Composite separator for lithium battery

A composite separator and lithium battery technology, applied in secondary batteries, battery pack parts, secondary battery repair/maintenance, etc., can solve problems such as limited effect, inhibit dendrite growth, prevent battery short circuit, and improve cycle efficiency effect on safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

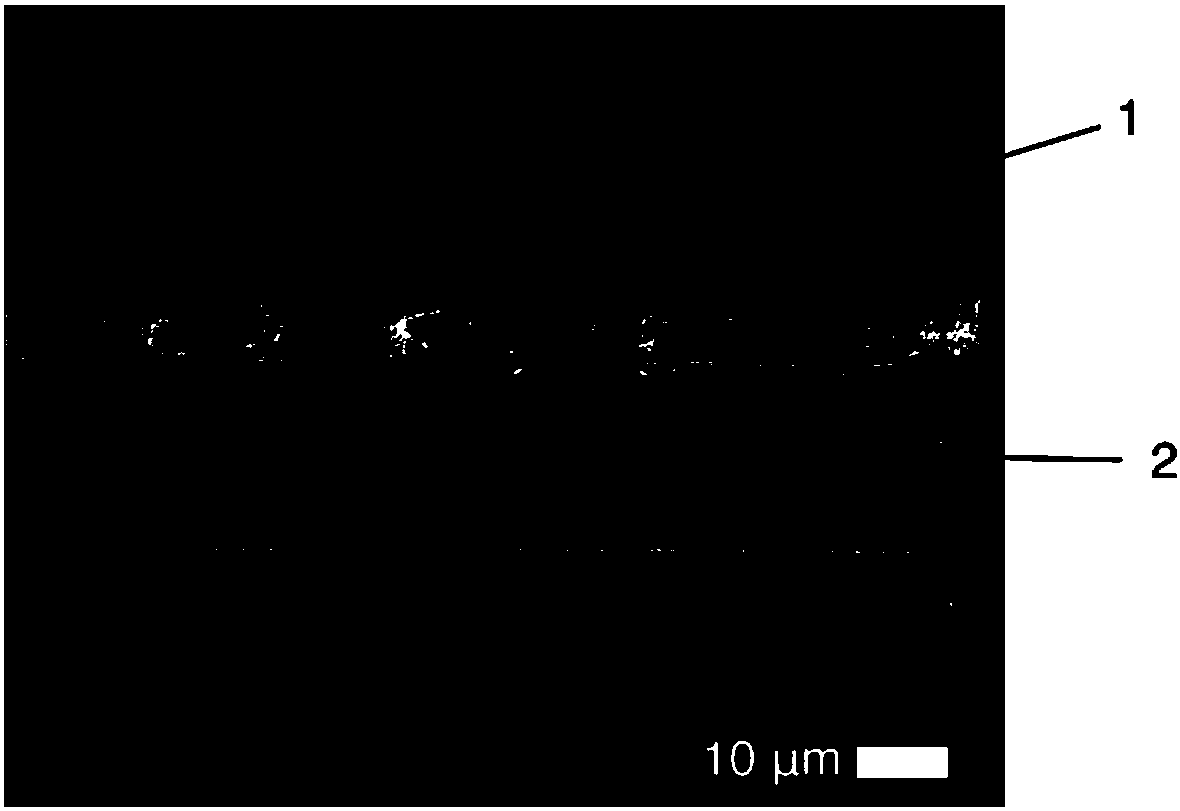

[0025] Embodiment 1: the lithium ion conductor Li 6.75 La 3 Zr 1.75 Ta 0.25 o 12 The nanoparticles are blended with a binder and dissolved in THF. Through suction filtration, the above mixed solution was filtered on a polypropylene (PP) membrane. Dry to obtain a composite separator that can be used for lithium batteries. In the diaphragm, the thickness of the inorganic lithium ion conductor layer is 5 μm, the thickness of the base layer polypropylene is 25 μm, and the thickness of the composite diaphragm is 30 μm. The ion conductivity of the inorganic lithium ion conductor material at room temperature is 1.5×10 -4 S cm -1 . The composite diaphragm can withstand the working temperature range of 20°C-120°C. The heat shrinkage rate of the composite diaphragm is 3%. The above diaphragm is matched with the positive electrode of lithium iron phosphate and the negative electrode of lithium metal. After performing electrochemical tests, it was found that at room temperature, a...

Embodiment 2

[0026] Embodiment 2: prepare tantalum-doped Li by electrospinning method 7 La 3 Zr 2 o 12 (LLZO) nanowires dispersed in the organic solvent n,n-dimethylformamide (DMF). Through suction filtration, the above mixed solution was filtered on a polypropylene membrane. Dry to obtain a composite separator that can be used for lithium batteries. In the diaphragm, the thickness of the inorganic lithium ion conductor layer is 10 μm, the thickness of the base layer is 25 μm, and the thickness of the composite diaphragm is 35 μm. The ion conductivity of the inorganic lithium ion conductor material LLZO is 9.5×10 at a working temperature of 90°C. -4 S cm -1 . The operating temperature range of the separator is 20°C-120°C. The heat shrinkage rate of the separator is 2%. The above separator is matched with the positive electrode of lithium cobaltate and the negative electrode of graphite. After performing electrochemical tests, it was found that at a high ambient temperature of 90°C, ...

Embodiment 3

[0027] Embodiment 3: use aluminum, tantalum co-doped Li 7 La 3 Zr 2 o 12 (LLZO) bulk target material, sputtering LLZO onto the polypropylene film to obtain a composite separator for lithium batteries. In the separator, the thickness of the inorganic lithium ion conductor layer is 10nm, the thickness of the base layer polypropylene is 25μm, and the thickness of the composite separator is 25μm. The ion conductivity of the inorganic lithium ion conductor material LLZO is 9.5×10 at a working temperature of 90°C. -4 S cm -1 . The operating temperature range of the diaphragm is 20°C-80°C. The heat shrinkage rate of the diaphragm is 4%. The above diaphragm is matched with the positive electrode of lithium cobaltate and the negative electrode of graphite. After performing electrochemical tests, it was found that at a high ambient temperature of 90°C, 3.0mA cm -2 Under the current density, after activation, the capacity attenuation is less than 5% in the range of 500 cycles, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com