Non-woven fabric for semipermeable membrane support

A technology of non-woven fabrics and semi-permeable membranes, applied in the field of non-woven fabrics for semi-permeable membrane supports, to achieve the effect of inhibiting thermal shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

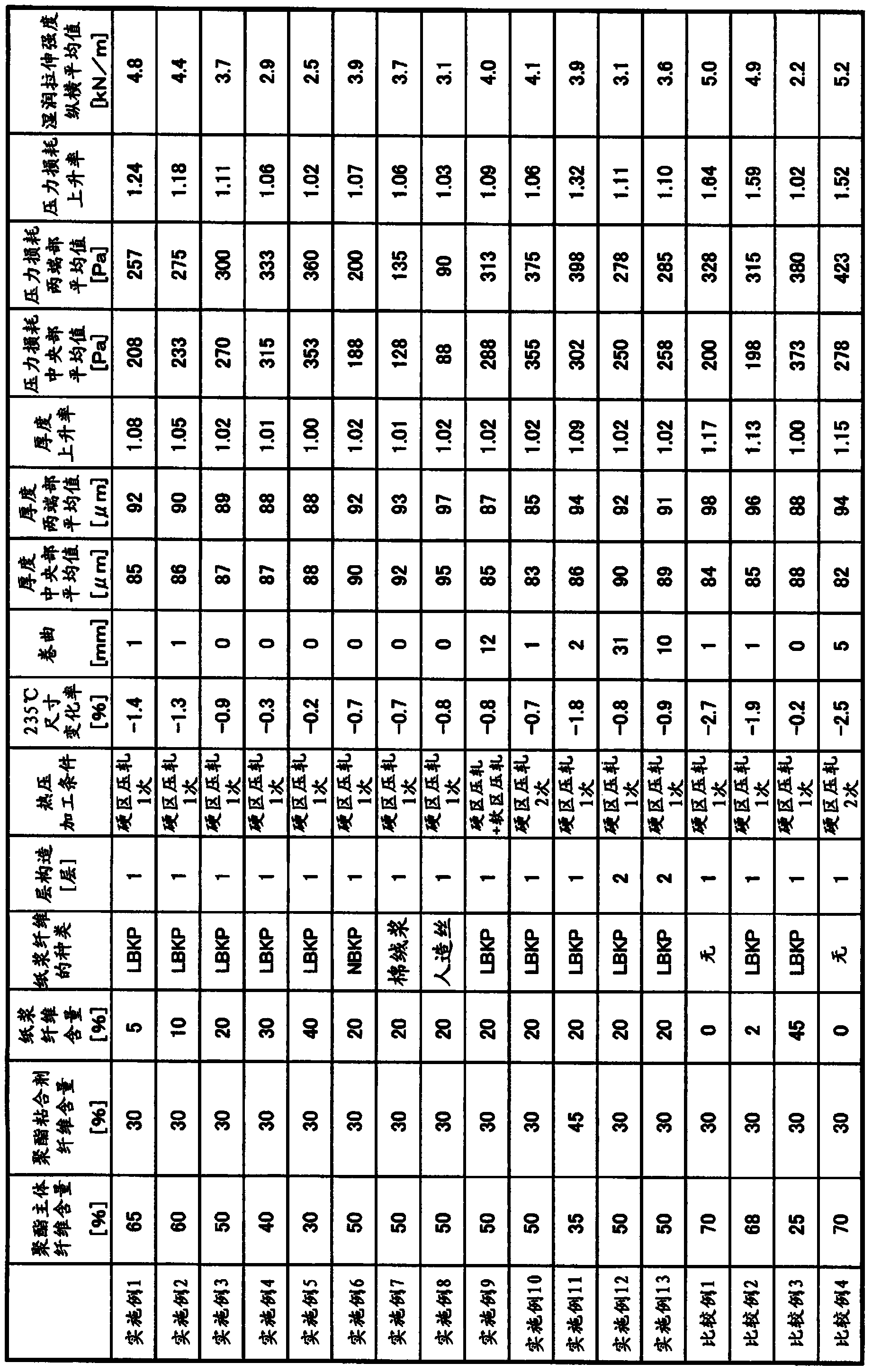

Examples

Embodiment 1)

[0068]

[0069] A commercially available polyester fiber (trade name: EP133, manufactured by KURARAY, melting point 260°C) with a thickness of 1.45 dtex and a cut length of 5 mm, 19.5 kg of a commercially available polyester fiber with a thickness of 1.2 dtex and a cut length of 5 mm Polyester binder fiber (trade name: TR07N, manufactured by Teijin Fiber Co., Ltd., melting point 230°C) and 1.5 kg of unknocked hardwood bleached kraft pulp (LBKP) are poured into water and dispersed by a disperser for 5 minutes to obtain a fiber concentration of 1 mass % Of fiber raw material pulp.

[0070]

[0071] Add water to the fiber raw material pulp to adjust the fiber concentration to 0.03% by mass. Put the fiber pulp into the headbox of the short wire paper machine. After the fiber pulp is made into paper, it is dried with a Yankee at a surface temperature of 120°C. The cylinder is dried to obtain a width of 1000mm and a weight of 70g / m per square meter 2 The continuous reeling of the base ...

Embodiment 2)

[0075] In the preparation of the fiber raw material slurry of Example 1, it was obtained in the same manner as in Example 1, except that the polyester main fiber was set to 18.0 kg, the polyester binder fiber was set to 9.0 kg, and the unknocked LBKP was set to 3.0 kg. Non-woven fabric for semipermeable membrane support.

Embodiment 3)

[0077] In the preparation of the fiber raw material slurry of Example 1, it was obtained in the same manner as in Example 1, except that the polyester main fiber was set to 15.0 kg, the polyester binder fiber was set to 9.0 kg, and the non-knocked LBKP was set to 6.0 kg. Non-woven fabric for semipermeable membrane support.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com