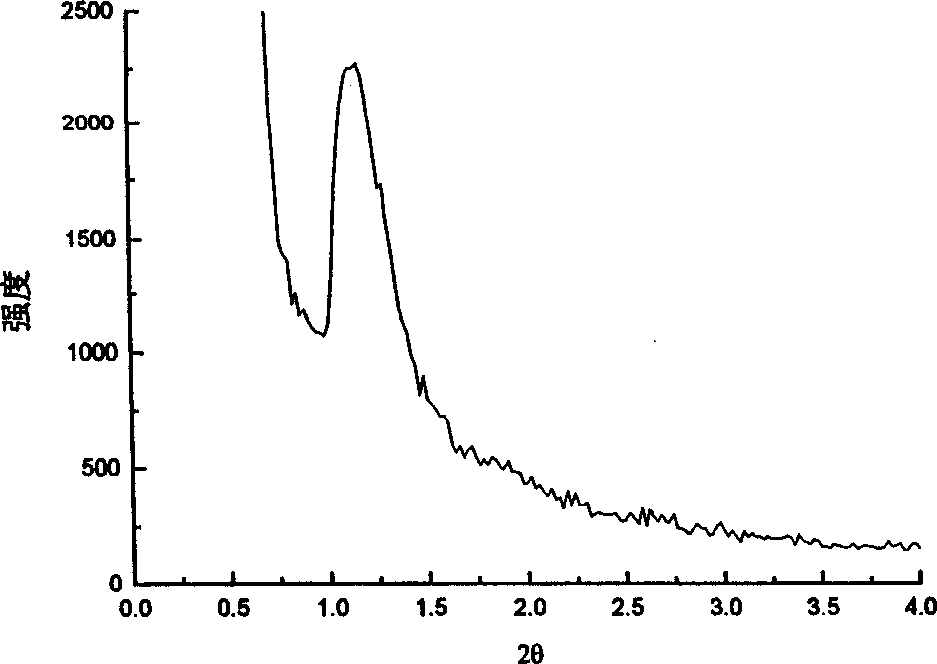

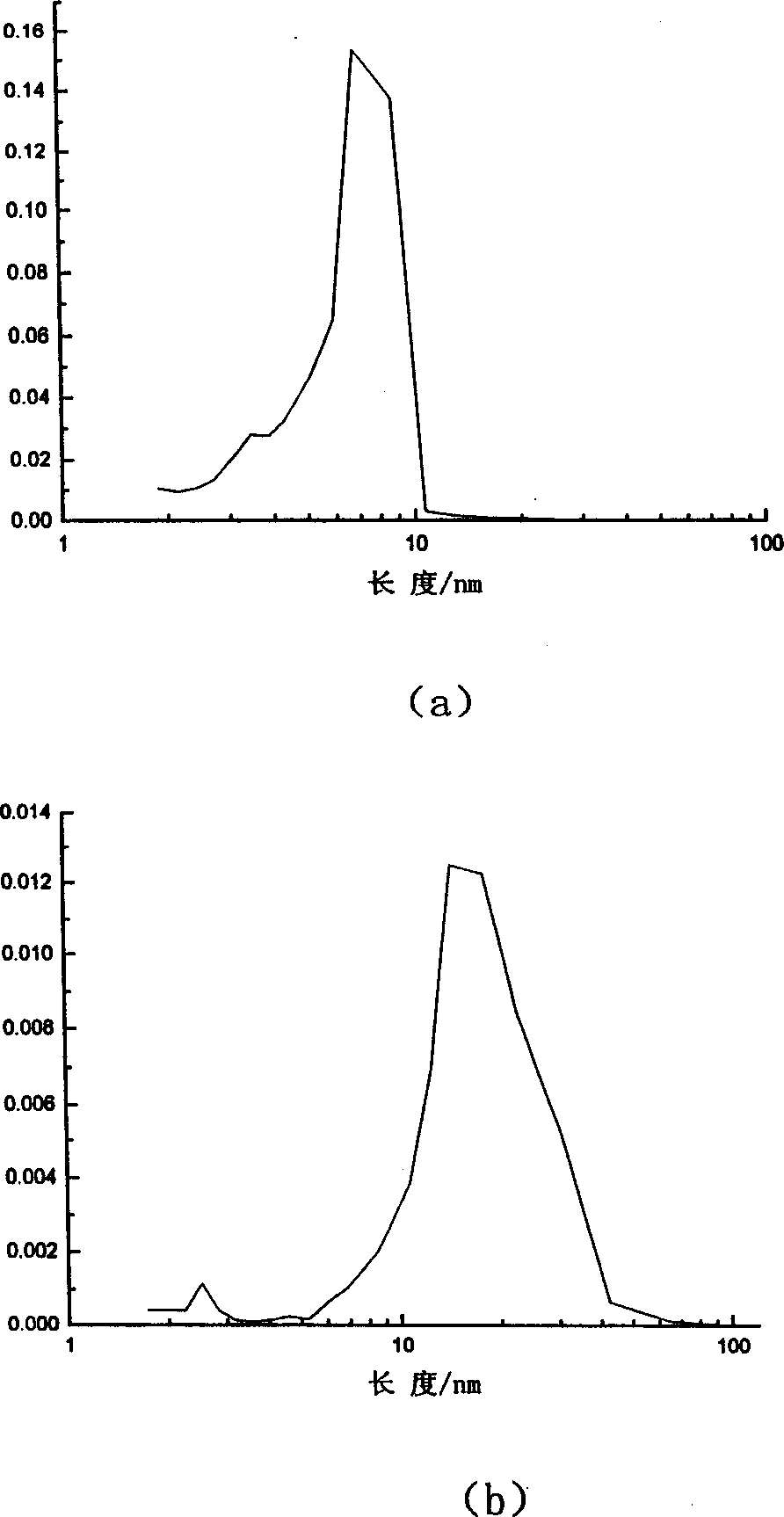

[0031] Mix 12ml tetrabutyl titanate and 4.7ml triethanolamine at room temperature, stir evenly, add 16ml water dropwise and measure the pH value to 8, continue stirring to obtain a homogeneous mixture, dry the above homogeneous mixture at 100°C for 12 hours and then solidify A homogeneous gel is formed, and then the gel is moved into a reaction kettle and crystallized at 150°C for 12 hours to obtain a block gel, and then the above product is calcined at a rate of 1°C / min to 600°C, Insulated for 10 hours, ground to obtain a white powder, its XRD diffraction pattern is as follows figure 1 As shown, the pore size distribution is as figure 2 as shown in a.

Embodiment 2

[0033] Mix 12ml tetrabutyl titanate and 4.7ml triethanolamine at room temperature, stir evenly, add 16ml water dropwise and measure the pH value to 8, continue stirring to obtain a homogeneous mixture, dry the above homogeneous mixture at 100°C for 12 hours and then solidify A homogeneous gel was formed, and then the gel was transferred into a reaction kettle for crystallization at a temperature of 150° C. for 48 hours to obtain a block gel that was equally divided into three parts. Extracted with a Soxhlet extractor for 24 hours, 48 hours, and 72 hours, the extract was ethanol solution, and the obtained massive gel was ground into powder, and the product pore size distribution obtained by extraction for 24 hours was as follows: figure 2 as shown in b.

Embodiment 3

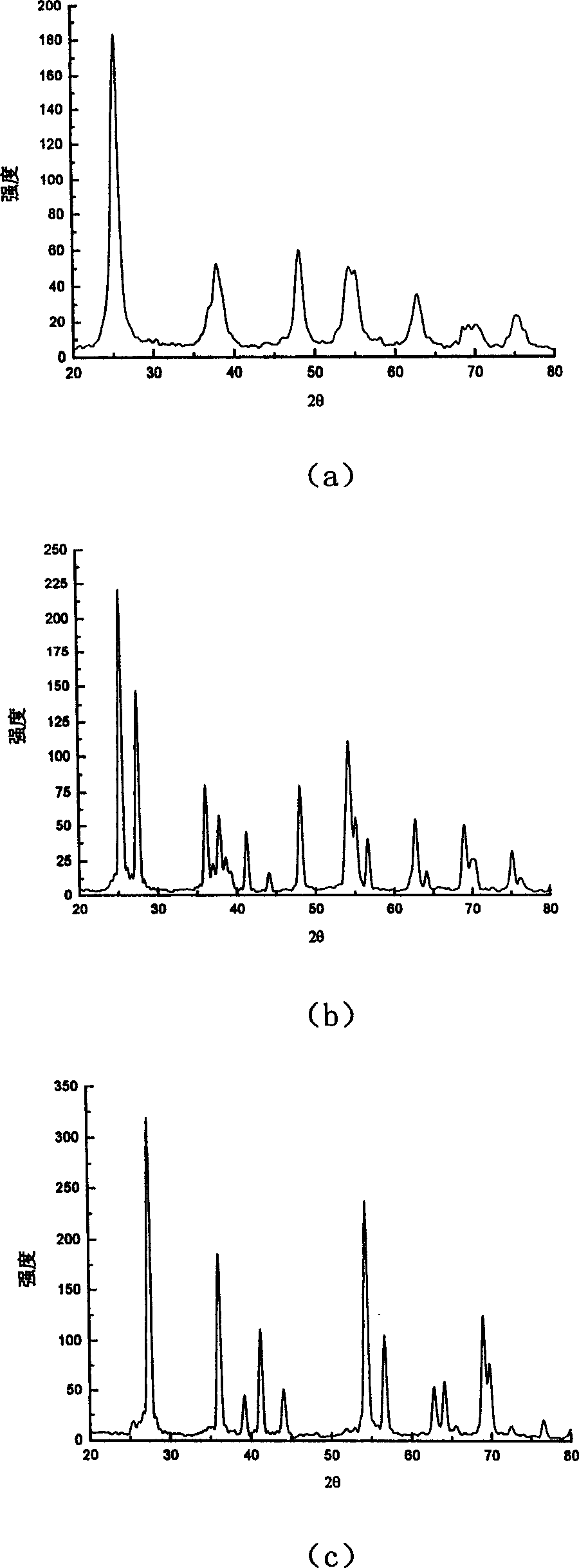

[0035] Mix 3.4ml tetrabutyl titanate and 6.7ml triethanolamine at room temperature, stir evenly, add 18ml water dropwise and measure the pH value to be 8, continue stirring to obtain a homogeneous mixture, dry the above homogeneous mixture at 180°C for 2 hours Solidify to form a homogeneous gel, then move the gel into the reaction kettle and crystallize at 180°C for 48 hours to obtain a block gel; then heat the above product at a rate of 5°C / min to 400°C after calcination , kept warm for 10 hours, and ground to obtain a white powder. Its XRD diffraction pattern is as image 3 as shown in a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com