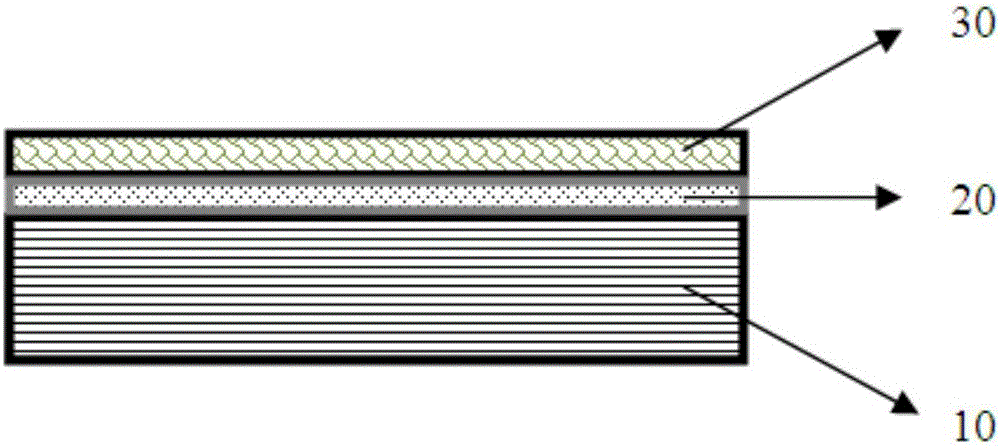

Lithium cathode used for lithium battery and provided with sandwich structure and preparation method thereof

A sandwich and lithium negative electrode technology, applied in the field of electrochemical batteries, can solve the problems of high temperature in the preparation process, unstable contact, easy water absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035]Under magnetic stirring, polyvinylidene fluoride (PVDF) with a mass fraction of 5% was dissolved in N-methylpyrrolidone (NMP). After PVDF was completely dissolved, doped polyaniline (PANI) polymer was added to it. Material, magnetic stirring for 4h to obtain a uniform slurry, and then coating the conductive current collector copper foil (Cu) with a 10 μm thick slurry by scraping on the coating machine, and then the coated material was placed at 55. After drying at ℃ for 12 h, the electrode precursor was obtained. Then the electrode precursor was punched into 14 μm small discs, loaded into a coin cell, and deposited at 0.5 mA / cm by electrochemical deposition. 2 deposition at a current density of 1mAh / cm 2 The metal lithium is inserted between the polymer material of the electrode precursor and the conductive current collector to obtain a sandwich-structured lithium anode.

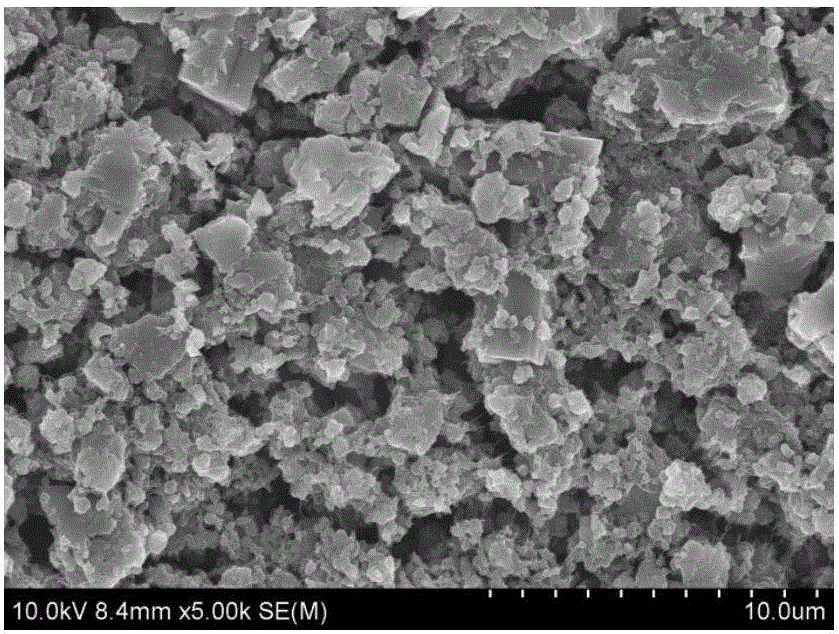

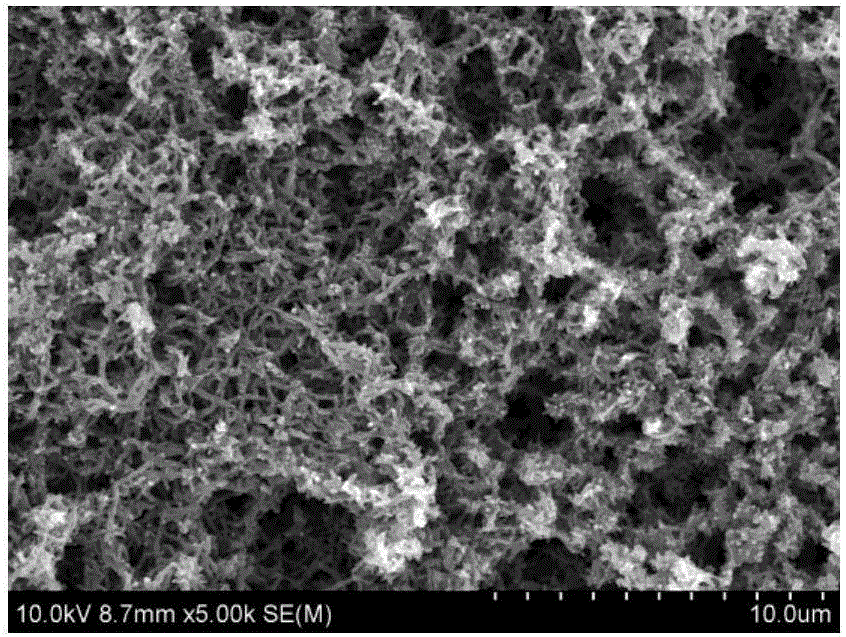

[0036] The surface scanning electron micrograph of the obtained electrode precursor is shown as ...

Embodiment 2

[0041] The PVDF with a mass fraction of 5% in Example 1 was replaced with PVDF with a mass fraction of 10% to prepare a sandwich structure lithium negative electrode, and the battery performance of the sandwich structure lithium negative electrode was tested, Figure 8 The results show that the performance of Example 2 is basically similar to that of Example 1, and the performance of Example 2 is slightly lower than that of Example 1, which may be due to the weakening of the conductivity after the PANI content is reduced. The internal polarization of the battery becomes larger.

Embodiment 3

[0043] The doped PANI in Example 1 was replaced by the intrinsic PANI, and a sandwich-structured lithium negative electrode was prepared. The battery performance of the sandwich-structured lithium negative electrode was tested, and the performance similar to that of Example 1 was obtained.

[0044] For typical method (b):

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com