Venting unit for a Die Casting device

a technology of die casting device and venting unit, which is applied in the direction of foundry moulds, moulding machine components, foundry moulding apparatus, etc., can solve the problems of only evacuating the mold cavity unsatisfactory, affecting the quality of the casting produced, and impairing the extraction capability, so as to reduce flow losses, improve the evacuation effect, and reduce the flow cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

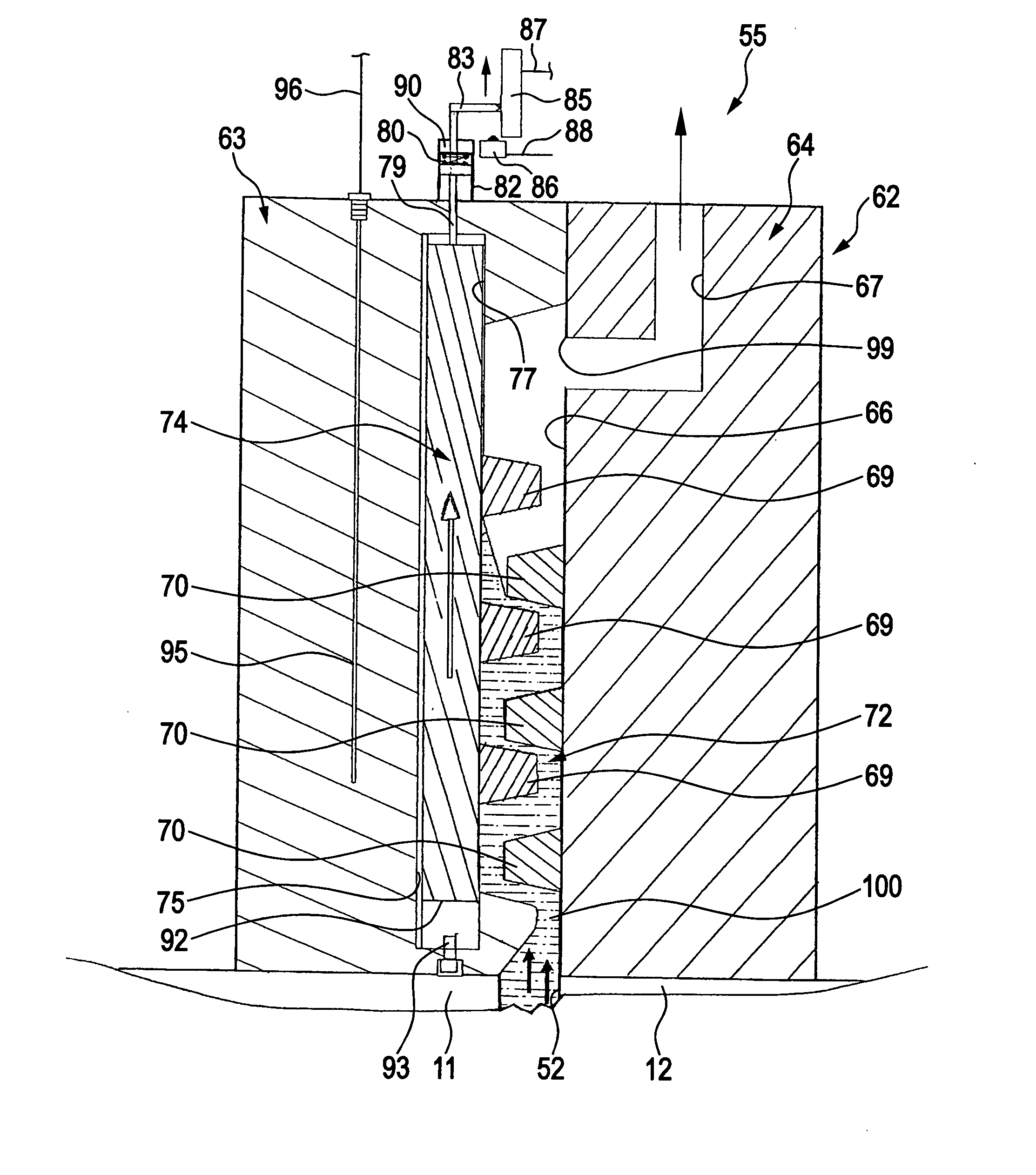

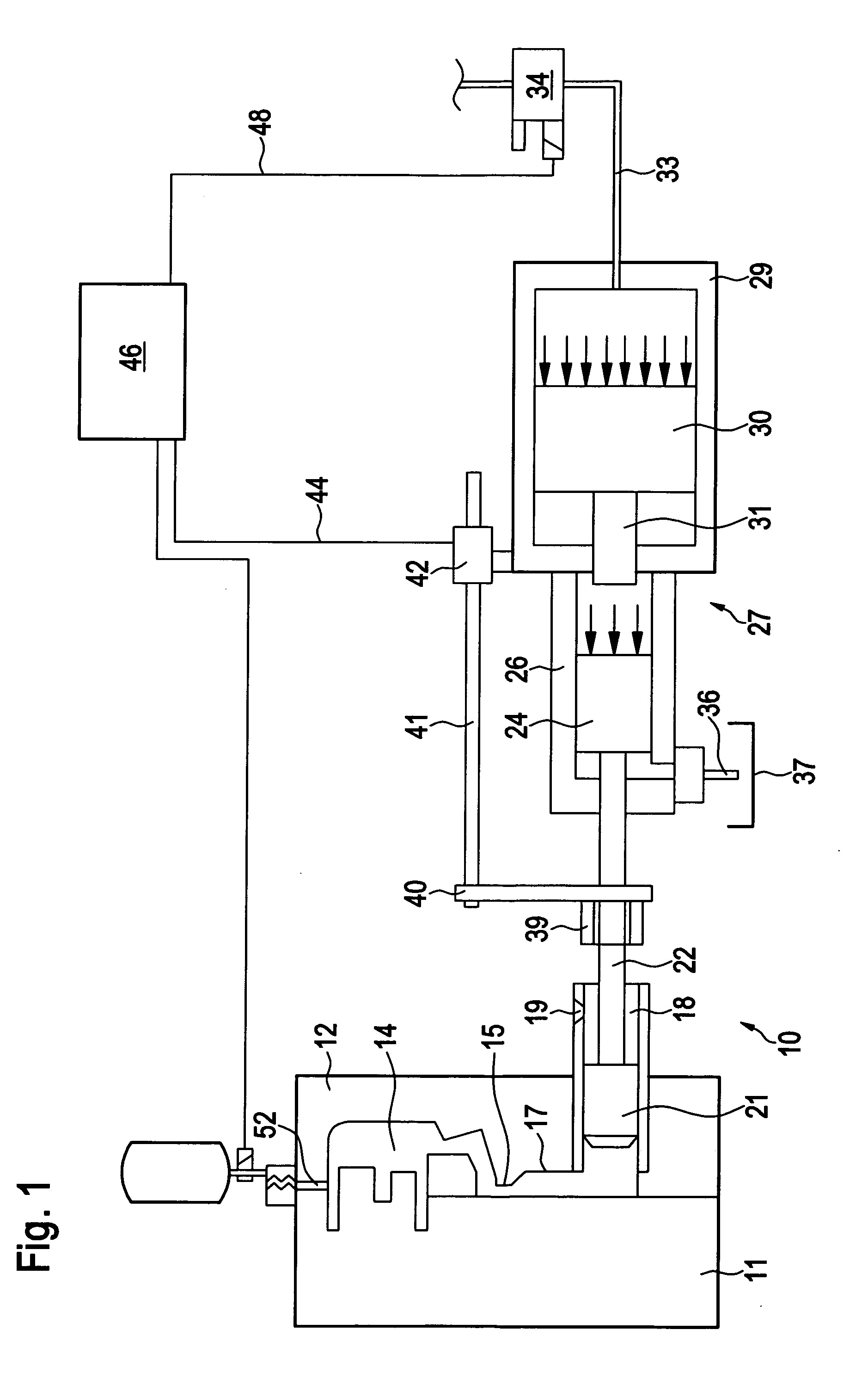

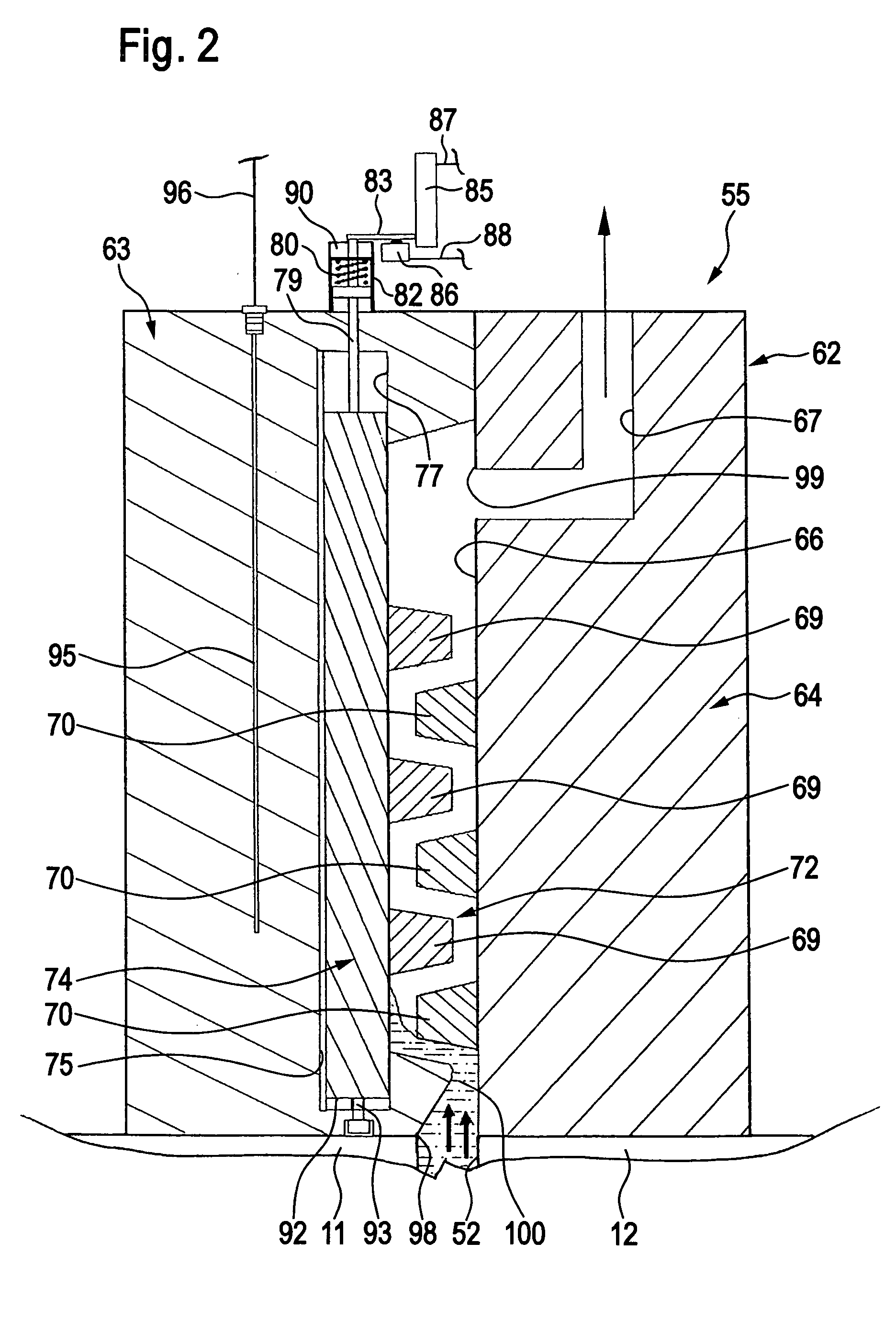

[0030]Schematically represented in FIG. 1 is a die casting device 10 according to the invention, which has a first, movable die half 11 and a second, fixed die half 12, which interact in the customary way with a die closing unit that is known per se, and therefore not represented in the drawing. Said closing unit comprises a movable platen and a fixed platen, which are not represented in the drawing to achieve a better overview and on each of which one of the two die halves 11, 12 is held in a known way. By means of the die closing unit, a predeterminable closing force can be exerted on the two die halves 11, 12. The two die halves 11, 12 form between them a mold cavity 14, which has the form of a casting to be cast and into which a casting material, for example a molten metal, preferably liquid aluminum or magnesium material, can be injected. For this purpose, the mold cavity 14 has an inlet opening, which is usually referred to as the “gate” and in FIG. 1 is provided with the desi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic restoring force | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com