Anode active material, method of preparing the same, anode and lithium battery containing the material

A negative active material and negative electrode technology, applied in the direction of active material electrodes, negative electrodes, electrode manufacturing, etc., can solve the problems of large irreversible capacity, hindering practical use, and undesired cycle characteristics of secondary lithium-ion batteries, etc., to achieve excellent charging and Effect of Discharge Characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

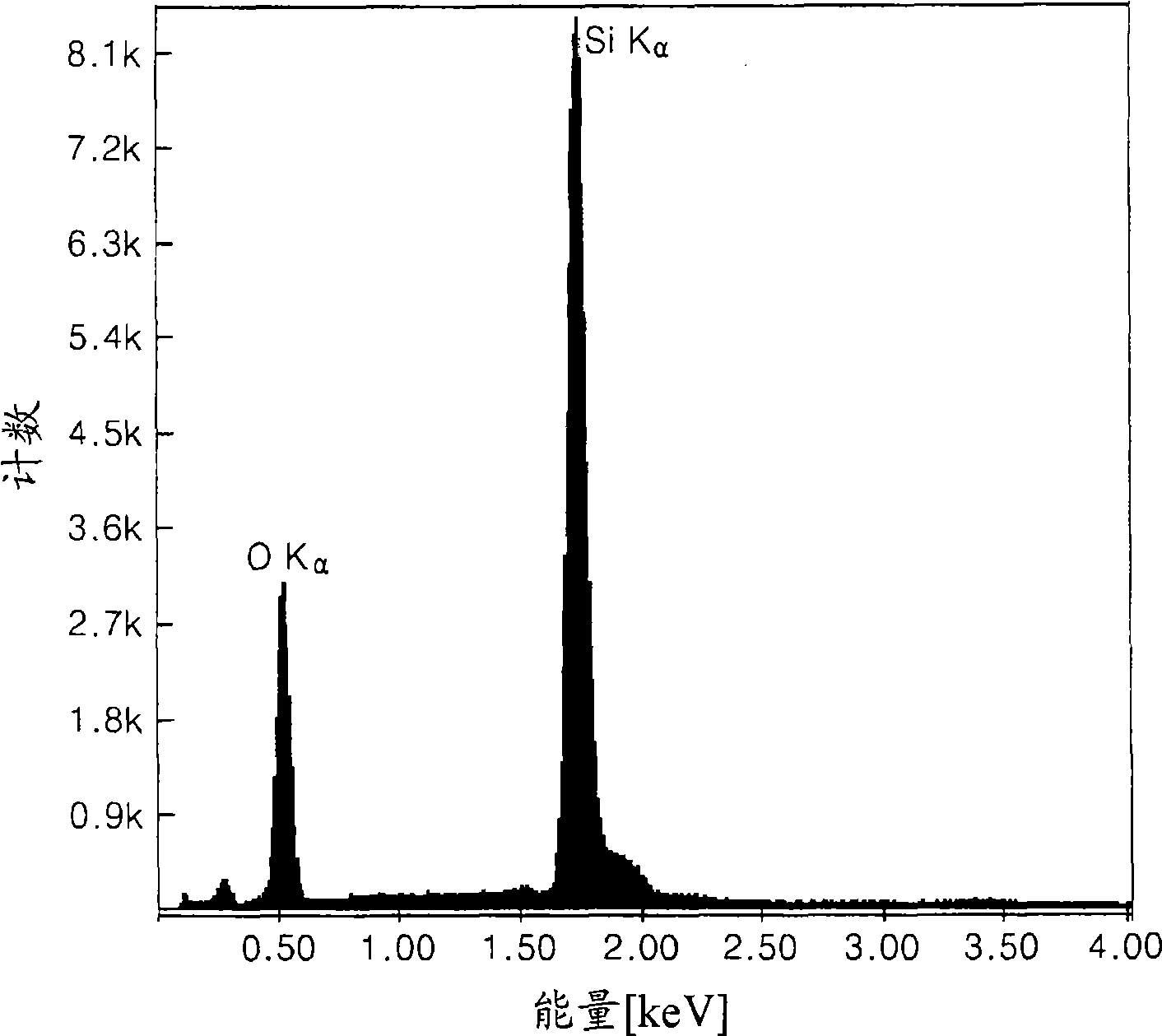

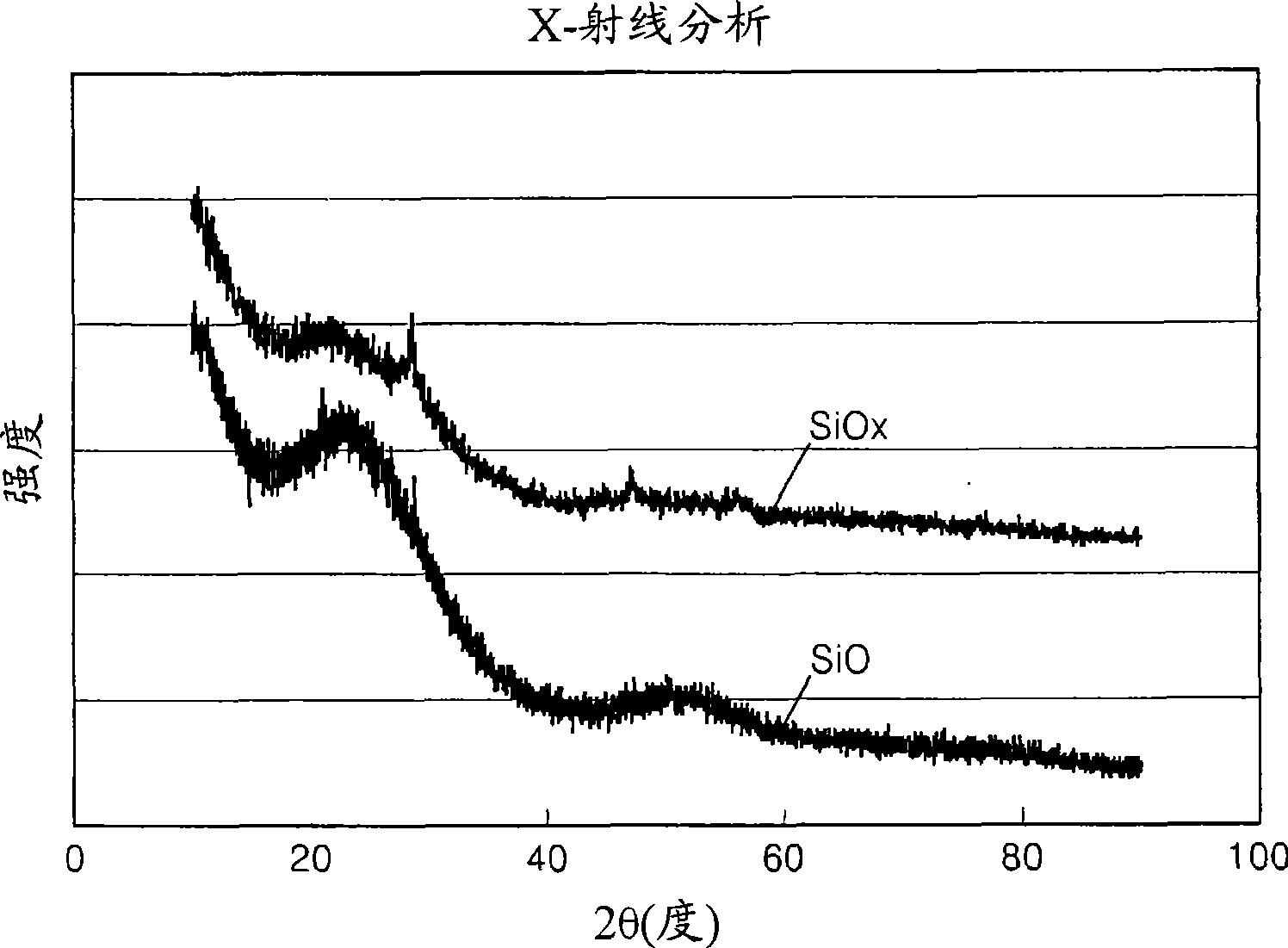

Embodiment 1

[0067] 1.05 g of a 0.53 mm thick Li membrane and 30 ml tetrahydrofuran (THF) were added to a 100 ml flask and mixed. The mixture was then placed in an ice bath. Then, 5cc trichlorosilane (HSiCl 3 , Aldrich) was added to the flask, and the mixture was allowed to react for 24 hours. 10 ml of ethanol was slowly added to the mixture and reacted for 3 hours. The resulting product was filtered with 0.5 μm filter paper, washed sequentially with ethanol, distilled water and acetone, and dried in an oven at 60° C. to obtain a partially oxidized silicon oxide precursor. The silicon oxide precursor was heat-treated at 900° C. in a nitrogen atmosphere to obtain silicon oxide.

Embodiment 2

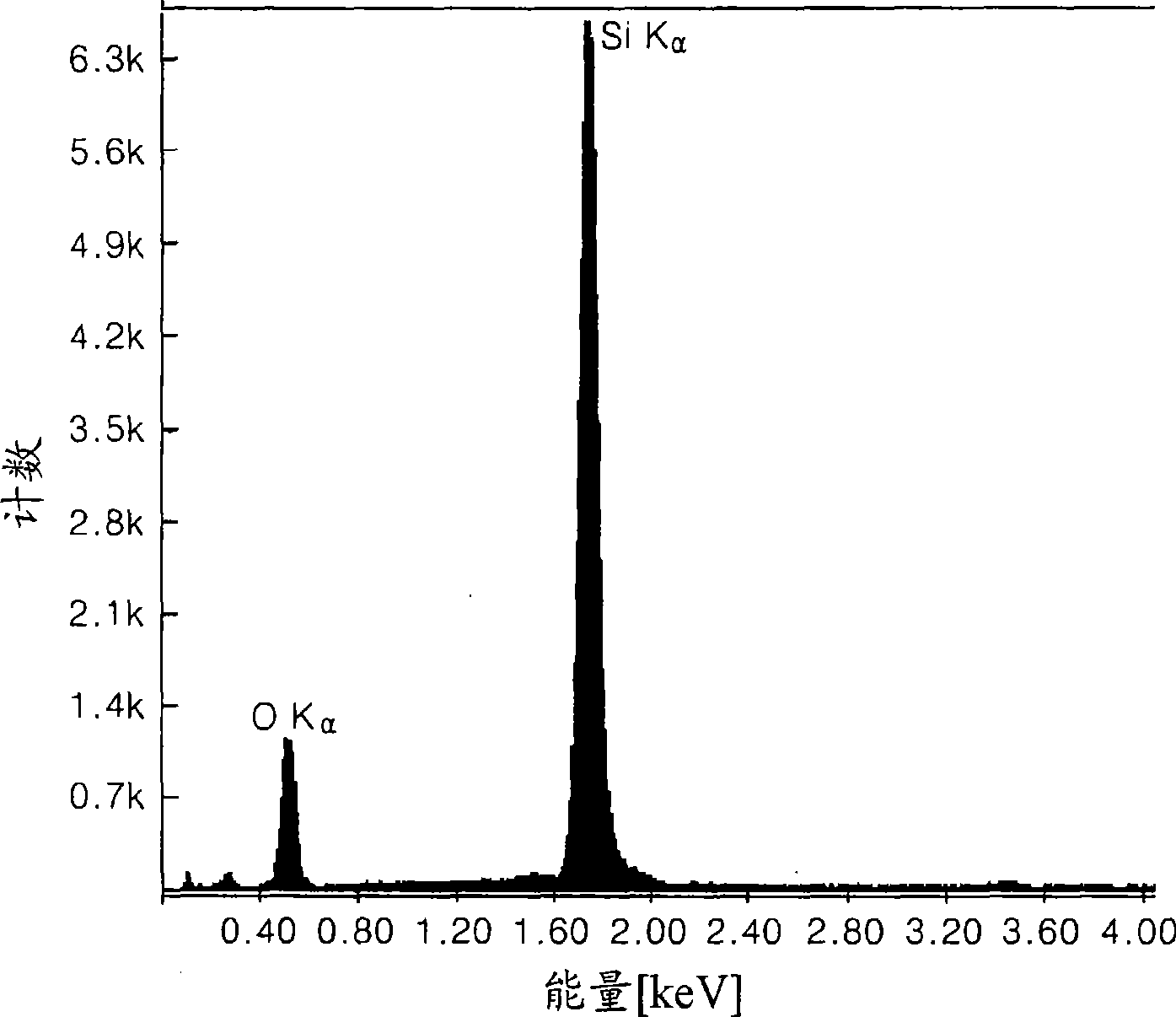

[0069] 0.2 g of the silica precursor prepared according to Example 1 and 0.08 g of pitch were mixed in 10 ml of THF. The solvent was evaporated for 1 h while the mixture was sonicated and stirred. The dried resulting product was heat-treated at 900° C. in a nitrogen atmosphere to obtain silicon oxide covered with carbonaceous material.

Embodiment 3

[0071] 1.05 g of a 0.08 mm thick Li membrane and 30 ml tetrahydrofuran (THF) were added to a 100 ml flask and mixed. The mixture was placed in an ice bath. Then, 5cc trichlorosilane (HSiCl 3 , Aldrich) was added to the flask, and the mixture was allowed to react for 24 hours. 10 ml of ethanol was slowly added to the mixture and reacted for 3 hours. The resulting product was filtered with 0.5 μm filter paper, washed sequentially with ethanol, distilled water and acetone, and dried in an oven at 60° C. to obtain a partially oxidized silicon oxide precursor. Then, 0.2 g of this silica precursor and 0.08 g of pitch were mixed in 10 ml of THF. The solvent was evaporated for 1 h while the mixture was sonicated and stirred. The dried resulting product was heat-treated at 900° C. in a nitrogen atmosphere to obtain silicon oxide covered with a carbonaceous material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com