Negative pole piece for lithium battery, preparation method of negative pole piece and lithium battery with negative pole piece

A negative electrode sheet and lithium battery technology, which is applied in the direction of battery electrodes, lithium batteries, non-aqueous electrolyte battery electrodes, etc., can solve the problems of graphite peeling off and large amount of addition, so as to improve the first-time efficiency, stability, and improvement The effect of cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

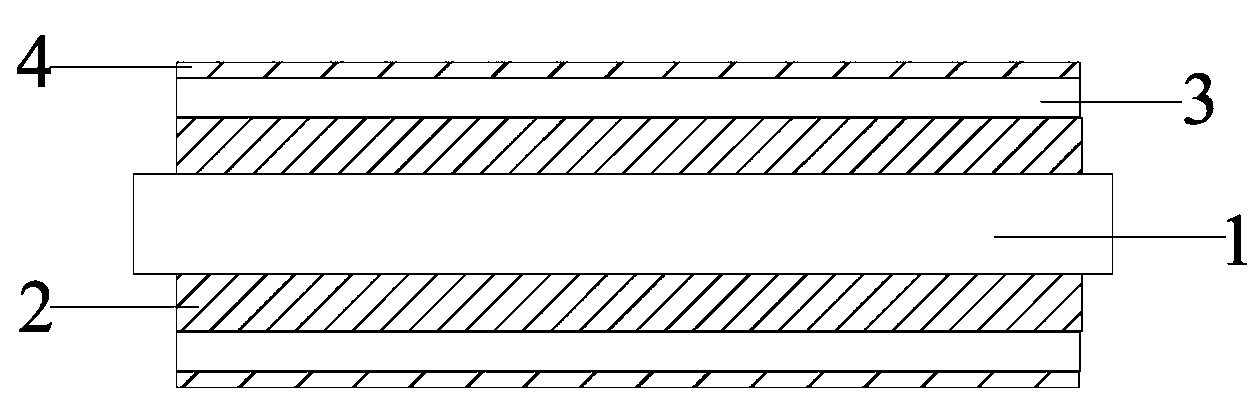

[0030] The invention provides a lithium battery negative electrode sheet, such as figure 1 As shown, it includes a current collector 1 and a graphite layer 2 disposed on the current collector 1, and also includes a protective layer 3 and a lithium metal layer 4, the protective layer 3 is disposed on the graphite layer 2, and the lithium metal layer 4 is disposed on the protective layer 3 superior.

[0031] In this embodiment, the thickness of the graphite layer 2 is 50 μm, the thickness of the protective layer 3 is 40 μm, and the thickness of the metal lithium layer 4 is 500 nm. Wherein, the protective layer 3 includes an adhesive, a conductive agent and an active material. The adhesive is sodium carboxymethyl cellulose-styrene butadiene rubber, the active material is hard carbon, and the conductive agent is superconducting carbon.

Embodiment 2

[0033] In this embodiment, the thickness of the graphite layer 2 is 10 μm, the thickness of the protective layer 3 is 1 μm, and the thickness of the metal lithium layer 4 is 100 nm. Wherein, the protective layer 3 includes an adhesive, a conductive agent and an active material, wherein the adhesive is polyacrylonitrile, the active material is silicon-aluminum alloy, and the conductive agent is carbon fiber. Other structures are the same as in Embodiment 1.

Embodiment 3

[0035] In this embodiment, the thickness of the graphite layer 2 is 200 μm, the thickness of the protective layer 3 is 100 μm, and the thickness of the metal lithium layer 4 is 2 μm. Wherein, the protective layer 3 includes an adhesive, a conductive agent and an active material, wherein the adhesive is polyimide, the active material is a tin-copper alloy, and the conductive agent is superconducting carbon. Other structures are the same as in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com