Preparation method of zirconium silicate powder

A technology for zirconium silicate and powder, which is applied in the field of sol-gel-assisted ultrasonic sonochemical method for preparing zirconium silicate powder, can solve the problems of high preparation temperature and short preparation time, and achieves low reaction temperature, short cycle, and high particle size. The effect of narrow diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

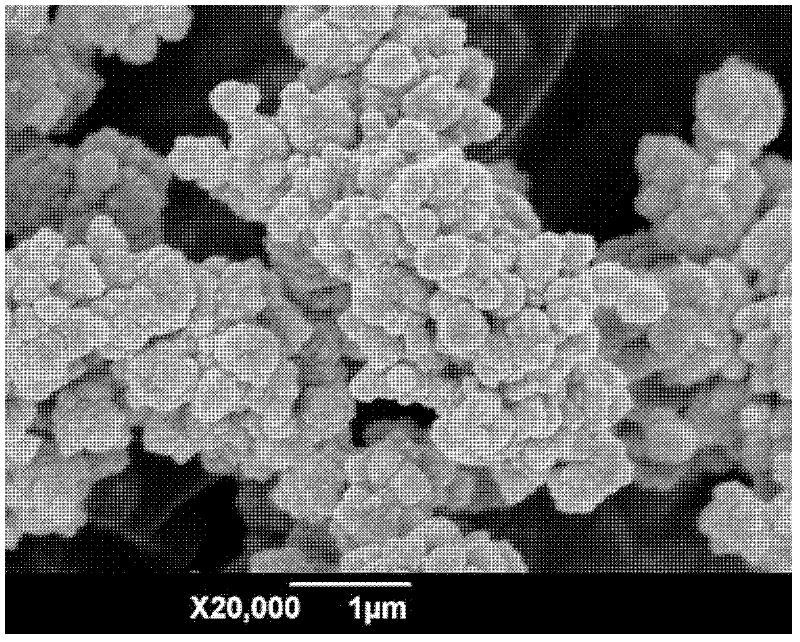

Image

Examples

Embodiment 1

[0015] 1) Separately analyze pure ZrOCl 2 ·8H 2 O, ethyl orthosilicate (CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 ), NaF was added into distilled water and stirred evenly to make ZrOCl 2 The molar concentration is the precursor A of 4mol / L, wherein ZrOCl 2 ·8H 2 O:CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 : The molar ratio of NaF is 2: 7: 1;

[0016] 2) Add hydrochloric acid dropwise to the precursor solution A to adjust the pH value to 1, and keep stirring to form sol B;

[0017] 3) Put sol B into the Erlenmeyer flask, then place the Erlenmeyer flask into an ultrasonic generator with a natural frequency of 80kHz, turn on the ultrasonic generator, and react for 12 hours at 60°C with an ultrasonic power of 300W. cool to room temperature;

[0018] 4) The reactants were taken out, collected by suction filtration through filter paper, washed with deionized water and absolute ethanol respectively, and dried in an electric blast drying oven at 40° C. to obtain zirconium silicate powder.

Embodiment 2

[0020] 1) Separately analyze pure ZrOCl 2 ·8H 2 O, ethyl orthosilicate (CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 ), NaF was added into distilled water and stirred evenly to make ZrOCl 2 The molar concentration is the precursor A of 6mol / L, wherein ZrOCl 2 ·8H 2 O:CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 : The molar ratio of NaF is 4: 4: 2;

[0021] 2) Add hydrochloric acid dropwise to the precursor solution A to adjust the pH value to 4.5, and keep stirring to form sol B;

[0022] 3) Put sol B into the Erlenmeyer flask, then place the Erlenmeyer flask into an ultrasonic generator with a natural frequency of 80kHz, turn on the ultrasonic generator, and react for 8 hours at 80°C with an ultrasonic power of 700W. Natural cooling to room temperature;

[0023] 4) The reactants were taken out, collected by suction filtration through filter paper, washed with deionized water and absolute ethanol respectively, and dried in an electric blast drying oven at 60° C. to obtain zirconium silicate po...

Embodiment 3

[0025] 1) Separately analyze pure ZrOCl 2 ·8H 2 O, ethyl orthosilicate (CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 ), NaF was added into distilled water and stirred evenly to make ZrOCl 2 The molar concentration is the precursor A of 2mol / L, wherein ZrOCl 2 ·8H 2 O:CH 3 CH 2 OSi(OCH 2 CH 3 ) 3 : The molar ratio of NaF is 6: 1: 3;

[0026] 2) Add hydrochloric acid dropwise to the precursor solution A to adjust the pH value to 6.5, and keep stirring to form sol B;

[0027] 3) Put sol B into the Erlenmeyer flask, then place the Erlenmeyer flask into an ultrasonic generator with a natural frequency of 80kHz, turn on the ultrasonic generator, and react for 5 hours at 100°C with an ultrasonic power of 1000W. cool to room temperature;

[0028] 4) The reactants were taken out, collected by suction filtration through filter paper, washed with deionized water and absolute ethanol respectively, and dried in an electric blast drying oven at 80° C. to obtain zirconium silicate powder.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com