Method for preparing flaky silicic acid zirconium nanocrystalline

A technology of zirconium silicate and nanocrystals, applied in nanotechnology, chemical instruments and methods, silicon compounds, etc., can solve the problems of high preparation temperature and short preparation time, and achieve low reaction temperature, short cycle and narrow particle size distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

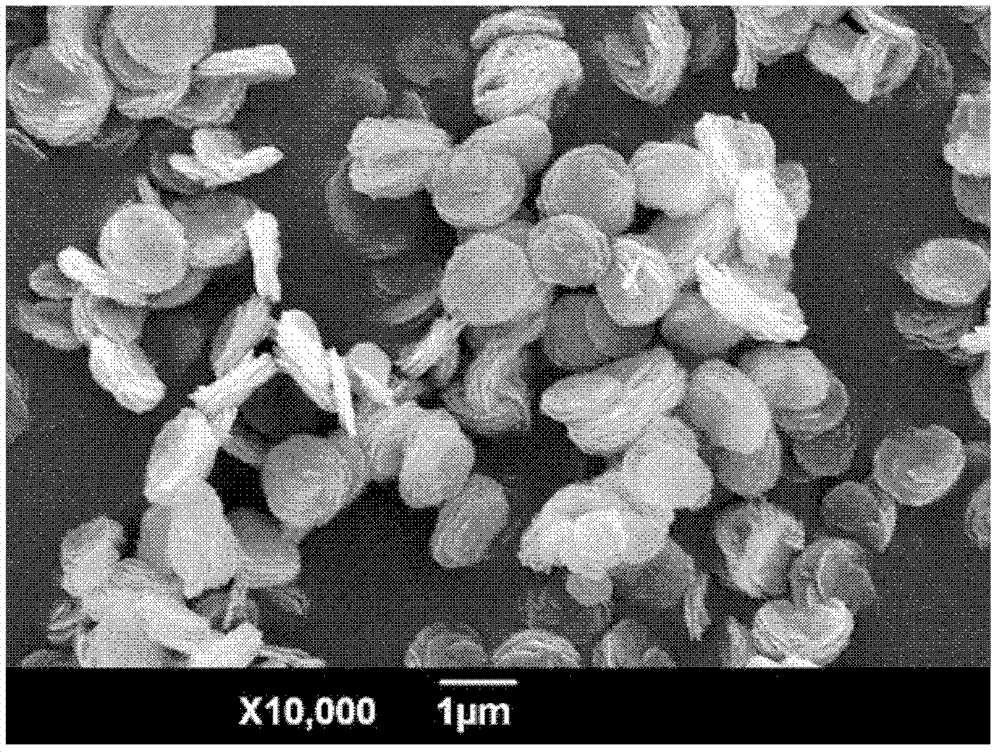

Image

Examples

Embodiment 1

[0016] 1) Separately analyze pure ZrCl 4 , ethyl orthosilicate (CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 ), cetyltrimethylammonium bromide (CTAB) was added into distilled water and stirred to make ZrCl 4 The molar concentration of the precursor solution A is 1.0mol / L, where ZrCl 4 :CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 : The molar ratio of CTAB is 2: 1: 6;

[0017] 2) Add hydrochloric acid dropwise to the precursor solution A to adjust the pH value to 1.5, and keep stirring to form sol B, and then age sol B at room temperature for 24 hours to obtain gel D;

[0018] 3) Put the gel D into a constant temperature drying oven to dry at 100°C, and put it into a mortar to grind after drying to obtain a powder E;

[0019] 4) Prepare the powder E into a suspension with a solid content of 20g / L, then pour the suspension into a hydrothermal reaction kettle, and control the filling ratio at 40%; then seal the hydrothermal kettle and put it into a microwave water reactor React at 280°C for 30 minu...

Embodiment 2

[0022] 1) Separately analyze pure ZrCl 4 , ethyl orthosilicate (CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 ), cetyltrimethylammonium bromide (CTAB) was added into distilled water and stirred to make ZrCl 4 The molar concentration of the precursor solution A is 0.7mol / L, where ZrCl 4 :CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 : The molar ratio of CTAB is 4: 3: 4;

[0023] 2) Add hydrochloric acid dropwise to the precursor solution A to adjust the pH value to 3.5, and keep stirring to form sol B, and then age sol B at room temperature for 36 hours to obtain gel D;

[0024] 3) Put the gel D in a constant temperature drying oven to dry at 150°C, and put it into a mortar to grind after drying to obtain the powder E;

[0025] 4) Prepare the powder E into a suspension with a solid content of 5g / L, then pour the suspension into a hydrothermal reaction kettle, and control the filling ratio at 60%; then seal the hydrothermal kettle, and put it into the microwave water React at 240°C for 45 minutes in...

Embodiment 3

[0028] 1) Separately analyze pure ZrCl 4 , ethyl orthosilicate (CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 ), cetyltrimethylammonium bromide (CTAB) was added into distilled water and stirred to make ZrCl 4 The molar concentration of the precursor solution A is 0.9mol / L, where ZrCl 4 :CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 : The molar ratio of CTAB is 7: 5: 2;

[0029] 2) Add hydrochloric acid dropwise to the precursor solution A to adjust the pH to 5, and keep stirring to form sol B, and then age sol B at room temperature for 72 hours to obtain gel D;

[0030] 3) Put the gel D into a constant temperature drying oven to dry at 200°C, and put it into a mortar for grinding after drying to obtain powder E;

[0031] 4) Prepare the powder E into a suspension with a solid content of 30g / L, then pour the suspension into a hydrothermal reaction kettle, and control the filling ratio at 80%; then seal the hydrothermal kettle, and put it into the microwave water React at 200°C for 60 minutes in a th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com