3D printing sand mold continuous type six-face automatic sand cleaning machine and sand cleaning method

A technology of 3D printing and sand cleaning machine, applied in the parts of molding machine, casting and molding equipment, metal processing equipment, etc. Reduce post-processing time, benefit your health, and improve automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

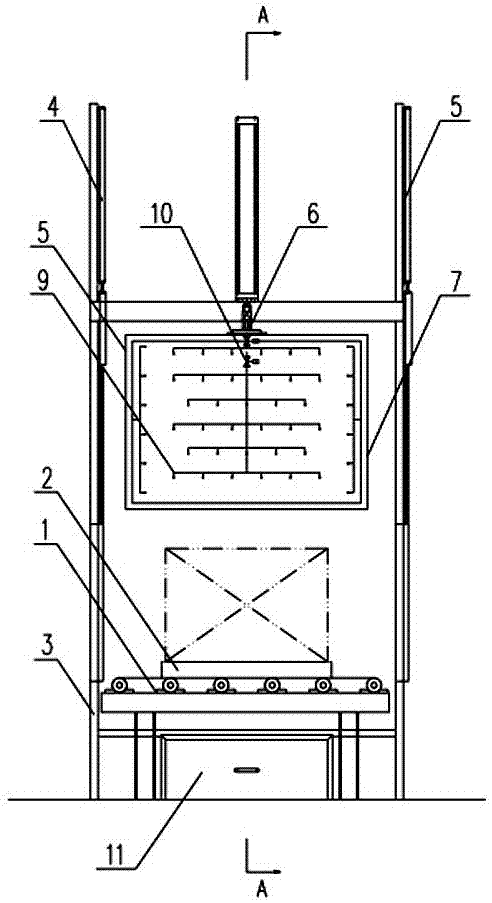

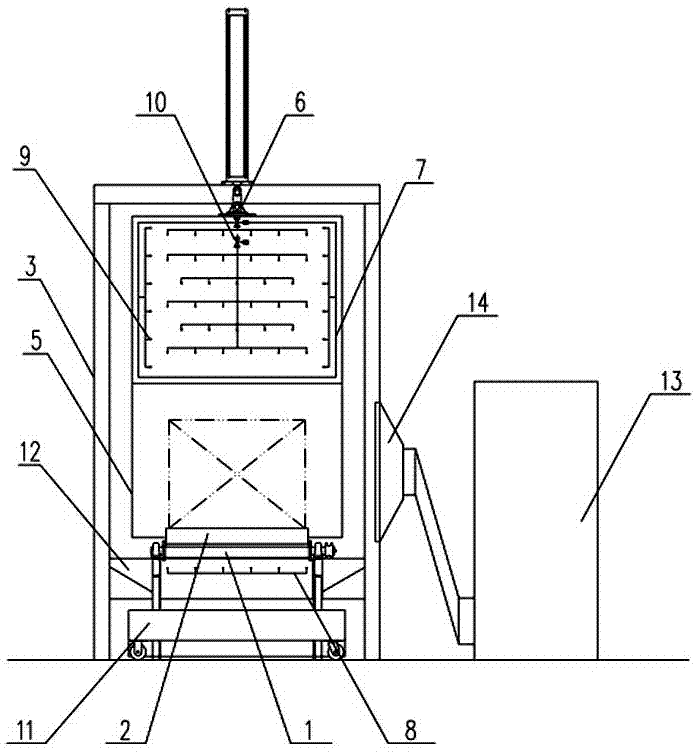

[0020] Such as figure 1 , 2 As shown, the continuous six-sided automatic sand cleaning machine for 3D printing sand molds of the present invention includes a roller conveyor 1 for conveying 3D printing sand molds (hereinafter referred to as sand molds), wherein the sand molds are contained at the bottom to facilitate bottom blowing and floating On the hollow pallet rack 2 where the sand falls; the front and rear sides of the sand cleaning machine shell 3 straddling the roller conveyor 1 are respectively provided with an inlet closing door 4 and an outlet closing door 5 with an automatic lifting structure. The sand cleaning machine The top of the shell 3 passes through a lifting mechanism such as an air cylinder 6 and an elevating sand blowing cover 7. The middle of the sand cleaning machine shell 3 is provided with a bottom blowing frame 8 under the roller conveyor 1. The top and left sides of the sand blowing cover 7 A set of blowing nozzles 9 covered with a flexible material l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com