Lithium battery negative electrode sheet and preparation method thereof as well as lithium battery preparation method

A technology of lithium battery and negative electrode sheet, applied in the field of lithium battery processing, can solve the problems of uneven thickness, volume expansion, low efficiency of initial charge and discharge, etc., to achieve uniformity and consistency, improve energy density, and save battery space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

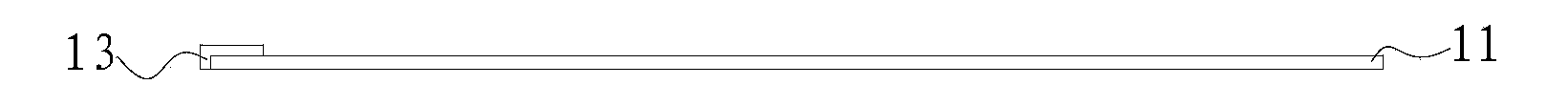

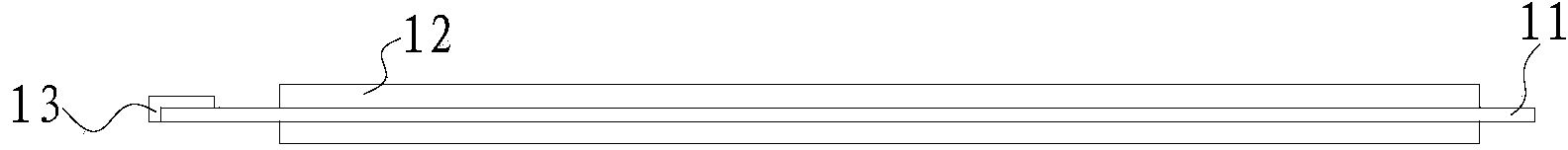

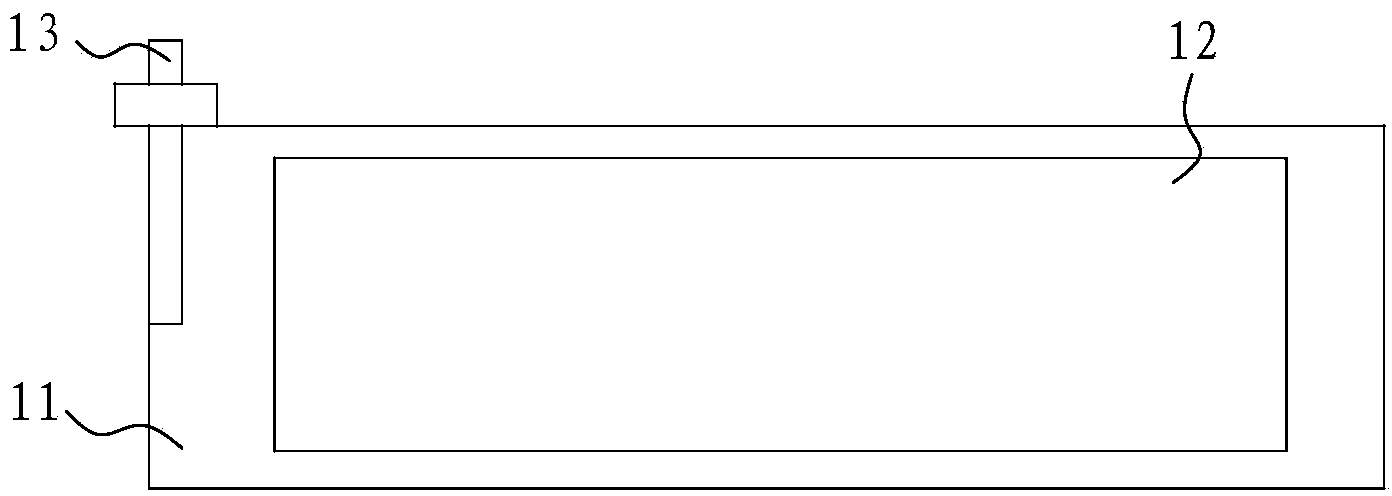

[0054] like Figures 1 to 3 As shown, a lithium battery negative electrode sheet described in this embodiment includes a negative electrode current collector 11 made of metal foil, a lithium layer 12 arranged on the surface of the negative electrode current collector 11 by electroplating, and a lithium layer 12 connected to the negative electrode current collector 11. The negative electrode tab 13; the negative electrode current collector 11 has a flat sheet structure, and the lithium layer 12 is uniformly arranged on the upper and lower surfaces of the negative electrode current collector 11.

[0055] The lithium battery negative electrode sheet described in this example is prepared by the following method:

[0056] Step S21, providing the negative electrode current collector as described above, and welding the negative electrode tab at one end of the negative electrode current collector;

[0057] Step S22: Electroplating a lithium layer on the surface of the negative electr...

Embodiment 2

[0086] like Figure 4 , 5 As shown, a lithium battery negative electrode sheet described in this embodiment includes a negative electrode current collector 21 made of metal foil, a lithium layer 22 arranged on the surface of the negative electrode current collector 21 by electroplating, and a lithium layer 22 connected to the negative electrode current collector 21. The upper and lower surfaces of the negative electrode collector 21 have a concave-convex structure, and the lithium layer 22 fills the grooves formed by the concave-convex structure and covers the upper and lower surfaces of the negative electrode current collector 21.

[0087] The lithium battery negative electrode sheet described in this example is prepared by the following method:

[0088] Step S21, providing the negative electrode current collector as described above, and welding the negative electrode tab at one end of the negative electrode current collector;

[0089] Step S22: Electroplating a lithium lay...

Embodiment 3

[0098] like Figure 4 , 5 As shown, a lithium battery negative electrode sheet described in this embodiment includes a negative electrode current collector 21 made of metal foil, a lithium layer 22 arranged on the surface of the negative electrode current collector 21 by electroplating, and a lithium layer 22 connected to the negative electrode current collector 21. The negative electrode tab 23; the negative electrode current collector 21 is a sheet structure with a concave-convex structure on the upper and lower surfaces, and the lithium layer fills the grooves formed by the concave-convex structure and covers the upper and lower surfaces of the negative electrode current collector 21.

[0099] The lithium battery negative electrode sheet described in this example is prepared by the following method:

[0100] Step S21, providing the above-mentioned negative electrode current collector;

[0101] Step S22: Electroplating a lithium layer on the surface of the negative electro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com