Automatic mould assembling device

An automatic and box-turning technology, applied in the parts of the molding machine, casting equipment, molds, etc., can solve the problems of low work efficiency, center error between the upper box and the lower box, and low product quality, so as to improve work efficiency, The effect of avoiding the deformation of the sand tire and ensuring the quality of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

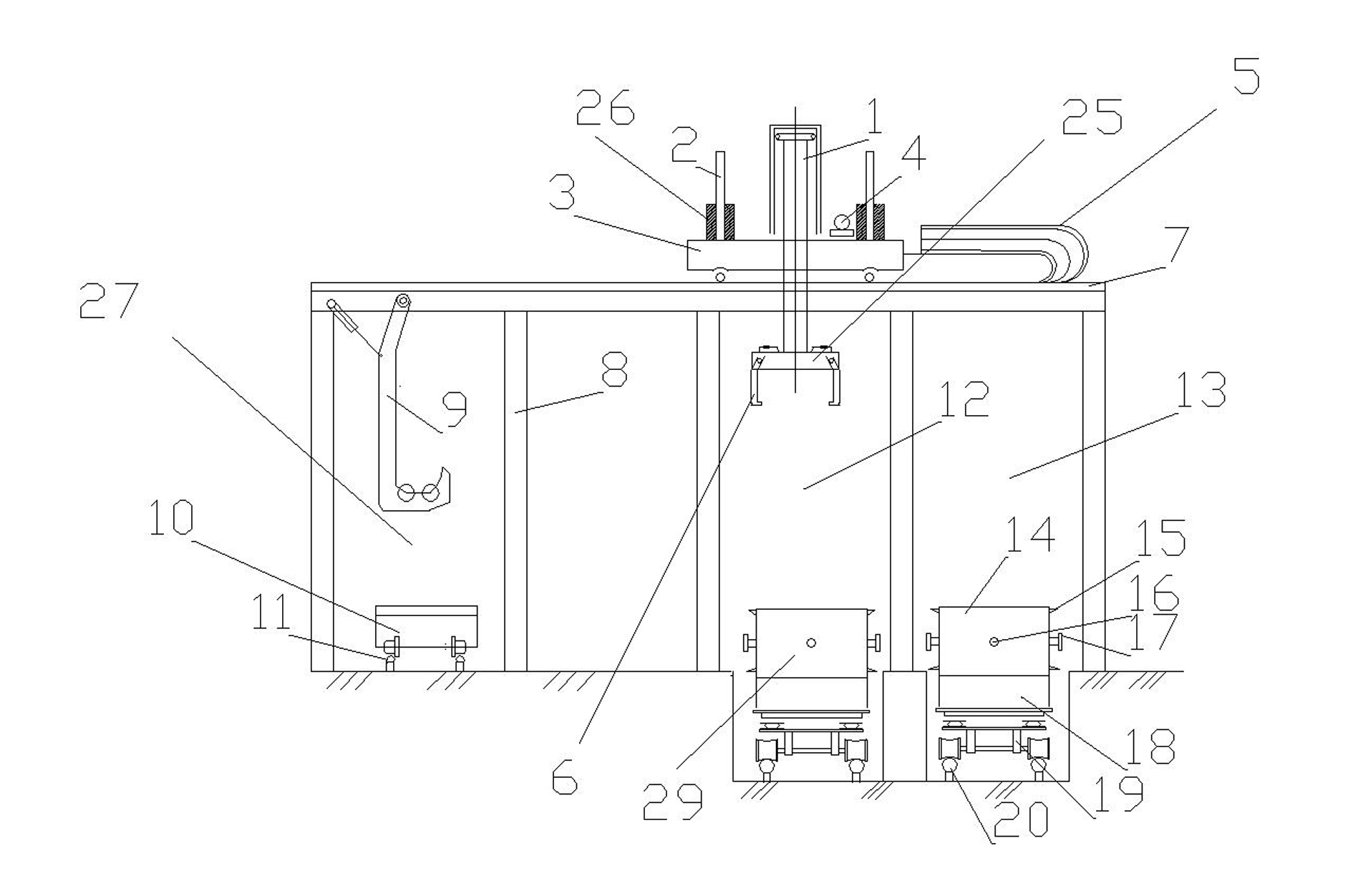

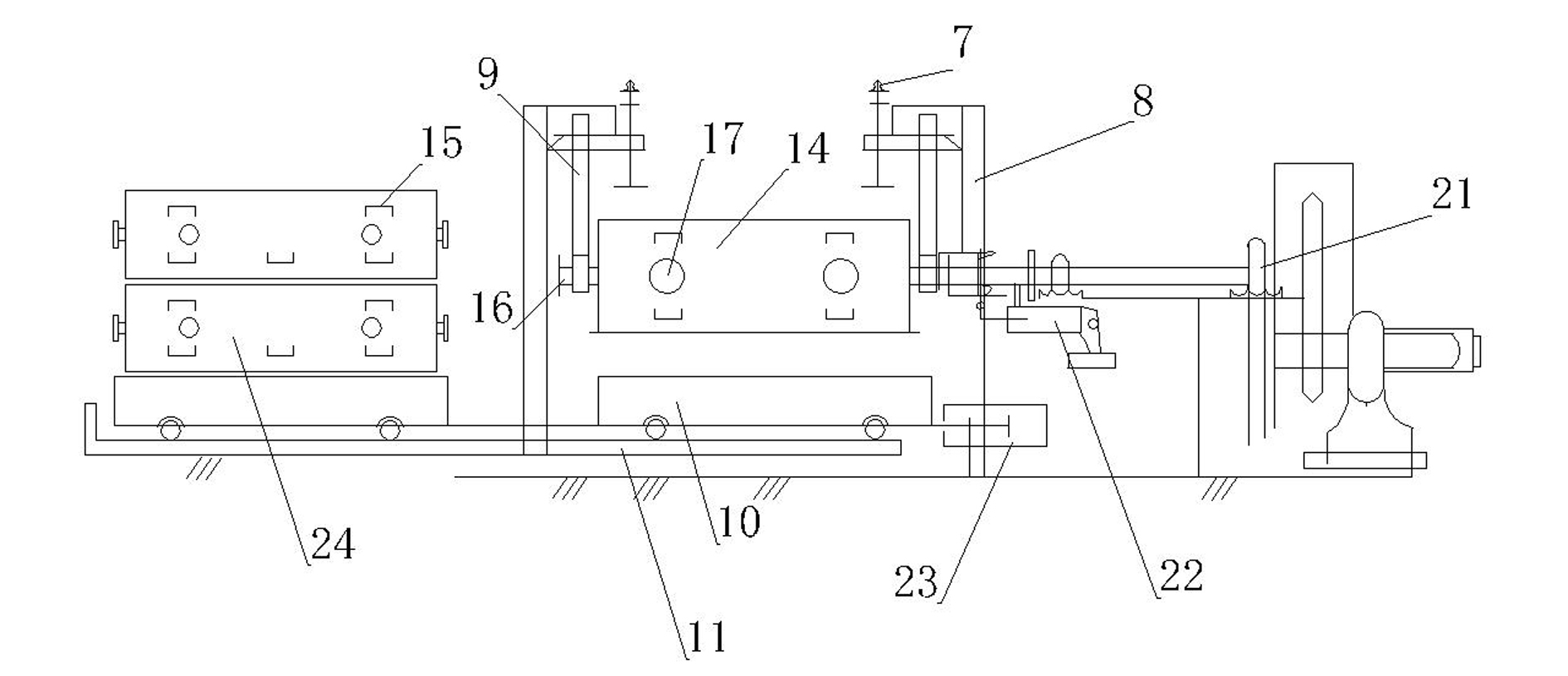

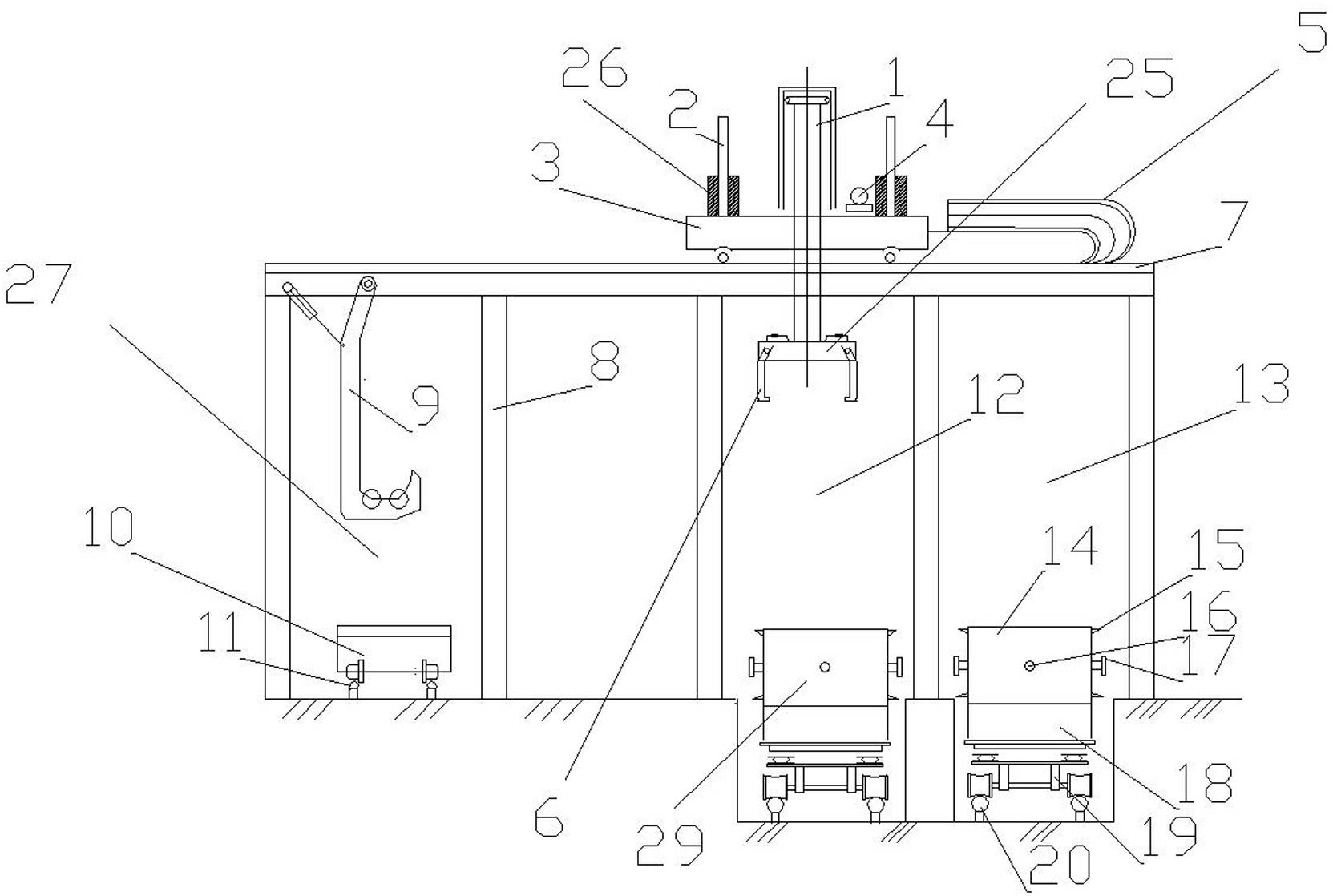

[0015] The structure of the automatic closing device is as follows: figure 1 , figure 2 As shown, it includes elevator 1, elevated rail 7, box closing trolley 10, box closing trolley rail 11, molding trolley 19, molding trolley rail 20, mold 18, lower sand box 14 and upper sand box 29 , It also includes a stripping mechanism and a box turning and closing system.

[0016] The elevated rail 7 is set on the pillar 8, and the operating trolley 3 is equipped with an operating mechanism 4, which allows the operating trolley 3 to run on the elevated rail 7, and the elevator 1 installed on the operating trolley 3 is connected to the power and the computer through the cable bridge 5 Automatic control cable, grab box frame 25 is installed on the elevating rod of lifter 1, grab box manipulator 6 is installed on the grab box frame 25, guider is installed between carrying running trolley 3 and lifter 1, and this guider is respectively installed in running Guide sleeve 26 and guide bar 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com