Double-station horizontal parting and removable flask shoot and squeeze molding machine

A horizontal parting, double-station technology, applied in the direction of molding machine, molding machine parts, manufacturing tools, etc., can solve the problem of high investment cost, achieve the effect of low investment cost, compact structure, and low probability of equipment failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

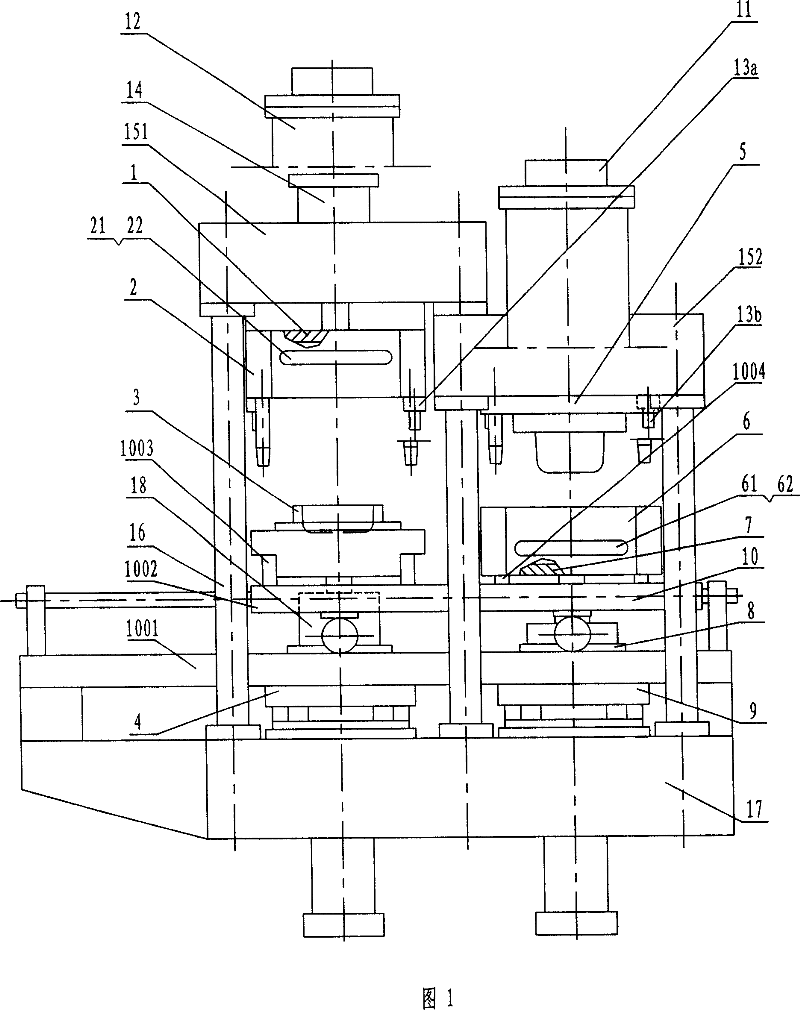

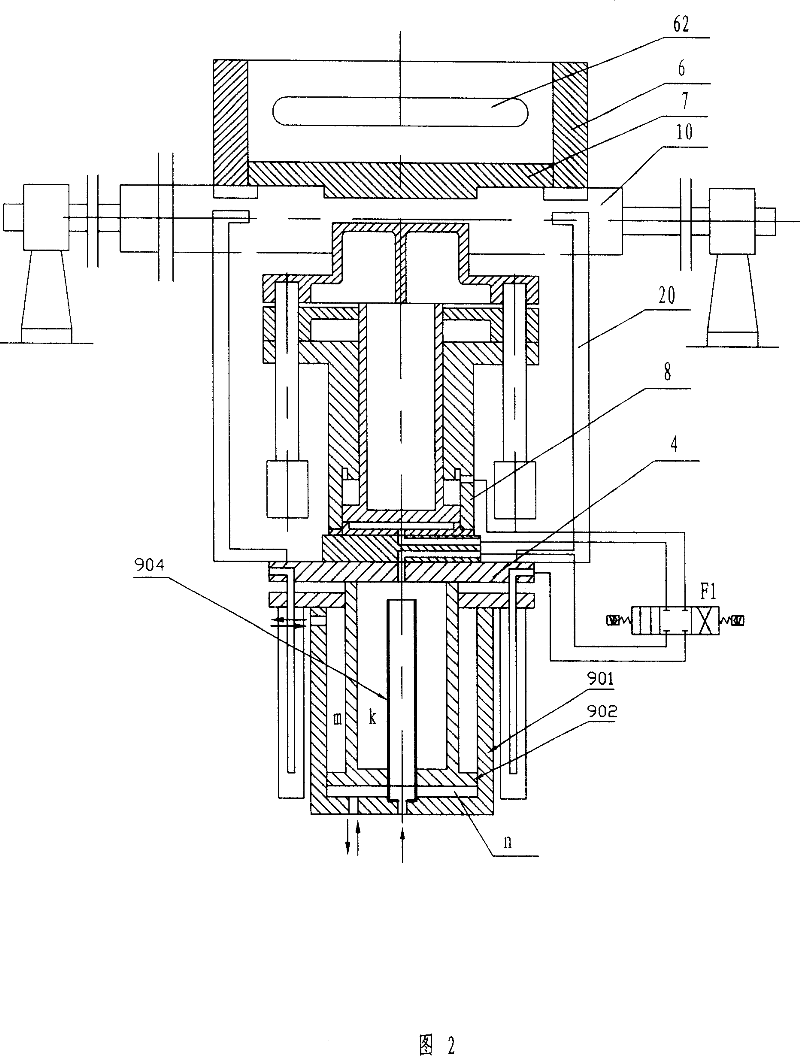

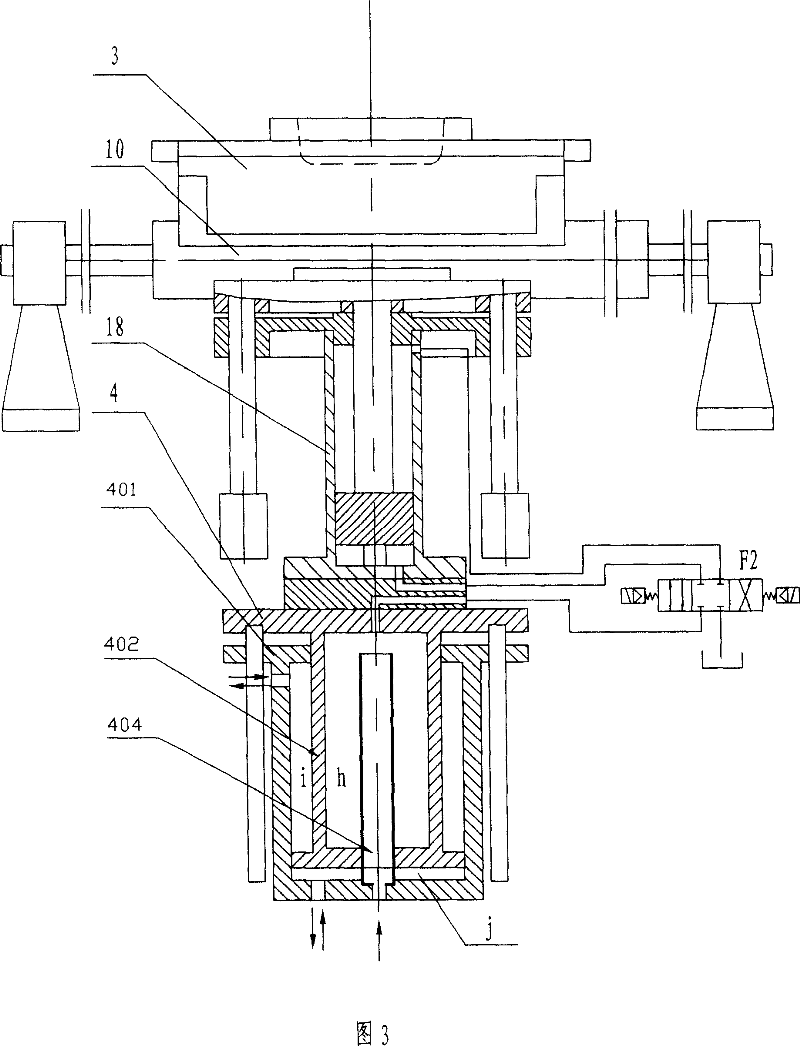

[0023] With reference to Fig. 1, a kind of double-station horizontal parting injection molding machine that is used for producing sand mold, comprises: base 17, is provided with column 16 on base 17 and one end of column 16 is connected with base 17, on column 16 Two crossbeams 151 and 152 are arranged on the other end of the cylinder, and one of the crossbeams 151 is provided with an upper sand mold compacting and unboxing oil cylinder 14 and an upper box double-side sand shooting mechanism 12, and the upper sandbox is connected to the crossbeam 151. 2. There are sand inlets 21, 22 on the front and rear sides of the upper sand box 2, respectively, and the sand inlets 21, 22 are respectively connected to the two sand outlets of the double-side sand shooting mechanism 12 of the upper box (refer to Fig. 7) to form a closed sand shooting channel on both sides. The upper sand mold compaction and box removal oil cylinder 14 includes a cylinder body and a piston rod. Pressing plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com