Ceramic diaphragm and preparation method therefor

A technology of ceramic diaphragm and thermally conductive ceramics, applied in electrical components, electrochemical generators, circuits, etc., can solve the problems of inability to conduct and disperse heat in time, overheating of diaphragm, poor thermal conductivity, etc., to reduce the risk of short circuit and improve thermal conductivity. performance, the effect of suppressing heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

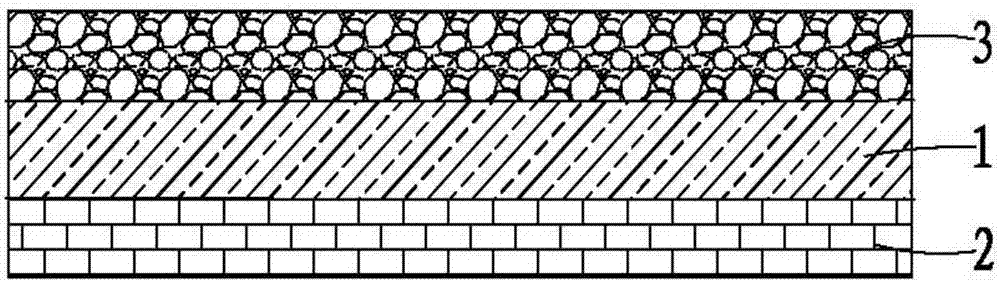

[0038] like figure 1 As shown, a ceramic diaphragm includes a base film 1, a heat-resistant ceramic coating 2 and a heat-conducting ceramic coating 3, the heat-resistant ceramic coating 2 is coated on one surface of the base film 1, and the heat-conducting ceramic coating 3 is coated on On the other surface of the base film 1, the thickness of the heat-resistant ceramic coating 2 is 4 μm, the thickness of the heat-conducting ceramic coating 3 is 6 μm; the average particle diameter of the heat-resistant ceramic particles is 0.5 μm, and the particle size distribution range is 0.01 to 4μm; the average particle size of the heat-conducting ceramic particles is 1μm, the particle size distribution range is 0.05-4μm, and the thermal conductivity of the heat-conducting ceramic particles is ≥80W / (m·K).

[0039] The preparation method of the ceramic diaphragm is as follows:

[0040] 1) Take a polypropylene microporous film with a thickness of 16 μm as the base film 1;

[0041] 2) Mix a...

Embodiment 2

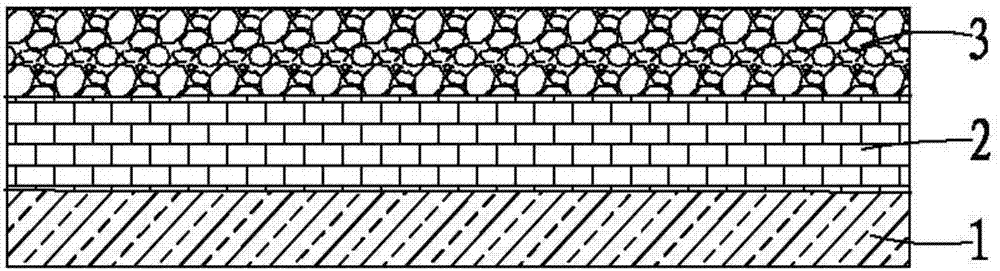

[0047] like figure 2 As shown, a ceramic diaphragm includes a base film 1, a heat-resistant ceramic coating 2 and a heat-conducting ceramic coating 3, the heat-resistant ceramic coating 2 is coated on one surface of the base film 1, and the heat-conducting ceramic coating 3 is coated on On the surface of the heat-resistant ceramic coating 2, wherein the thickness of the heat-resistant ceramic coating 2 is 8 μm, and the thickness of the heat-conducting ceramic coating 3 is 10 μm; the average particle diameter of the heat-resistant ceramic particles is 3 μm, and the particle size distribution range is 0.5 to 6μm; the average particle size of the heat-conducting ceramic particles is 4μm, the particle size distribution range is 0.5-8μm, and the thermal conductivity of the heat-conducting ceramic particles is ≥100W / (m·K).

[0048] The preparation method of the ceramic diaphragm is as follows:

[0049] 1) Take a polyethylene microporous film with a thickness of 16 μm as the base fil...

Embodiment 3

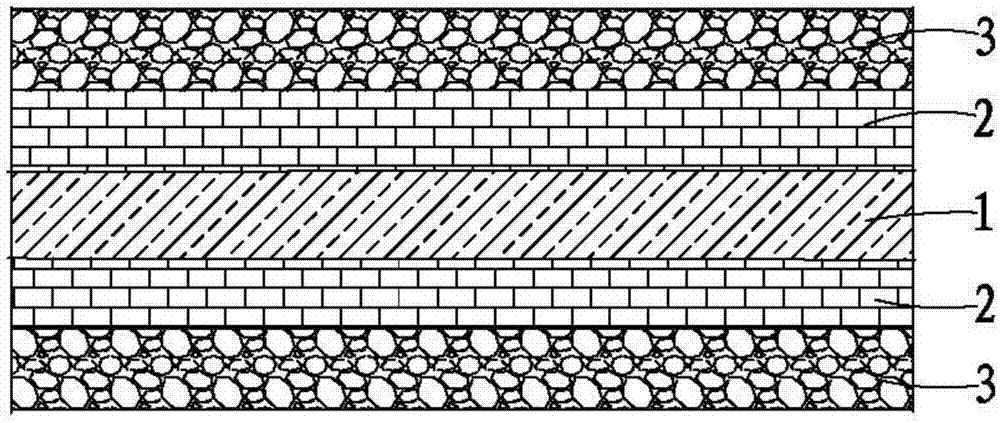

[0056] like image 3 As shown, a ceramic diaphragm includes a base film 1, a heat-resistant ceramic coating 2 and a heat-conducting ceramic coating 3, the heat-resistant ceramic coating 2 is coated on both surfaces of the base film 1, and the heat-conducting ceramic coating 3 is coated respectively Covered on the surface of two heat-resistant ceramic coatings 2, wherein the thickness of a single heat-resistant ceramic coating 2 is 4 μm, and the thickness of a single heat-conducting ceramic coating 3 is 5 μm; the average particle size of heat-resistant ceramic particles is 0.2 μm , the particle size distribution range is 0.01-2μm; the average particle size of the heat-conducting ceramic particles is 0.5μm, the particle size distribution range is 0.05-3μm, and the thermal conductivity of the heat-conducting ceramic particles is ≥100W / (m·K).

[0057] The preparation method of the ceramic diaphragm is as follows:

[0058] 1) Take a polypropylene microporous film with a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com