Aerogenerator of triethylamine

A technology of gas generator and triethylamine, which is applied to casting molding equipment, casting molds, cores, etc., can solve the problem of low consumption, achieve the effects of reducing amine consumption, controlling environmental pollution, and improving the quality of sand cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

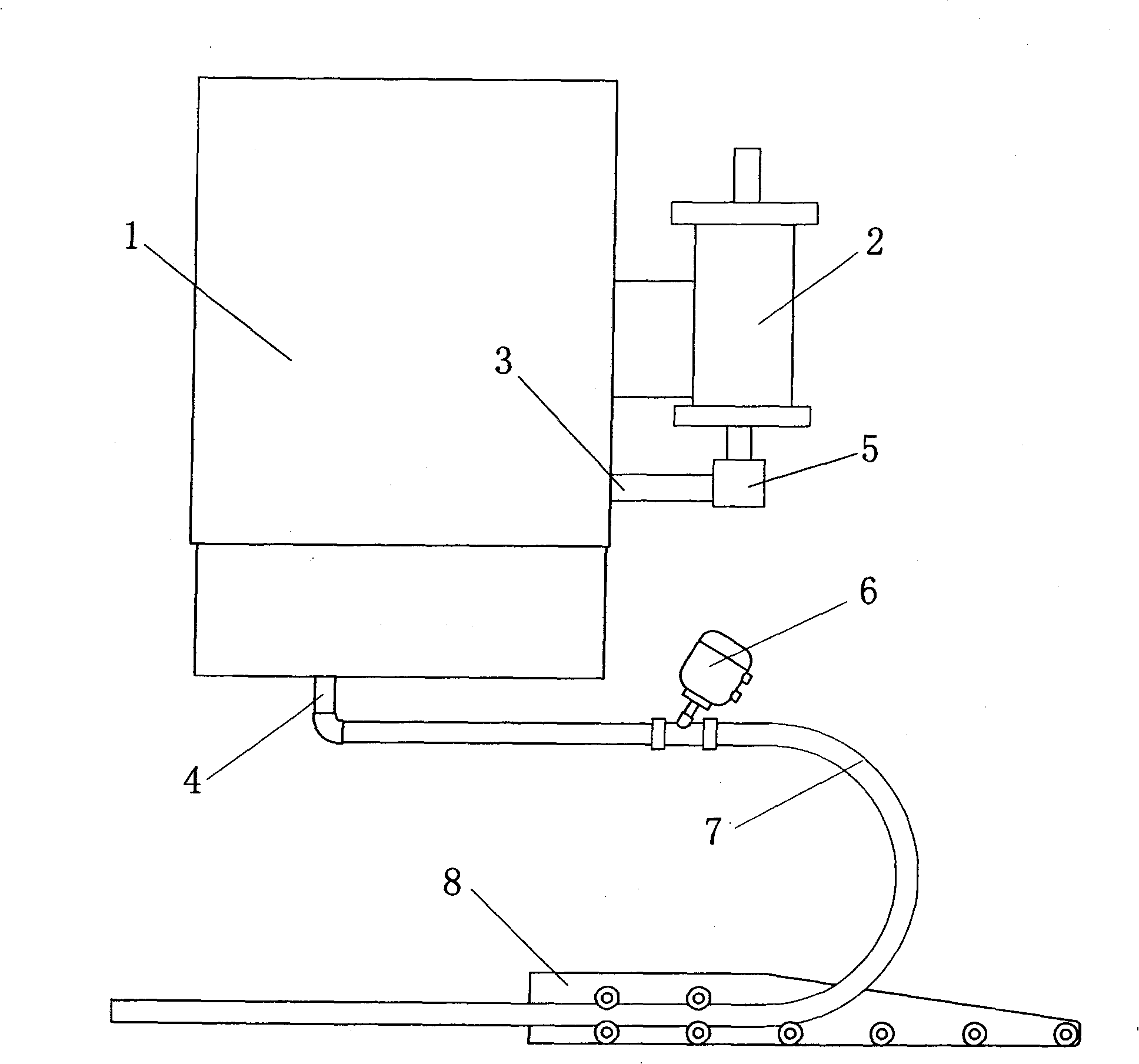

[0015] Such as figure 1 As shown, the triethylamine gas generator of the present invention includes a vaporizer 1 and a closed quantitative amine addition device 2 . The amine delivery pipe 16 on the closed quantitative amine addition device 2 is connected to the amine addition port 3 on the vaporizer 1 through the angle valve 5, and the liquid amine is vaporized in the vaporizer 1 and enters the prepared sand through the vaporized amine outlet 4 through the amine blowing pipe 7. in the core box. The amine blowing pipe 7 runs in the guide bracket 8, and the guide bracket 8 guides the amine blowing pipe 7. A stop valve 6 is installed on the amine blowing pipe 7 .

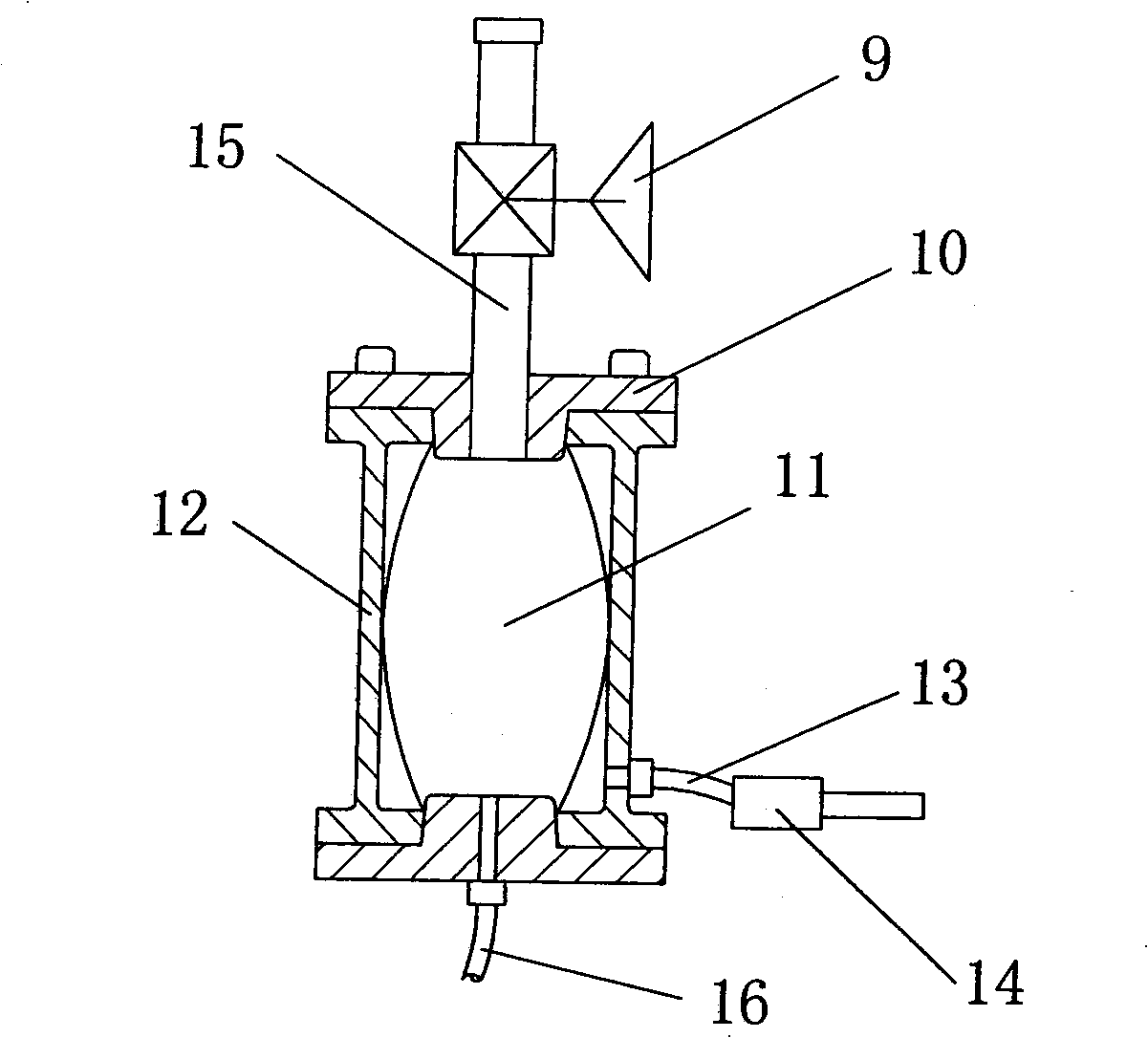

[0016] The structure of closed quantitative amine addition device 2 is as follows: figure 2 As shown, it mainly includes a tank body 12, a head 10, a capsule 11 and a pressure regulating valve 14. The capsule 11 is installed in the tank body 12, and its two ends are press-fitted on the upper and lower ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com