Negative electrode paste mixing process with pre-lithiation effect, and lithium battery

A negative electrode slurry and pre-lithiation technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of complex lithium supplementation process, poor lithium supplementation effect, and potential safety hazards, so as to improve safety and conductivity , enhance the effect of conductive type

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

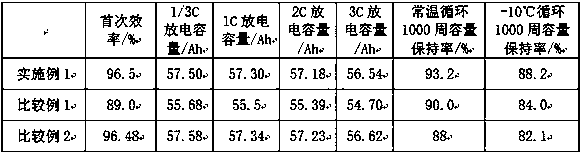

Examples

Embodiment 1

[0036] A negative electrode slurry mixing process with pre-lithiation effect, which is produced by the following stirring process, the process includes:

[0037] (1) Put 17kg of artificial graphite, 0.51kg of SP, 0.51kg of PVDF and other powders into the mixing tank together, set the stirring speed to 30 rpm, the dispersion speed to 500 rpm, and dry mix for 20 minutes; (2) Add 1.7kg CNT conductive paste, set the stirring speed to 15 rpm, the dispersion speed to 500 rpm, and stir for 30 minutes; (3) Add 6.5kg NMP, set the stirring speed to 30 rpm, and the dispersion speed to 1500 rpm, Stir for 80 minutes; (4) Add 7kg of NMP, set the stirring speed to 35 rpm, disperse at 2000 rpm, and stir for 80 minutes; (5) Add 2kg of electrolyte (1 mol / L concentration of LiPF 6 , 1.5% VC and 1.5% PS dissolved in a mixed solvent of ethylene carbonate / dimethyl carbonate / methyl ethyl carbonate to make an electrolyte) and 0.2kg metal lithium sheet, set the stirring speed to 35 rpm, The dispersio...

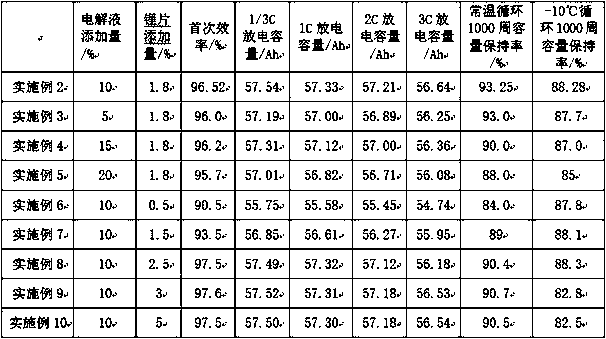

Embodiment 2

[0047] A negative electrode slurry mixing process with pre-lithiation effect, which is produced by the following stirring process, the process includes:

[0048] (1) Put 17kg of artificial graphite, 0.51kg of SP, 0.51kg of PVDF and other powders into the mixing tank together, set the stirring speed to 30 rpm, the dispersion speed to 500 rpm, and dry mix for 20 minutes; (2) Add 1.7kg CNT conductive paste, set the stirring speed to 15 rpm, the dispersion speed to 500 rpm, and stir for 30 minutes; (3) Add 6.5kg NMP, set the stirring speed to 30 rpm, and the dispersion speed to 1500 rpm, Stir for 80min; (4) Add 7kg of NMP, set the stirring speed to 35 rpm, disperse at 2000 rpm, and stir for 80min; (5) Add 1.7kg of electrolyte (1 mol / L concentration of LiPF6, 1.5%VC and 1.5% PS dissolved in a mixed solvent of ethylene carbonate / dimethyl carbonate / methyl ethyl carbonate to make an electrolyte) and 0.306 kg metal lithium sheet, set the stirring speed to 35 rpm, and the dispersion spe...

Embodiment 3

[0050] The difference from Example 1 is that in step (5), 0.85 kg of electrolyte (1 mol / liter concentration of LiPF6, 1.5% VC and 1.5% PS dissolved in ethylene carbonate / dimethyl carbonate / methyl ethyl carbonate The electrolyte is prepared in a mixed solvent of base ester).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com