Robot sand core lock core, core setting method and system

A technology of robots and industrial robots, applied in the direction of cores, manipulators, parts of molding machines, etc., can solve the problems of low work efficiency, hidden dangers of railway traffic safety, and high labor intensity, so as to improve labor productivity and improve safety and reliability. , The effect of improving the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

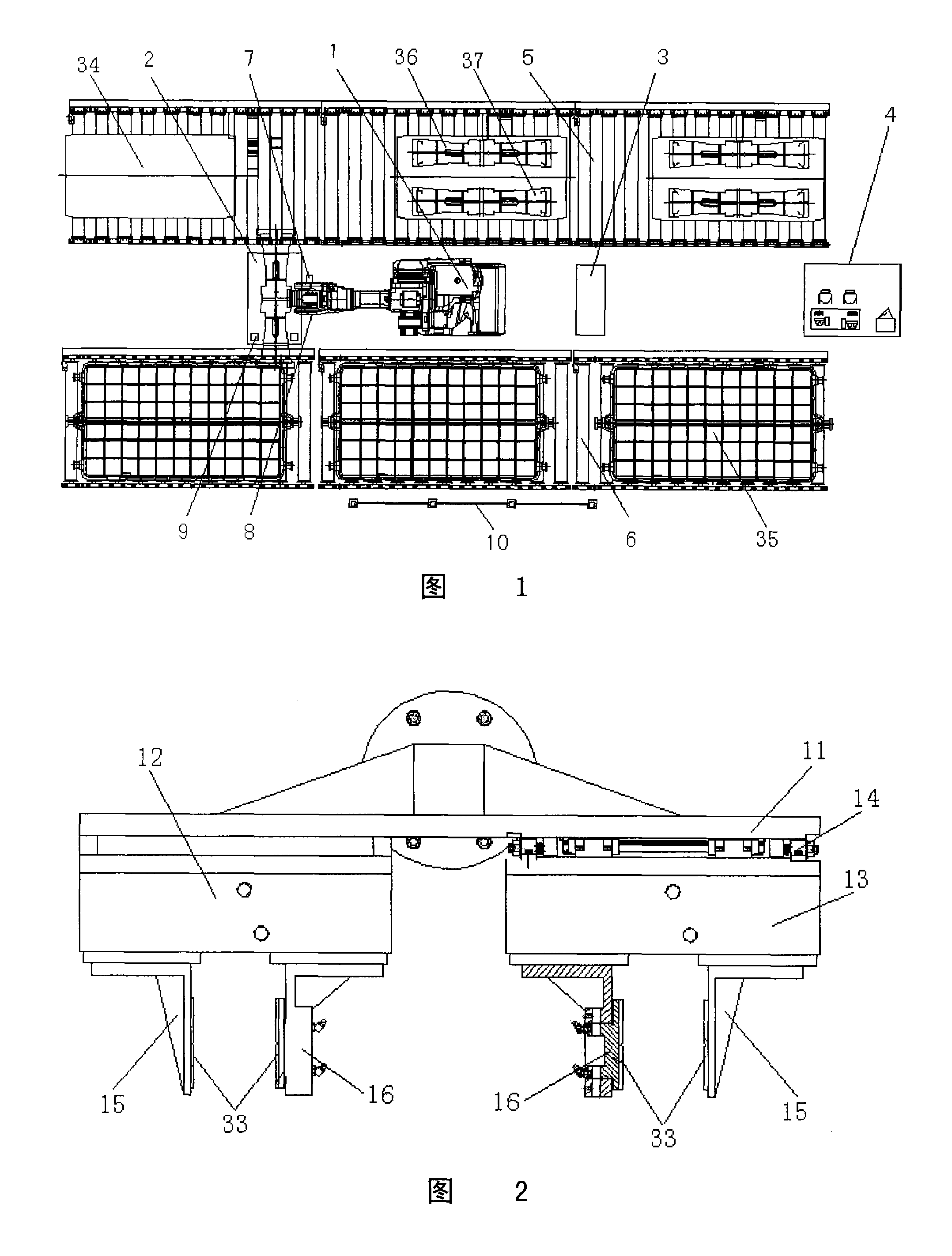

[0026] As shown in Figure 1, the present invention comprises a prior art multi-degree-of-freedom industrial robot 1, a lock core platform 2, an intermediate station platform 3, a central control room 4, a sand core conveying roller table 5 and a sand box Conveyor roller table 6. A three-dimensional scanner 7 and a flexible fixture 8 are connected to the actuator end of the robot 1, and a set of displacement measuring device 9 is installed on the lock cylinder platform 2, such as a LVDT (linear displacement sensor) measuring device, and a sand core conveying roller table 5 And a sand box conveying roller table 6 is made up of the roller shaft passage driven by motor and sprocket drive device respectively, is arranged in parallel on the both sides of robot 1 and lock cylinder platform 2. A safety barrier 10 is provided at an appropriate position around...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com