A kind of uv photooxygen machine with inner surface coated with aluminum products and its manufacturing process

A technology of aluminum products and photo-oxygen machine, which is applied in the direction of separation method, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low utilization rate of honeycomb or foam photocatalyst, decrease of waste gas degradation efficiency, low utilization rate of UV light, etc. Achieve the effects of easy oxidative degradation, improved degradation efficiency, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

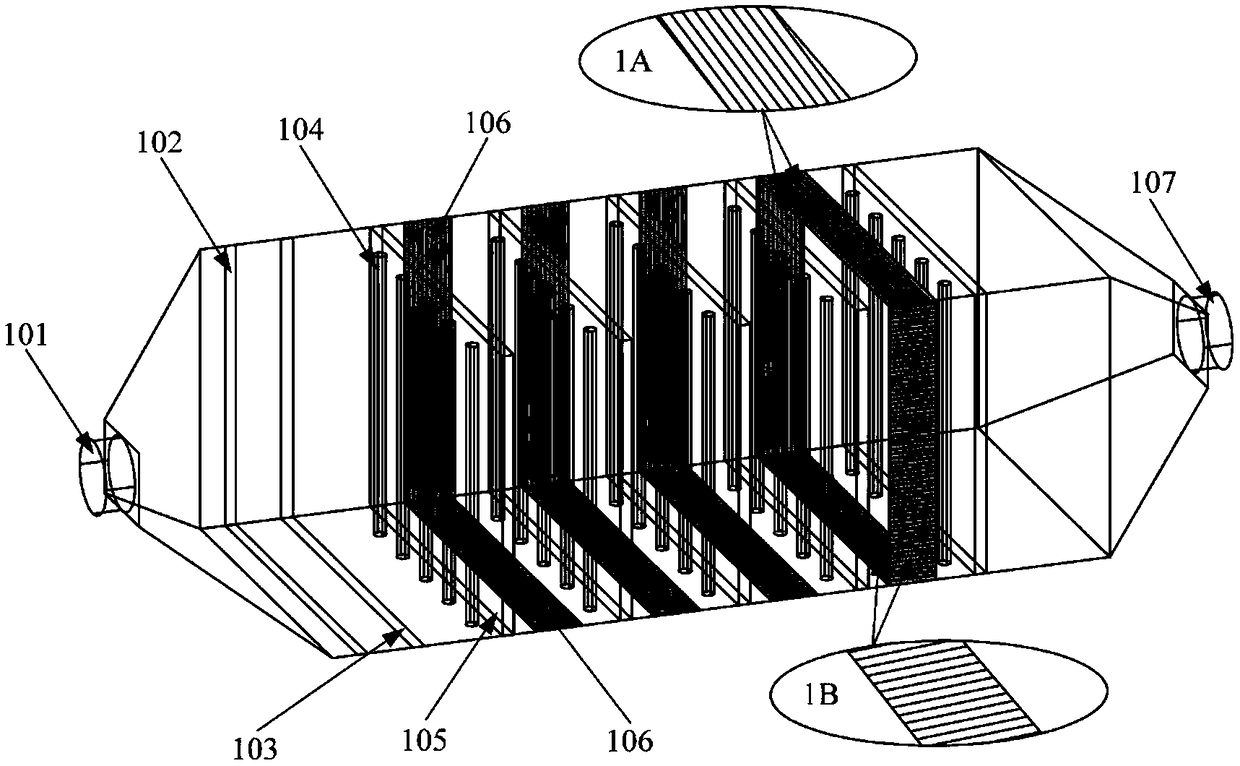

[0053] combined with figure 1 , it can be seen that the exhaust gas treatment process is as follows: first, the exhaust gas enters the interior of the photo-oxygen machine through the inlet (101) of the photo-oxygen machine, and then enters the UV photocatalytic oxidation stage through the splitter plate (102) and the primary filter (103). In 104, its power is 150W) and the UV light and photocatalyst (105 in the figure, its composition is TiO 2 , the coating weight is 4g / m 2 ), the exhaust gas molecules are degraded into harmless CO 2 and H 2 O. This embodiment provides a UV light oxygen machine without any special reflection design on the inner surface, and uses the mixed gas of toluene and air as the waste gas source, controls the concentration of toluene to be 100ppm, and then under different wind speeds (1~5m / s) test the exhaust gas concentration at its outlet, and calculate the purification efficiency of the UV light oxygen machine, such as Figure 4 shown.

Embodiment 2

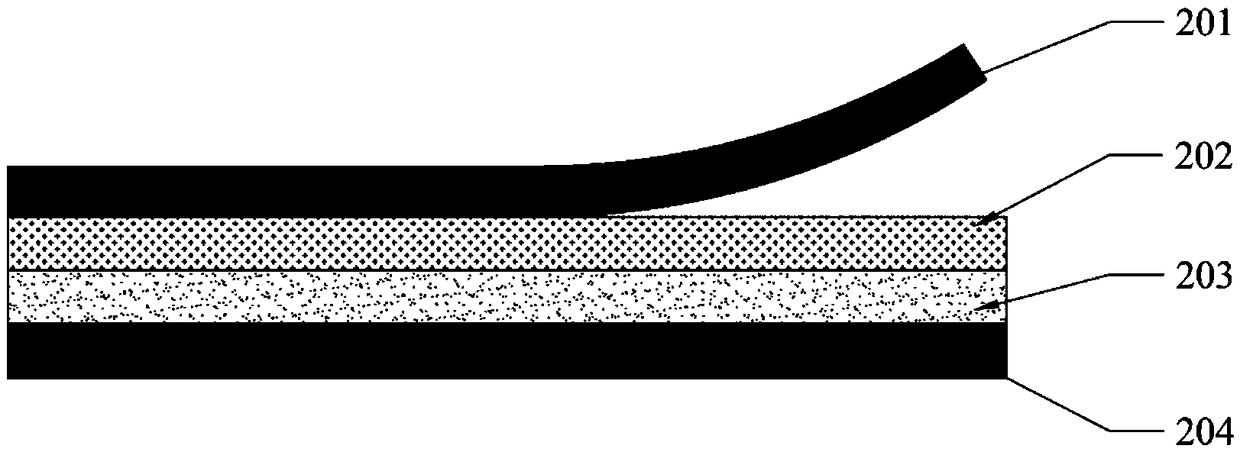

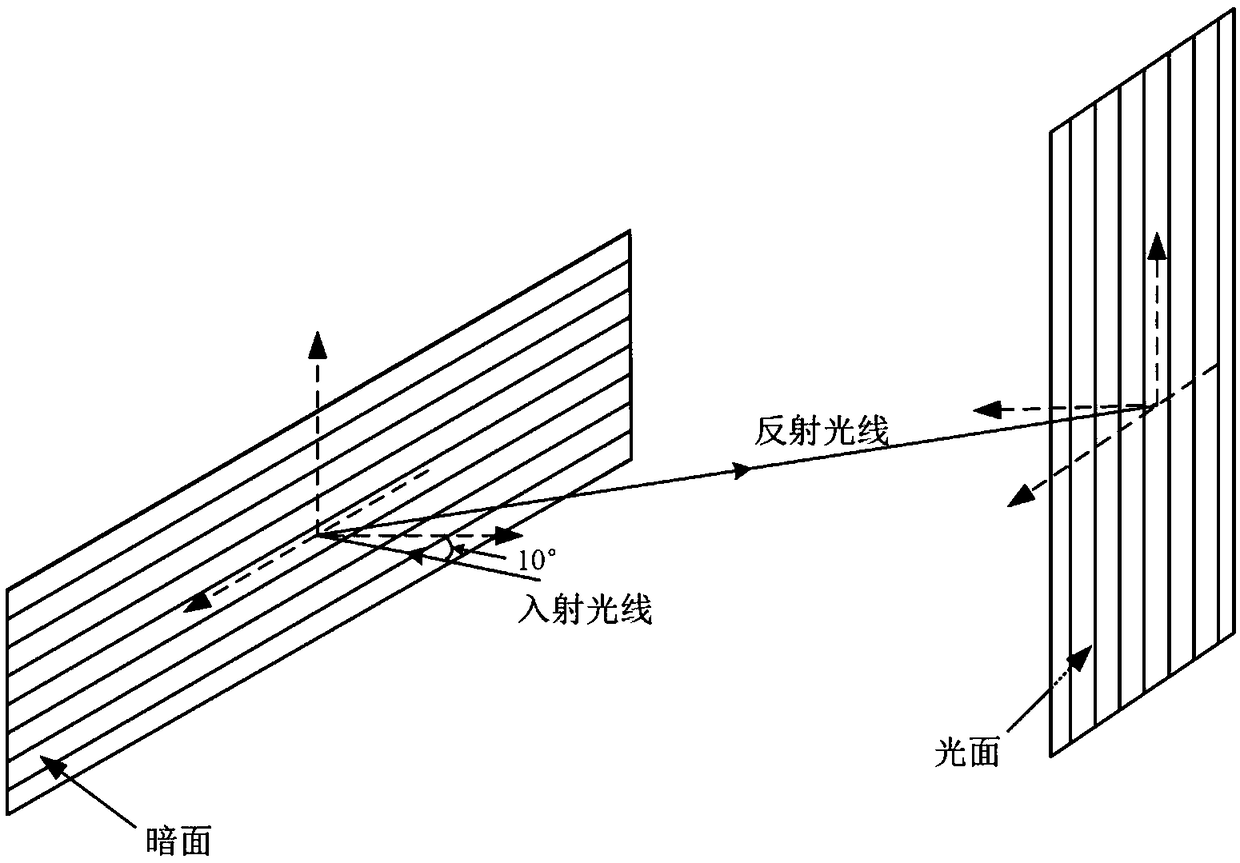

[0055] combined with figure 1 And attached figure 2 , the present embodiment provides a kind of UV photo-oxygen machine and its manufacturing process that the inner surface is covered with aluminum foil, in the position of certain width (such as figure 1 The position shown in 106) is pasted with an aluminum foil tape with a thickness of 0.1mm (such as figure 2 ), and the orientation of the aluminum foil attached to the surrounding inner surfaces is the same (the two opposite inner surfaces are both smooth surfaces), then test the exhaust gas concentration at the outlet at different wind speeds, and calculate the purification efficiency of the UV light oxygen machine, Such as Figure 4 shown. In addition, it should be noted that the power of the UV lamp, the catalyst, the grammage of catalyst coating and the concentration of the exhaust gas source in this embodiment are all the same as those in Embodiment 1.

Embodiment 3

[0057] combined with figure 1 And attached figure 2 , this embodiment is basically the same as Embodiment 2, and also provides a UV light oxygen machine and its manufacturing process with aluminum foil on the inner surface. Or a position with a certain width on the inner surface of the shell between the foam photocatalysts (such as figure 1 The position shown in 106) is pasted with an aluminum foil tape with a thickness of 0.15mm (such as figure 2 ), and the orientations of the aluminum foils attached to two sets of opposite inner surfaces of the surrounding inner surfaces are perpendicular to each other (one side of the two opposite inner surfaces is a smooth side, and the other side is a dark side), and then at different wind speeds Next, test the exhaust gas concentration at its outlet, and calculate the purification efficiency of the UV light oxygen machine, such as Figure 4 shown. The power of the UV lamp, the catalyst, the grammage of the catalyst coating and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com