Two-channel sonic surface wave gas sensors having humidity compensate function

A gas sensor, humidity compensation technology, used in the analysis of fluids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc. The same problem, to achieve good environmental stability, reduce the gap, increase the effect of humidity compensation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

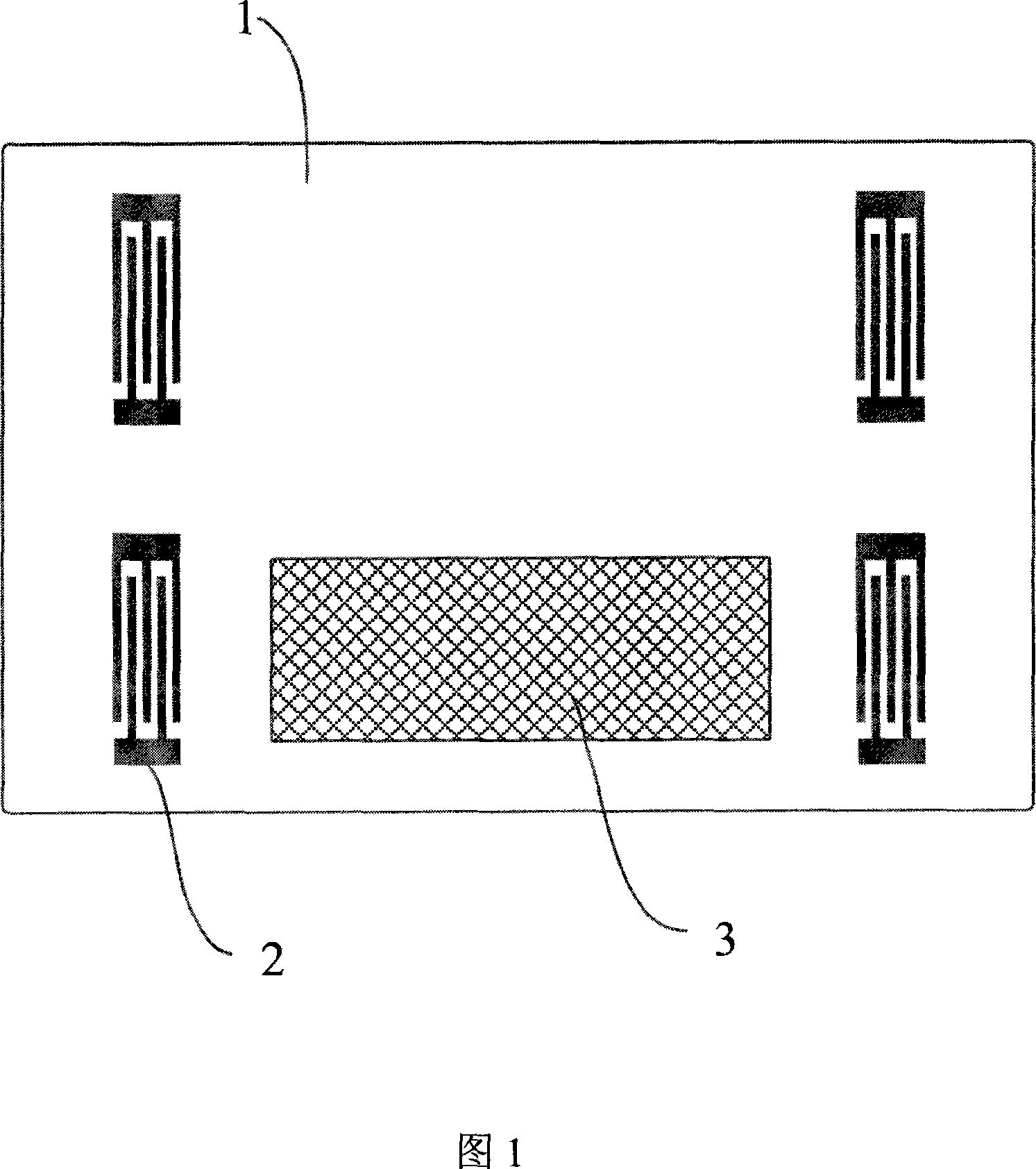

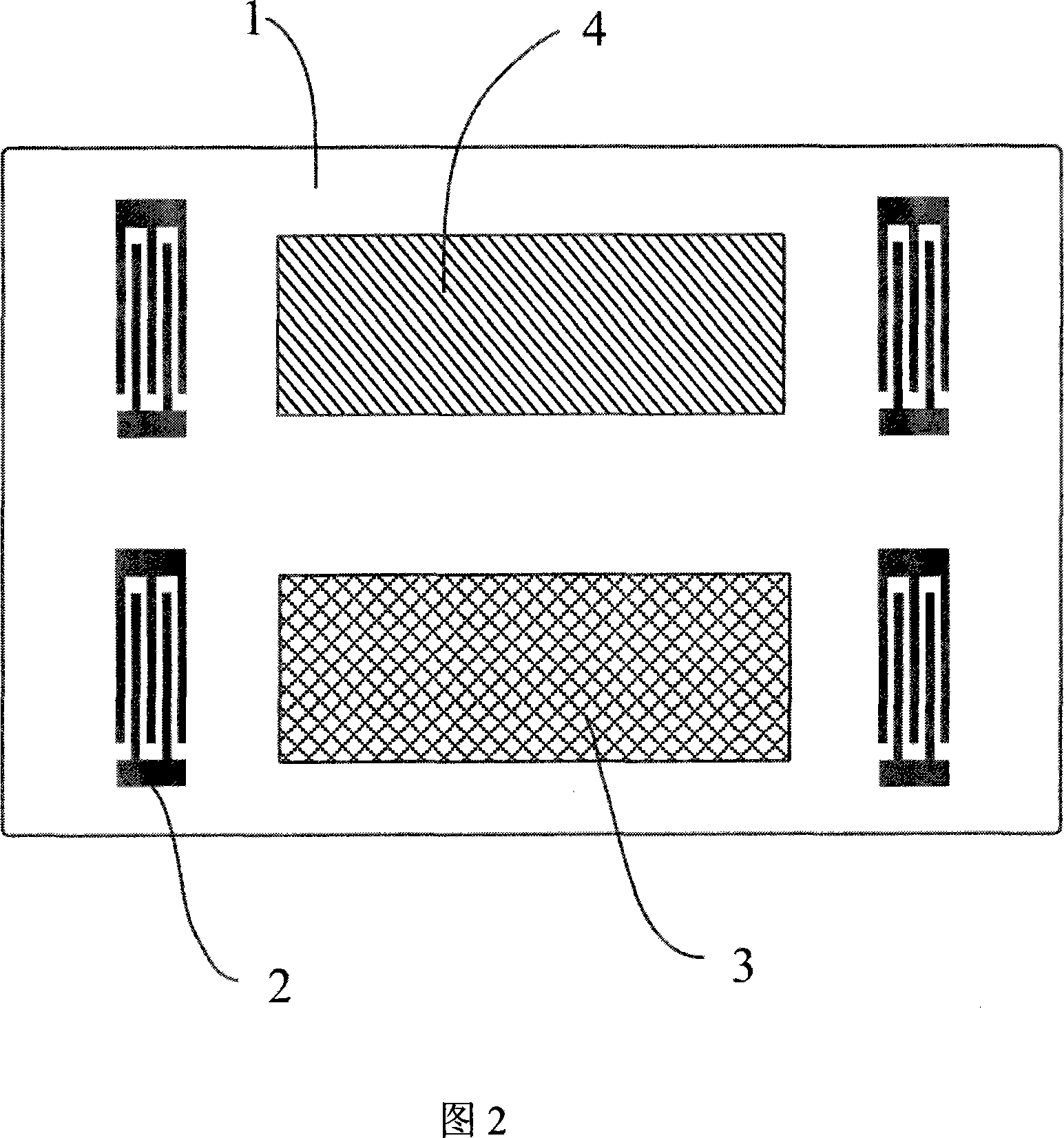

[0021] As shown in FIG. 2 , the surface acoustic wave gas sensor includes: a piezoelectric substrate 1 , interdigital electrodes 2 , a sensitive film 3 , and a humidity compensation film 4 . There are two groups of electrodes 2, which respectively constitute two transmission channels of the surface acoustic wave, and the electrodes 2 are prepared on the surface of the piezoelectric substrate 1 by photolithography technology. A sensitive thin film is coated on one of the surface acoustic wave channels to form a measurement channel, while a humidity compensation film is coated on the other channel to form a reference channel.

[0022] The preparation method of the dual-channel surface acoustic wave gas sensor with humidity compensation function provided by the present invention is as follows (example):

[0023] The piezoelectric substrate 1 chooses ST-quartz; a layer of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com