Addition-curable silicone composition

A silicone composition, addition curing technology, applied in the direction of electrical solid devices, semiconductor/solid device manufacturing, semiconductor/solid device components, etc., to achieve excellent adhesion and inhibit thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0155]

[0156] Polyorganosiloxane (D24) can be produced by the method shown below, for example.

[0157] That is, put into the reaction vessel selected from R ep Si(OR 6 ) 3 The trifunctional silane represented by R ep R 6 Si(OR 6 ) 2 Difunctional silanes represented by R ep R 6 2 Si(OR 6 ) of monofunctional silanes represented by at least one epoxy group-containing silane compound and R 7 2 Si(OR 6 ) represents a silane compound having an alkenyl group, and if necessary, put in R 8 Si(OR 6 ) 3 Trifunctional silanes represented by and / or represented by R 8 2 Si(OR 6 ) 2 For the bifunctional silane shown, the liquid is made alkaline and heated to perform partial hydrolysis, followed by condensation reaction.

[0158] In the above formula, R ep Represents a 1-valent organic group with an epoxy group, R 6 represents an alkyl group, R 7 Represents a monovalent hydrocarbon group selected from alkenyl, alkyl and aryl, R 8 Indicates an alkyl or aryl group. ...

Embodiment

[0197] Examples of the present invention are described below, but the present invention is not limited to these Examples. In addition, in the following examples, the viscosity is the measured value at 25 degreeC.

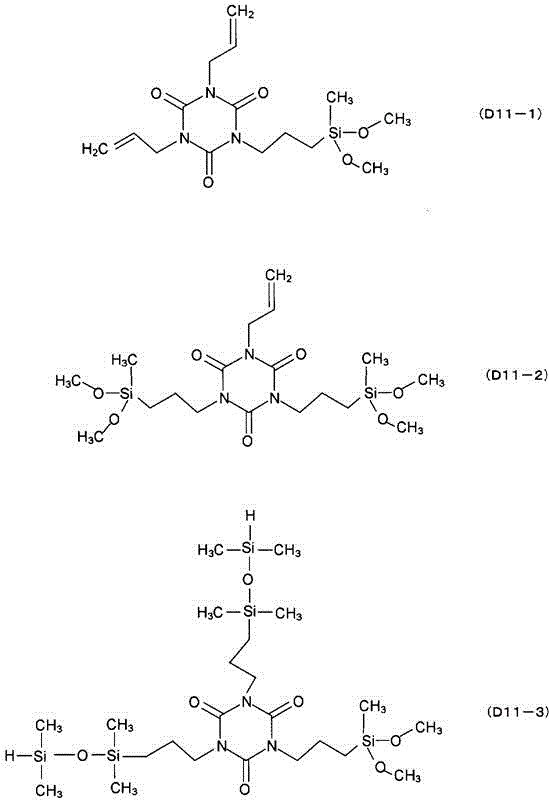

[0198] In the following examples and comparative examples, the following compounds and the like were used as (A) to (G) components. In the following description, Vi represents a vinyl group, Me represents a methyl group, and Ph represents a phenyl group.

[0199] (A) Component: Polyorganosiloxane (A1), Polyorganosiloxane (A2)

[0200] (Organopolysiloxane (A1): Linear methyl vinyl polysiloxane (A11))

[0201] Take the average composition formula: (ViMe 2 SiO 1 / 2 )(Me 2 SiO 2 / 2 ) m1 (ViMeSiO 2 / 2 ) m2 (ViMe 2 SiO 1 / 2 ) represents a linear methyl vinyl polysiloxane with an average degree of polymerization of 450 (m1=448, m2=0), a viscosity of 5000 mPa·s, and an average of 2 vinyl groups per molecule.

[0202] (Organopolysiloxane (A1): Linear methyl vinyl pol...

Synthetic example 1

[0225] 185.9 g (0.788 mol) of 3-glycidoxypropyltrimethoxysilane, 347.1 g (2.888 mol) of dimethyldimethoxysilane, 178.5 g (1.313 mol) After methyltrimethoxysilane of 34.7g (0.263mol) of methylvinyldimethoxysilane and 105g of toluene, 1.02g of 6N sodium hydroxide (NaOH) aqueous solution and 53g of ion-exchanged water were added and carried out Stir.

[0226] Heat the mixture in the reaction vessel until the liquid temperature becomes 30°C. At this time, the above four silane compounds (3-glycidyloxypropyltrimethoxysilane, dimethyldimethoxysilane, dimethyldimethoxysilane, etc.) Silane, methyltrimethoxysilane, and methylvinyldimethoxysilane) partial hydrolysis reaction of the methoxy group, began to generate heat. Even after heating was stopped, heat generation continued, and the temperature was raised to 50° C. while the reaction mixture became transparent. When continuing to stir and the temperature begins to decrease, add ion-exchanged water (the ion-exchanged water added at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com