Part for cast production fabricated by wet type paper-making method

A technology for castings and components, applied in the field of manufacturing components for casting manufacturing, can solve problems such as inability to use cores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

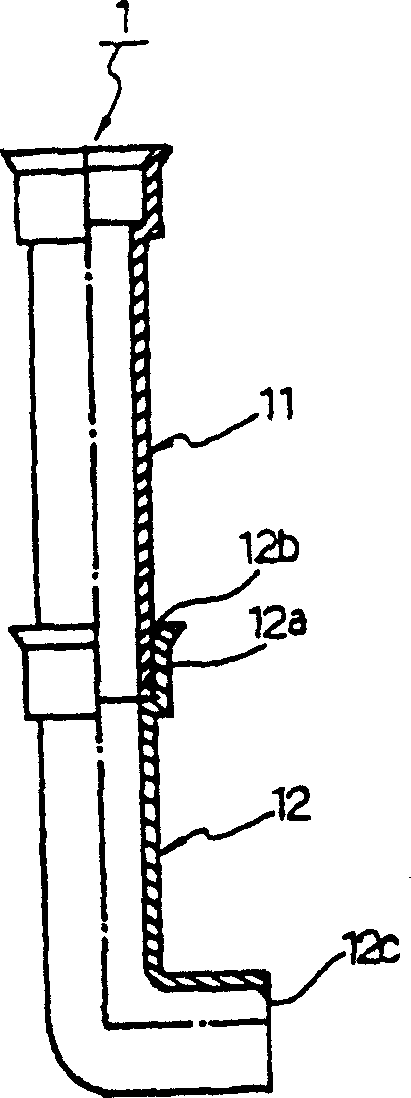

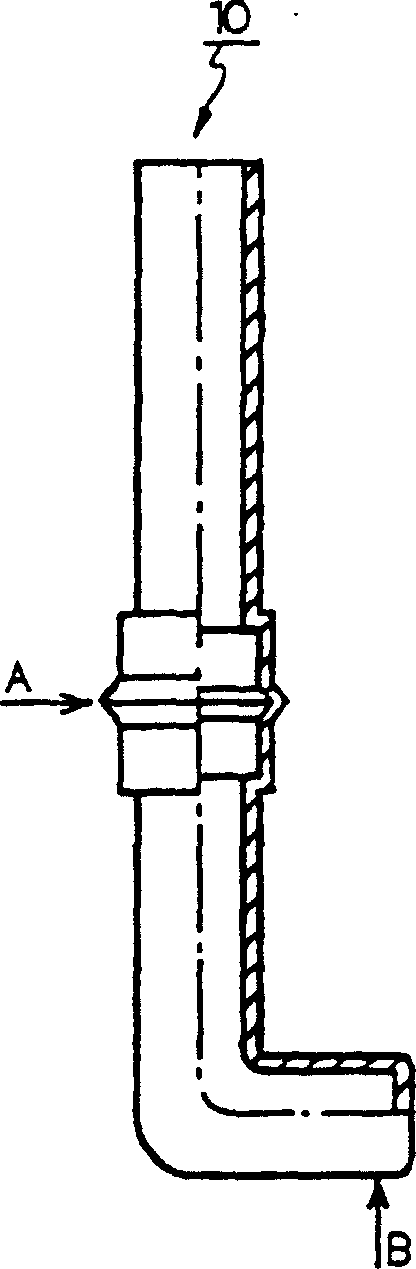

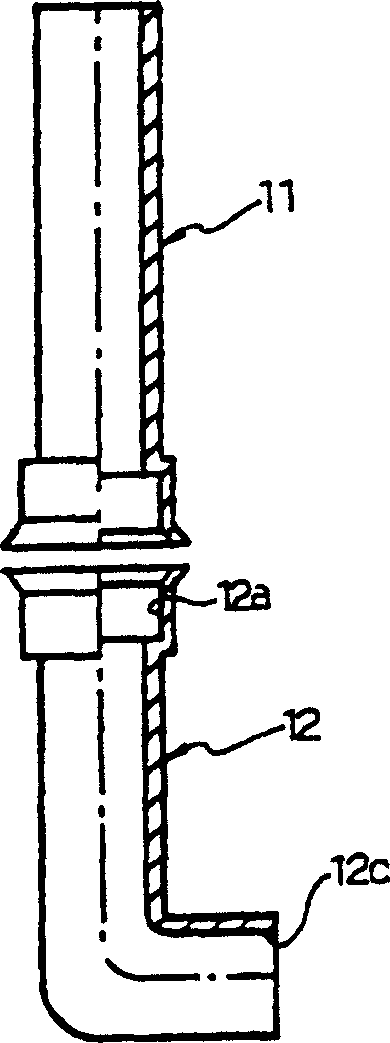

[0094] After forming a predetermined fiber laminate with the following raw material slurry, the fiber laminate is dewatered and dried to obtain a sprue for sprue having the shape shown in Figure 2(a) and having the following physical properties (manufactured by casting Use paper-made components, weighing about 16g).

[0095]

[0096] After dispersing the organic fibers and inorganic fibers blended below into water and adjusting to a slurry of about 1% (the weight ratio of the total weight of organic fibers and inorganic fibers to water is 1%), the following binder and The flocculant is added to the slurry, and the mixing ratio (weight ratio) of the organic fiber, the inorganic fiber, and the binder is adjusted to a raw material slurry having the following value.

[0097] [Combination of raw material slurry]

[0098] Organic fiber: old newspaper, average fiber length is 1mm, drainage (hereinafter referred to as CSF) is 150cc;

[0099] Inorganic fiber: carbon fiber (manufactured by...

Embodiment 2

[0117] After forming a predetermined fiber laminate with the following raw material slurry, the fiber laminate is dehydrated and dried to obtain an intermediate molded body having the shape shown in FIG. 2(a). In addition, the following binder was impregnated on the intermediate molded body, dried and thermally cured to obtain a sprue runner having the following physical properties (paper-made member for casting production, weight approximately 28 g).

[0118]

[0119] Disperse the organic fibers and inorganic fibers blended below in water and adjust to a slurry of about 1% (the total weight of organic fibers and inorganic fibers is 1% by weight relative to water), and then add the following adhesive to the slurry The mixing ratio (weight ratio) of the organic fiber, the inorganic fiber, and the binder is adjusted to a raw material slurry having the following value.

[0120] [Mixing of raw material slurry]

[0121] Organic fiber: old newspaper, average fiber length is 1mm, CSF is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com