Solar cell backboard

A technology for solar cells and back sheets, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reducing water vapor transmission rate, cumbersome composite process, poor insulation effect, etc., to avoid the decline of coating covering power, The effect of simple process flow and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation process of titanium dioxide-coated layered silicate composite particles is as follows:

[0030] (1) To prepare slurry, add the dried phyllosilicate powder into water, ball mill at 300-1000r / min for 10-40min, add ball-milling aids and continue to mill at 300-1000r / min for 30-90min.

[0031] (2) Add titanium dioxide to the ball mill, adjust the pH of the slurry to be between 2.0 and 7.5, mill at 300-1000r / min for 10-40min, add ball milling aids and continue to mill at 300-1000r / min for 30- 90min;

[0032] (3) Washing, filtering, drying, and sieving the obtained slurry to obtain composite particles of titanium dioxide-coated layered silicate.

[0033] The ball milling aid is silane, titanate, aluminate, polyethylene glycol, stearic acid, acrylic acid, methacrylic acid, crotonic acid, maleic acid, polyacrylic acid or its salts, sodium hexametaphosphate, DTAB , TTAB, CTAB, OTAB, preferably, the ball milling aid is one or more of polyethylene glycol, polyacr...

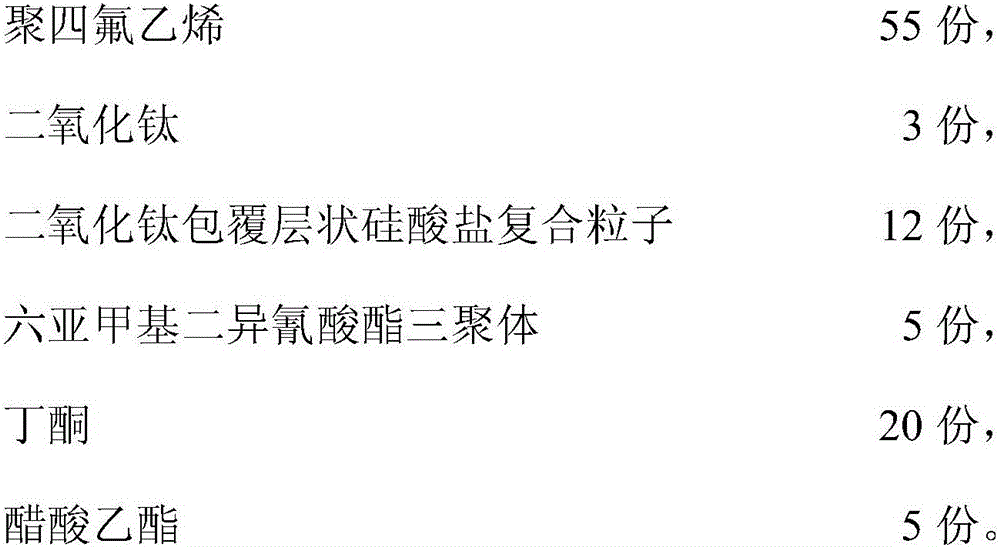

Embodiment 1

[0042] Weather-resistant layer: fluorocarbon resin coating, in which,

[0043]

[0044] 1. The preparation process of composite particles:

[0045] (1) To prepare the slurry, dry 10 parts of sericite with a d50 of 1.80 μm at low temperature, add it to deionized water, ball mill it at 800 r / min for 30 minutes, add 0.1 part of aminopropyltrimethoxysilane coupling agent and continue the ball milling, The ball milling speed is 800r / min and the ball milling time is 40min.

[0046] (2) Add 2 parts of titanium dioxide with a d50 of 0.36 μm into (1), ball mill at 600r / min for 30min, add hydrochloric acid to adjust the pH to 5.0, and continue ball milling at 600r / min for 50min. Washing, filtering, drying, and sieving to obtain composite particles of sericite coated with titanium dioxide.

[0047] The ball milling medium is zirconia, the size ratio is 1.5mm: 1.2mm: 0.8mm = 4:3:3, and the ball-to-material ratio is about 4:1. The slurry concentration was 50%.

[0048] 2. Add 20 par...

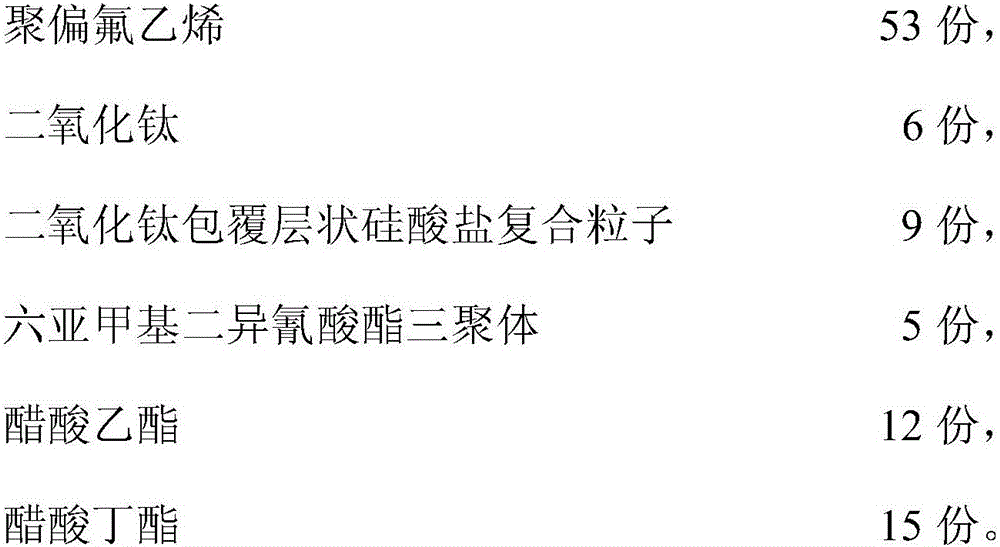

Embodiment 2

[0053] Weather-resistant layer: fluorocarbon resin coating, in which,

[0054]

[0055] 1. The preparation process of composite particles:

[0056] (1) To prepare slurry, dry 5 parts of sericite with d50=0.40 μm at low temperature, add it into deionized water, ball mill at 800r / min for 30min, add 0.1 part of aminopropyltrimethoxysilane coupling agent and continue ball milling, The ball milling speed is 800r / min and the ball milling time is 40min.

[0057] (2) Add 4 parts of d50=0.36 μm titanium dioxide to (1) and ball mill at 600r / min for 30min, add hydrochloric acid to adjust the pH to 5.0, and continue ball milling at 600r / min for 50min. Washing, filtering, drying, and sieving to obtain composite particles of sericite coated with titanium dioxide.

[0058] 2. The ball milling medium is zirconia, the size ratio is 1.5mm: 1.2mm: 0.8mm = 4:3:3, and the ball-to-material ratio is about 4:1. The slurry concentration was 50%. Add 12 parts of ethyl acetate and 15 parts of but...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com