Quantitative sand adding mechanism and quantitative sand adding method of core shooter

A core shooting machine and quantitative bucket technology, which is applied in the parts of molding machines, molding machines, metal processing equipment, etc., can solve the problem that quantitative sanding is not very accurate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

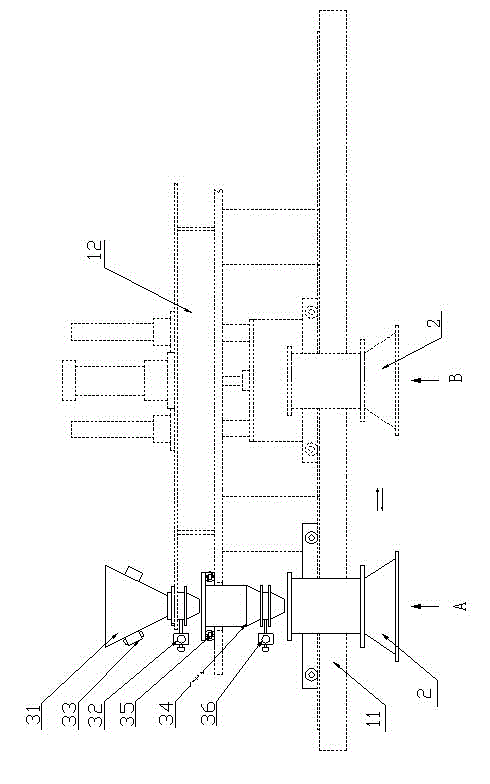

[0027] see figure 1 , as shown in the legend therein, a quantitative sanding mechanism of a core shooting machine, the core shooting machine has a lower frame 11 and an upper frame 12 located above the lower frame 11, the lower frame 11 is provided with a movable The above-mentioned quantitative sand adding mechanism includes a sand storage bucket 31, a first sand filling valve 32 and a vibrating motor 33, the sand storage bucket 31 is installed on the upper frame 12, and the first sand filling valve 32 is arranged on the sand storage The sand outlet of the bucket 31, the vibration motor 33 is installed on the outer wall of the sand storage bucket 31, the first sand adding valve 32 is an adjustable valve, the quantitative sand adding mechanism also includes a quantitative bucket 34, and the quantitative bucket 34 is connected through a weighing element 35 On the upper frame 12, the sand inlet of the quantitative bucket 34 is connected to the sand outlet of the sand storage buc...

Embodiment 2

[0038] The rest are the same as the first embodiment, the difference is that the above-mentioned first sanding valve is an electromagnetic valve, the above-mentioned weighing element is a weight sensor, and the above-mentioned automatic control device includes a controller, a first electromagnetic valve driver, a second electromagnetic driver and a motor driver, the weight sensor is connected to the input end of the controller, the first sanding valve is connected to the output end of the controller through the first electromagnetic valve driver, and the second sanding valve is connected to the output end of the controller through the second electromagnetic valve driver. connected to the output end of the above-mentioned controller, and the above-mentioned vibration motor is connected to the output end of the above-mentioned controller through the above-mentioned motor driver.

[0039] The following introduces a quantitative sanding method for a core shooter, using the quantita...

Embodiment 3

[0047] All the other are identical with described embodiment one, and difference is that above-mentioned quantitative sanding method comprises the steps:

[0048] (1) Close the above-mentioned second sand-filling valve, turn on the vibrating motor of the above-mentioned sand storage hopper, open the above-mentioned first sand-filling valve through the above-mentioned controller and air control valve driver, and adjust the valve port of the above-mentioned first sand-filling valve to the maximum amount of sand The diameter is DN, adding molding sand to the above-mentioned quantitative hopper, and the above-mentioned weighing element weighs the weight of the molding sand in the quantitative hopper in real time, and transmits the weighing result to the above-mentioned controller;

[0049] (2) When the weight of the molding sand in the quantitative hopper weighed by the weighing element reaches 15 / 24M, adjust the valve port of the first sand adding valve to 21 / 30DN through the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com