Patents

Literature

73results about How to "Good temperature compensation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

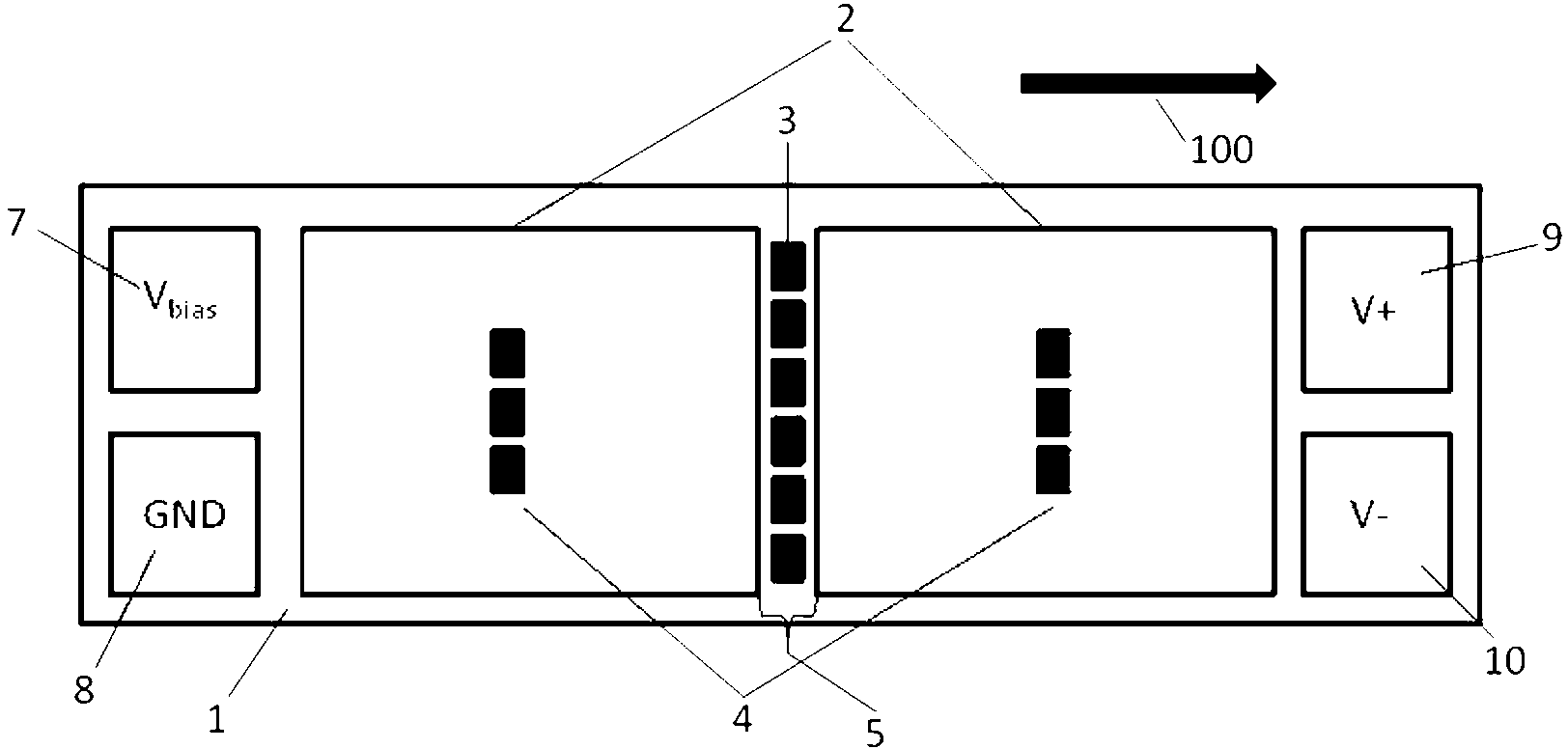

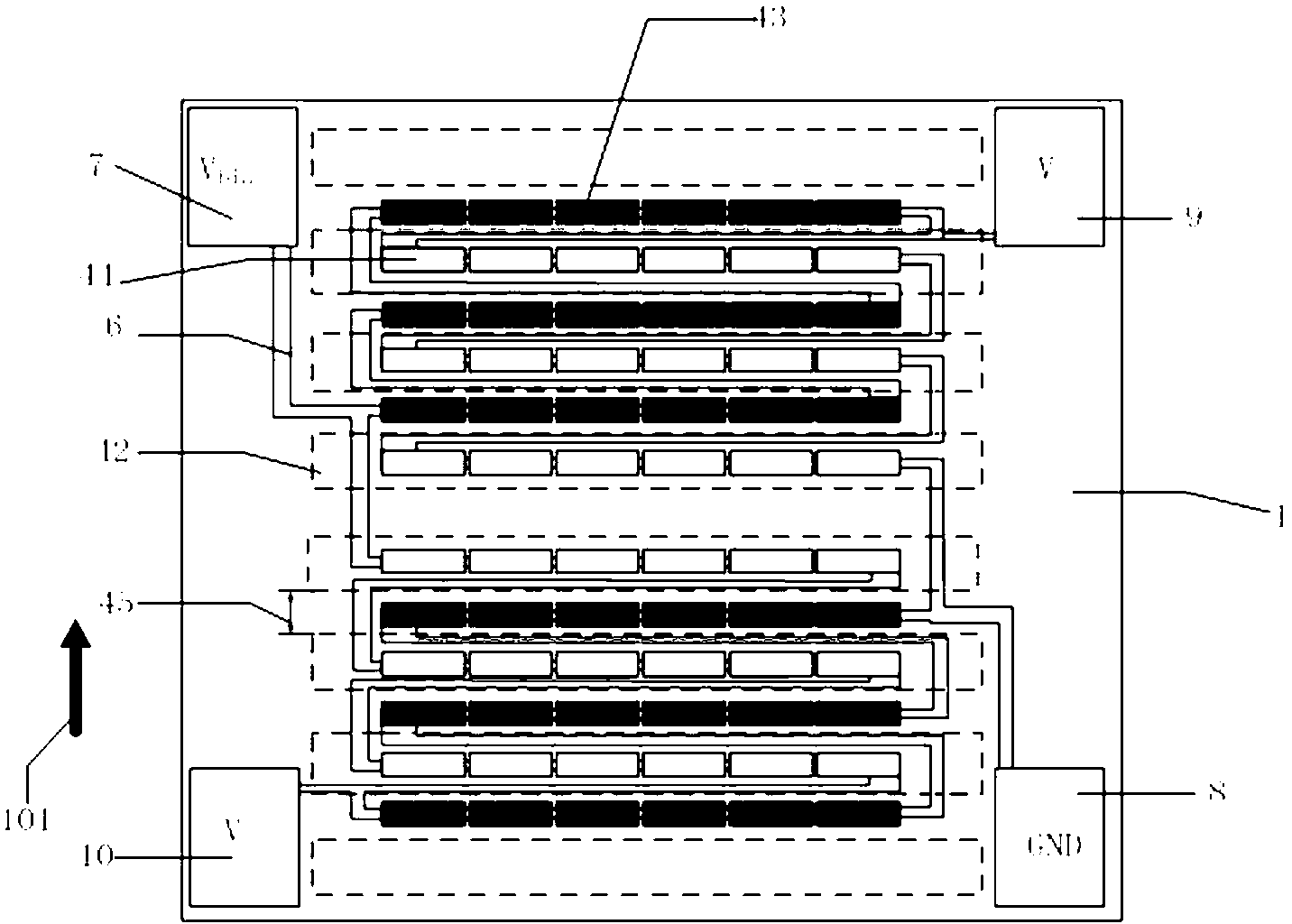

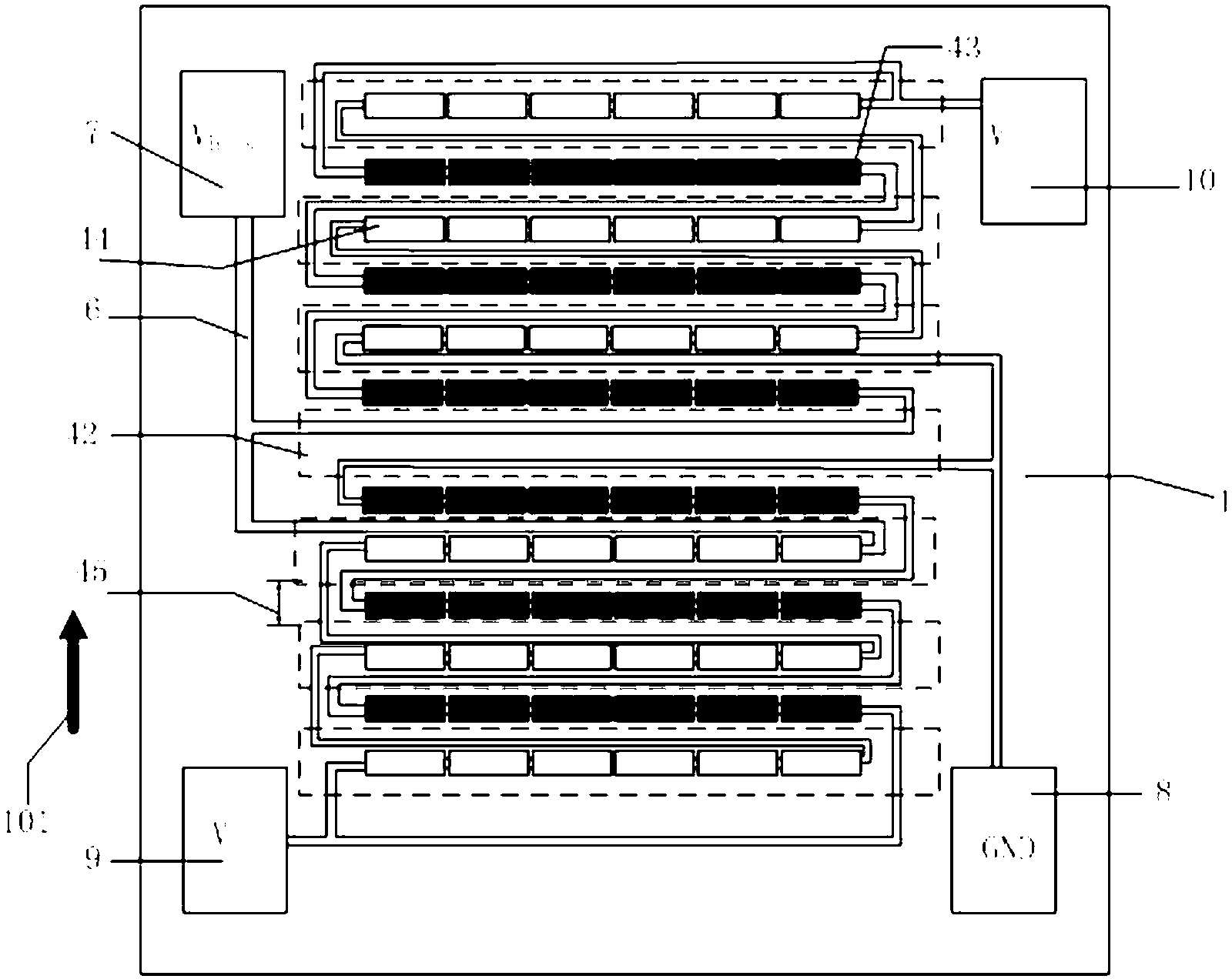

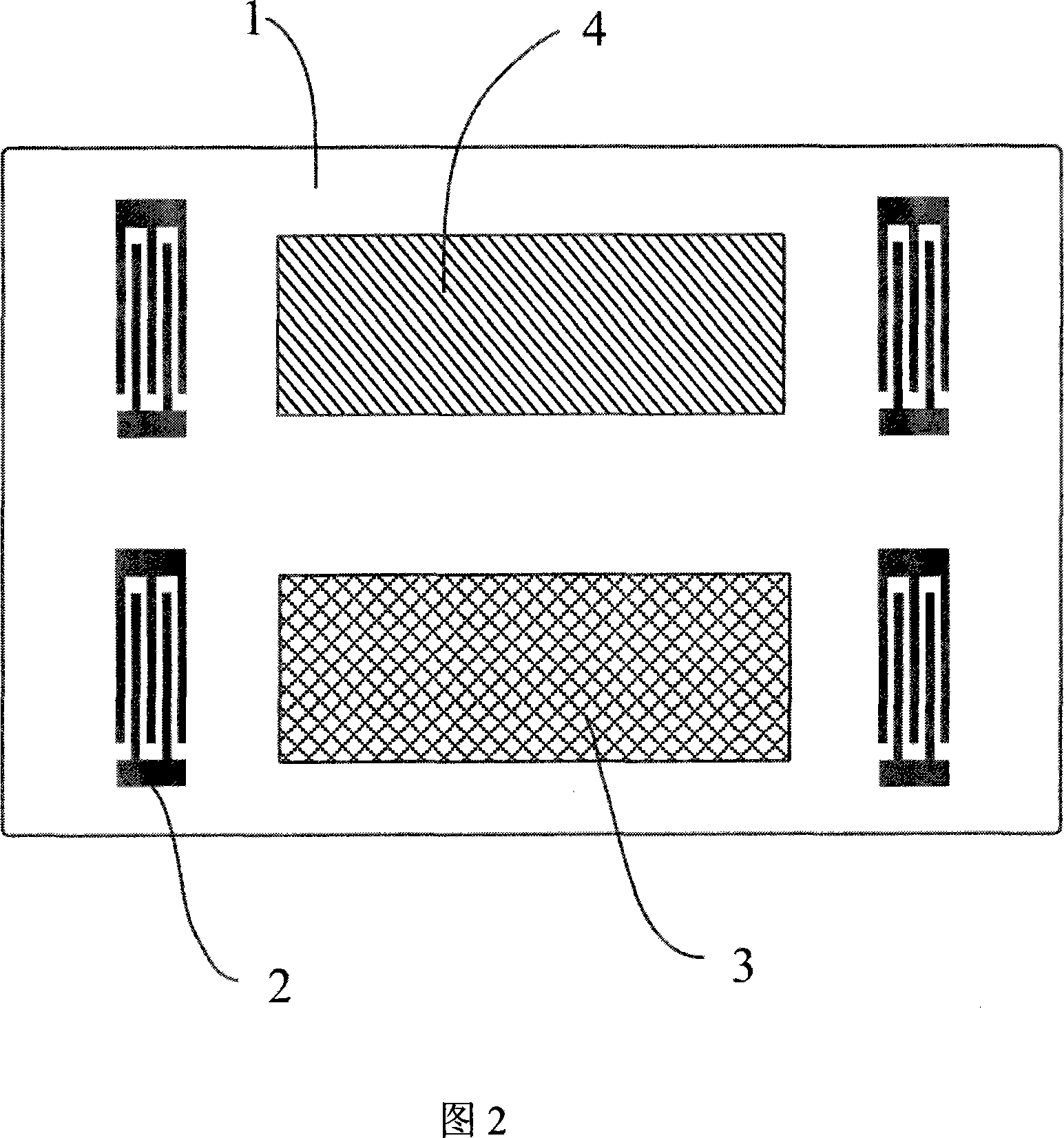

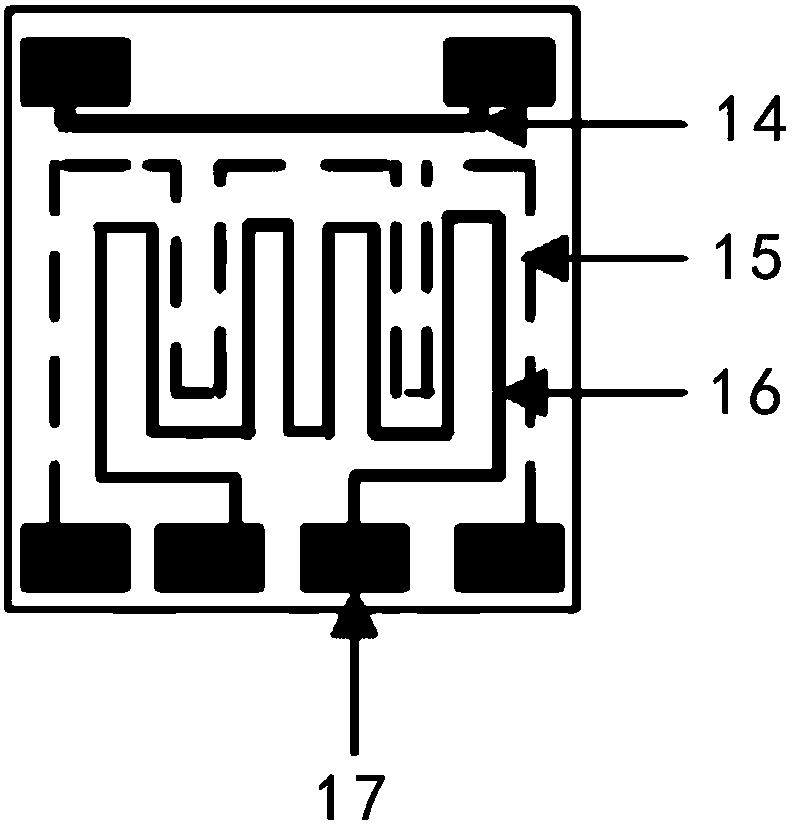

Single-chip bridge-type magnetic field sensor

ActiveCN103267955AImprove linearityHigh sensitivityMagnetic measurementsReference comparisonElectricityElectrical resistance and conductance

The invention relates to a single-chip bridge-type magnetic field sensor which comprises a substrate, reference arms, sensing arms, shielding structures and bonding pads, wherein each reference arm and each sensing arm are respectively provided with at least two rows / lines of reference element strands and sensing element strands, each reference element strand and each sensing element strand are formed by one or multiple identical magneto-resistor sensing elements which are electronically connected, the reference element strands and the sensing element strands are arranged and placed in a staggered mode, each magneto-resistor sensing element is one kind of sensing elements selected from AMR, GMR or TMR, each shielding structure is corresponding arranged on each reference element strand, one sensing element strand is located at the interval position between two shielding structures, and one shielding structure is a long-strip-shaped array which is made of soft magnetic materials permalloy. The single-chip bridge-type magnetic field sensor can be achieved in three bridge structures such as quasi bridge, half bridge and full bridge. The single-chip bridge-type magnetic field sensor has the advantages of being small in size, low in cost, small in offset, high in sensitivity, and good in linearity and temperature stability.

Owner:MULTIDIMENSION TECH CO LTD

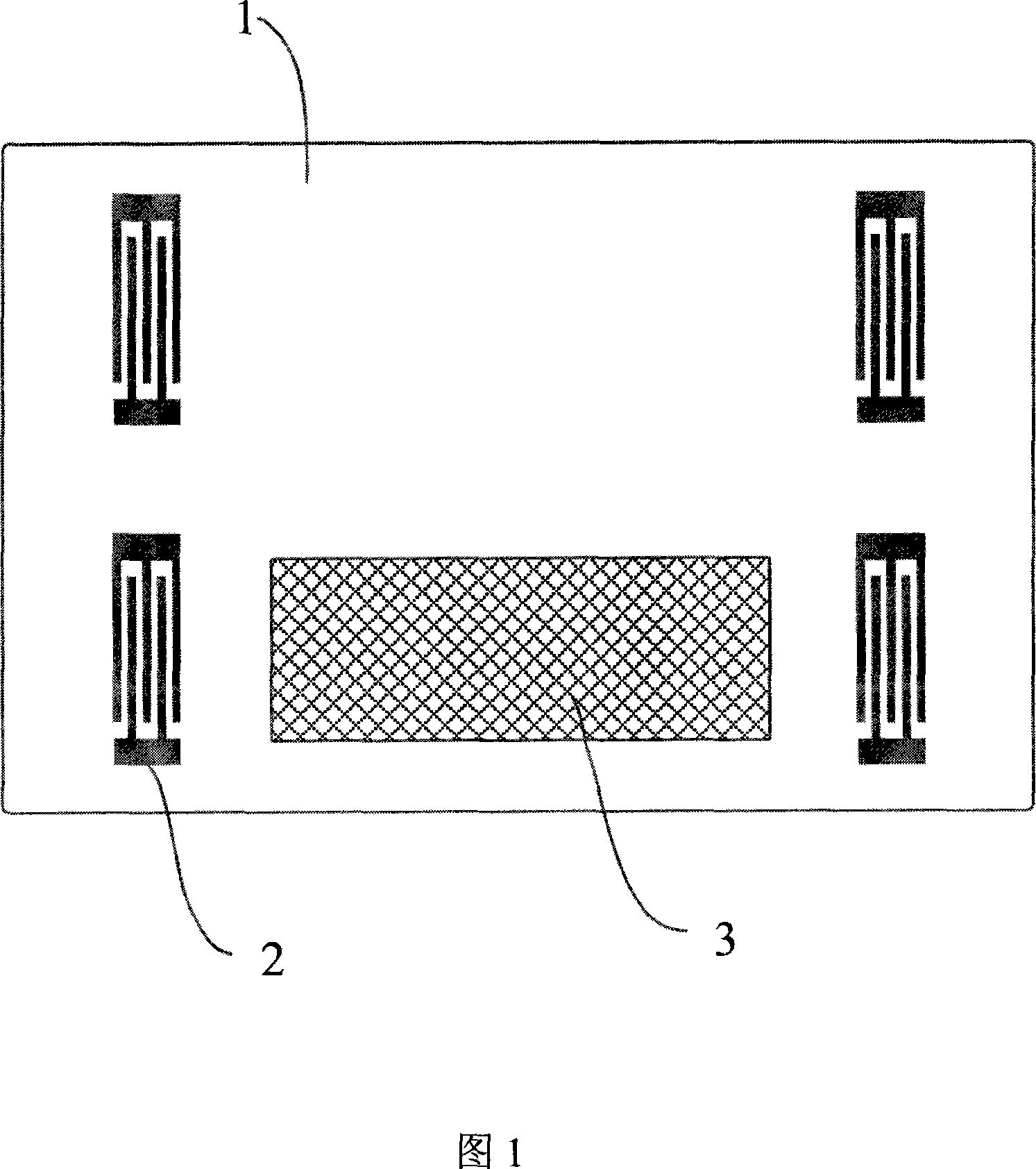

Two-channel sonic surface wave gas sensors having humidity compensate function

InactiveCN101135670AGood environmental stabilityReduce temperature drift gapAnalysing fluids using sonic/ultrasonic/infrasonic wavesElectricityAcoustics

The invention comprises a piezoelectric baseboard and two pairs of interdigital electrodes; said interdigital electrodes are located on the piezoelectric baseboard to construct both parallel acoustic surface wave measuring channel and reference channel. It features the following: coating a sensitive film on the measuring channel; coating a temperature compensation film on the reference channel.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

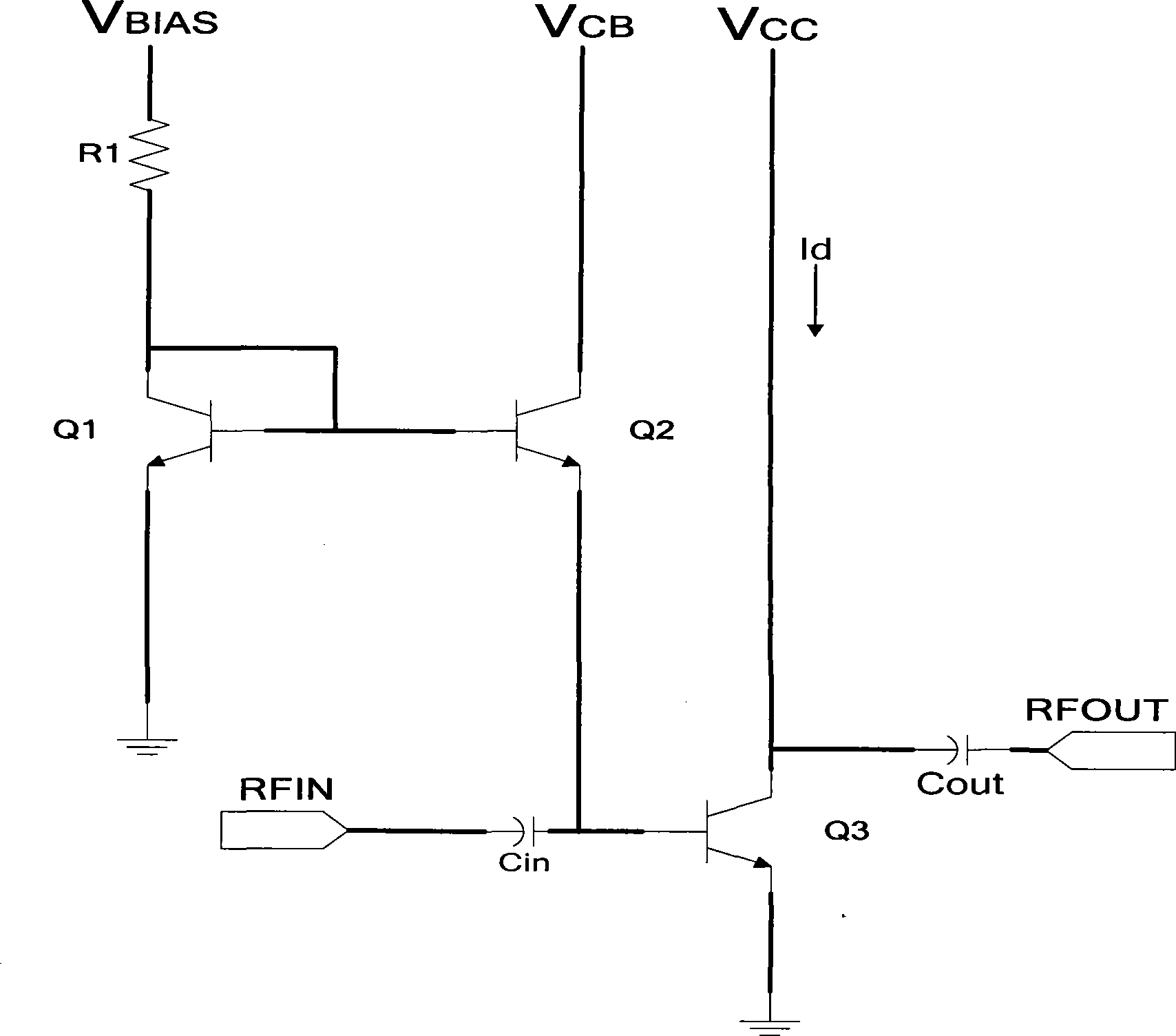

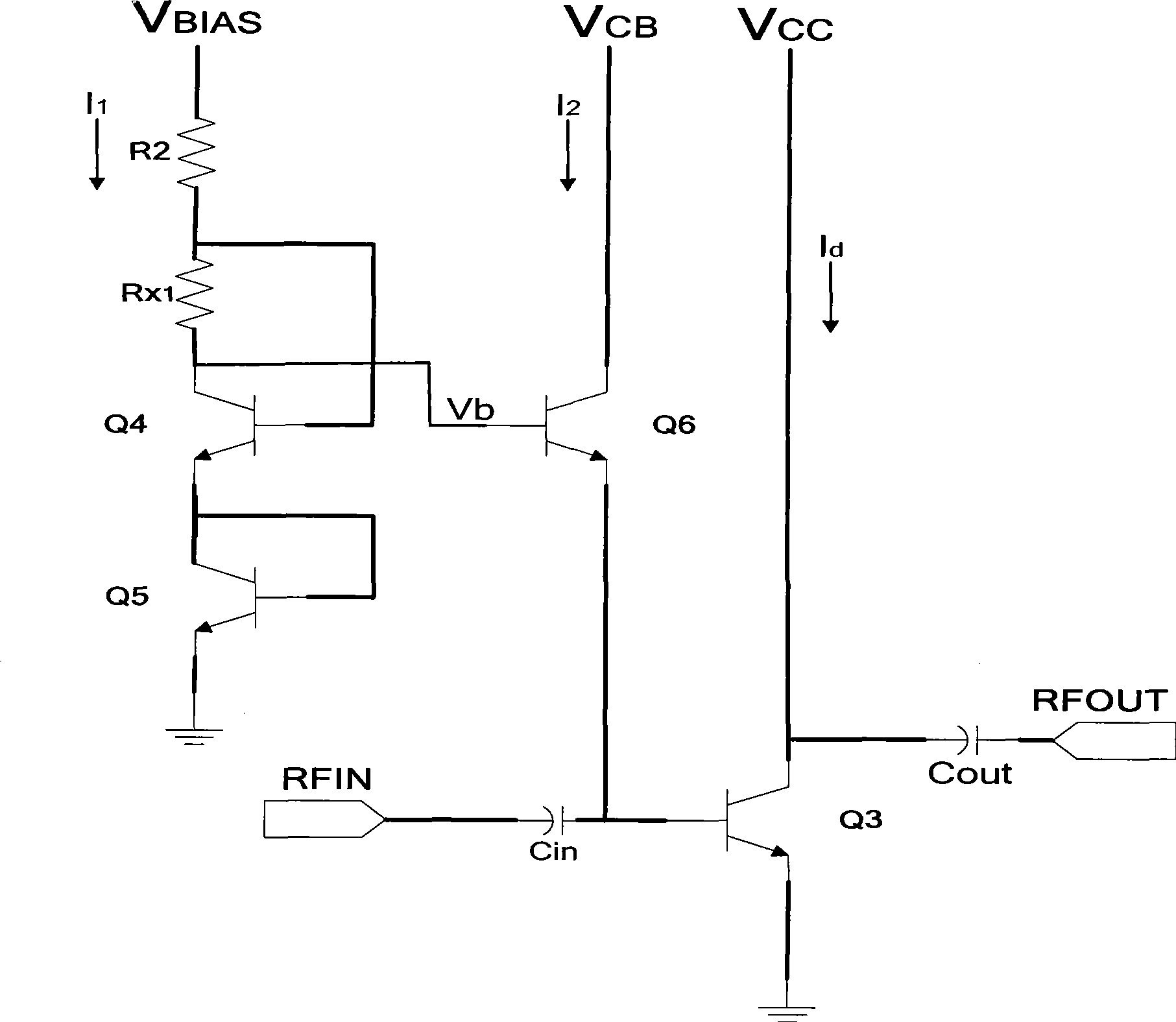

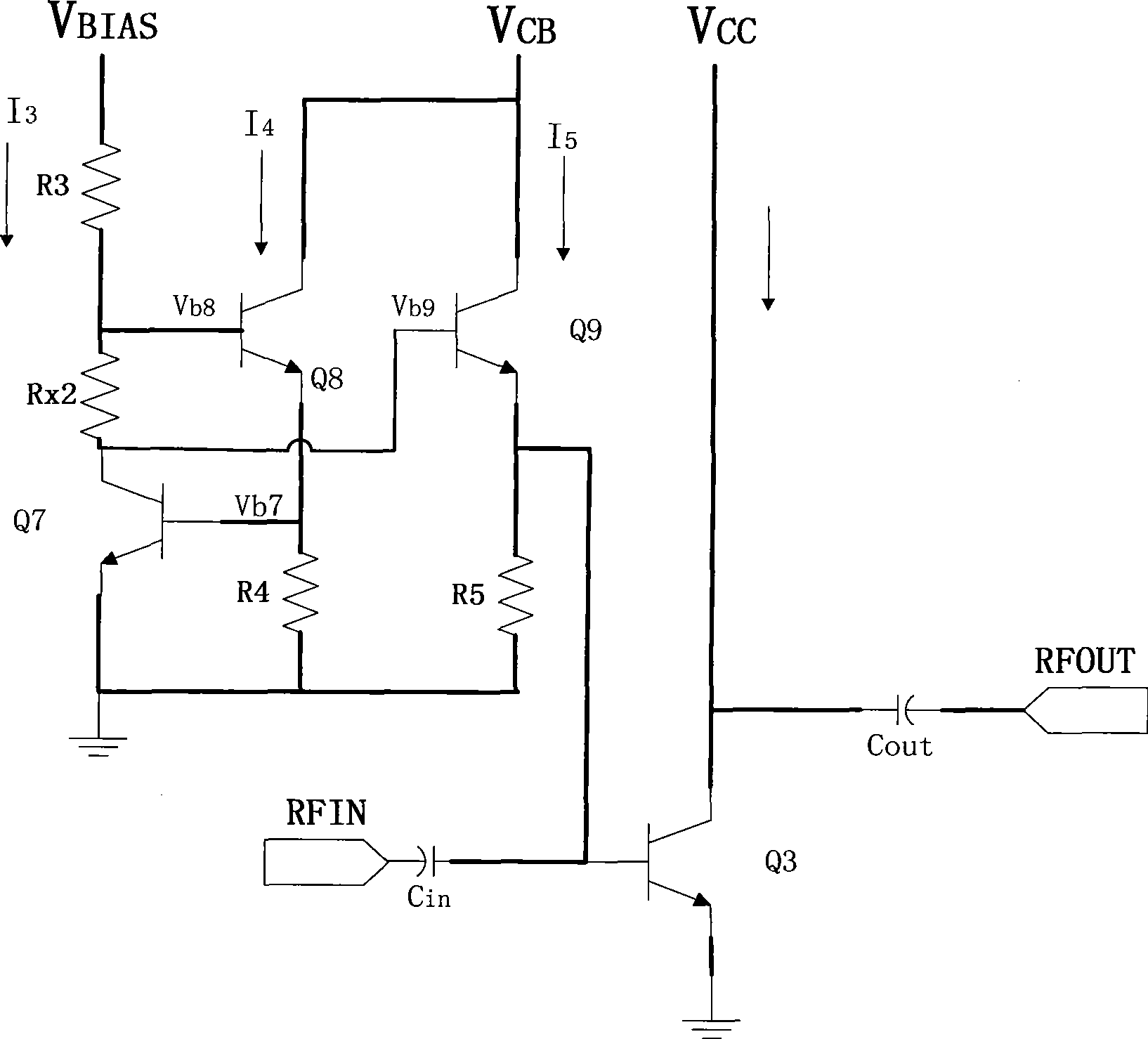

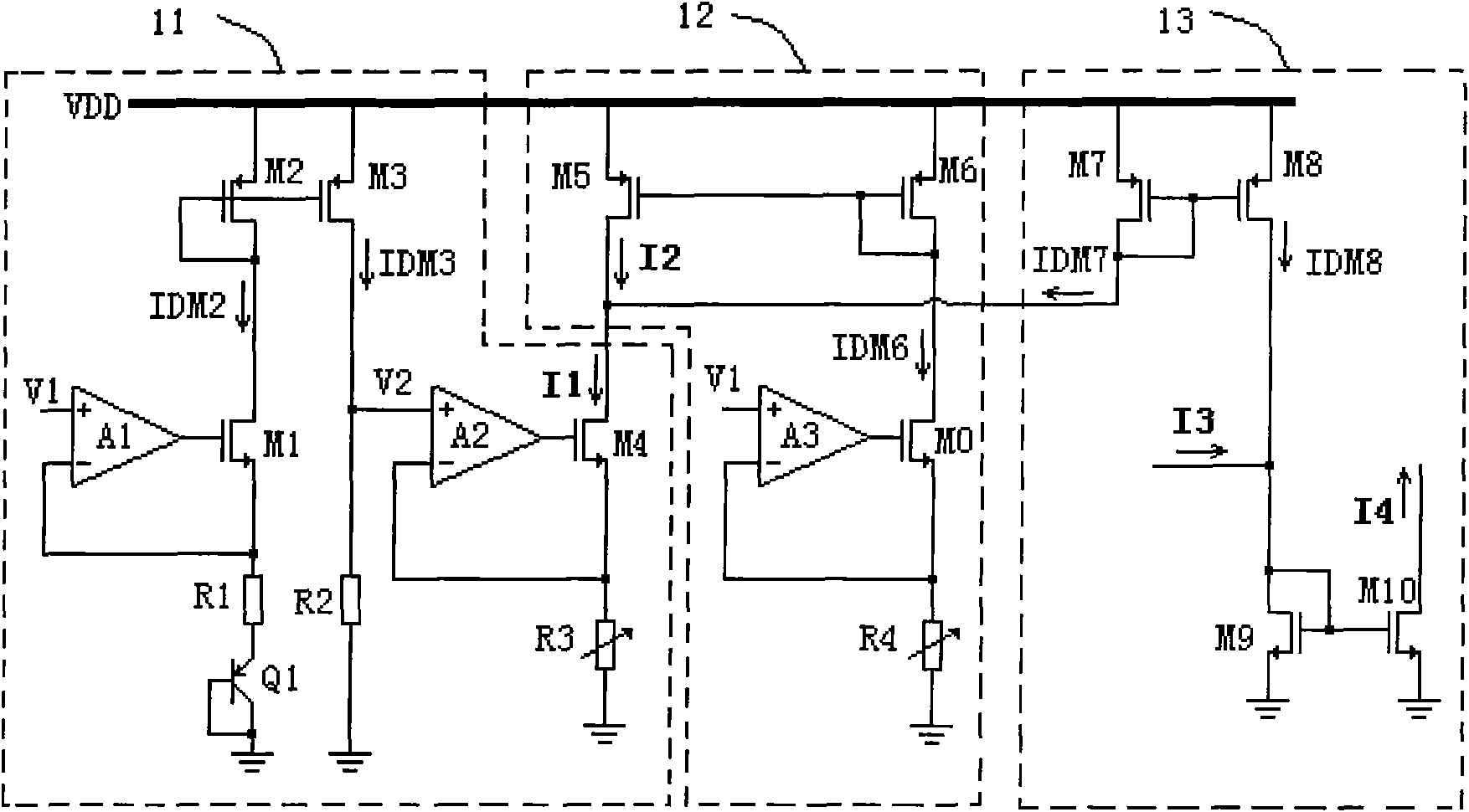

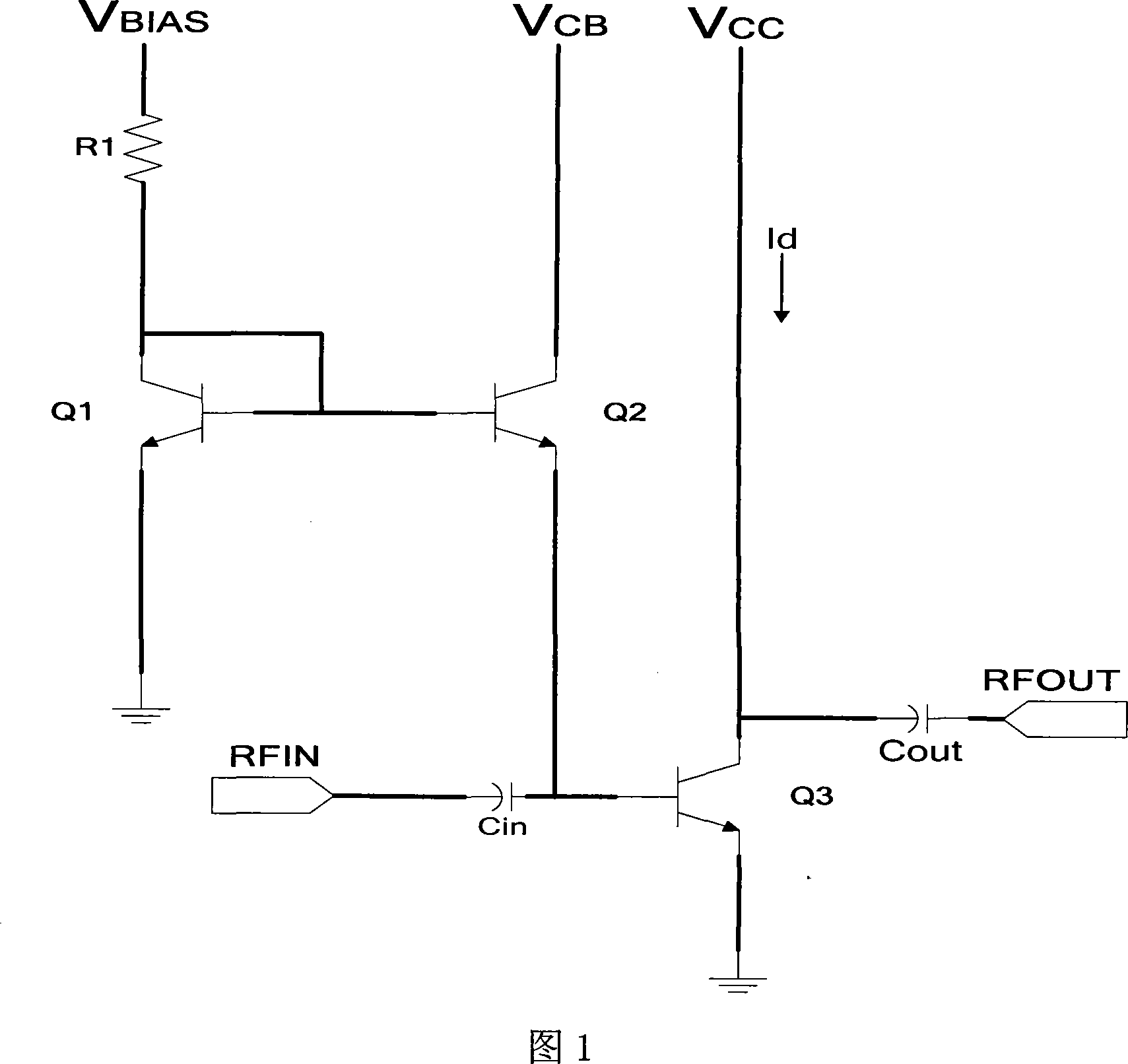

Radio frequency power amplifier circuit

ActiveCN101394152AReduce dependenceImprove stabilityHigh frequency amplifiersAmplifier modifications to reduce temperature/voltage variationElectrical resistance and conductanceEngineering

The invention discloses a circuit of a radio-frequency power amplifier, which comprises a bias circuit and an amplification circuit. A resistance compensating structure is designed in the bias circuit, that is, a compensating resistance is added to the bias circuit. The added compensating resistance has two functions: (1) increasing the voltage compensation of the bias circuit and reducing the dependency of the circuit on the bias voltage; and (2) enhancing the temperature compensation of the bias circuit. The change of the bias voltage or temperature causes the electric current changes of Q4 and Q5 or Q7 and Q8 of NPN tube, the change quantity of VBE of voltage generated by the electric current changes between a base electrode and a collector electrode can be compensated efficiently by the change quantity of two ends of R*1 or R*2, thereby ensuring the circuit is not sensitive to the bias voltage and the temperature.

Owner:RDA TECH

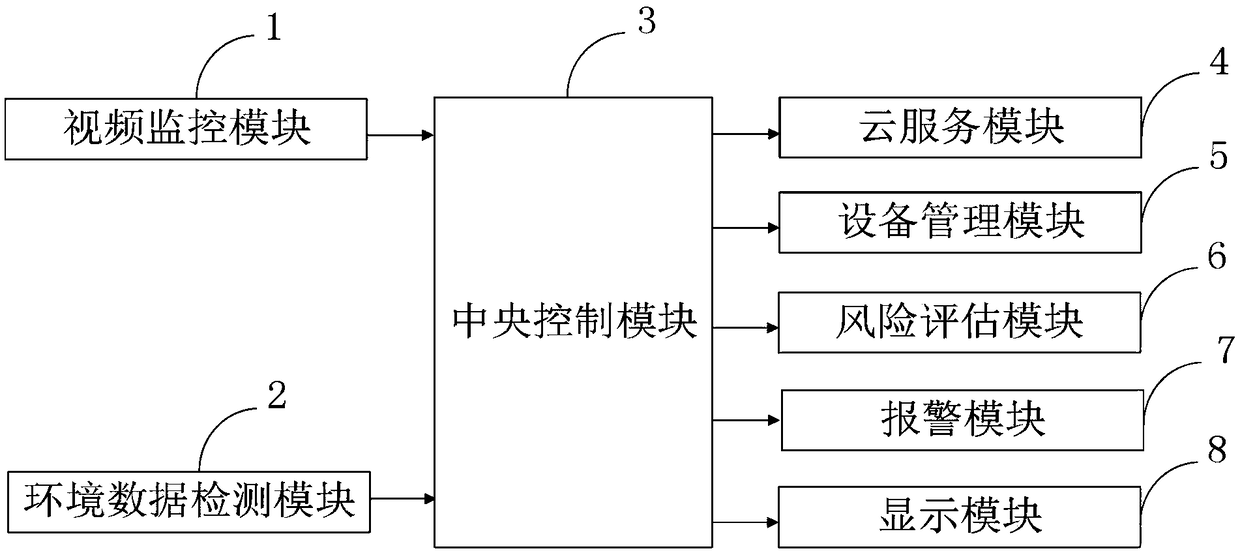

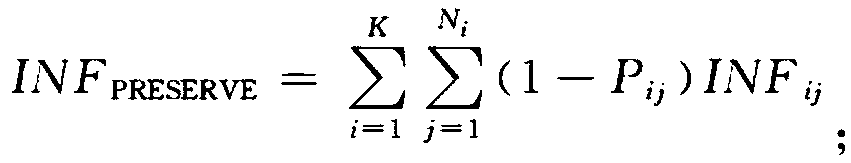

A big data visualization system and method for an underground comprehensive pipe corridor

InactiveCN109408686AImprove accuracyImprove reliabilityForecastingResourcesVideo monitoringThe Internet

The invention belongs to the technical field of integrated pipe gallery engineering. Disclosed is a big data visualization system and method for an underground comprehensive pipe corridor. The big data visualization system of the underground comprehensive pipe corridor comprises a video monitoring module, an environmental data detection module, a central control module, a cloud service module, a device management module, a risk assessment module, an alarm module and a display module. The big data visualization system comprises a video monitoring module, an environmental data detection module,a central control module, a cloud service module, a device management module, a risk assessment module, an alarm module and a display module. The invention establishes an Internet of Things communication framework between the security, ventilation, power supply, drainage, lighting and fire fighting equipment in the pipeline corridor and the cloud server platform through a management module, utilizes the Internet of Things technology, and greatly facilitates the management of the operation and maintenance equipment. At the same time, through the risk assessment module, the invention can construct a comprehensive pipe corridor disaster chain Bayesian network model according to the evolution law of a plurality of potential disasters in the comprehensive pipe corridor, predict the occurrence probability of each disaster in the pipe corridor and evaluate the loss degree of the pipe corridor, thereby proposing a scientific and effective comprehensive pipe corridor pregnant source chain broken disaster reduction mechanism and measures.

Owner:CHINA CONSTR SECOND BUREAU INSTALLATION ENG

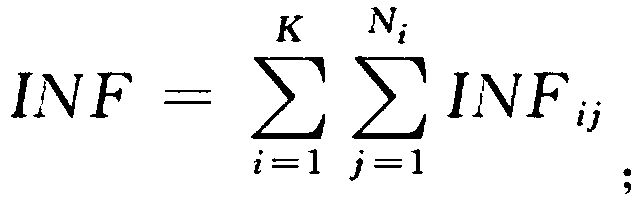

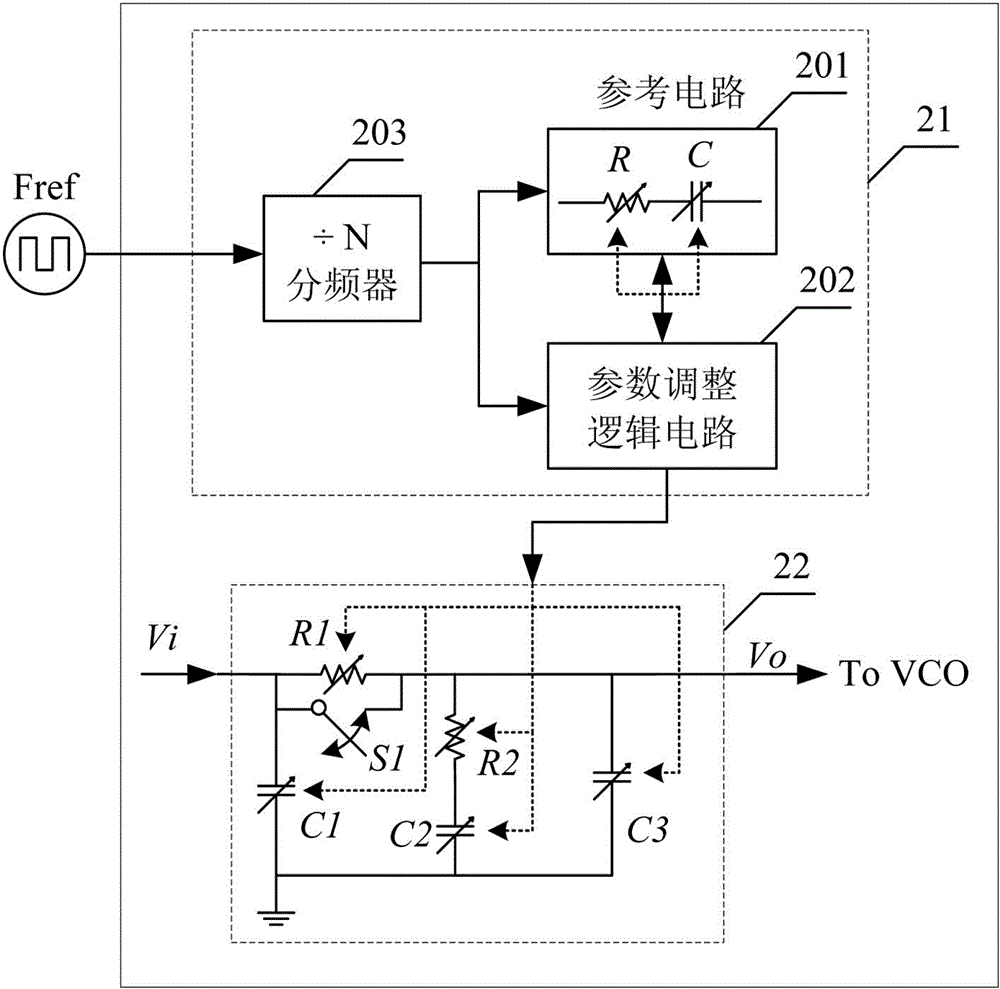

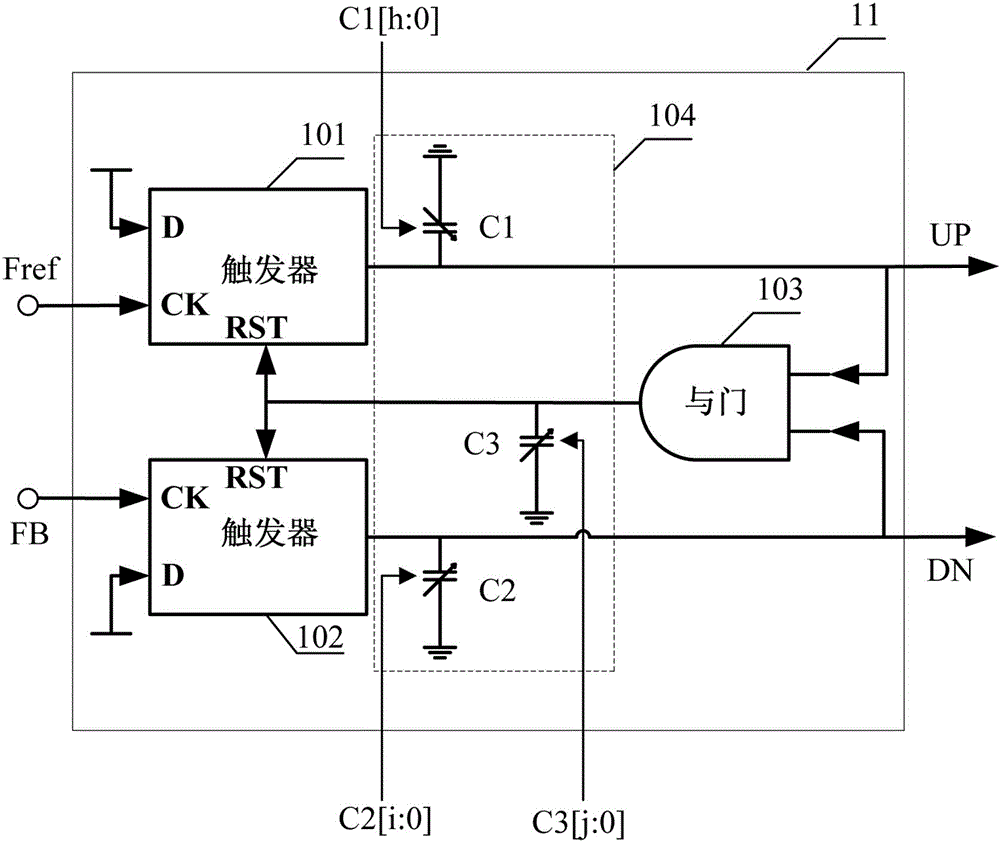

Self-calibration device and method for loop parameters of phase-locked loop

The invention discloses a self-calibration device and method for the loop parameters of a phase-locked loop. The self-calibration device comprises a phase frequency detector, a charge pump, a loop filter, a loop parameter correcting module and a main frequency divider. The phase frequency detector, the charge pump and the loop filter are sequentially connected. The loop parameter correcting module shares a common reference signal Fref input end with the phase frequency detector, and is connected to the loop filter. The main frequency divider is connected with the output end of the loop filter and passes through the main frequency detector to be fed back and input to the feedback input end of the phase frequency detector. The self-calibration device and method for the loop parameters of the phase-locked loop can overcome the defects that in the prior art, the area of a chip is large, manufacturing cost is high, and a temperature compensation effect is bad are overcome, and achieve the advantages of being small in chip area, low in manufacturing cost and good in temperature compensation effect.

Owner:WUXI ZHONGKE MICROELECTRONICS IND TECH RES INST

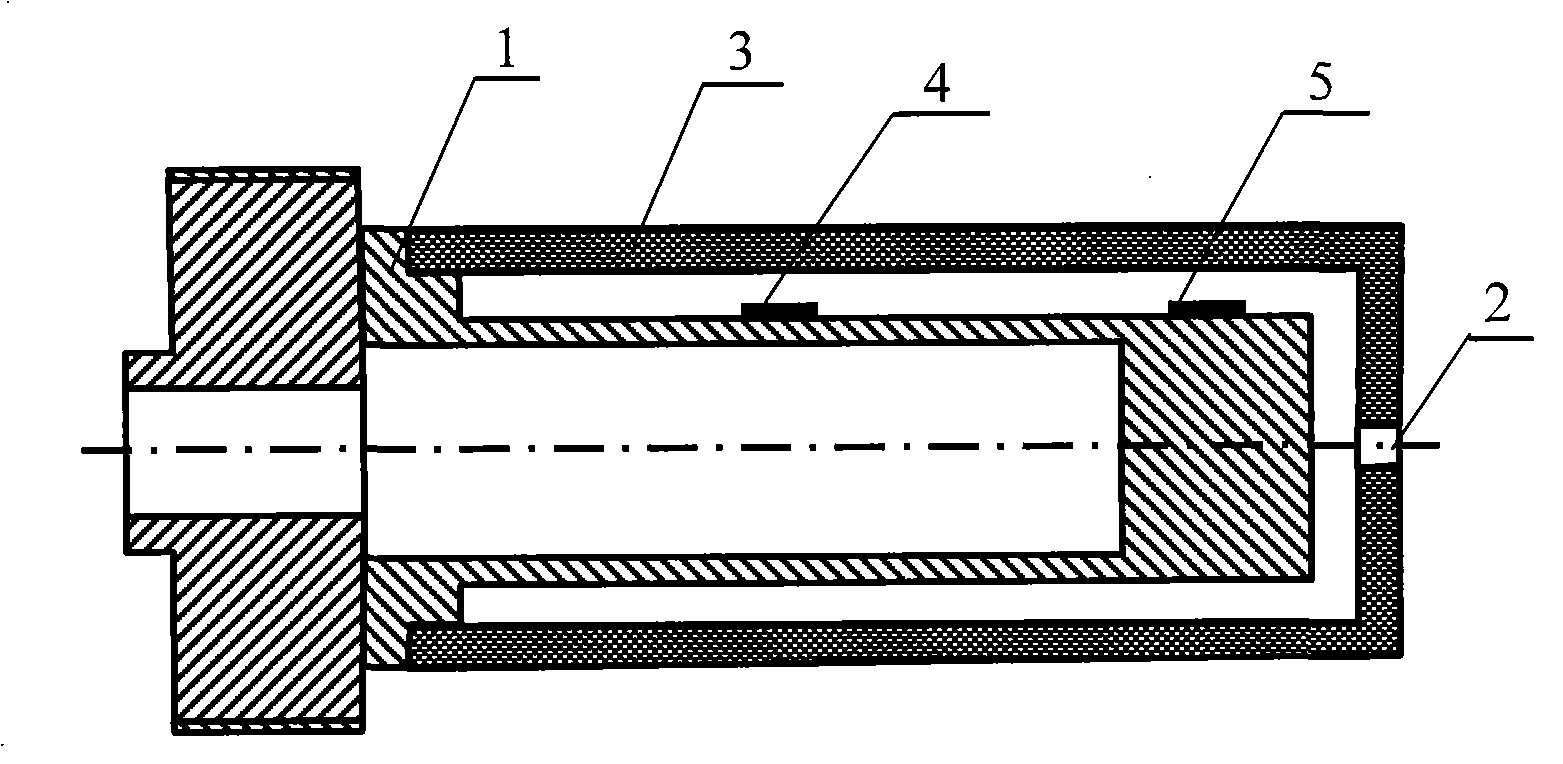

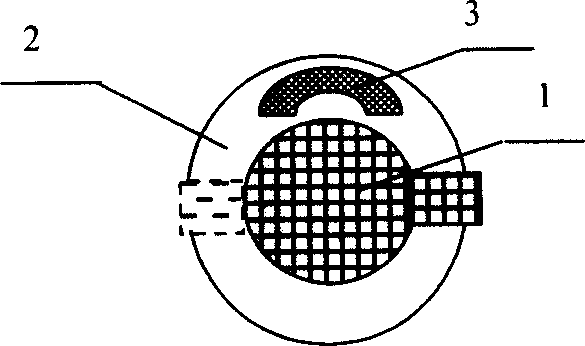

Inner arced ceiling thin wall straining cartridge throw-in type optical fibre Bragg grating pressure sensor

InactiveCN101266179AExpand the measurement rangeGuaranteed tightnessFluid pressure measurement by optical meansGratingOperating temperature range

An inner arc top thin wall strain cylinder drop-type optical fiber Bragg grating pressure sensor, belonging to the field of sensor technology, relates to a drop-type optical fiber Bragg grating pressure sensor for pressure measurement, characterized in that the inner side top of a metal thin wall inner cylinder is arc structured; both of the pressure-measuring optical fiber Bragg grating and the temperature compensating optical fiber Bragg grating are packaged in metallization; the pressure-measuring optical fiber Bragg grating is welded to the outer wall side of the metal thin wall inner cylinder axially with metal; the temperature compensating optical fiber Bragg grating is welded to the top outer side of the metal thin wall inner cylinder with metal; the pressure-measuring optical fiber Bragg grating is vertical to temperature compensating optical fiber Bragg grating to each other; two signal extraction single mode fibers are also packaged in metallization locally when passing through an optical fiber exit hole, and welded to the optical fiber exit hole with metal so as to close the optical fiber exit hole. The invention improves pressure-measuring range for a pressure sensor so as to solve the crossing sensitive problem of two Bragg gratings, which enhances operating temperature range for the sensor.

Owner:DALIAN UNIV OF TECH

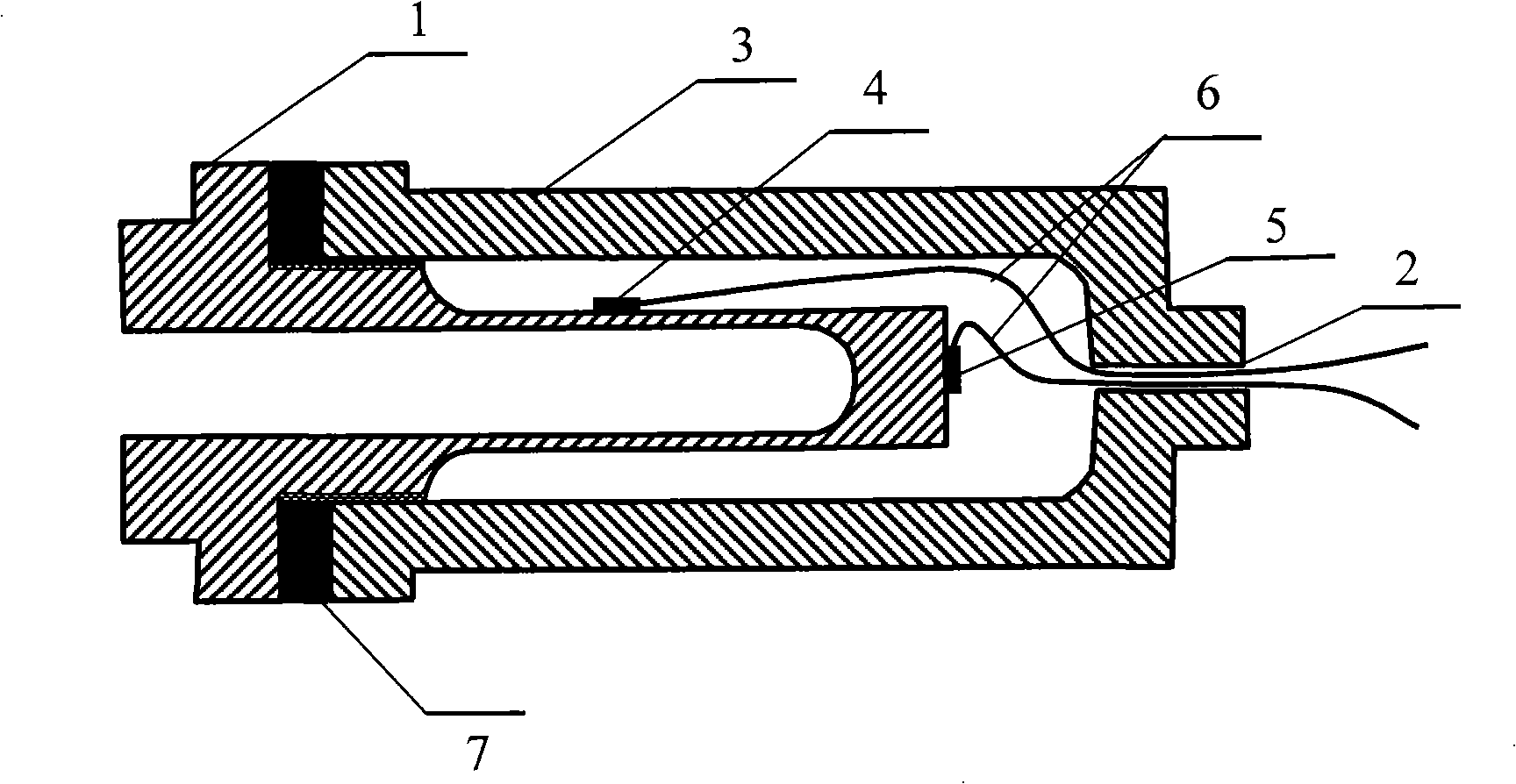

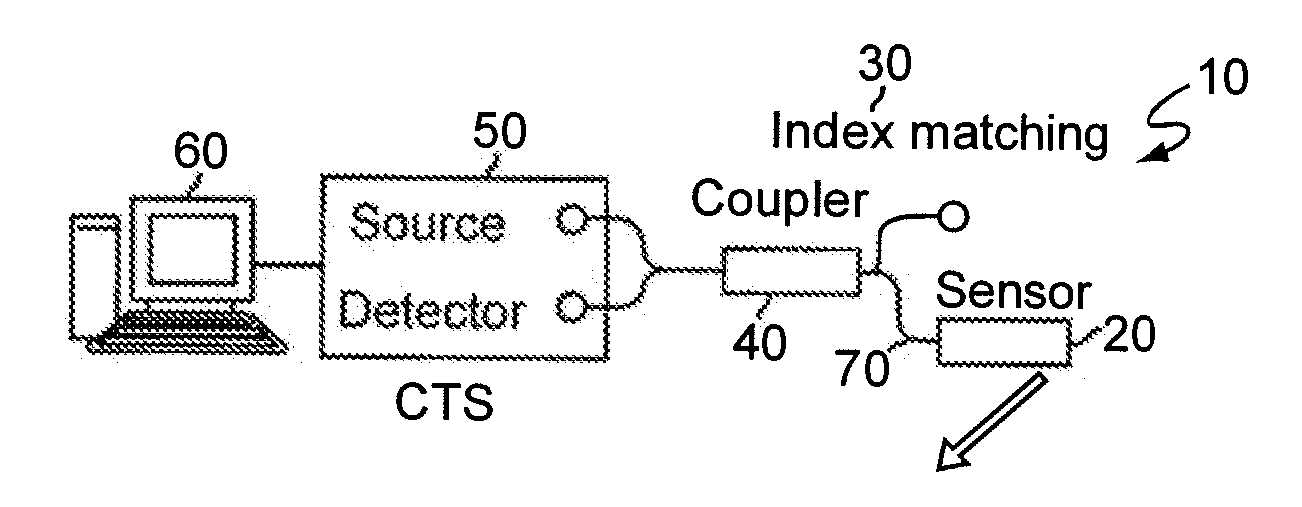

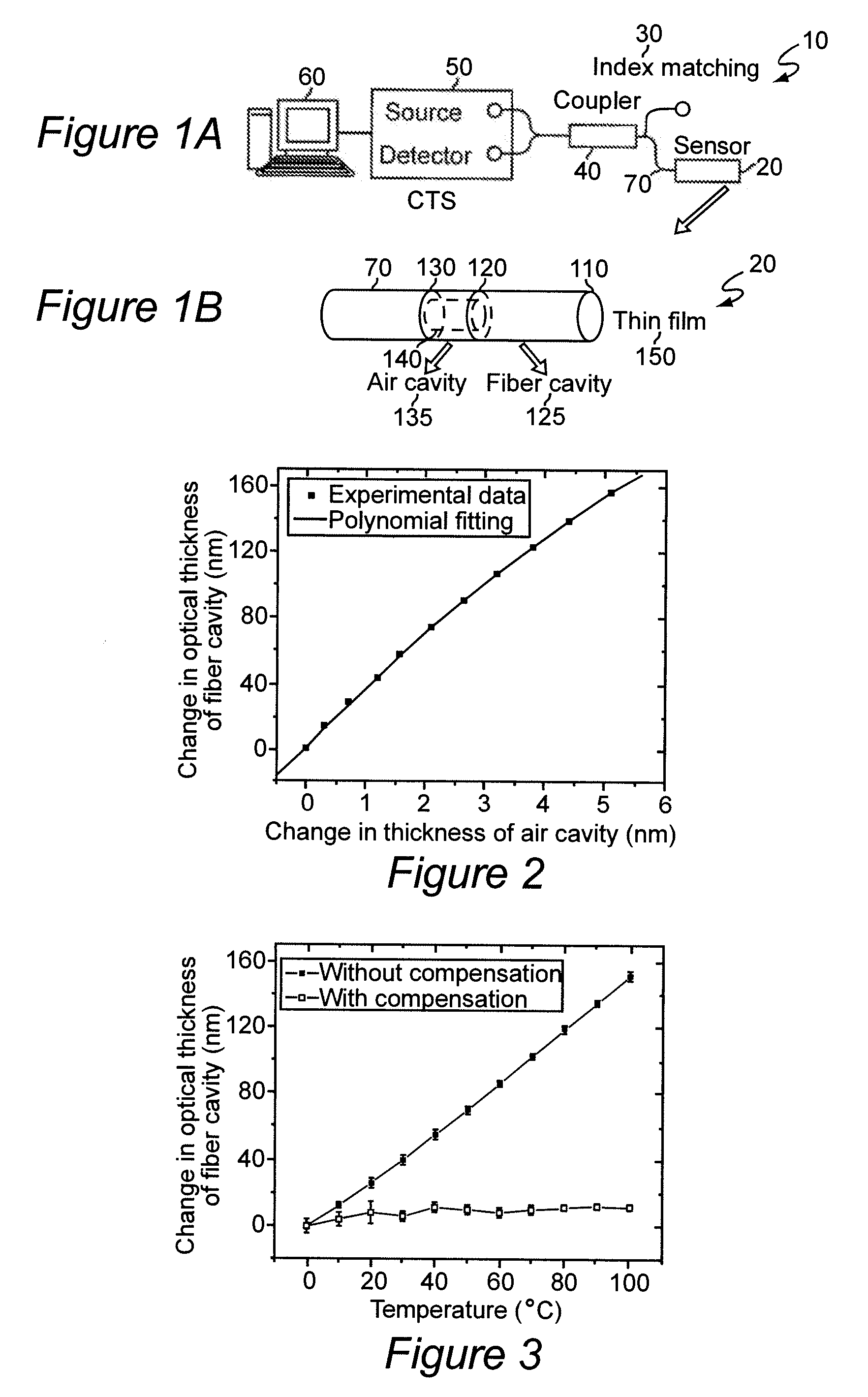

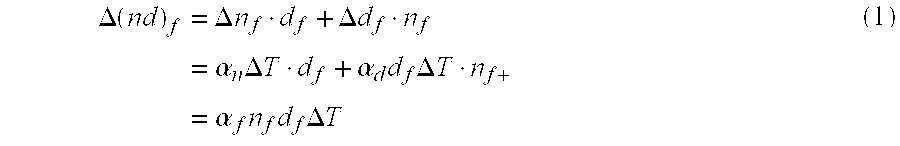

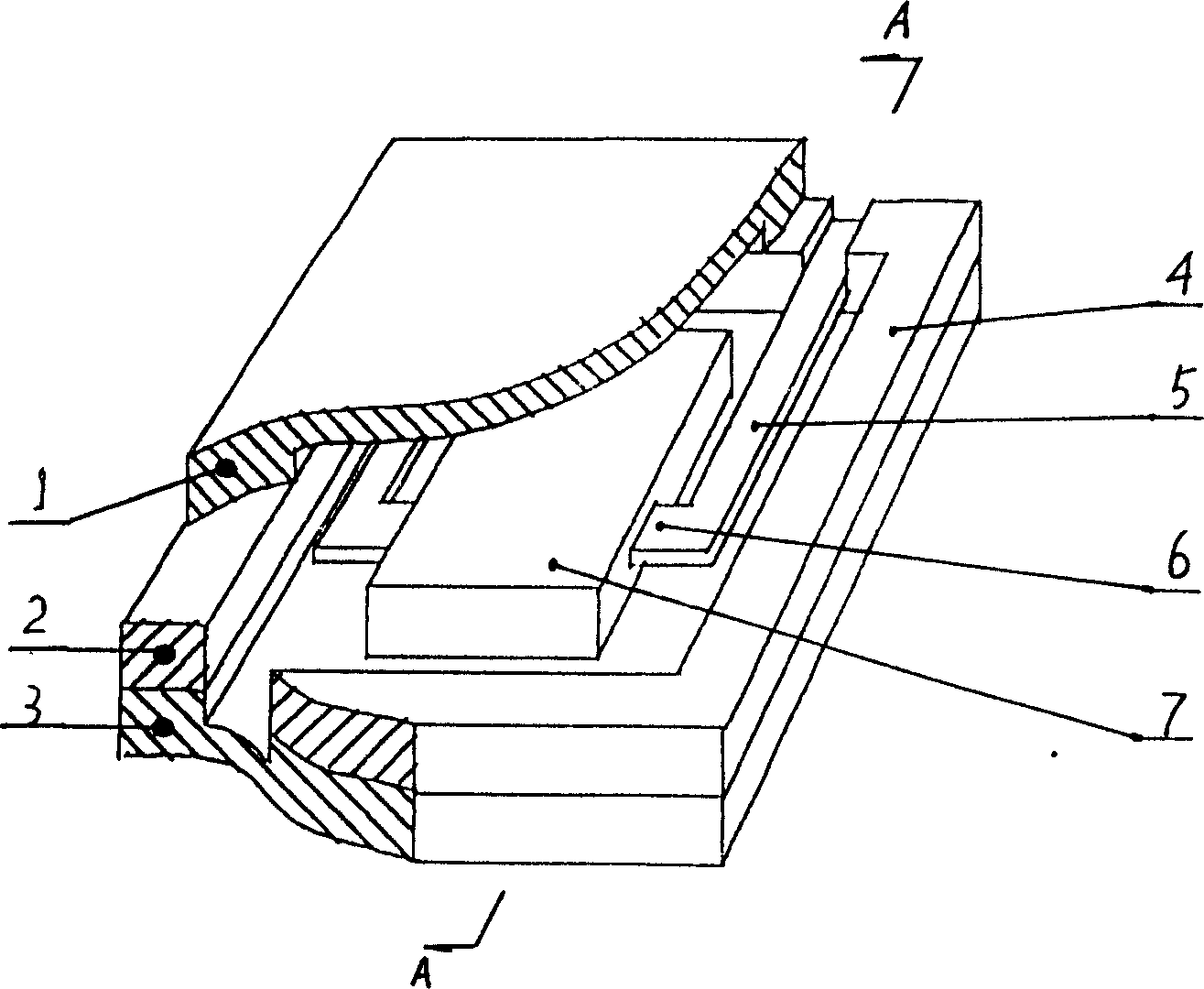

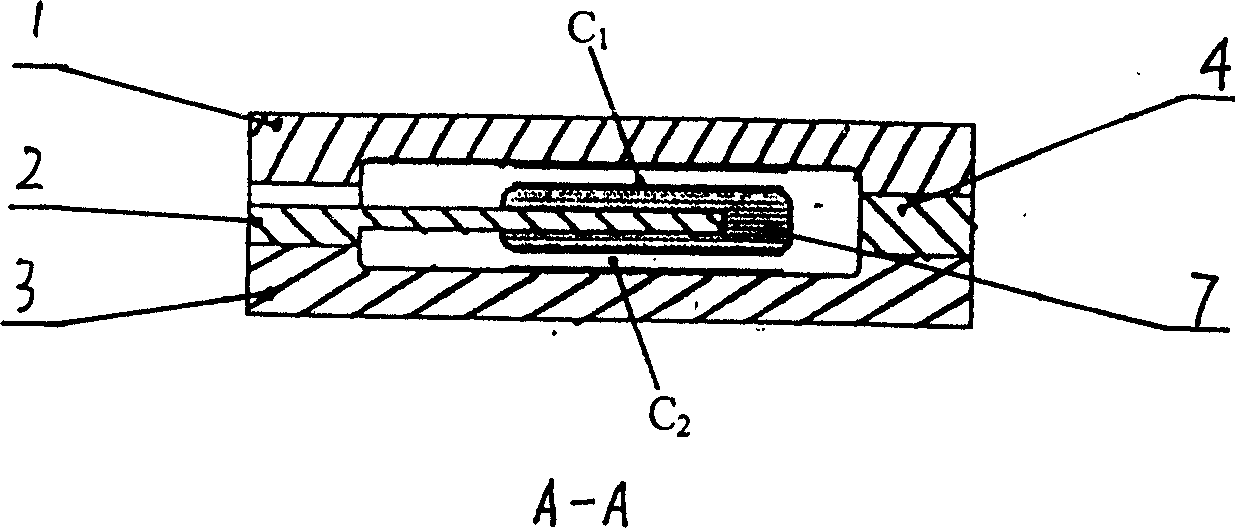

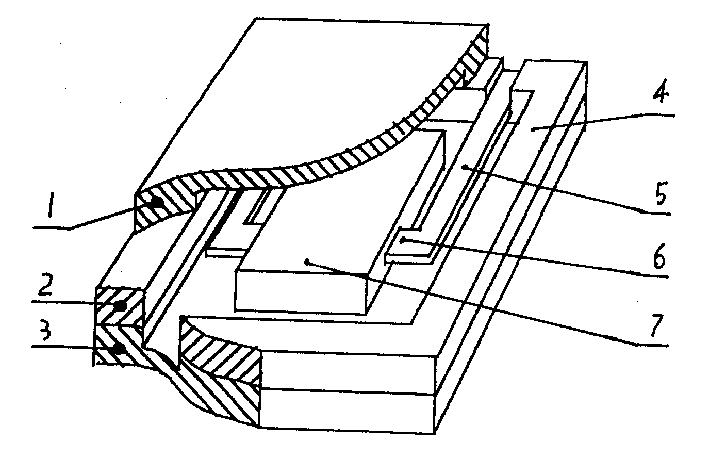

Multi-cavity fabry-perot interferometric thin-film sensor with built-in temperature compensation

InactiveUS20070115480A1Good temperature compensation effectPhase-affecting property measurementsInterferometersThin film sensorThin membrane

A fiber optic sensor includes at least two Fabry-Perot (FP cavities) defined by at least three partially reflecting surfaces which individually and together are capable of generating different interference spectra which are affected by temperature. One of the FP cavities is formed at an end of the sensor and includes a surface which is capable of supporting a thin film, the optical thickness of which is to be measured. The other FP cavity between the lead-in fiber and the first FP cavity thus does not include the film and can thus independently provide highly accurate temperature information for calibrating the optical length of the second FP cavity and compensation for temperature effects on measurement of the thin film supported thereon, preferably by subtraction of a calibrated temperature-dependent change in optical length of the second FP cavity from the measurement made.

Owner:VIRGINIA TECH INTPROP INC

A self-compensating concrete-integrated strain gauge

InactiveCN102269567AReduce volumeEliminate the effect of detection sensitivityElectrical/magnetic solid deformation measurementFiberElectrical resistance and conductance

The invention discloses a self-compensating concrete integrated strain gauge, which is mainly characterized in that a compensation resistor is provided on the strain gauge, the compensation resistor and the working piece form a half-bridge or full-bridge working mode, and the compensation resistor adopts a high-precision resistor with no stress output Or small grid strain gauges, which can automatically compensate the influence of temperature on the bridge and wires, overcome the difficulty that it is impossible to equip each measuring point with a compensation block and ensure that its temperature and change are consistent; it can also eliminate the influence of wire length on detection sensitivity At the same time, the reinforced fiber insulation base and flexible waterproof sealing material are used to carry out the overall waterproof sealing treatment, which not only ensures the technical requirements of the insulation resistance of the strain gauge, but also has the effect of convenient, fast, accurate and safe on-site installation. .

Owner:陈彦平

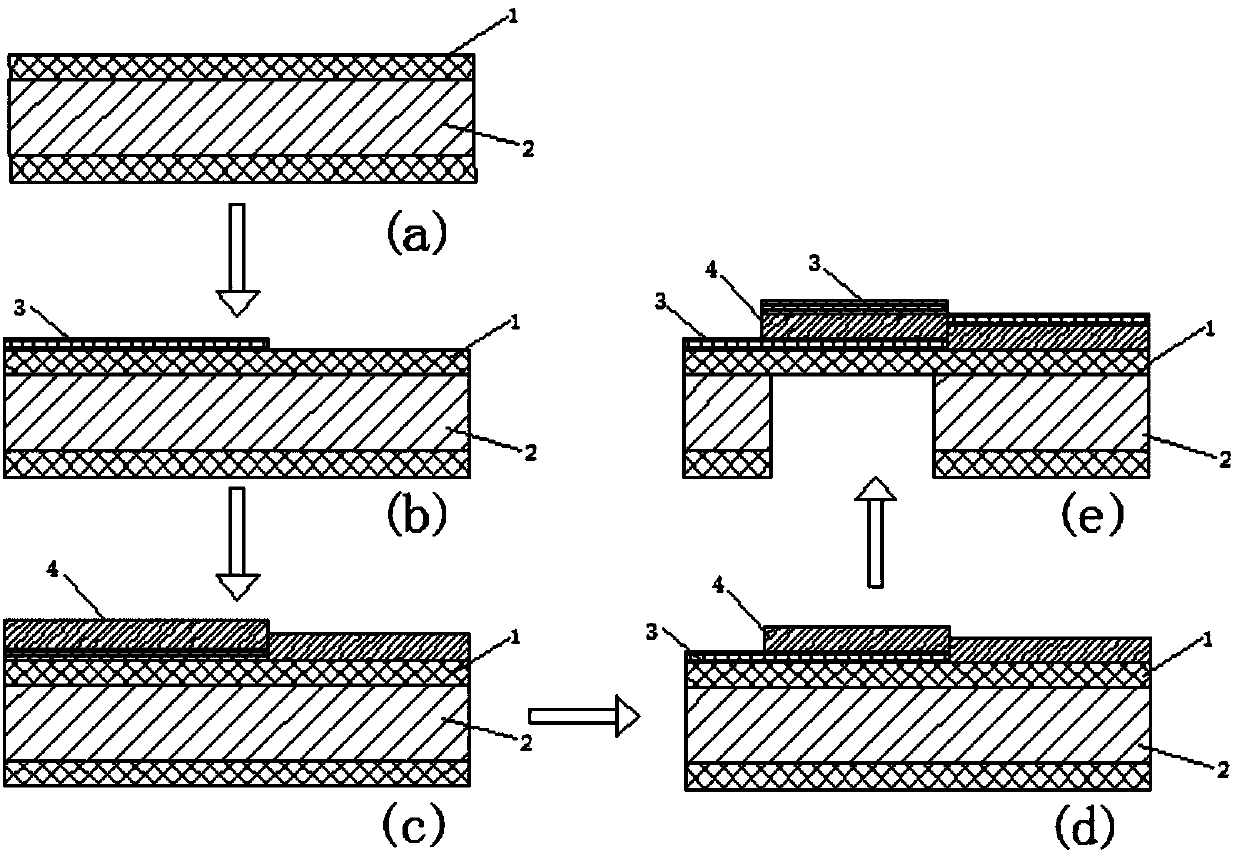

Method for manufacturing acoustic wave device

ActiveUS8997320B2Improve accuracyFacilitates temperature compensationPiezoelectric/electrostrictive device manufacture/assemblyLiquid surface applicatorsThermal sprayingAcoustic wave

Owner:MURATA MFG CO LTD

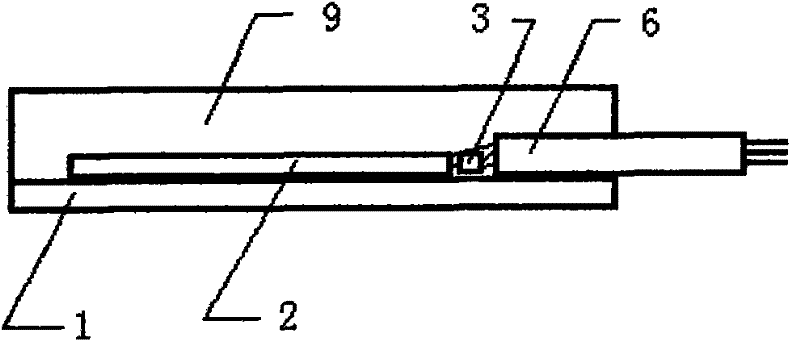

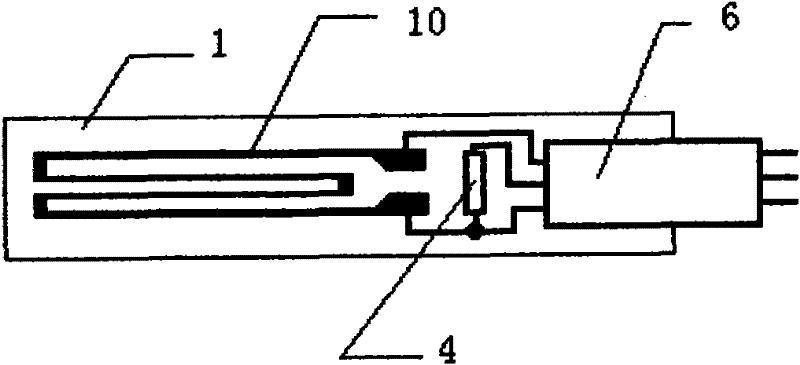

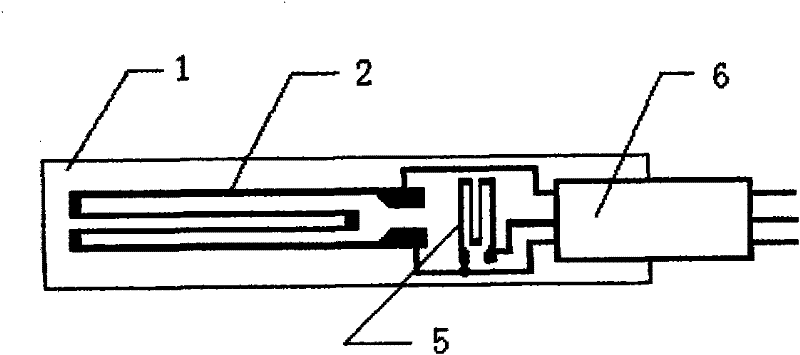

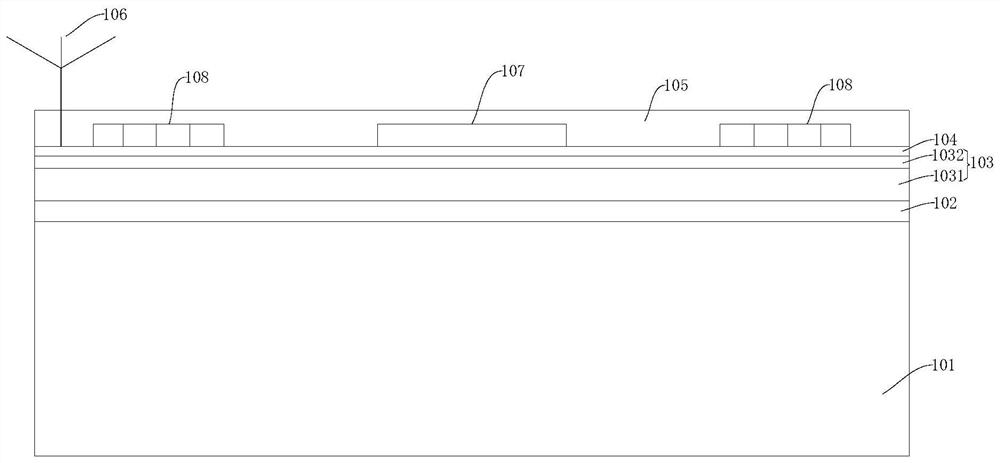

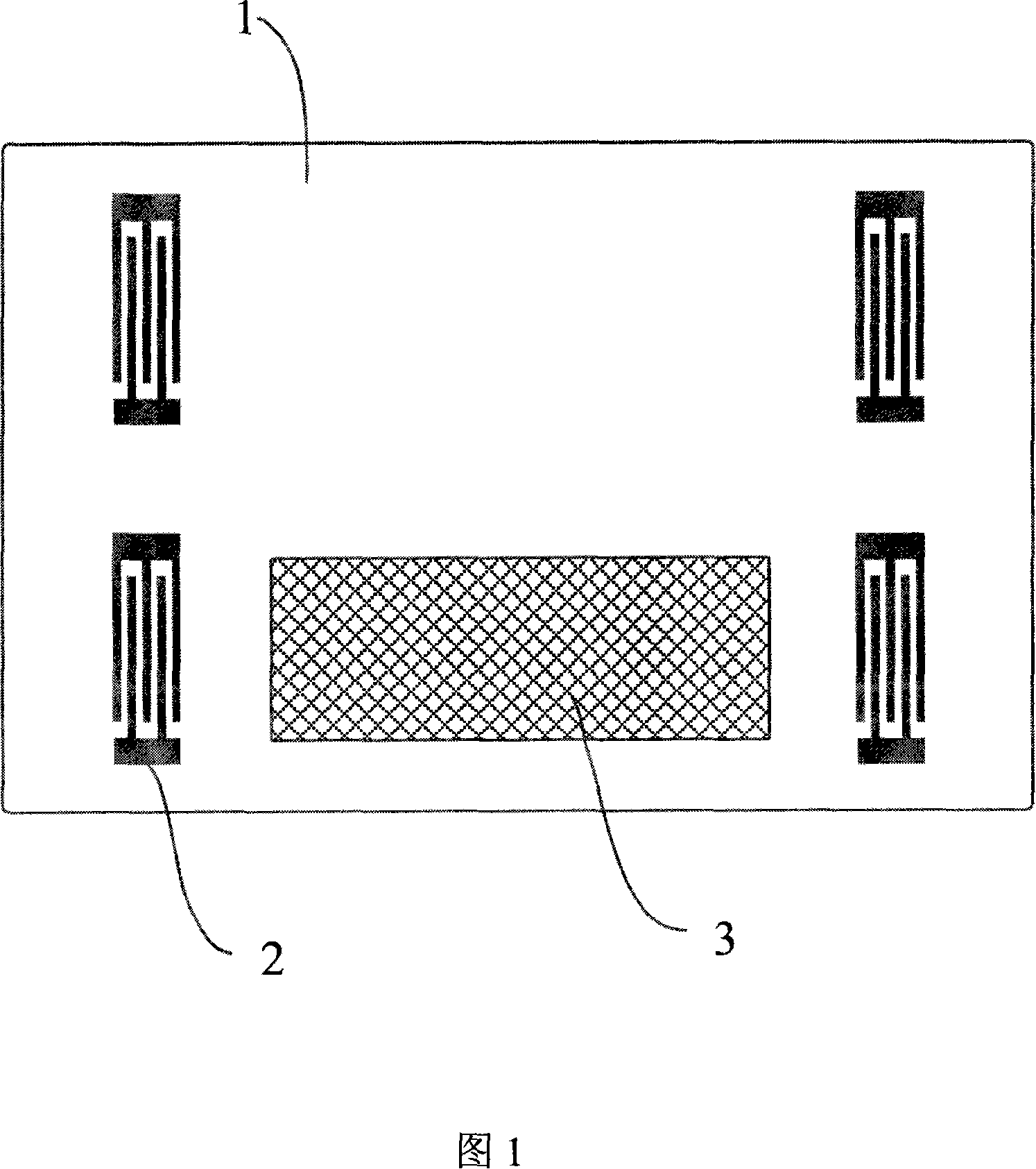

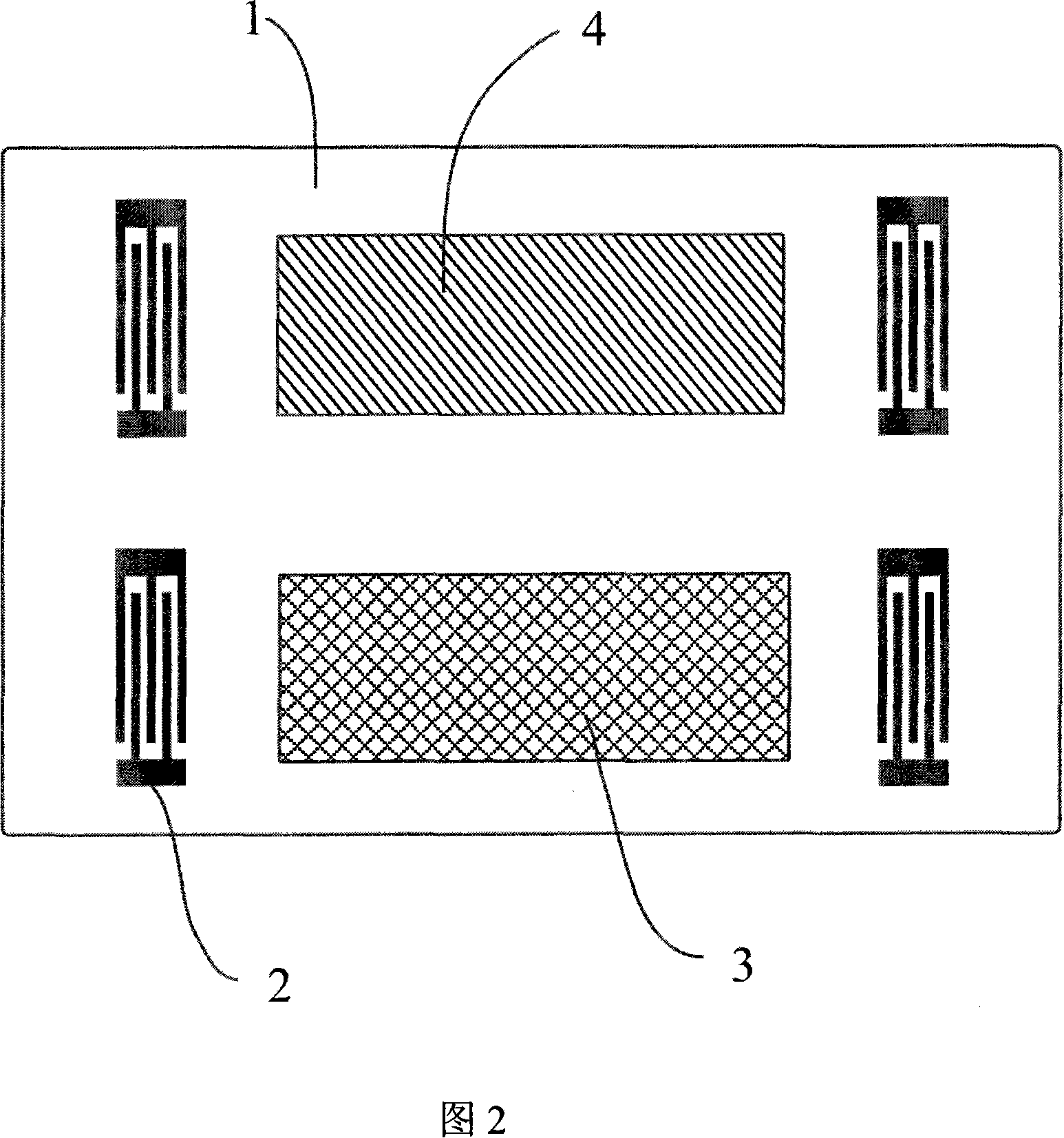

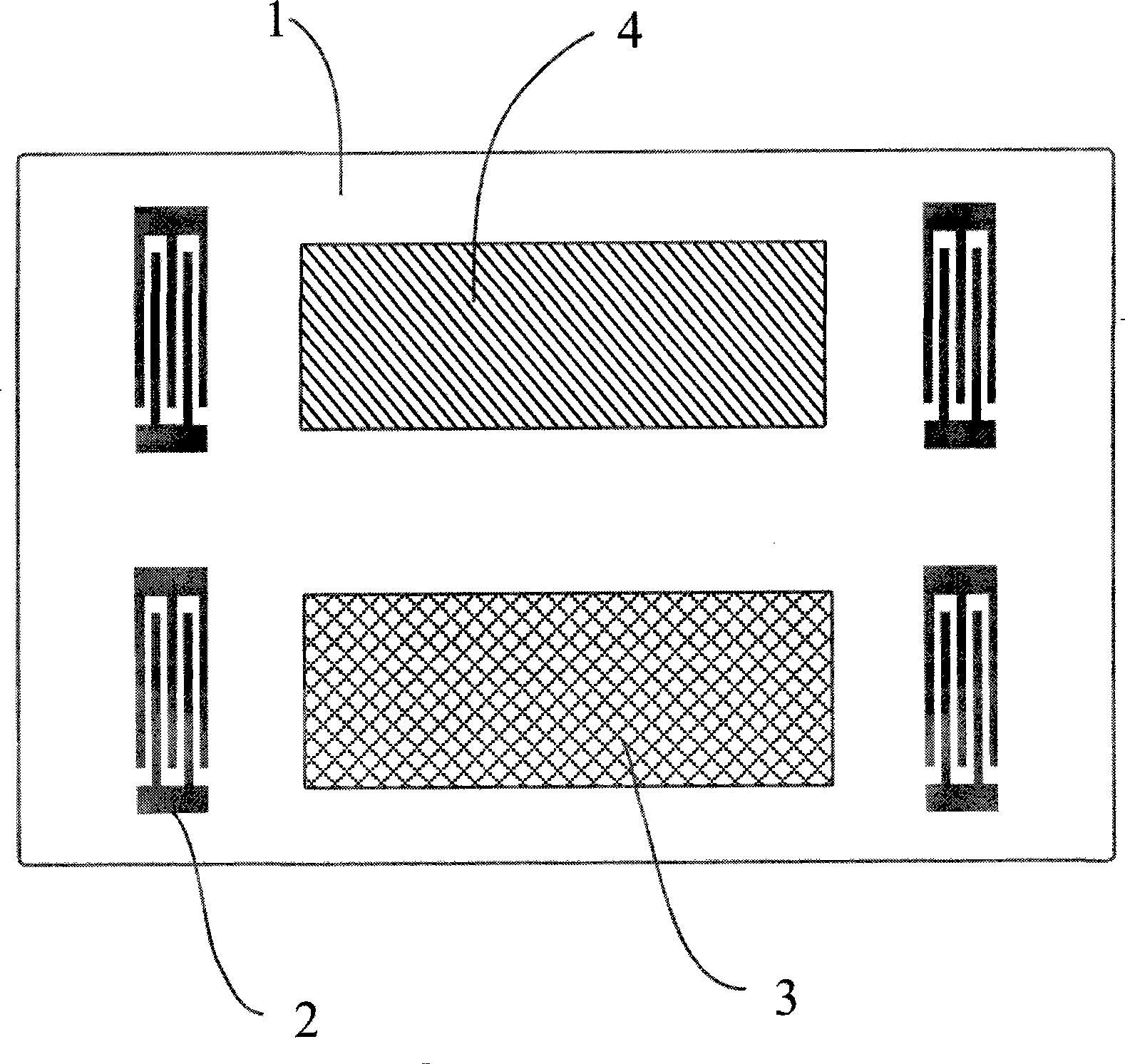

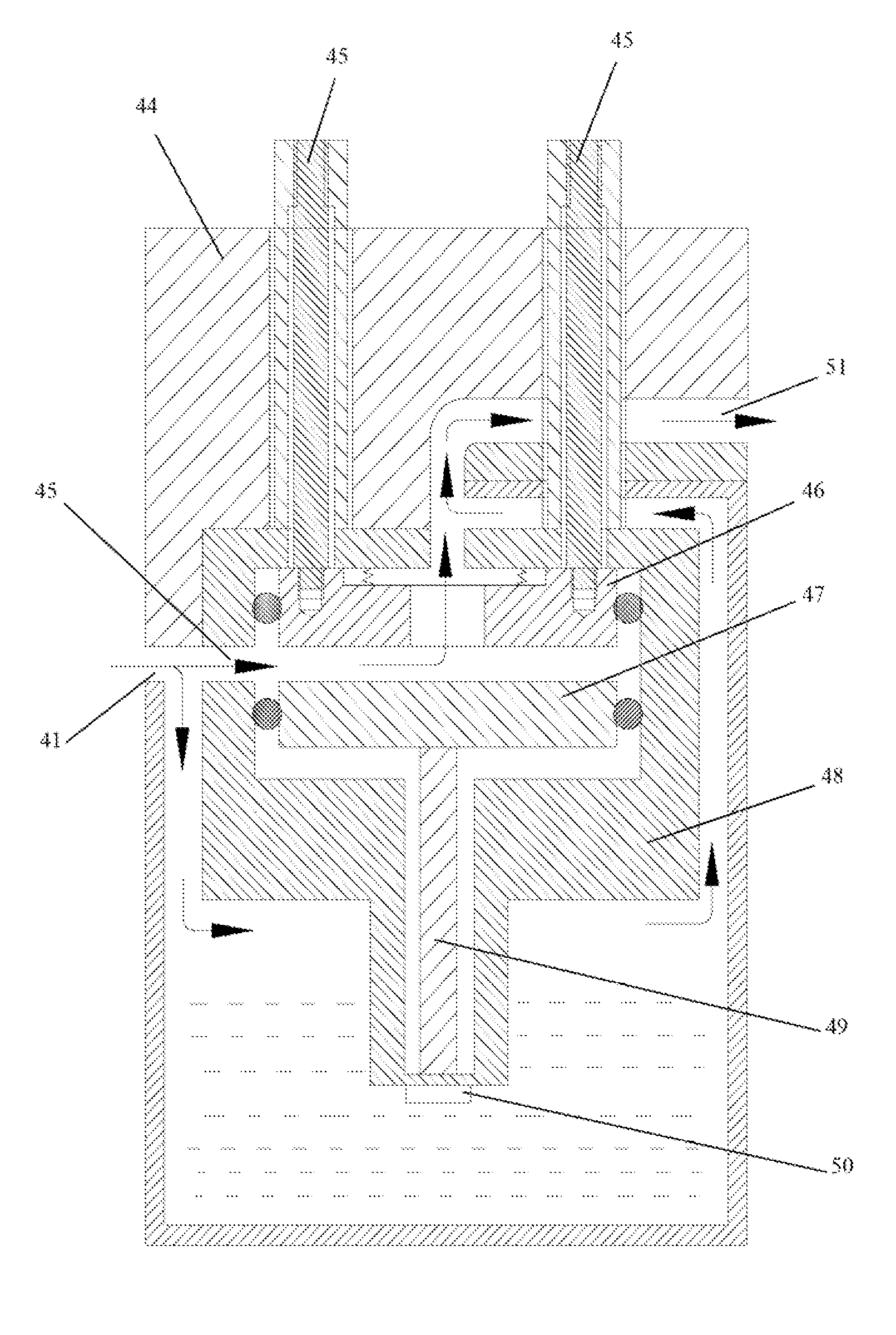

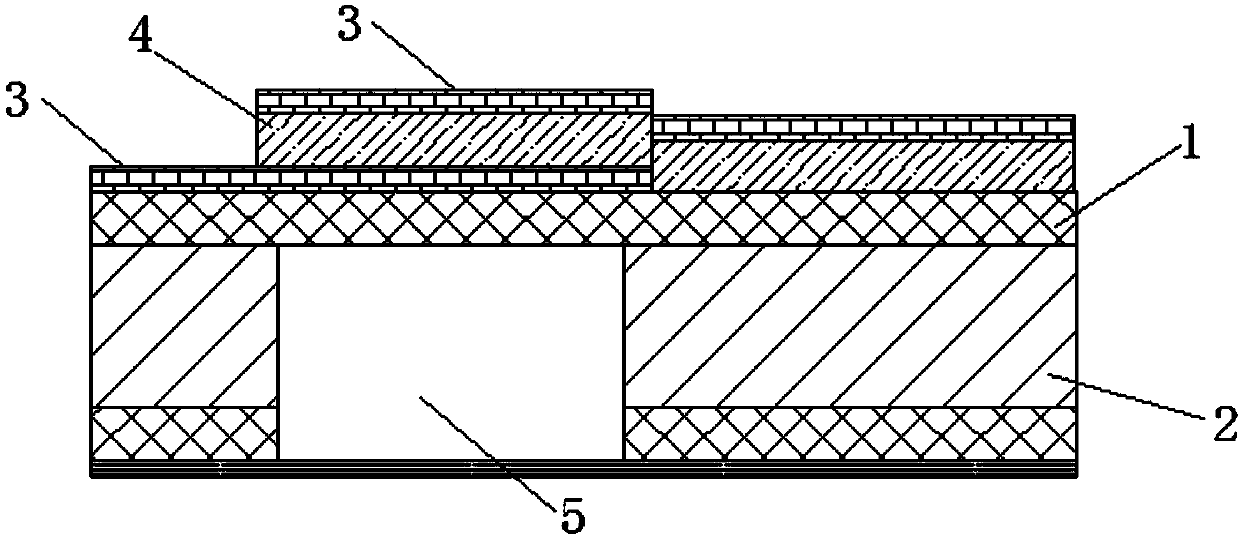

Thin film hydrogen sensor with self-heating function and temperature compensation function

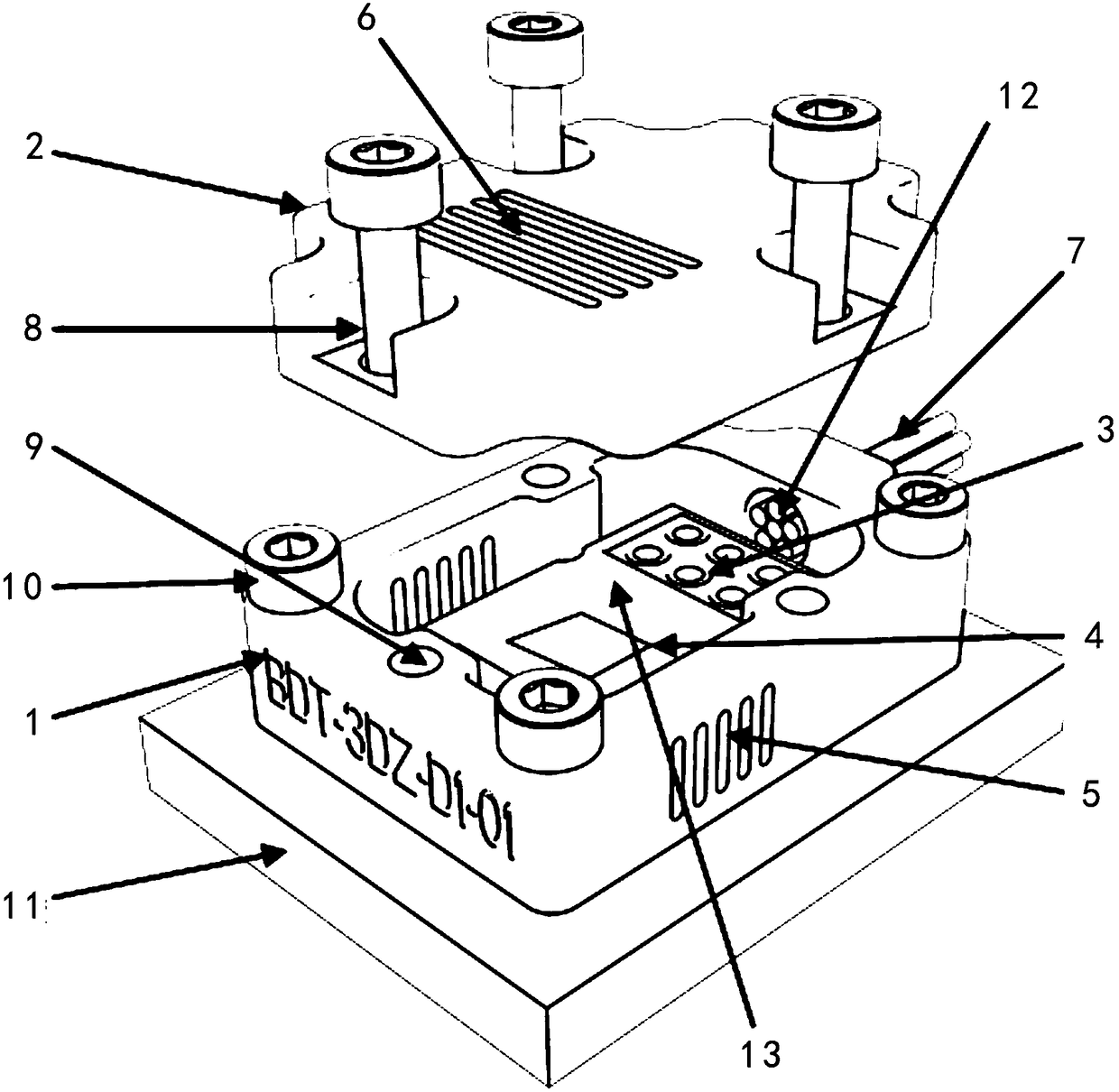

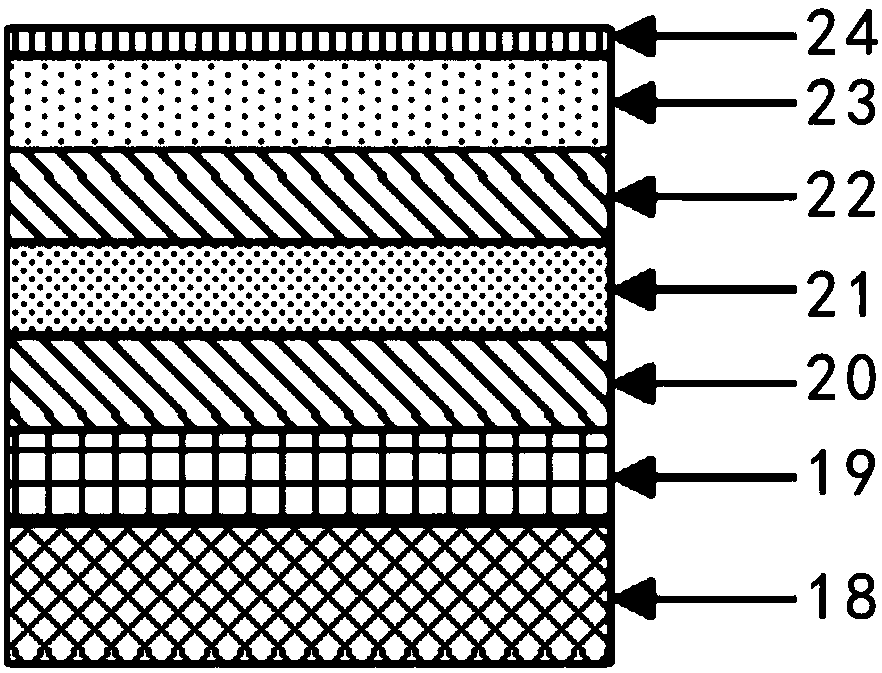

PendingCN108169294AShort heat equilibration timeImprove temperature compensation effectMaterial resistanceHydrogen sensorResistance wire

The invention discloses a thin film hydrogen sensor with a self-heating function and a temperature compensation function. The thin film hydrogen sensor comprises a shell, a top cover, a sensor chip and an adapter circuit board. The adapter circuit board is arranged on the bottom part of an inner cavity of the shell; the sensor chip is arranged on the adapter circuit board; a welding plate is arranged on the adapter circuit board; a terminal of the sensor chip is connected with the welding plate; an inner end of a cable penetrates through a cable hole so as to be connected with the welding plate; the sensor chip is sequentially provided with a base layer, an insulation layer, a lower-layer hydrogen resistance layer, a heating / temperature measuring layer, an upper-layer hydrogen resistance layer, a hydrogen sensitive layer and an anti-oxidation layer from bottom to top; the heating / temperature measuring layer is provided with a temperature measuring resistance wire and a heating resistance wire; the hydrogen sensitive layer is provided with a hydrogen sensitive resistance wire. According to the thin film hydrogen sensor provided by the invention, the heating resistance wire is arranged on the sensor chip, so that the sensor chip has a self-heating function; the sensor chip is packaged into a sealed inner cavity of the shell, so that a temperature compensation function is conveniently improved, and the measurement accuracy is improved; through arranging the adapter circuit board, the thin film hydrogen sensor is convenient to apply.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

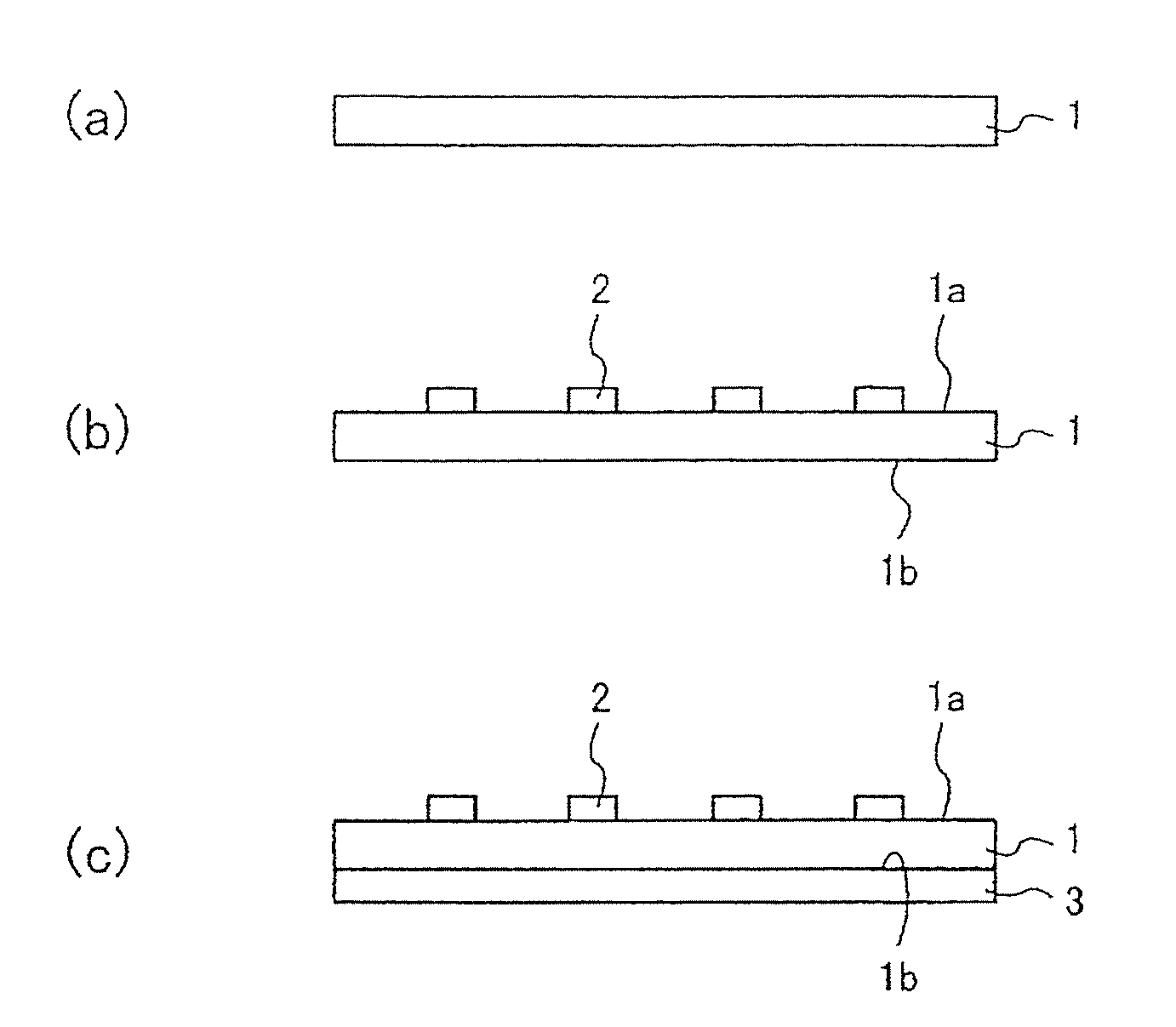

Method for manufacturing acoustic wave device

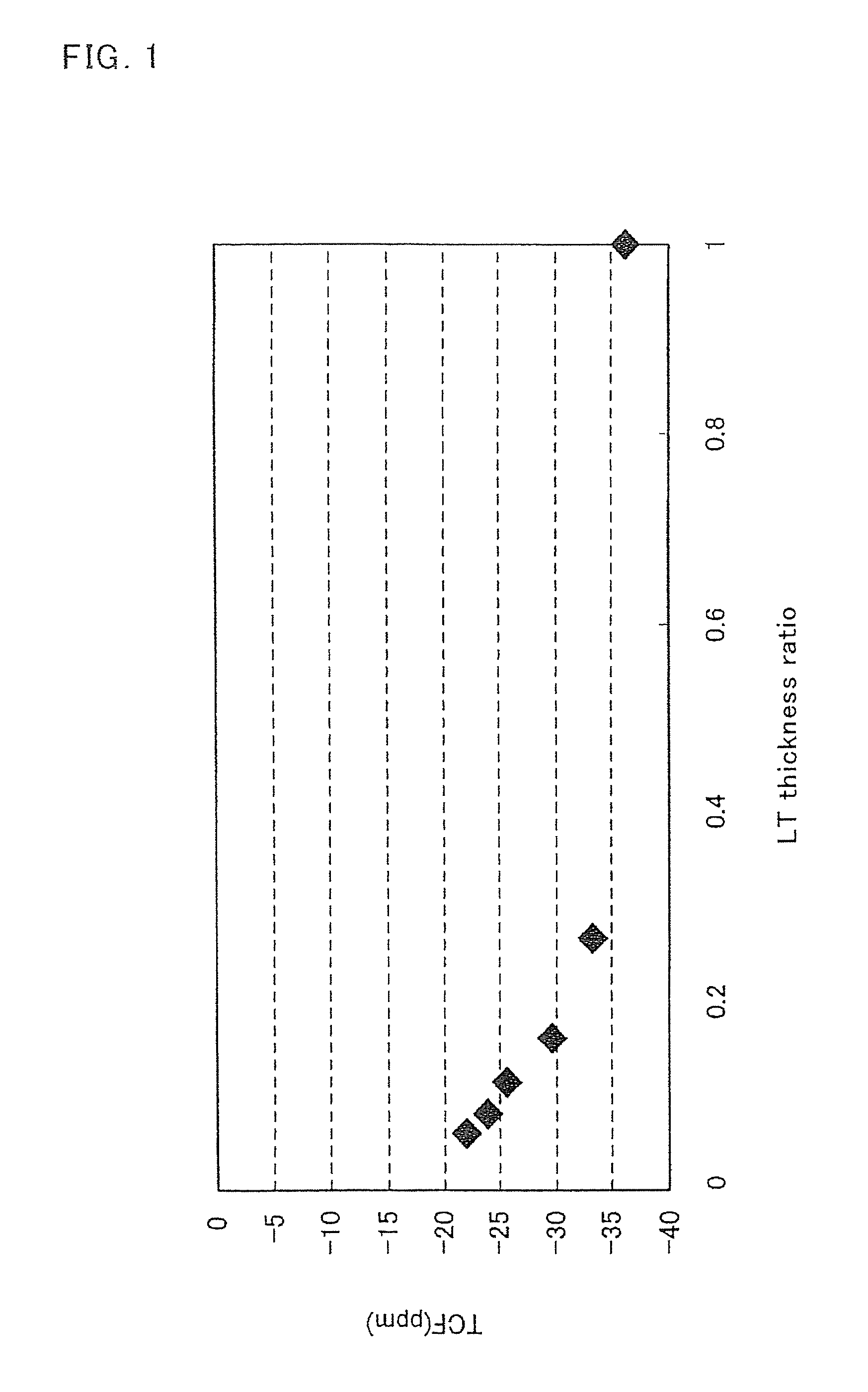

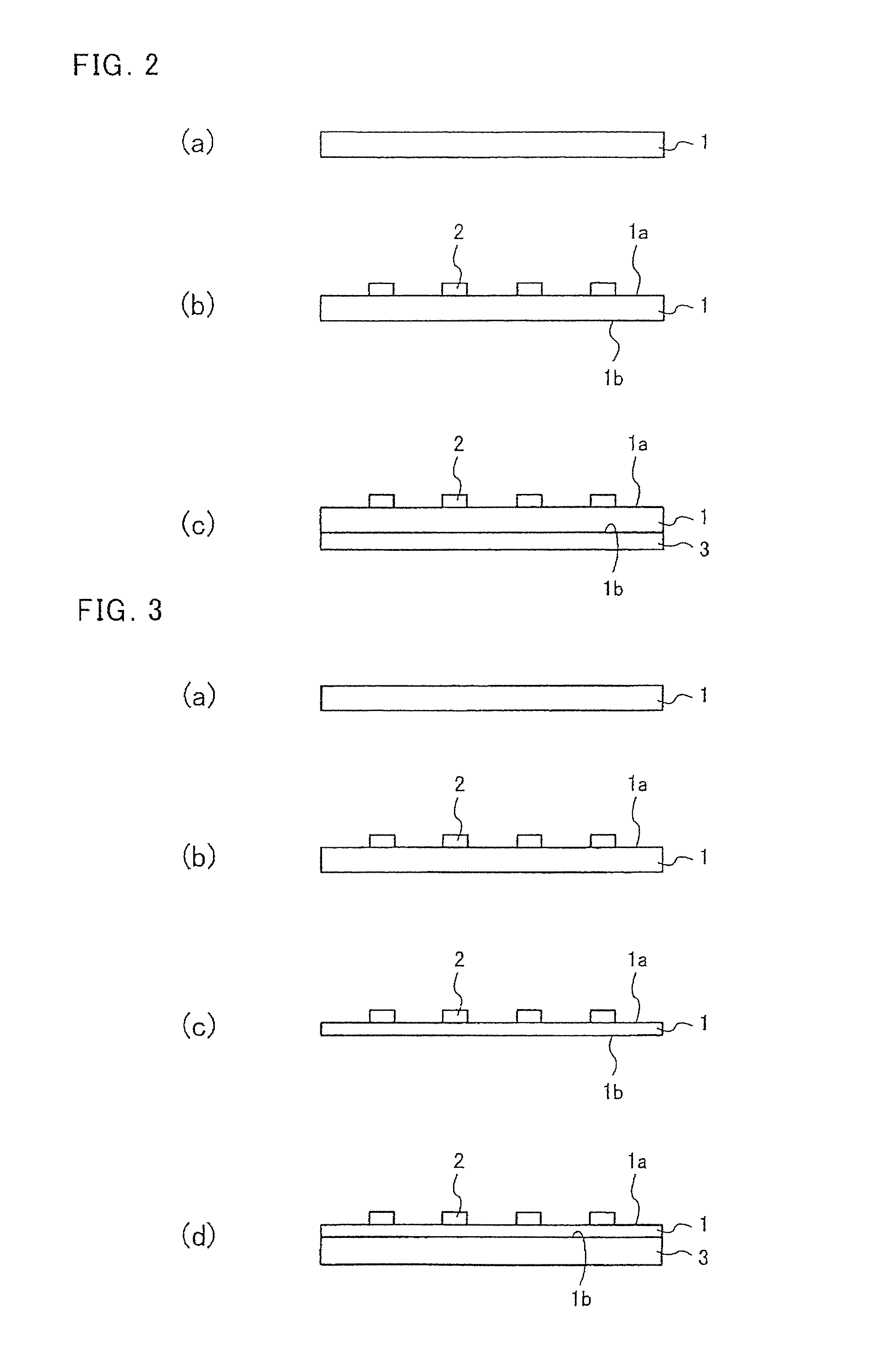

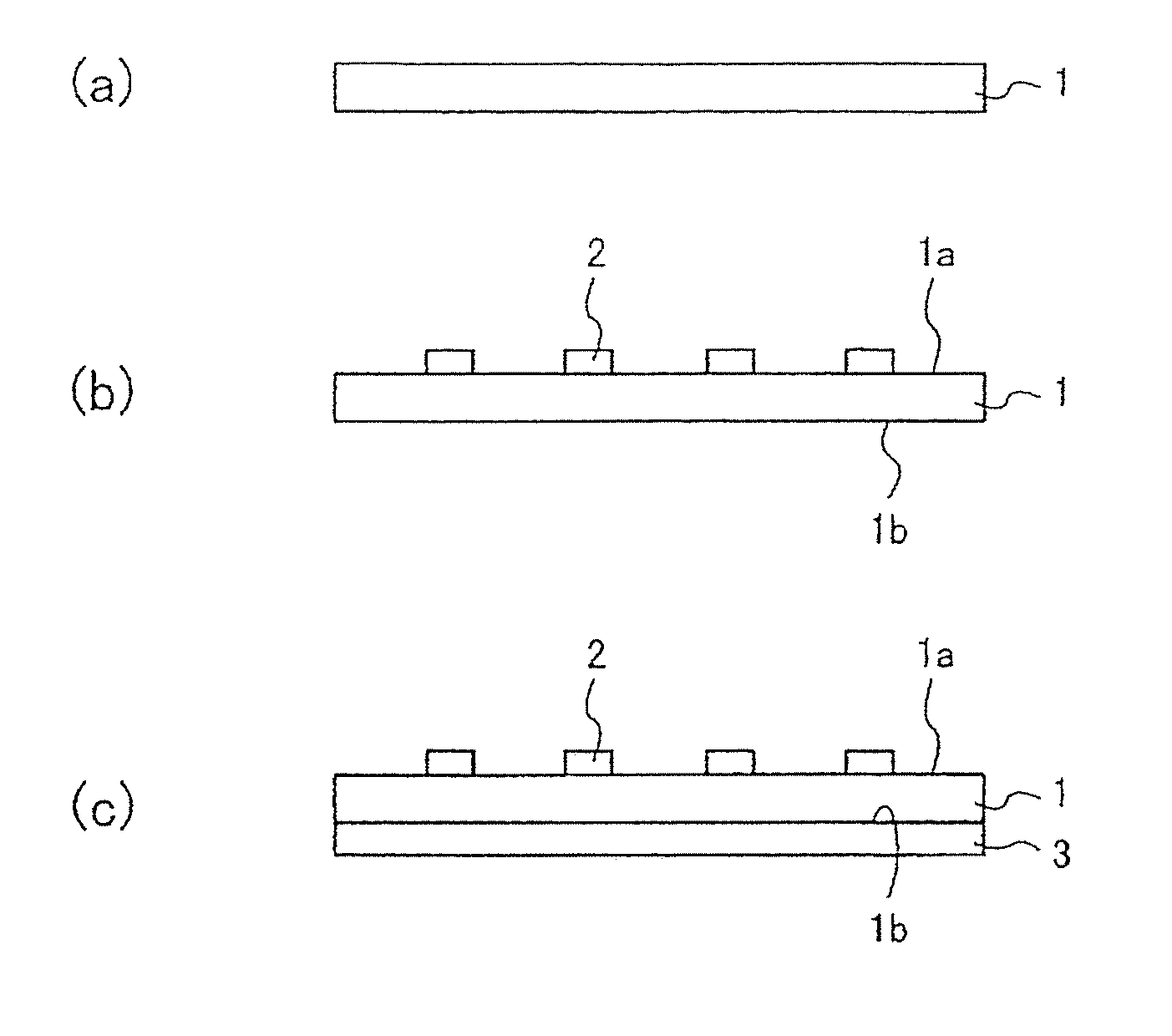

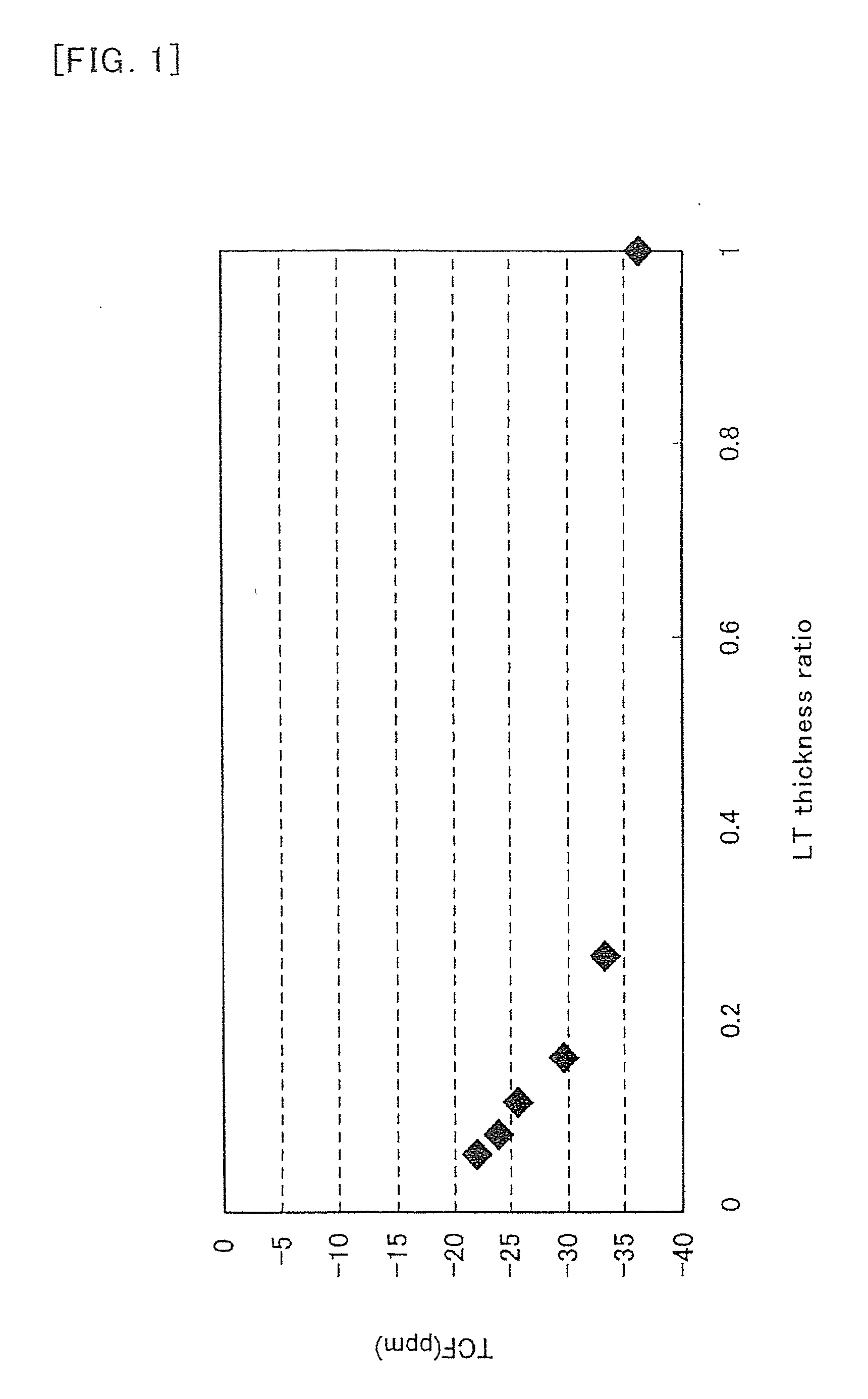

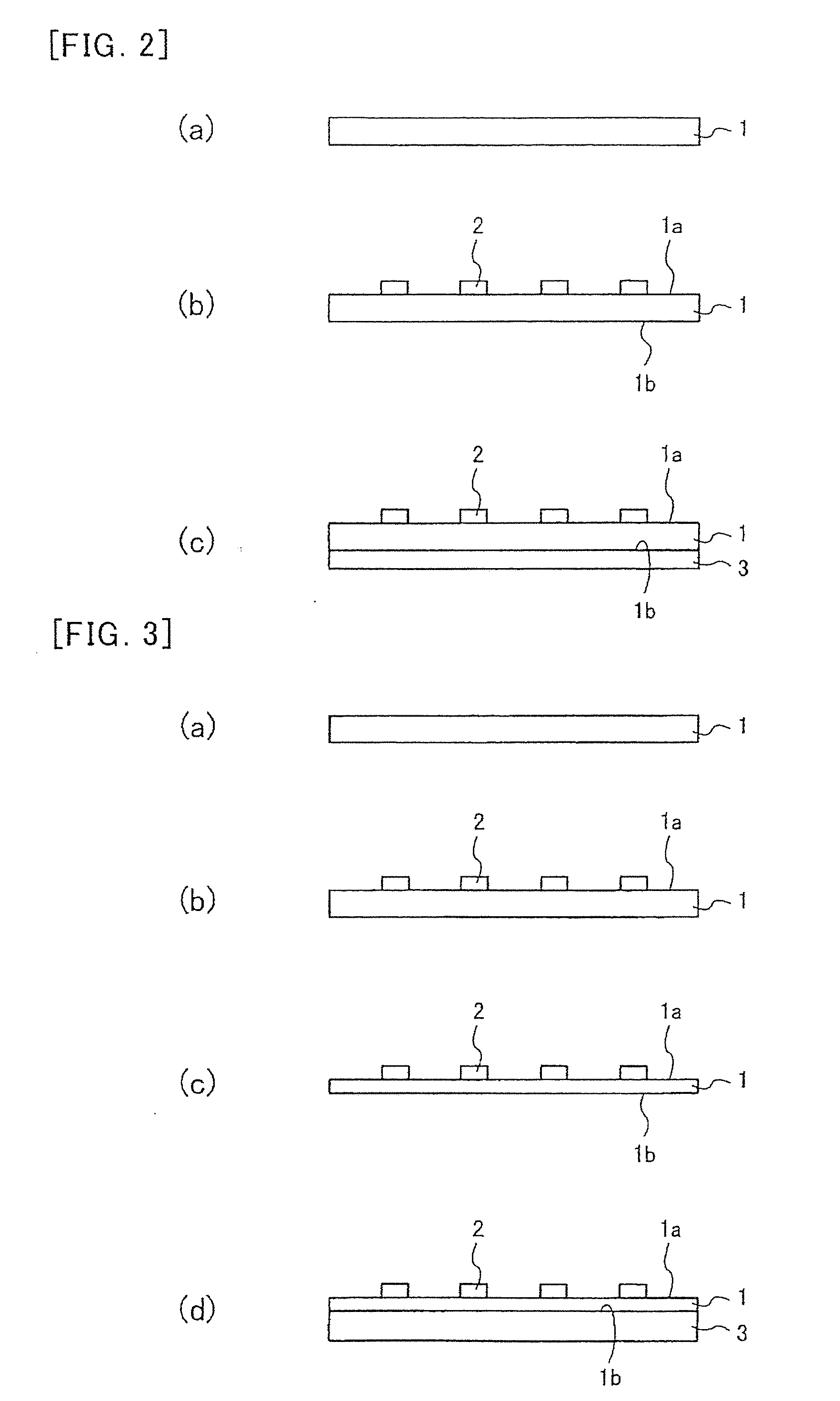

ActiveUS20100293770A1Enhance TCFImprove rigidityPiezoelectric/electrostrictive device manufacture/assemblyMolten spray coatingThermal sprayingAcoustic wave

Provided is a method for manufacturing an acoustic wave device that has an excellent temperature coefficient of frequency (TCF) and high accuracy of IDT pattern forming and is capable of resisting high temperature processing of 200 degrees or more. The method for manufacturing an acoustic wave device according to the present invention includes forming an IDT (2) on a principal surface (1a) of a piezoelectric substrate (1), and forming a film by thermal spraying a material (3) having a smaller linear thermal expansion coefficient than the piezoelectric substrate onto an opposite principal surface (1b) of the piezoelectric substrate (1) where the IDT (2) is formed.

Owner:MURATA MFG CO LTD

Acceleration earthquake sensor

InactiveCN1538192AImprove linearityIncrease temperatureSeismic signal receiversCantilevered beamFixed frame

An ecceleration-type earthquake sensor is composed of upper and lower electrode with recess, and an intermediate electrode, which is composed of fixing frame, mass block, cantilever beam and transverse beam and can be horizontally moved between two fixed electrodes. Its advantages are high linearity and temp drift and compensation, and small size.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

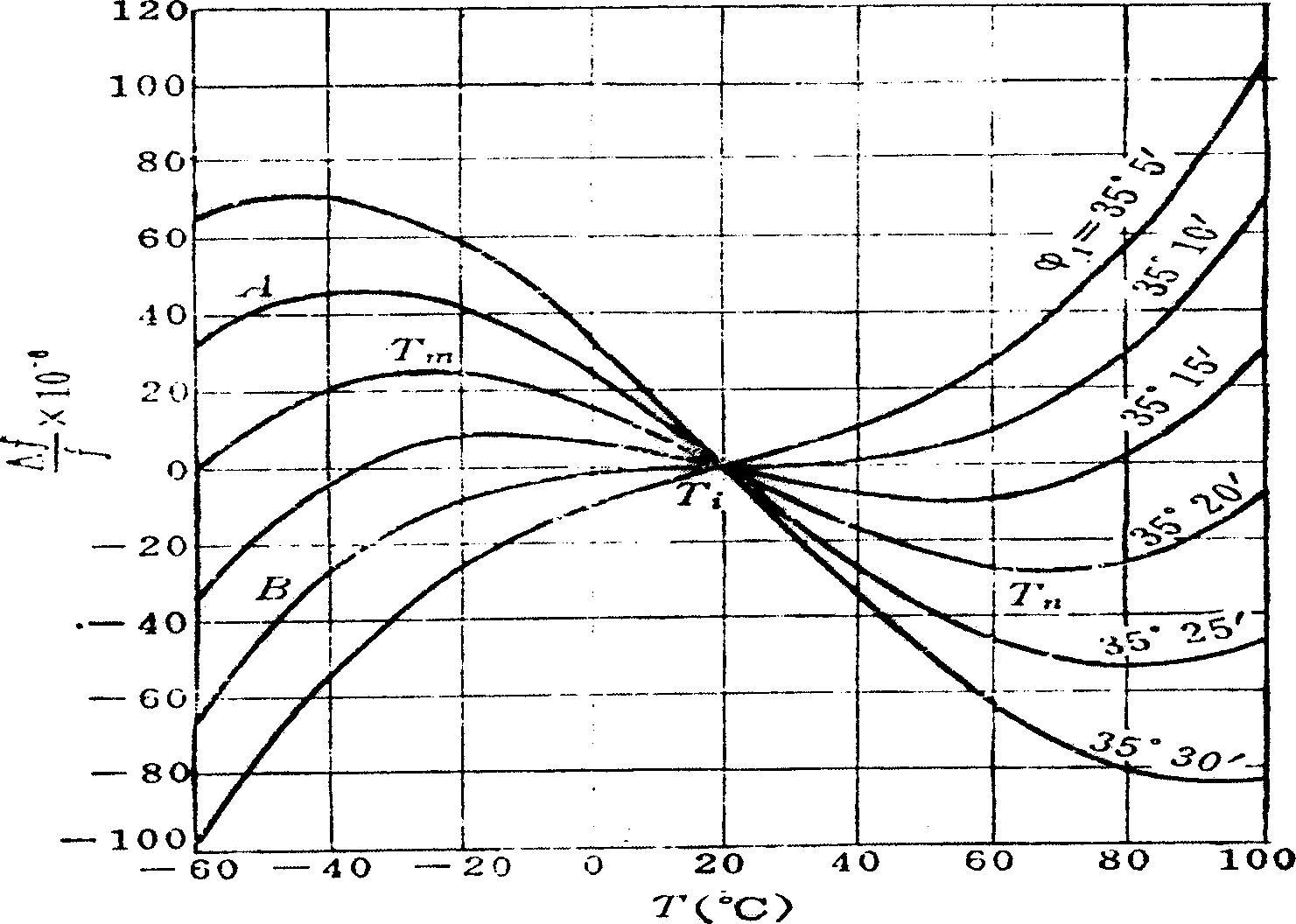

Method for stress compensation of crystal frequency temperature characteristic based on temperature sensing material

InactiveCN1671047ASimple lineSimple structureImpedence networksResonatorCrystal oscillator frequencies

This invention discloses a method for compensating crystal frequency temperature property based on temperature sensing material stress, which contains using vacuum plating method to plate temperature sensing double-metal material on the crystal chip or electrode of crystal resonator which can compensate the frequency variation due to temperature of crystal. Said method can make the frequency temperature property of crystal reach positive and negative 0.2ppm and simply the current circuit of temperature compensation with small volume and low cost.

Owner:XIDIAN UNIV

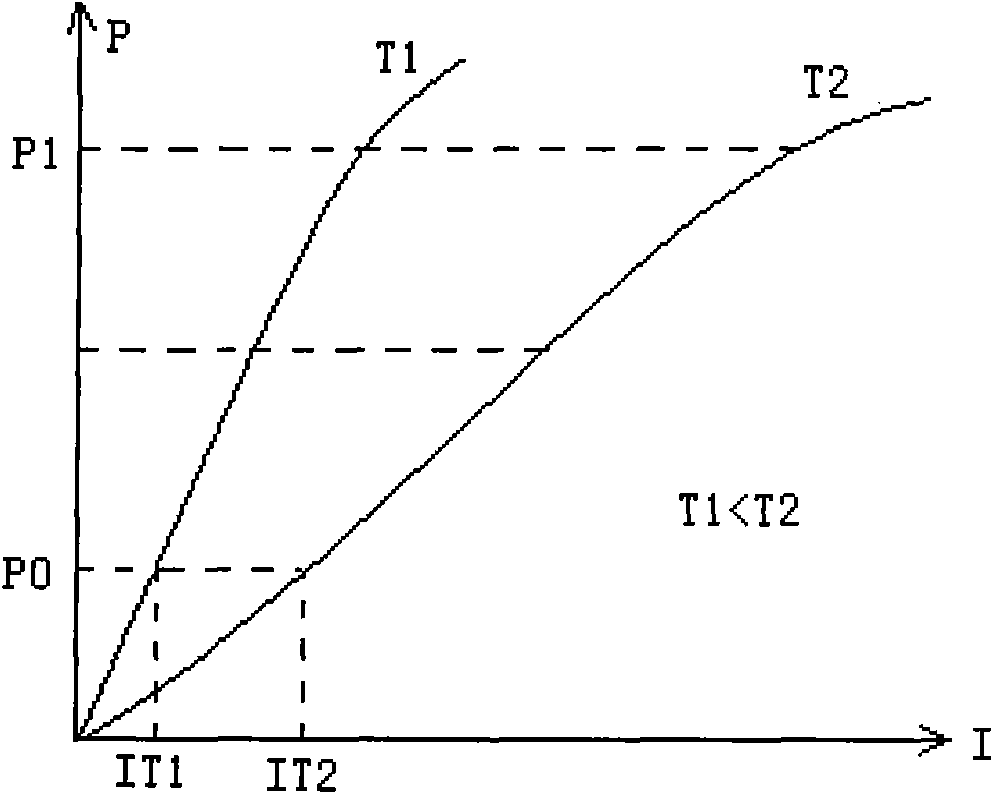

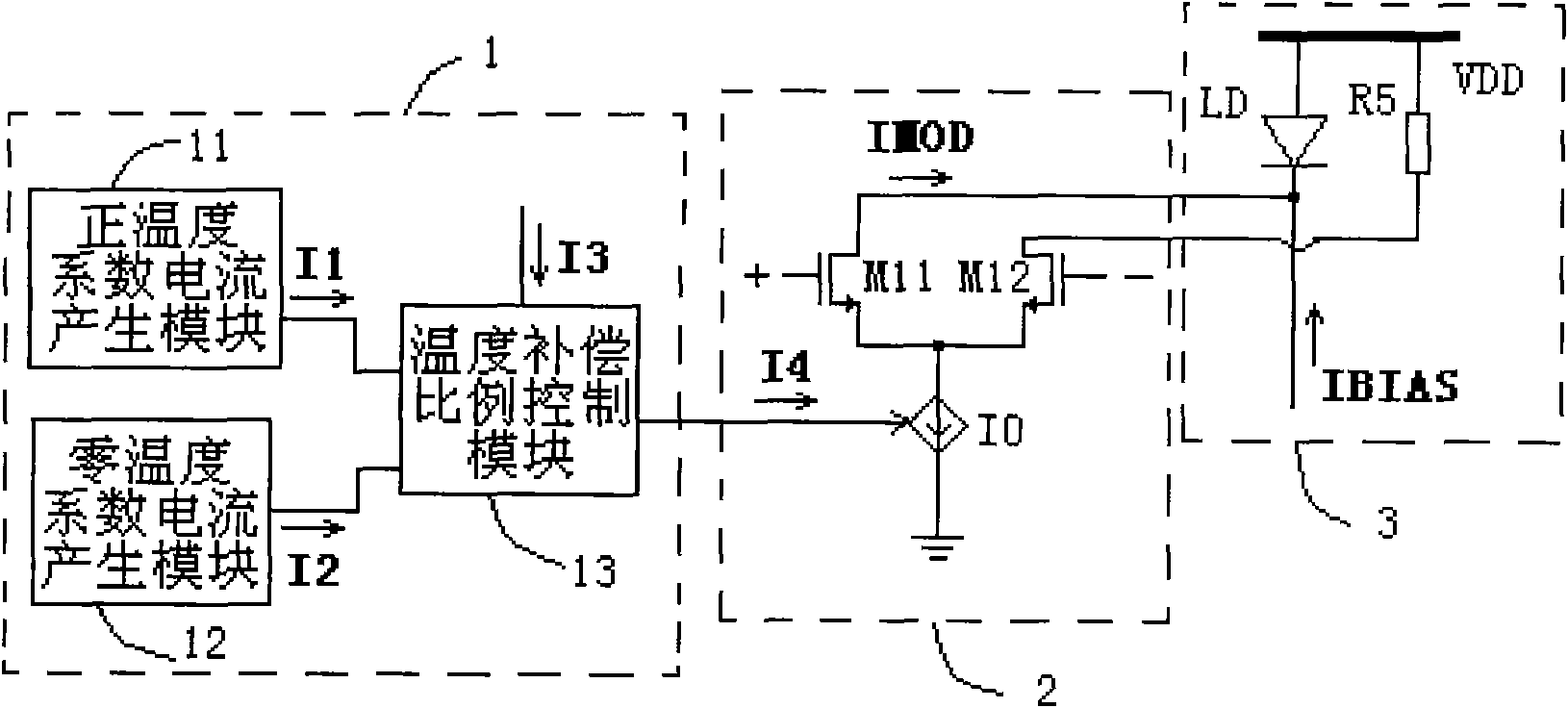

Temperature compensation circuit for laser drive

InactiveCN102064765AFlexible adjustment of compensation ratioStable extinction ratioOscillations generatorsCurrent generationPositive temperature

The invention discloses a temperature compensation circuit for a laser drive, comprising a positive temperature coefficient current generation module, a zero temperature coefficient current generation module and a temperature compensation proportion control module, wherein the output ends of the positive temperature coefficient current generation module and the zero temperature coefficient current generation module are respectively connected with the input end of the temperature compensation proportion control module; the positive temperature coefficient current generation module can be used for generating positive temperature coefficient current increasing with the temperature rise so as to determine a slope factor for temperature compensation; the zero temperature coefficient current generation module can be used for generating zero temperature coefficient current irrelevant with the temperature so as to determine the initial temperature of the temperature compensation; and the temperature compensation proportion control module can be used for sampling the difference between the positive temperature coefficient current and the zero temperature coefficient current and overlapping the difference with the external input current for controlling compensation current to determine the compensation current and further control the proportion of the temperature compensation, The temperature compensation circuit can be used for flexibly adjusting the compensation proportion of a laser and stabilizing the extinction ratio, adapts to the temperature characteristics of different lasers, and has strong generality.

Owner:FENGHUO COMM SCI & TECH CO LTD +1

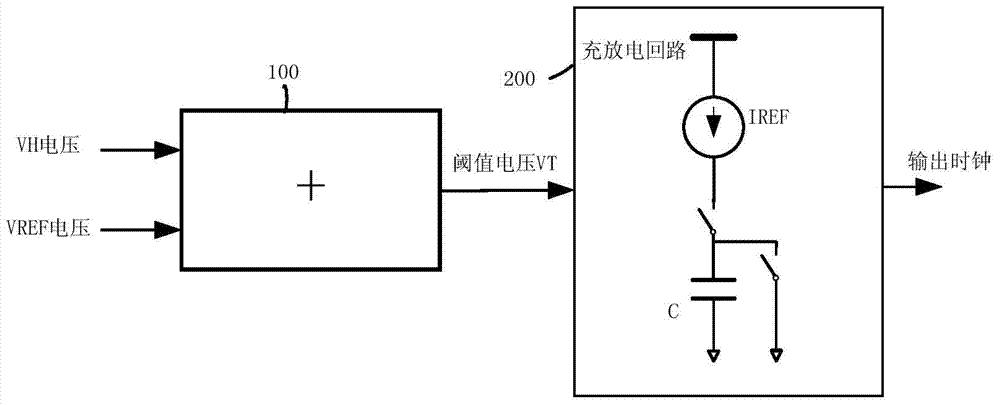

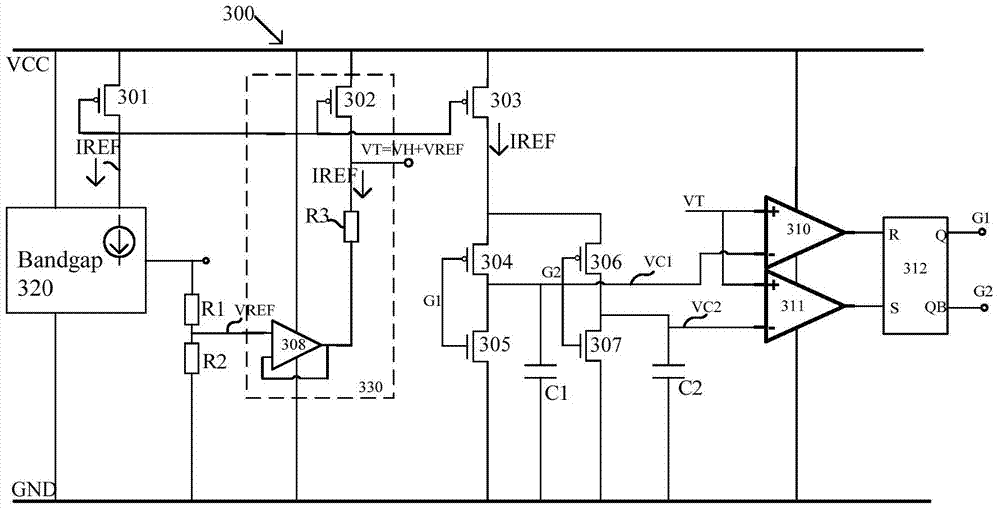

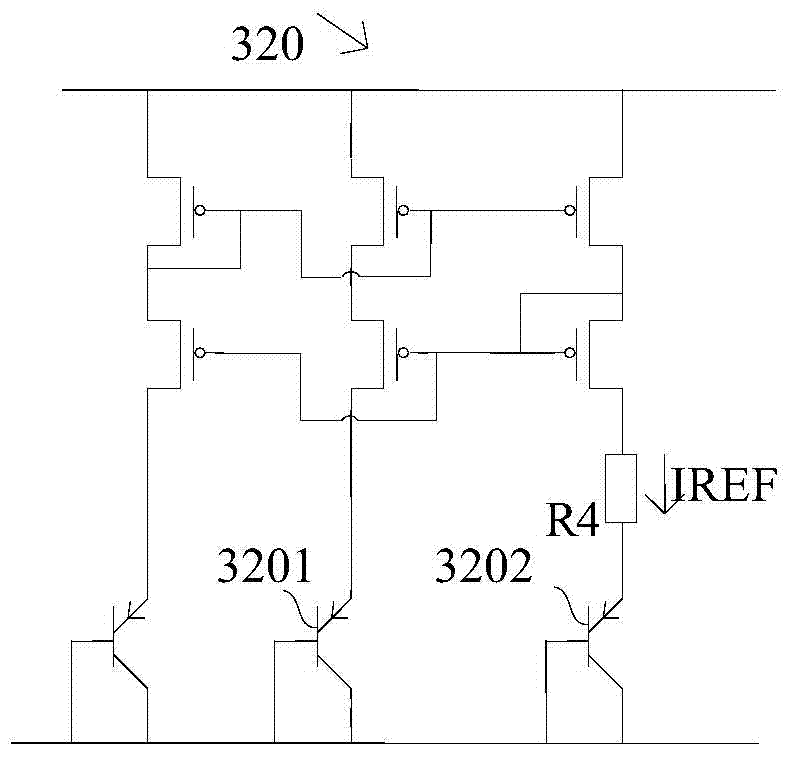

Oscillator circuit with temperature compensation function

InactiveCN103795344AGood duty cycleSmall temperature coefficientOscillations generatorsCapacitanceCompensation effect

The invention discloses an oscillator circuit with a temperature compensation function. The oscillator circuit comprises a reference current generation circuit, a reference source, a VH voltage generation circuit, a voltage adding circuit for adding a reference voltage to a VH voltage, and a charging and discharging control unit. The charging and discharging control unit takes a threshold voltage VT as a charging and discharging threshold value, and controls a current IREF to charge or discharge a capacitor C between the threshold voltage and the ground. When the capacitor C is charged to reach the threshold voltage, logic output reverse is triggered and repeatedly conducted. By means of the oscillator circuit, the output clock frequency is compensated for along with the change of the temperature through a resistor with the positive temperature coefficient, the temperature coefficient of the output clock frequency is small, the discreteness is small, the temperature compensation effect is improved, transfer between different processes is facilitated, and the oscillator circuit is suitable for large-scale mass production and application; meanwhile, an output clock can still have a good duty ratio at the high frequency.

Owner:CHIPSEA TECH SHENZHEN CO LTD

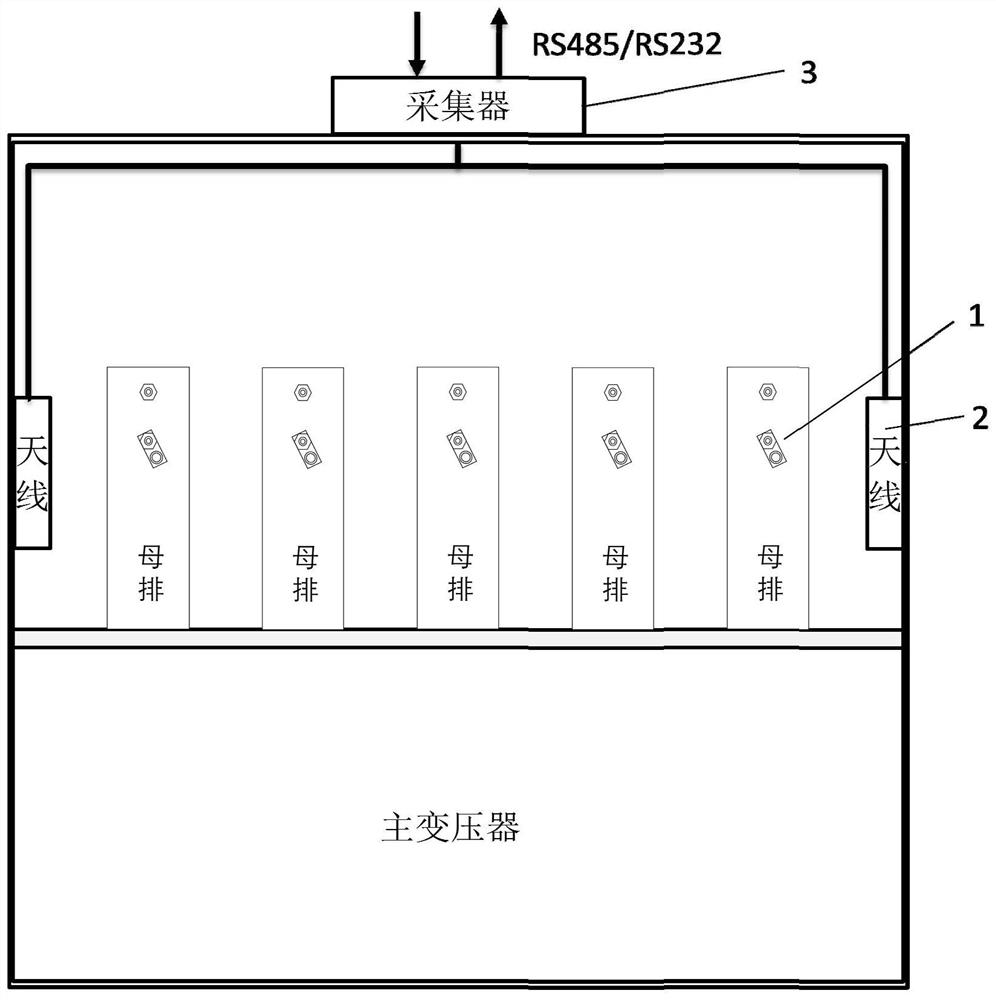

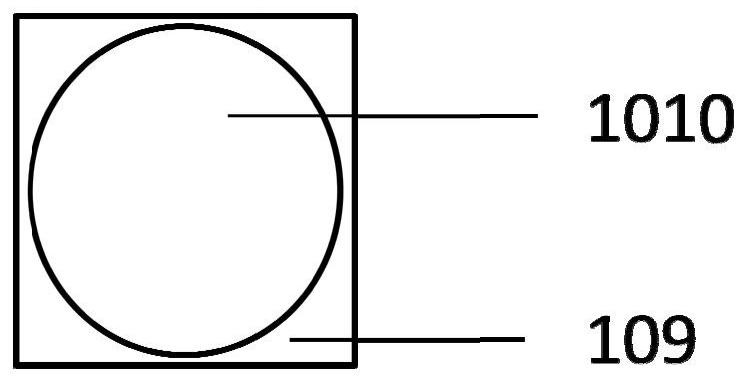

Wireless passive temperature sensing system for main transformer cabinet of electric locomotive

InactiveCN112179518ARealize online temperature monitoring functionAchieve readThermometer detailsThermometers using physical/chemical changesGratingTransformer

The invention discloses a wireless passive temperature sensing system for a main transformer cabinet of an electric locomotive. The wireless passive temperature sensing system comprises a surface acoustic wave temperature sensing unit, an antenna unit and an acquisition unit, the surface acoustic wave temperature sensing unit is mounted at a to-be-measured temperature in a main transformer cabinetof the electric locomotive, and is connected with the acquisition unit through the antenna unit; and the surface acoustic wave temperature sensing unit comprises a substrate, a piezoelectric substrate, an antenna module, an interdigital transducer and a reflecting grating. The piezoelectric substrate comprises a sound wave conduction substrate and a piezoelectric film positioned on the sound waveconduction substrate; the sound wave conduction substrate is located on the substrate, and the antenna module, the interdigital transducer and the reflecting grating are located on the piezoelectricfilm; and a sound absorption layer is laid on the surface of the piezoelectric film and used for absorbing bulk acoustic wave signals in the acoustic surface waves. The system has the advantages of high frequency, low time delay, high sound velocity, high reliability, high adaptability and the like.

Owner:ZHUZHOU NAT INNOVATION RAILWAY TECH CO LTD

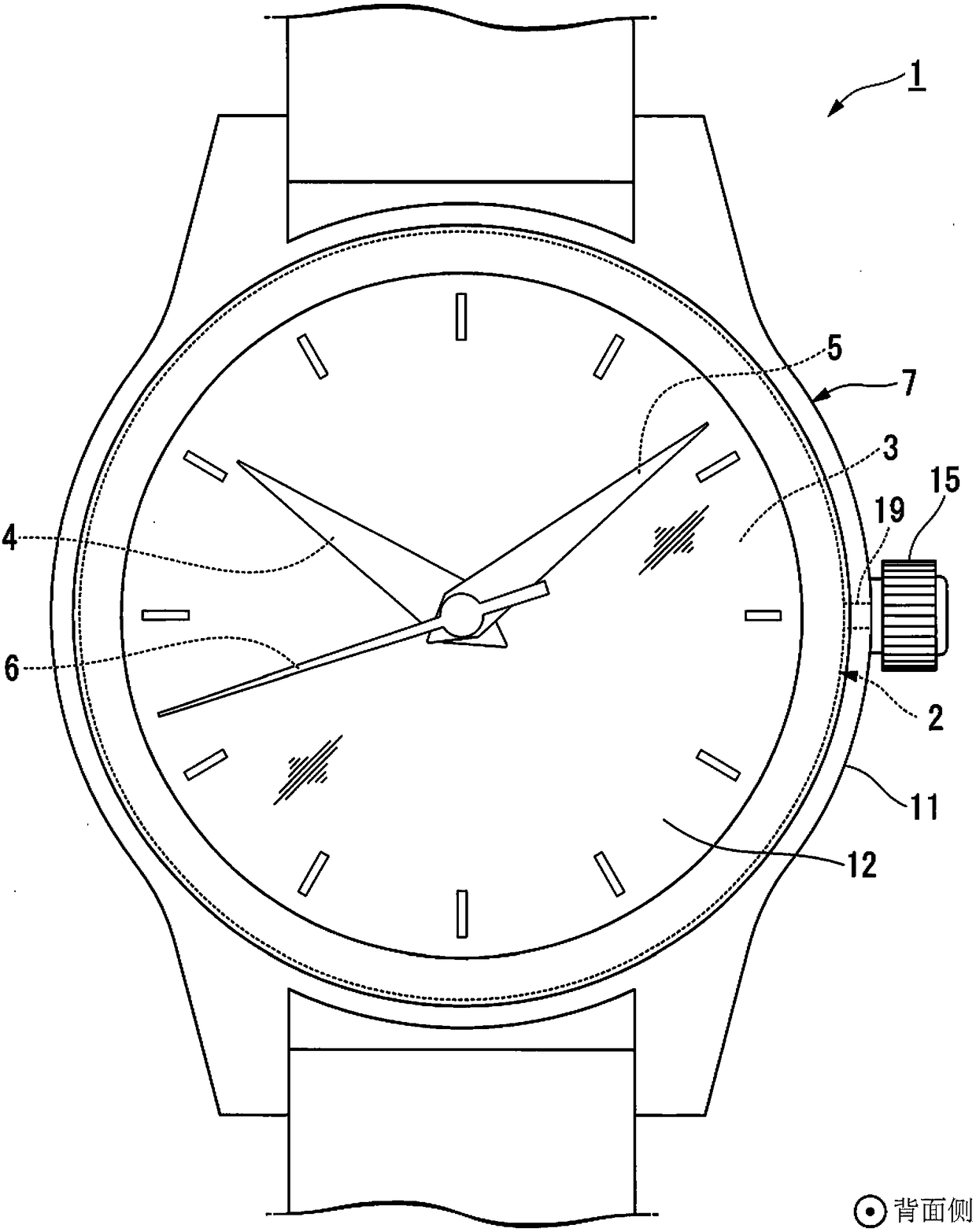

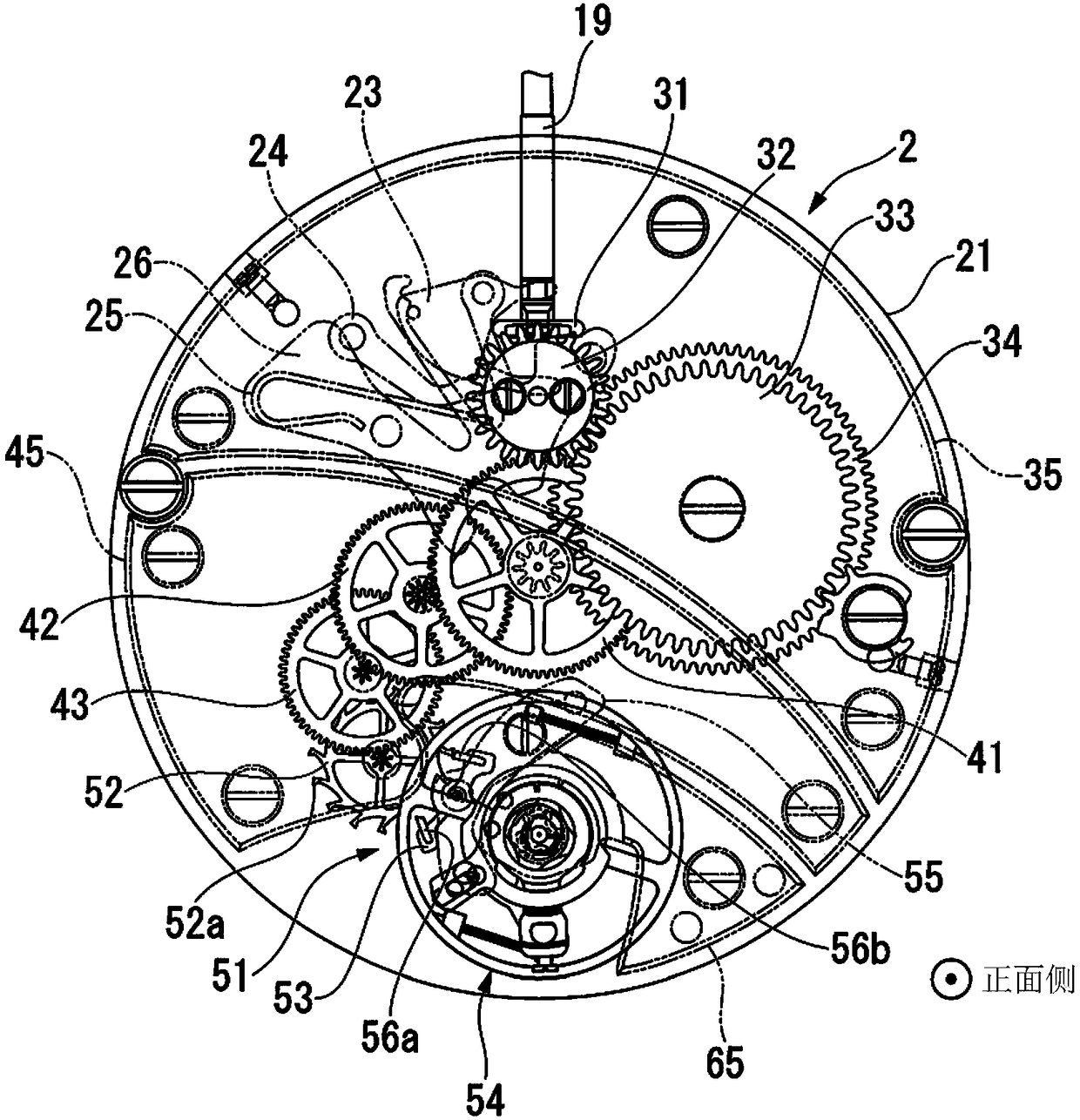

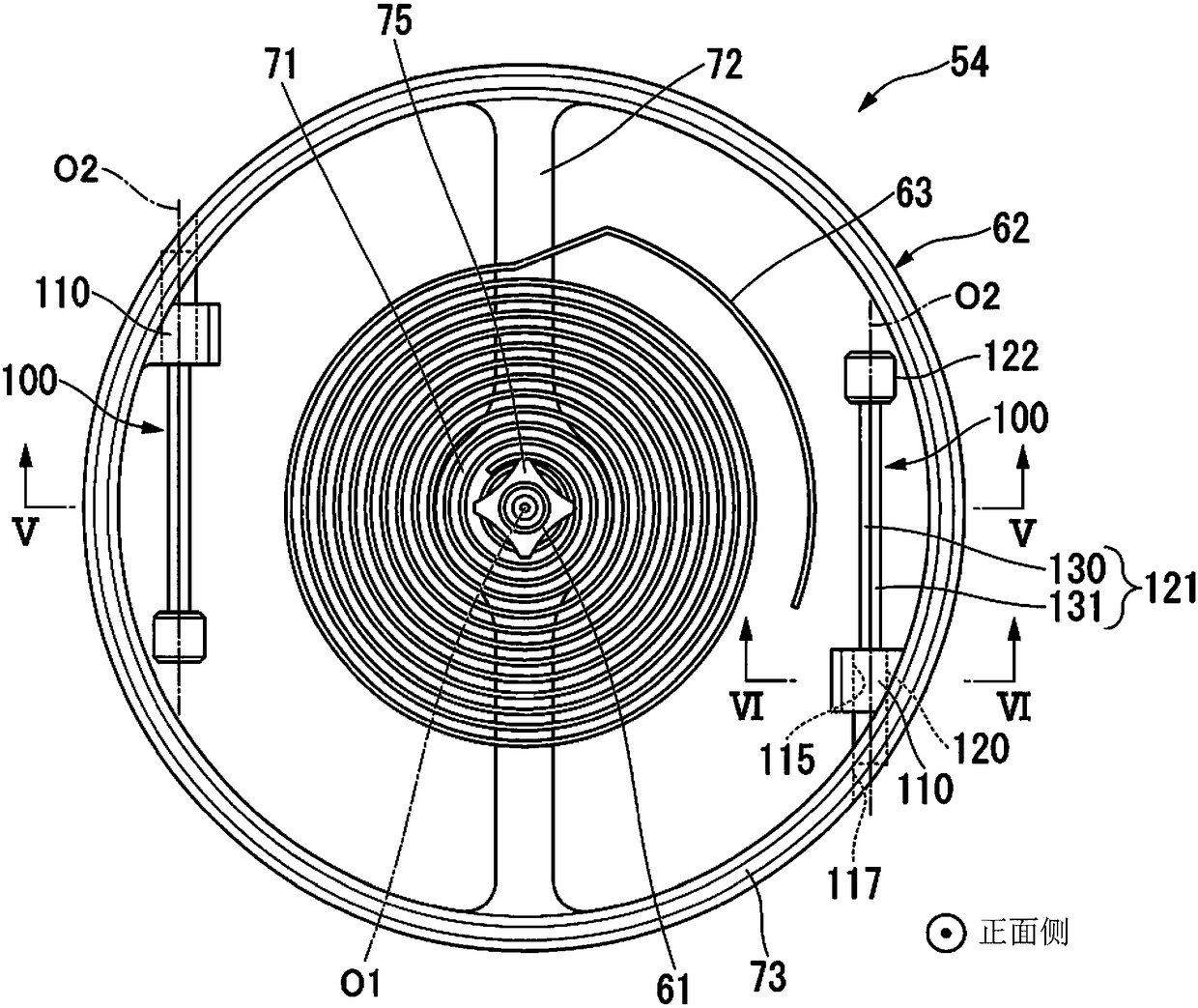

Temperature-compensate-type hair-spring balance wheel, movement, and timepiece

ActiveCN108375891AGood temperature compensation effectImprove qualityFrequency stabilisation mechanismEngineeringExpansion rate

The invention provides a temperature-compensate-type hair-spring balance wheel, a movement, and a timepiece. The hair-spring balance wheel is provided with: a hair-spring balance wheel body, which hasa swing shaft (61) extending along a first axis (O1) and rotating around the first axis (O1) by means of power from a balance spring (63); and an adjusting unit (100), which extends along a second axis (O2) at a position which is rotationally symmetric to the first axis (O1) on the hair-spring balance wheel body and is configured to adjust the position around the second axis (O2); herein, the adjusting unit includes double metal sheets (121), which are formed by stacking materials having different thermo-expansion rates in a direction being crossed to the second axis (O2).

Owner:SEIKO INSTR INC

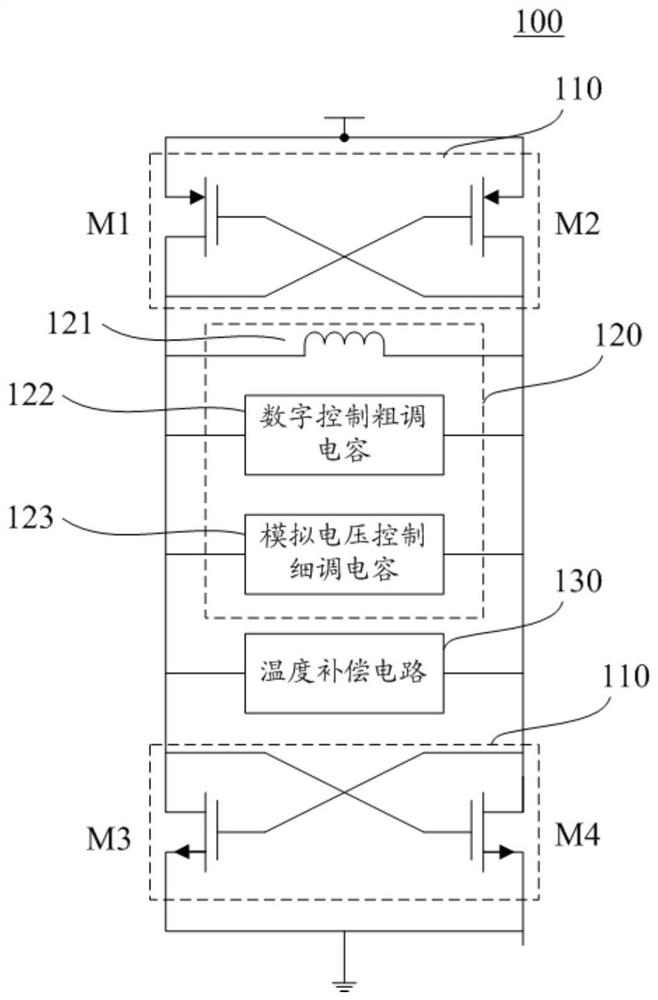

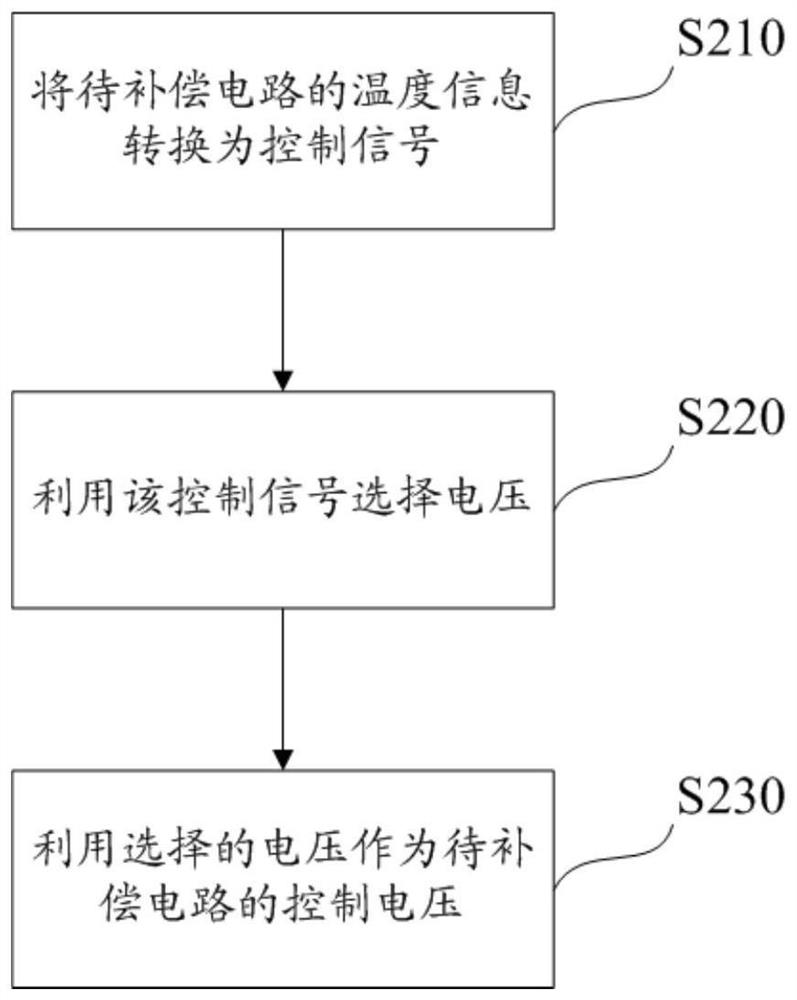

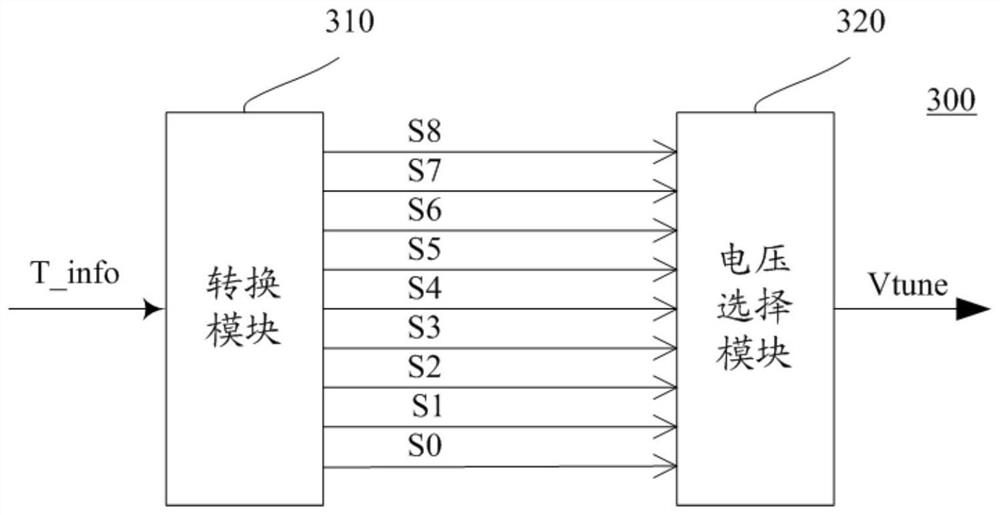

Temperature compensation method and auxiliary circuit, and voltage-controlled oscillation device

InactiveCN111756371AGood temperature compensation effectAchieve temperature compensation effectPulse automatic controlControl signalHemt circuits

The invention provides a temperature compensation method, a temperature compensation auxiliary circuit and a voltage-controlled oscillation device, so as to improve the performance of a voltage-controlled oscillator. The temperature compensation auxiliary circuit comprises a conversion module and a voltage selection module, wherein an input end of the conversion module is used for inputting temperature information, and the conversion module is used for converting the temperature information into a control signal and outputting the control signal; and the voltage selection module is coupled tothe conversion module, selects a voltage under the action of the control signal output by the conversion module, and outputs the selected voltage.

Owner:上海奥令科电子科技有限公司

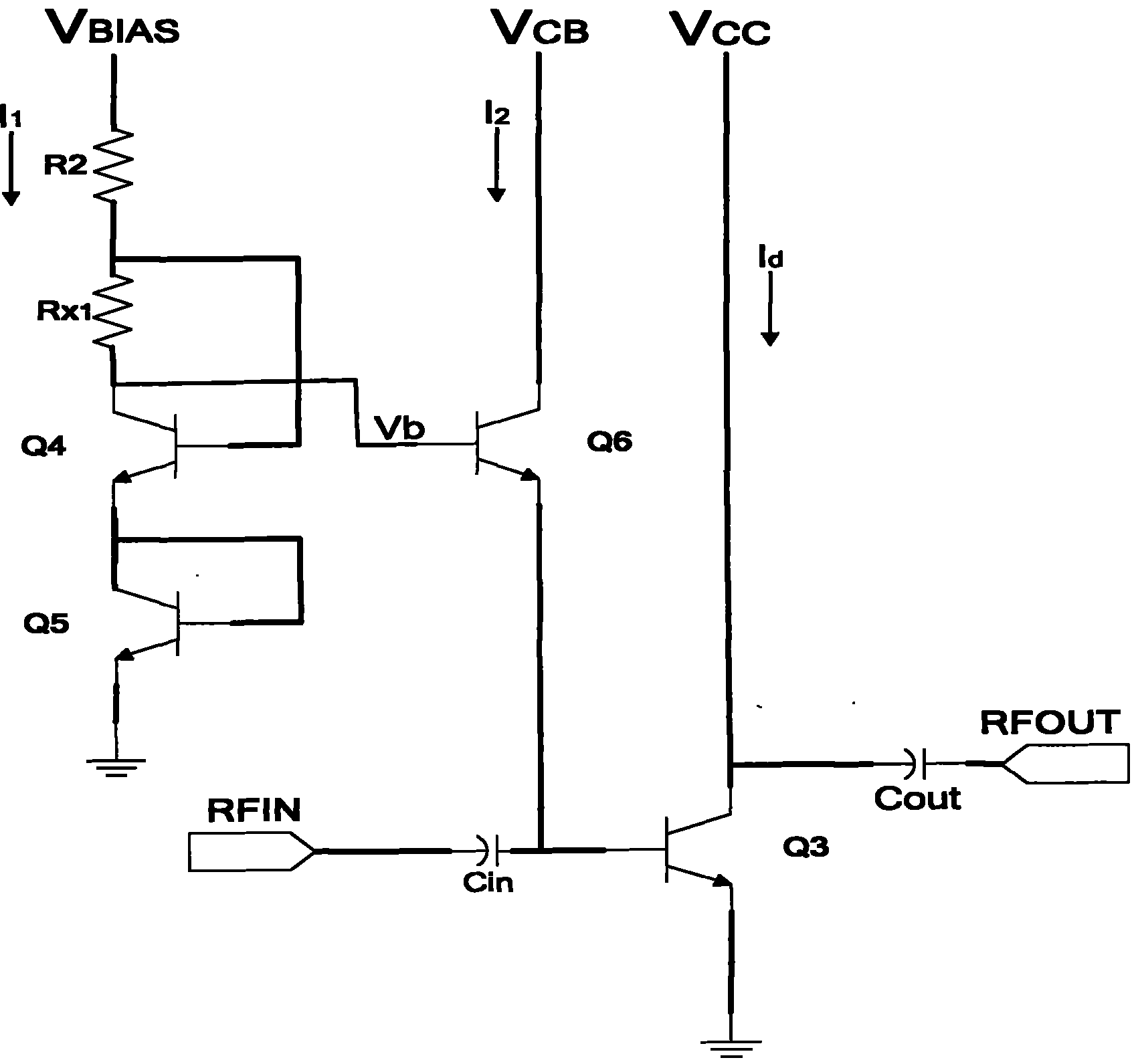

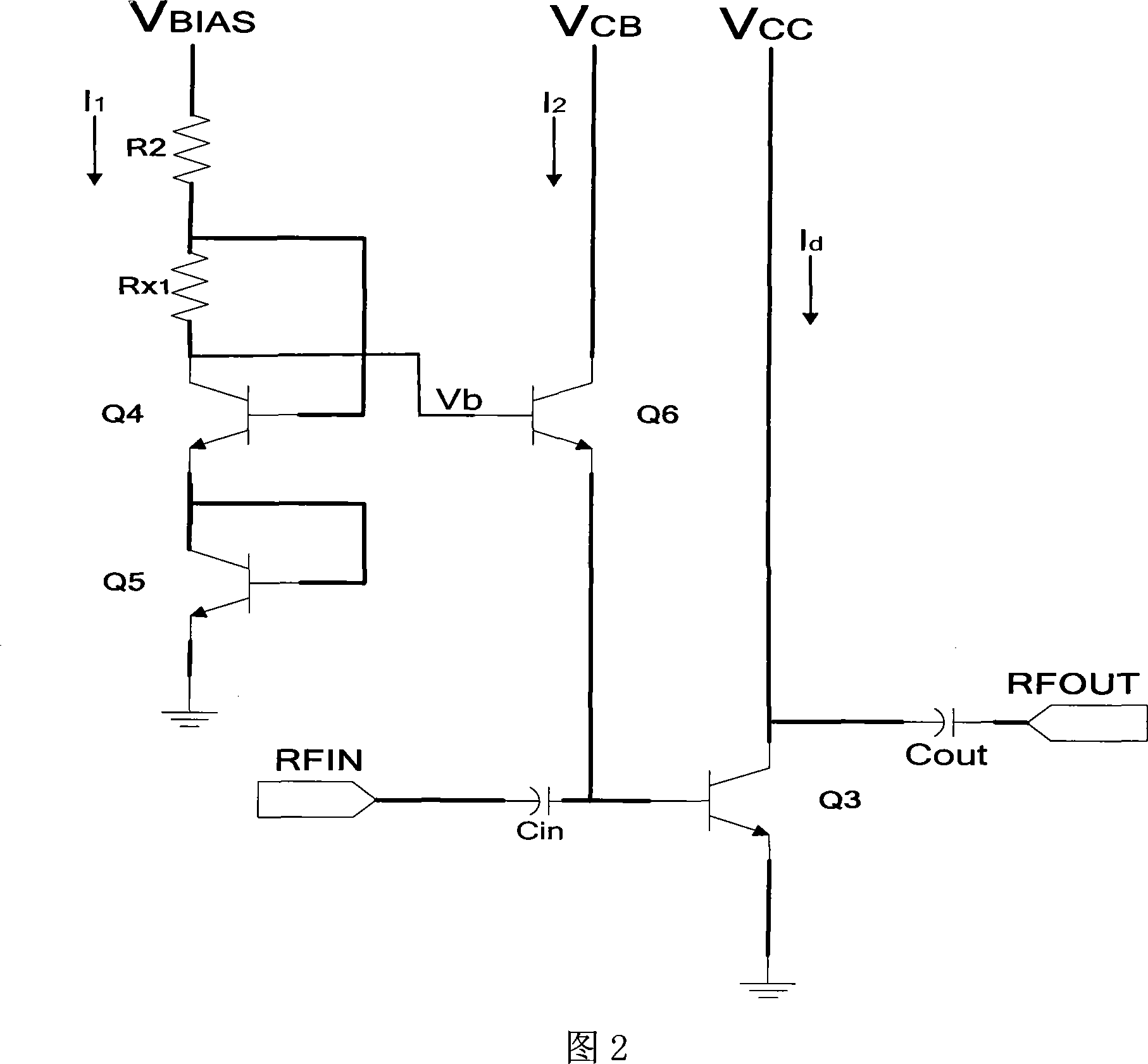

Radio frequency power amplifier circuit

ActiveCN101394152BReduce dependenceImprove stabilityHigh frequency amplifiersAmplifier modifications to reduce temperature/voltage variationElectrical resistance and conductanceEngineering

The invention discloses a circuit of a radio-frequency power amplifier, which comprises a bias circuit and an amplification circuit. A resistance compensating structure is designed in the bias circuit, that is, a compensating resistance is added to the bias circuit. The added compensating resistance has two functions: (1) increasing the voltage compensation of the bias circuit and reducing the dependency of the circuit on the bias voltage; and (2) enhancing the temperature compensation of the bias circuit. The change of the bias voltage or temperature causes the electric current changes of Q4and Q5 or Q7 and Q8 of NPN tube, the change quantity of VBE of voltage generated by the electric current changes between a base electrode and a collector electrode can be compensated efficiently by the change quantity of two ends of R*1 or R*2, thereby ensuring the circuit is not sensitive to the bias voltage and the temperature.

Owner:RDA TECH

Method for forming surface acoustic wave resonance device

ActiveCN114884480AIncreasing the thicknessQuality improvementImpedence networksEngineeringSemiconductor

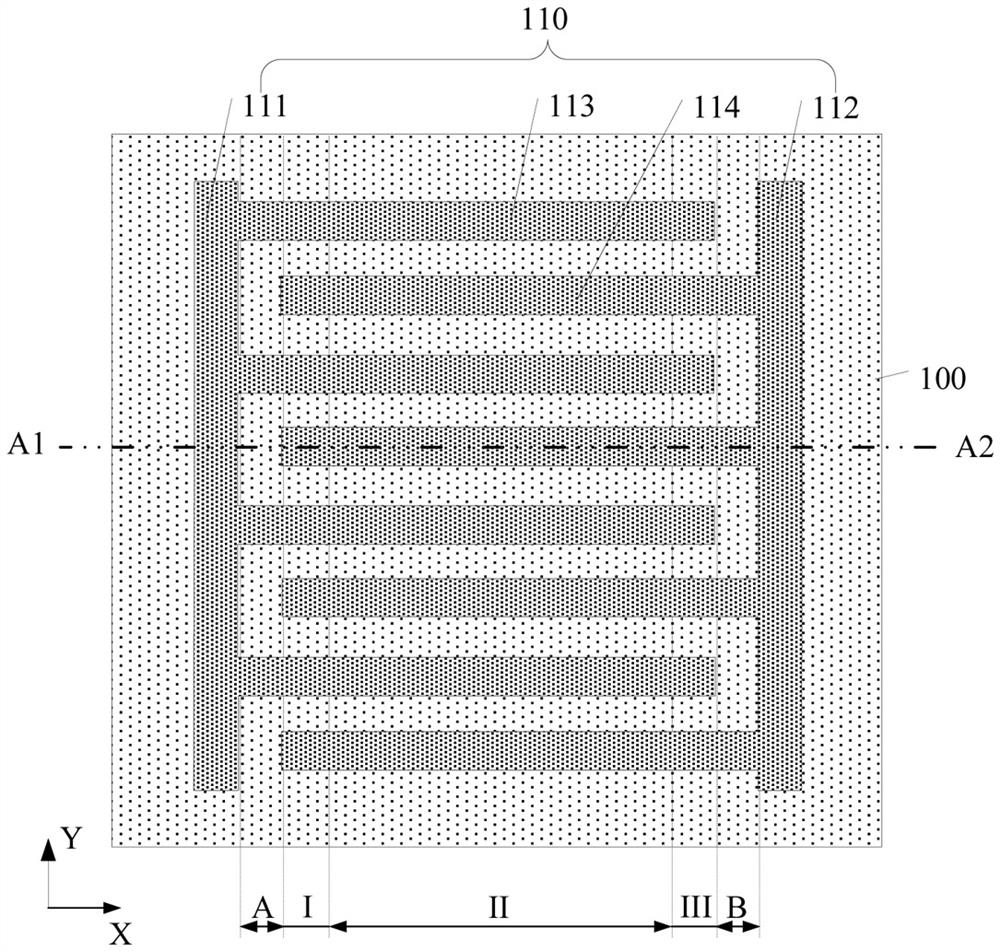

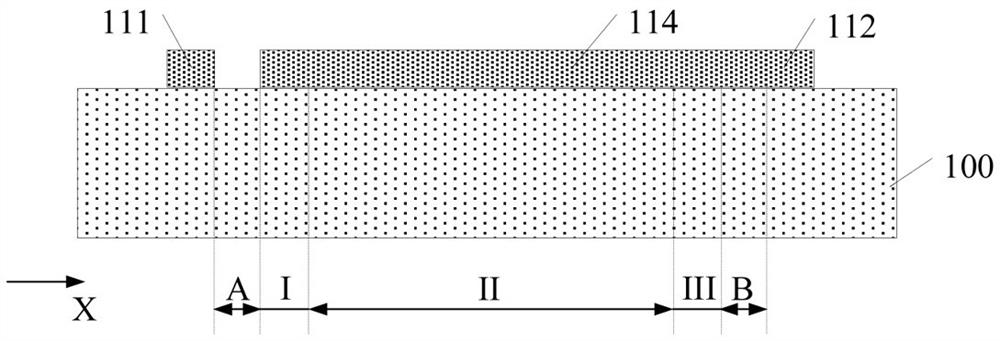

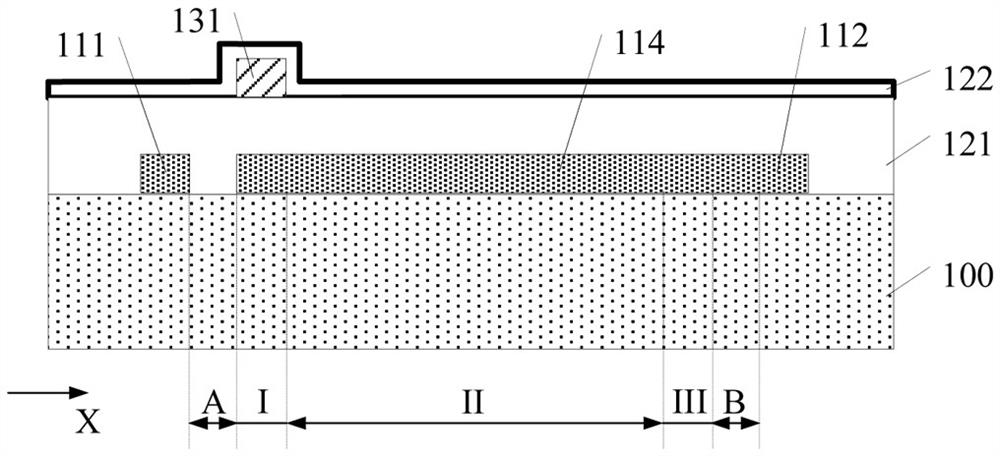

A method for forming a surface acoustic wave resonance device relates to the technical field of semiconductors, and comprises the following steps: providing a piezoelectric substrate which comprises a first spacer region, a first region, a second region, a third region and a second spacer region which are sequentially arranged along a first direction; forming an electrode layer on the surface of the piezoelectric substrate, wherein the electrode layer comprises a first bus, a second bus, a plurality of first electrode strips connected with the first bus, and a plurality of second electrode strips connected with the second bus; a first temperature compensation layer is formed on the surfaces of the piezoelectric substrate and the electrode layer, the first temperature compensation layer comprises a first compensation area and a second compensation area, and the surface, on the first compensation area, of the first temperature compensation layer is higher than the surface, on the second compensation area, of the first temperature compensation layer; and forming a first load layer located on the first region and a second load layer located on the third region on the surface of the first temperature compensation layer. Therefore, an existing forming process is improved.

Owner:CHANGZHOU CHEMSEMI CO LTD

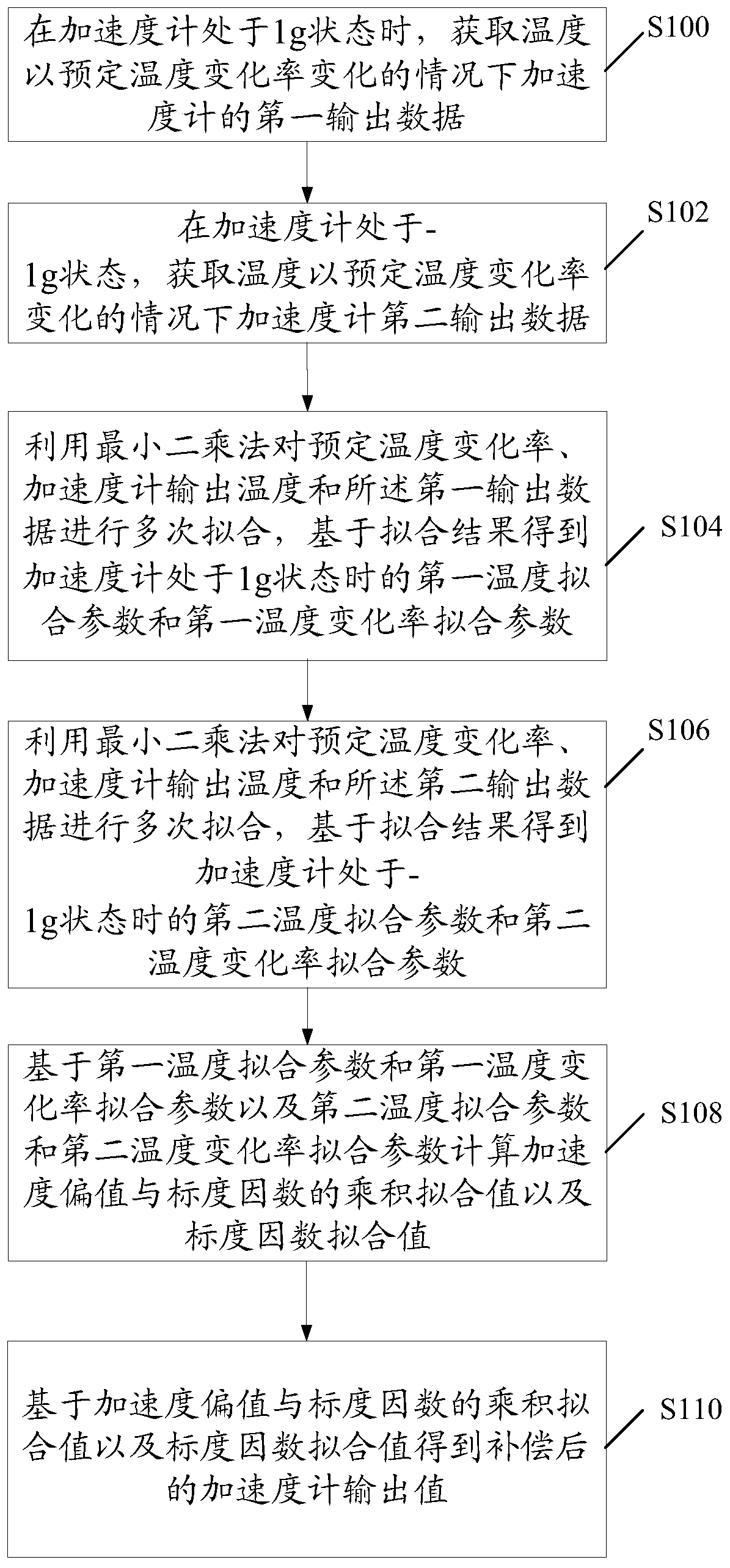

Accelerometer compensation method

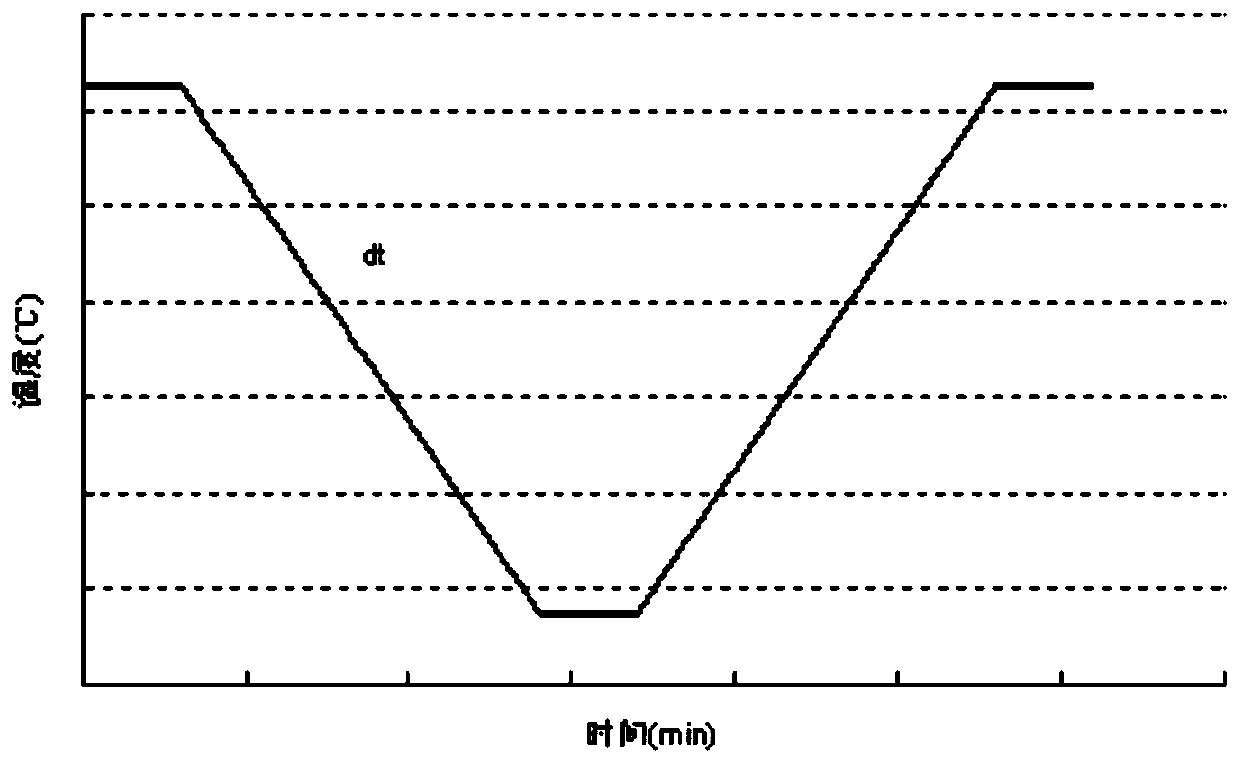

InactiveCN110988399AGood temperature compensation effectHigh precisionTesting/calibration of speed/acceleration/shock measurement devicesAccelerometerEngineering

The invention relates to the technical field of inertia instrument manufacturing, and discloses an accelerometer compensation method. The method comprises the following steps: acquiring first output data when the temperature is changed at a predetermined temperature change rate at 1g; acquiring second output data when the temperature is changed at a predetermined temperature change rate at-1g; fitting the preset temperature change rate, the accelerometer output temperature and the first output data for multiple times, and obtaining a first temperature fitting parameter and a first temperaturechange rate fitting parameter at 1g based on a fitting result; fitting the preset temperature change rate, the accelerometer output temperature and the second output data for multiple times, and obtaining a second temperature fitting parameter and a second temperature change rate fitting parameter at-1g based on a fitting result; calculating a product fitting value and a scale factor fitting valueof the acceleration deviation value and the scale factor; and obtaining a compensated accelerometer output value based on the product fitting value of the acceleration offset value and the scale factor and the scale factor fitting value. Therefore, the temperature compensation effect of the accelerometer can be improved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Two-channel sonic surface wave gas sensors having humidity compensate function

InactiveCN101135670BGood environmental stabilityReduce temperature drift gapAnalysing fluids using sonic/ultrasonic/infrasonic wavesElectricityAcoustics

The invention comprises a piezoelectric baseboard and two pairs of interdigital electrodes; said interdigital electrodes are located on the piezoelectric baseboard to construct both parallel acoustic surface wave measuring channel and reference channel. It features the following: coating a sensitive film on the measuring channel; coating a temperature compensation film on the reference channel.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

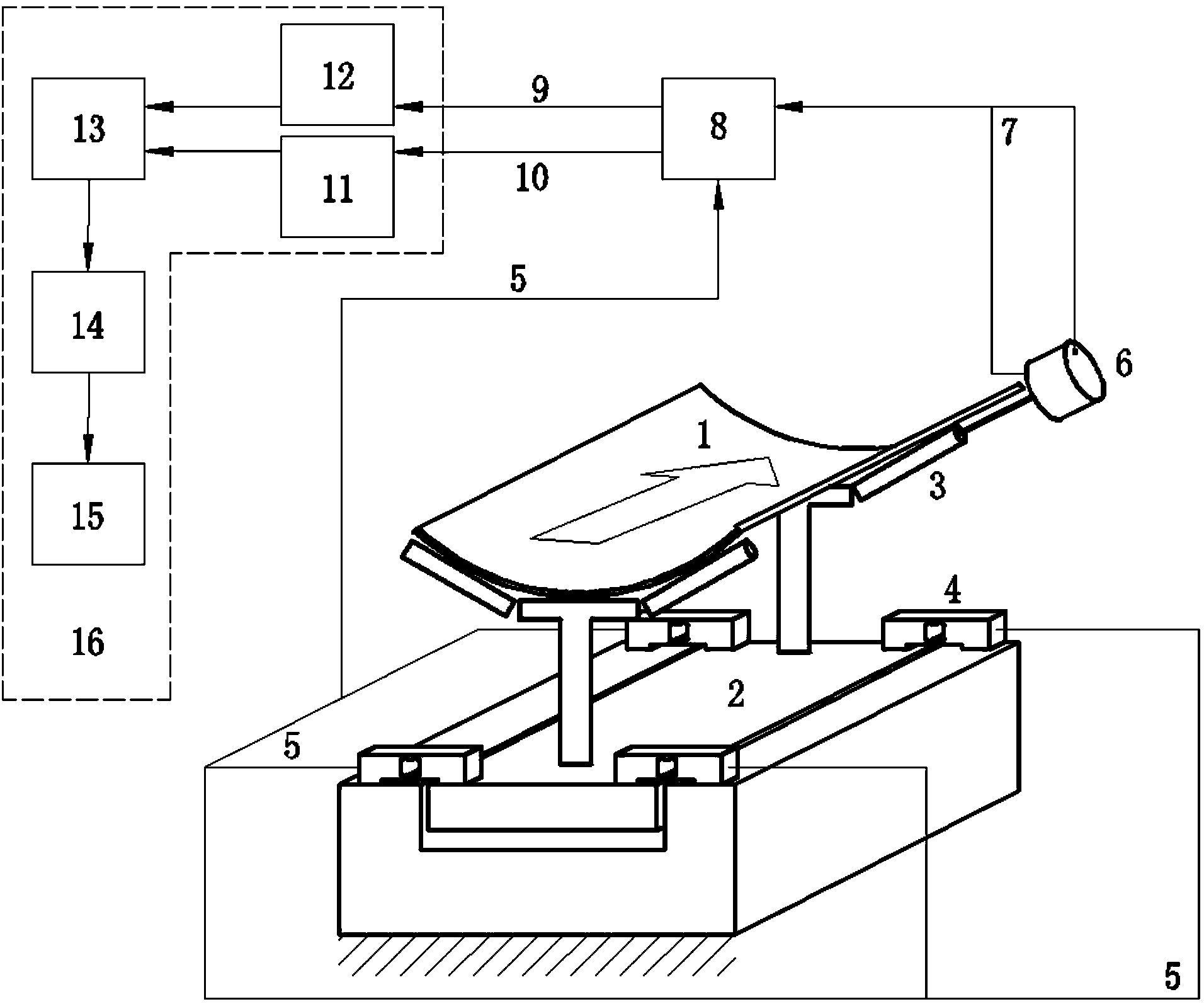

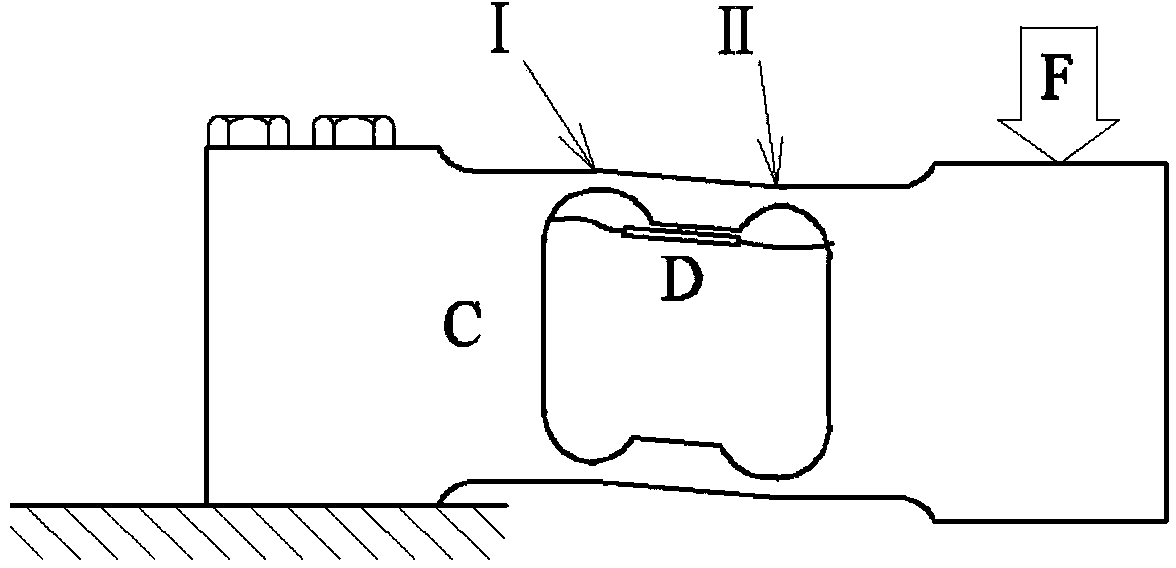

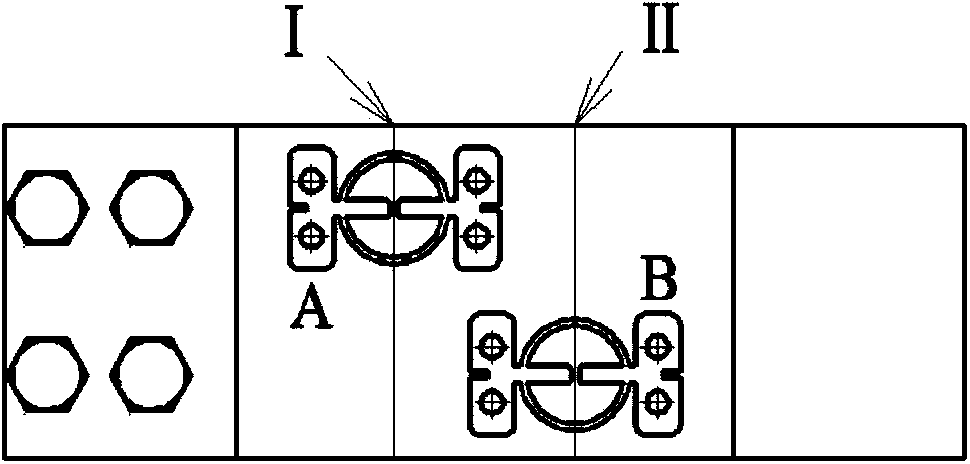

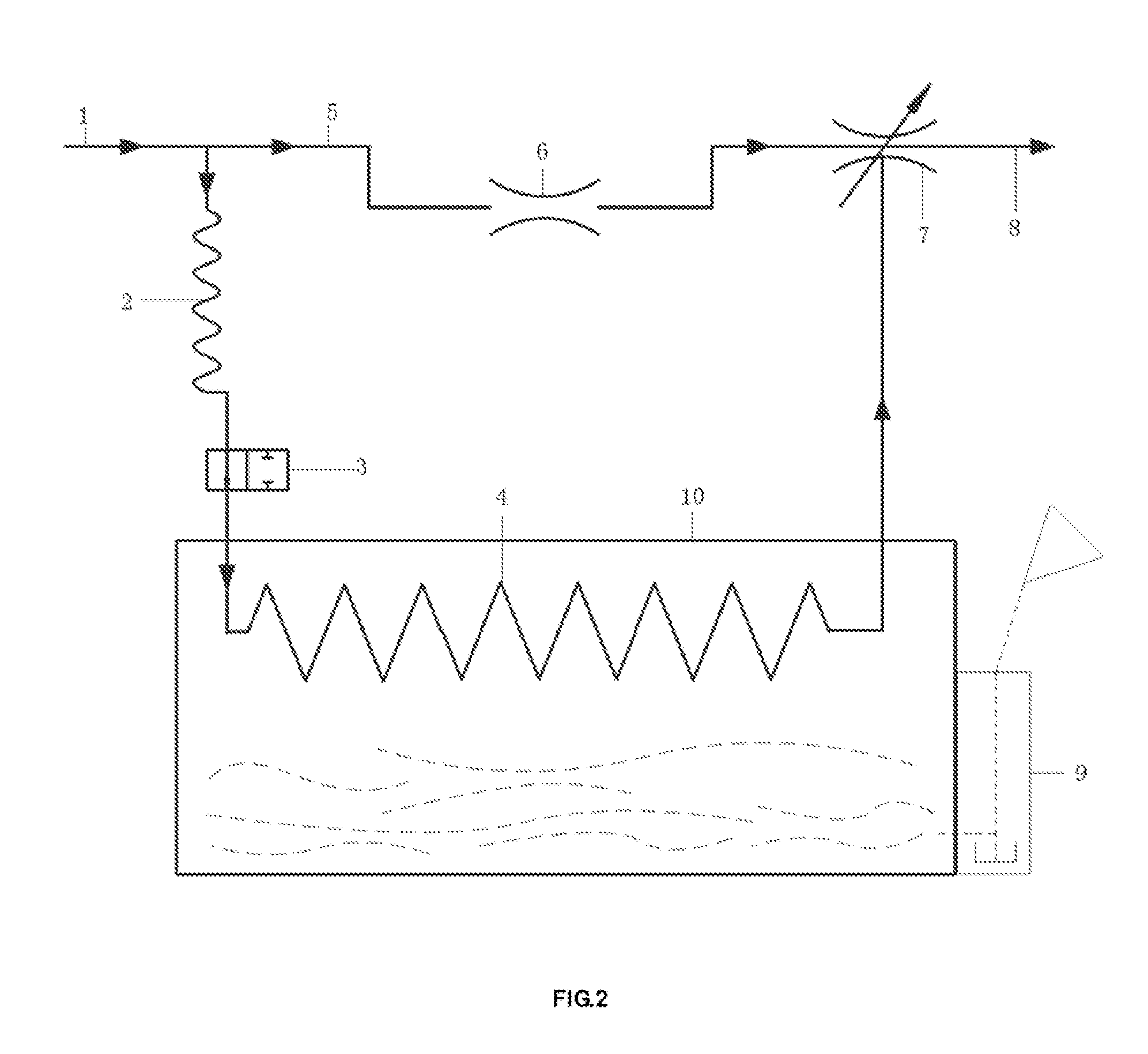

All-fiber sensing belt conveyor weighing device and weighing method thereof

ActiveCN103884406AUnaffected by temperature changesImprove anti-interference abilityWeighing apparatus for continuous material flowControl roomLoad cell

The invention discloses an all-fiber sensing belt conveyor weighing device and a weighing method thereof. The weighing device comprises a belt conveyor belt (1), a weighing frame (2), a belt conveyor rolling wheel (3), a fiber weighing sensor, a speed fiber sensor, a fiber splicing box (8) and a control room (16). The belt conveyor rolling wheel (3) is arranged on the weighing frame (2). The belt conveyor belt (1) is arranged on the belt conveyor rolling wheel (3). The fiber weighing sensor is arranged on the weighing frame (2). The speed fiber sensor is connected with the belt conveyor rolling wheel (3). The fiber weighing sensor and the speed fiber sensor are respectively connected with the fiber splicing box (8) via fibers. The fiber splicing box (8) and the control room (16) are connected via the fibers. The control room (16) processes the received signals and displays weighing weight and belt speed. The weighing device is suitable for more accurate weighing of bulk materials in dusty, moist and corrosive operation occasions and / or flammable and explosive operation occasions.

Owner:CHINA PETROLEUM & CHEM CORP +2

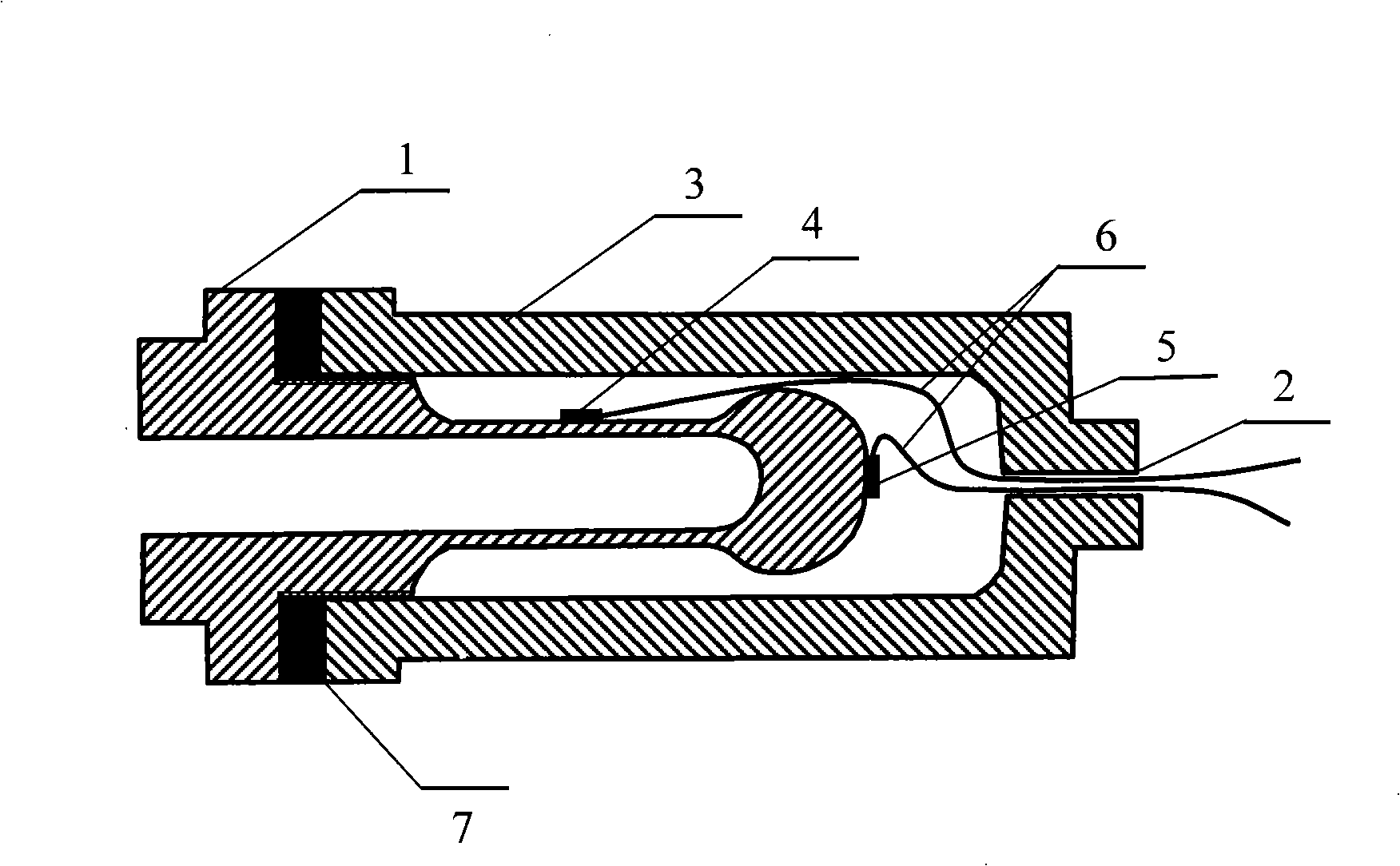

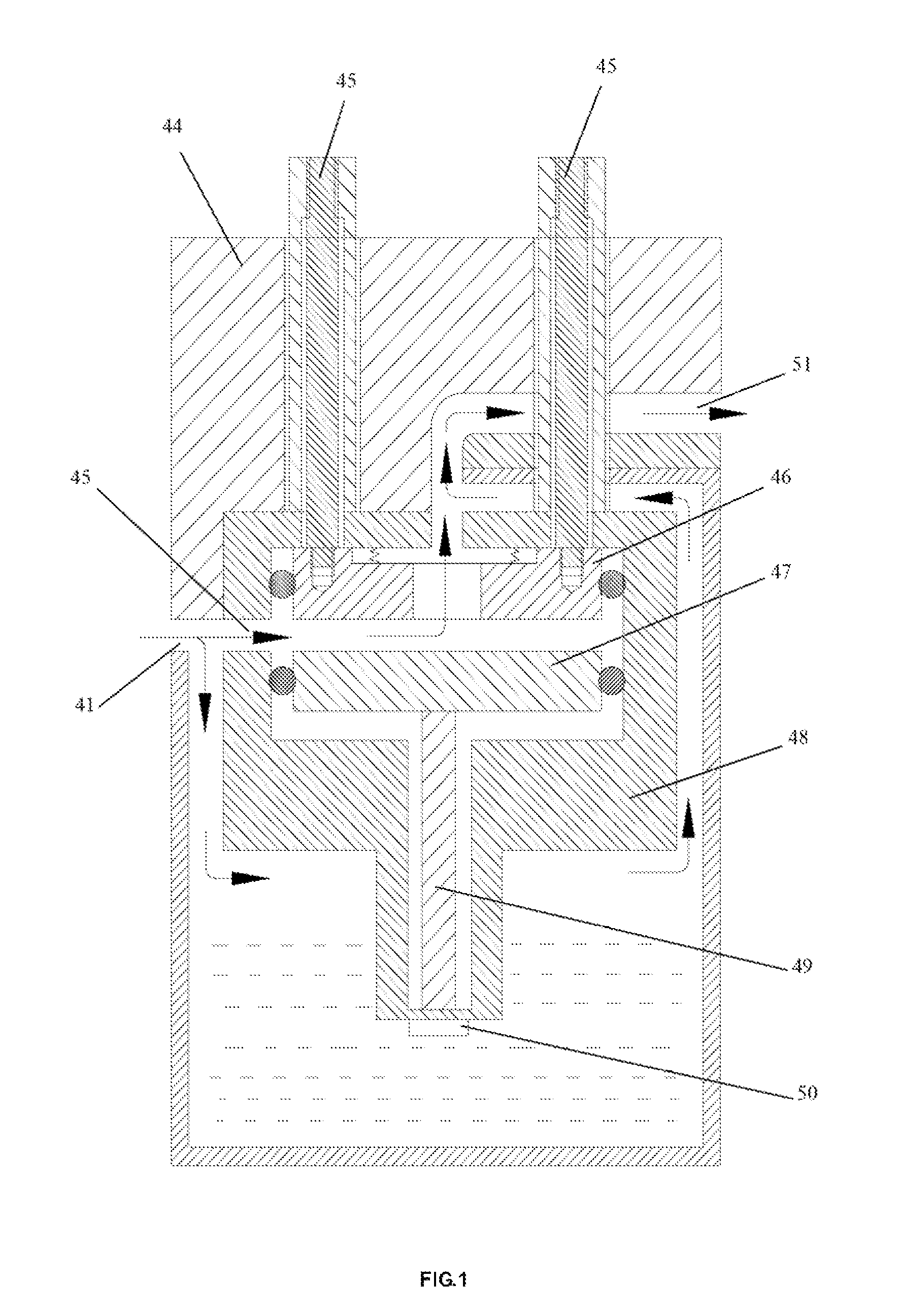

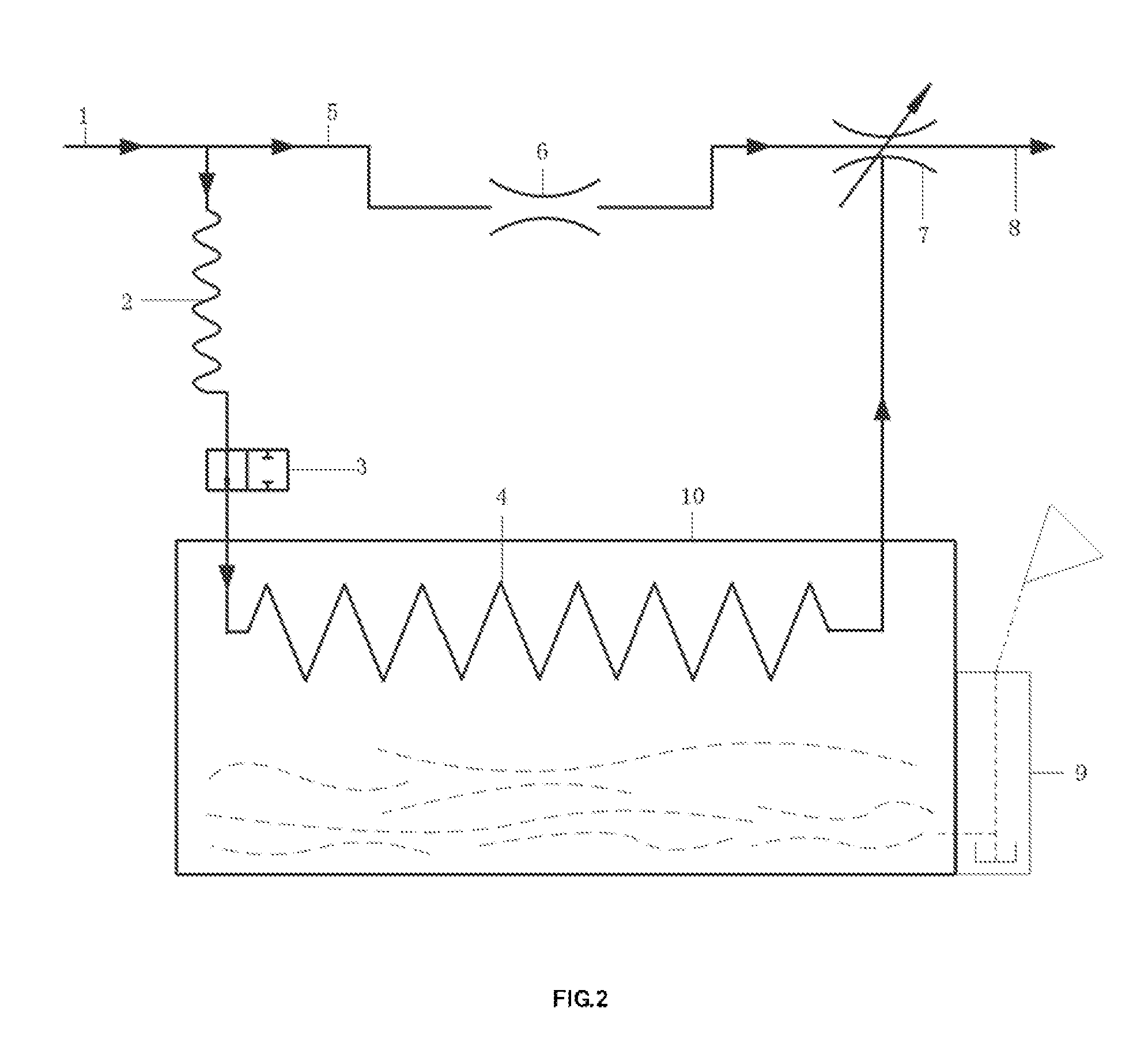

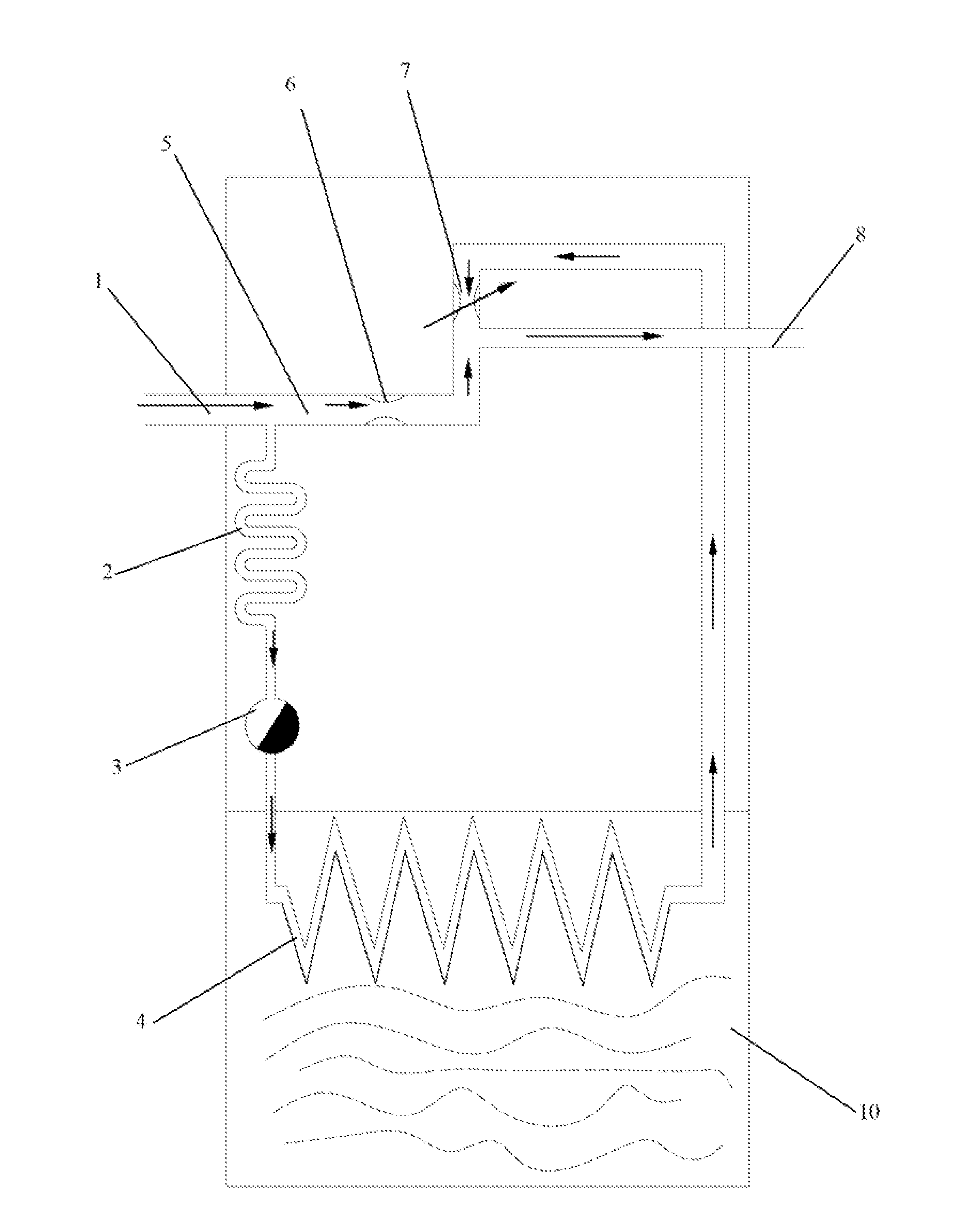

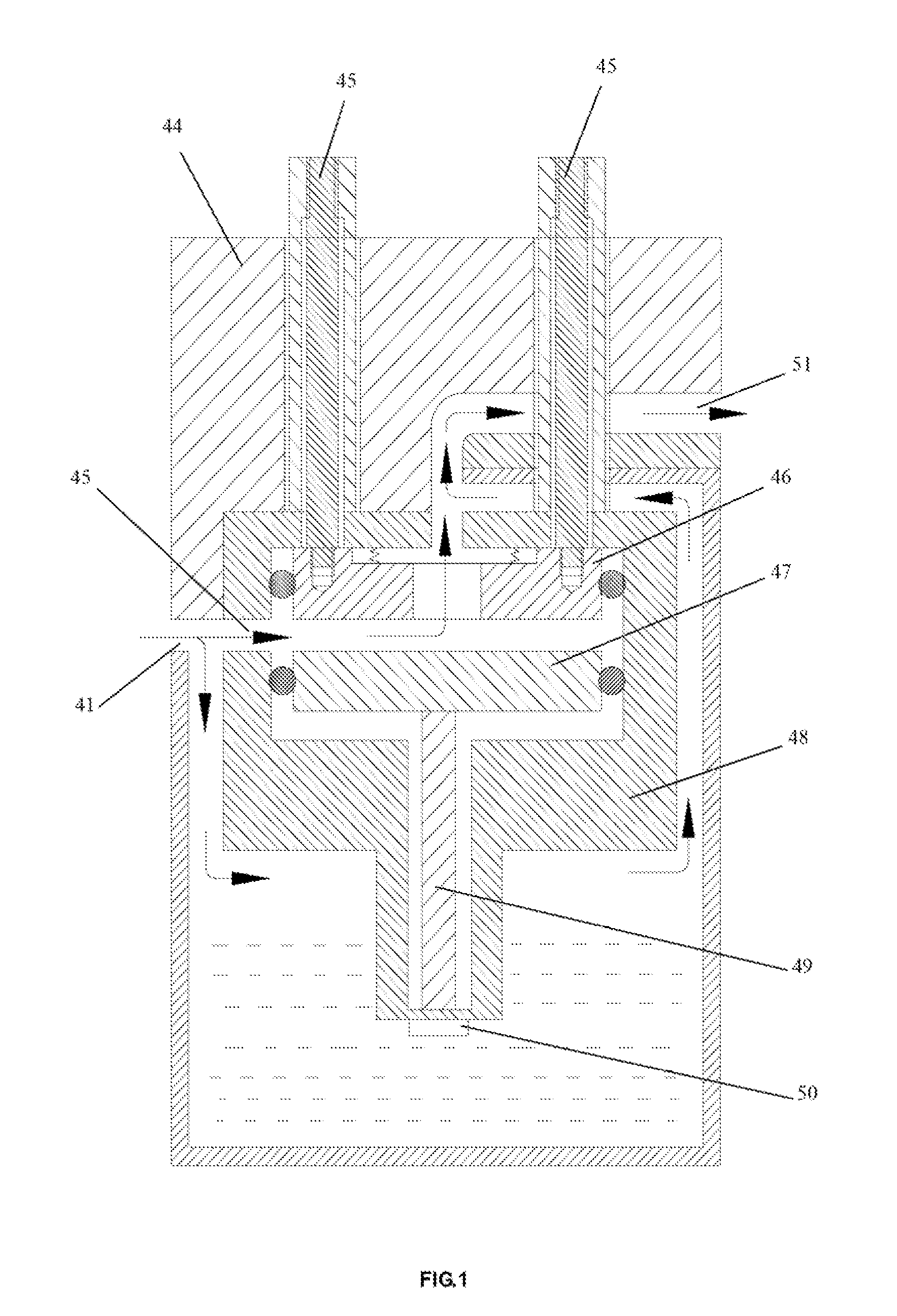

Anesthetic vaporizer and temperature compensation unit

ActiveUS8813744B2Good temperature compensation effectRespiratorsMedical devicesAnesthetic AgentEngineering

An anesthetic vaporizer and a temperature compensation unit are disclosed. The temperature compensation unit, which cooperates with a vaporizing chamber having a bottom wall, includes a first device connected to the bottom wall of the vaporizing chamber for contacting with liquid anesthetic agent in the vaporizing chamber and changing in length according to temperature change of the liquid anesthetic agent, and a second device connected to the vaporizing chamber. A gas flow gap through which a gas flow passes is formed between the first and second devices. The gas flow gap becomes larger as temperature of the liquid anesthetic agent rises and smaller as the temperature of the liquid anesthetic agent drops. Since the first device is connected with the bottom wall of the vaporizing chamber, the first device will directly contact with the liquid anesthetic agent regardless of the liquid level of the anesthetic agent, as long as there is liquid agent in the vaporizing chamber; therefore the efficiency of heat exchange is high and the effect of temperature compensation is good.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

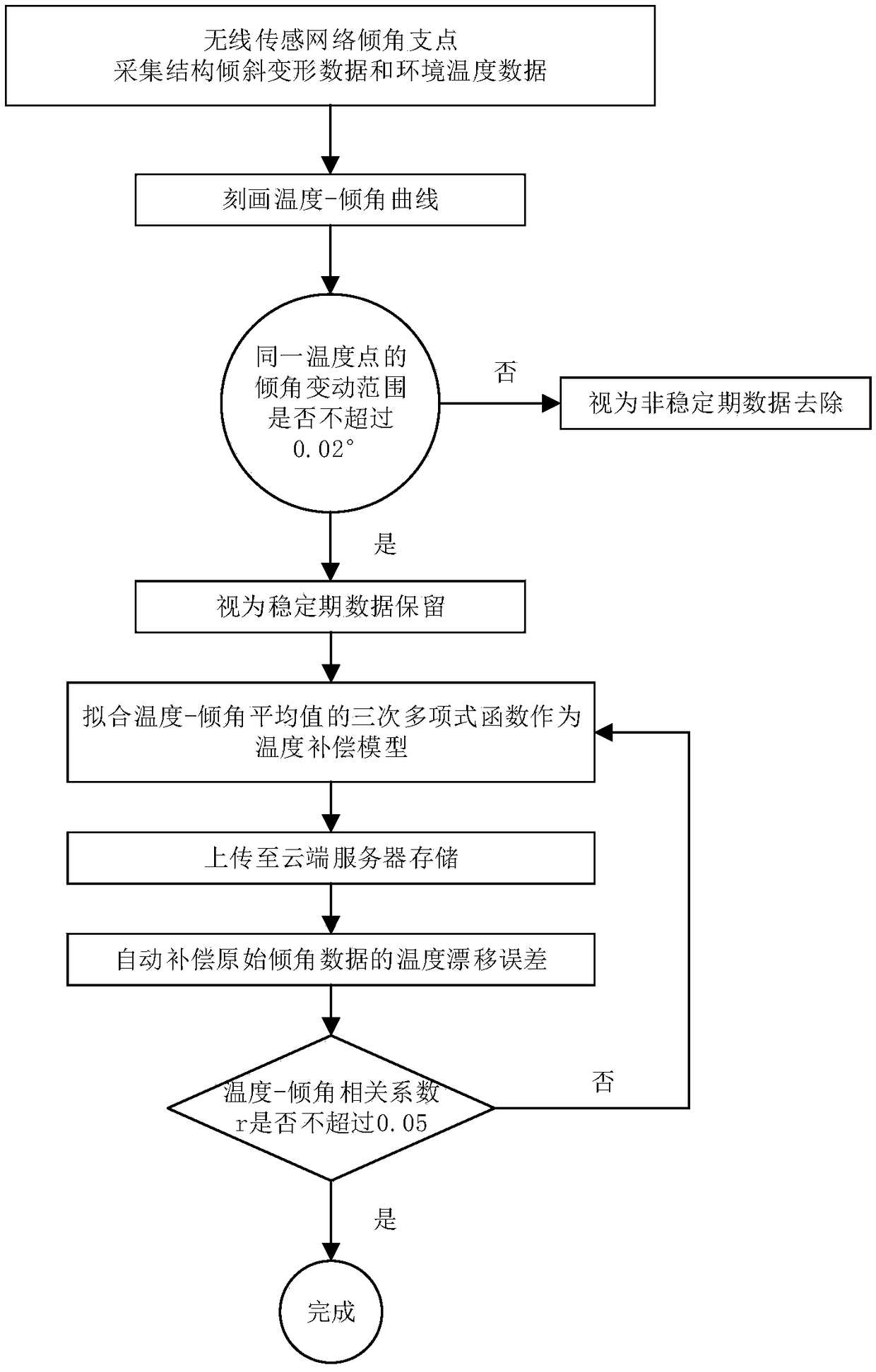

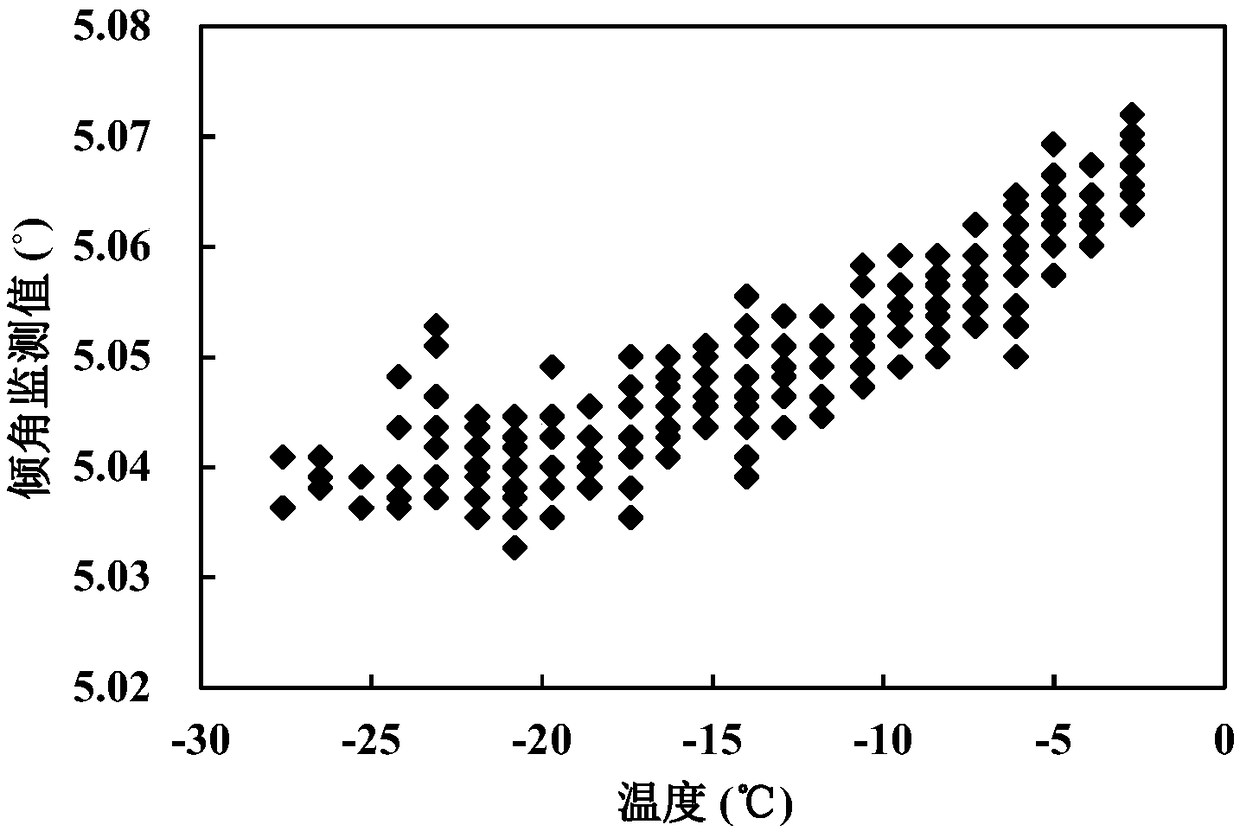

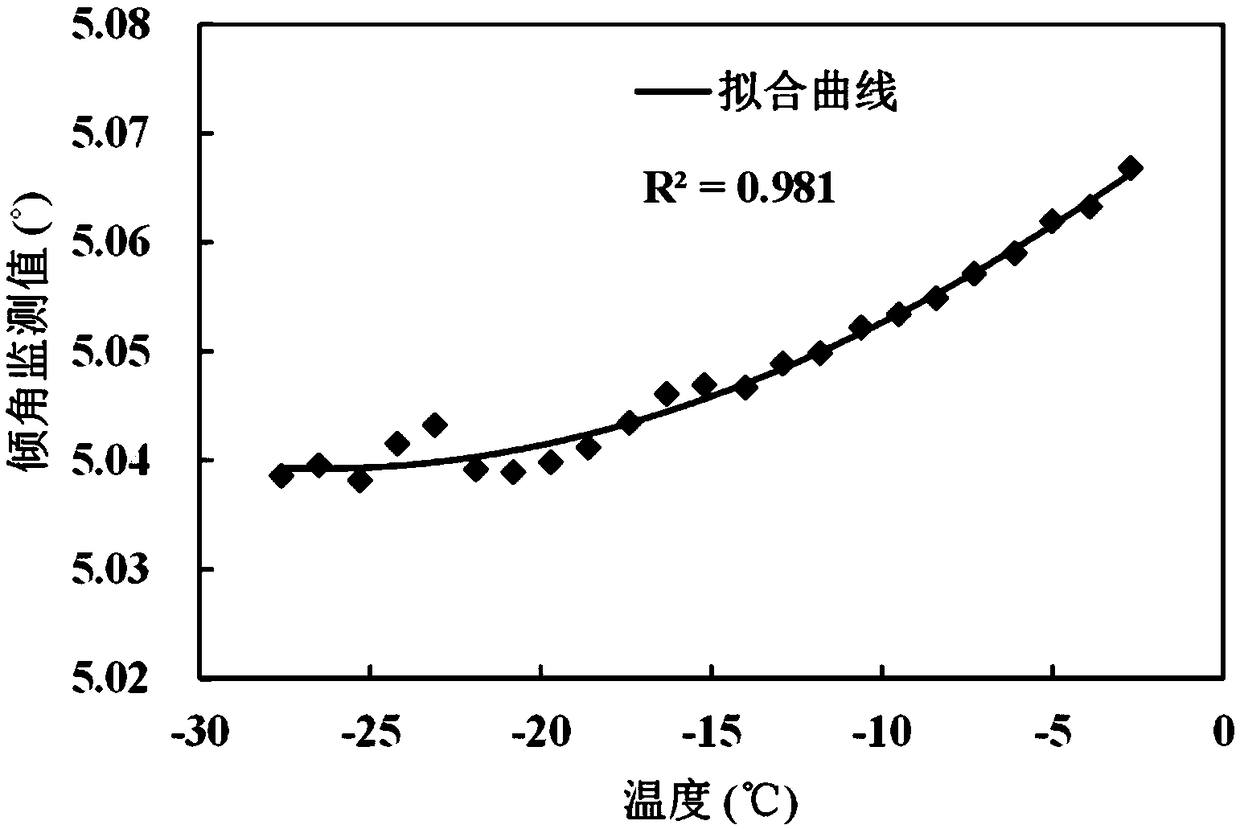

Temperature compensation method for wireless sensor network dip fulcrum

ActiveCN109211193ALow costImprove temperature compensation efficiencyTransmission systemsIncline measurementEngineeringTemperature testing

The invention relates to a temperature compensation method for a wireless sensor network dip fulcrum. The temperature compensation method comprises the following steps that (1) angel values and temperature values of a to-be-detected structure object within the monitoring cycle are collected through the wireless sensor network dip fulcrum; (2) the structure stability period, namely the time periodduring which a structure does not generate inclination and deformation, is determined according to the angel values within the monitoring cycle; (3) a temperature compensation model of the wireless sensor network dip fulcrum is established, and a temperature compensation coefficient is calculated; and (4) according to the temperature compensation model after obtaining the temperature compensationcoefficient, the collected angle values of the wireless sensor network dip fulcrum are automatically compensated. Compared with the prior art, the temperature compensation method has the advantages that temperature testing is not needed, automatic compensation is conducted, the compensation efficiency is improved, and a field application environment is fit.

Owner:TONGJI UNIV

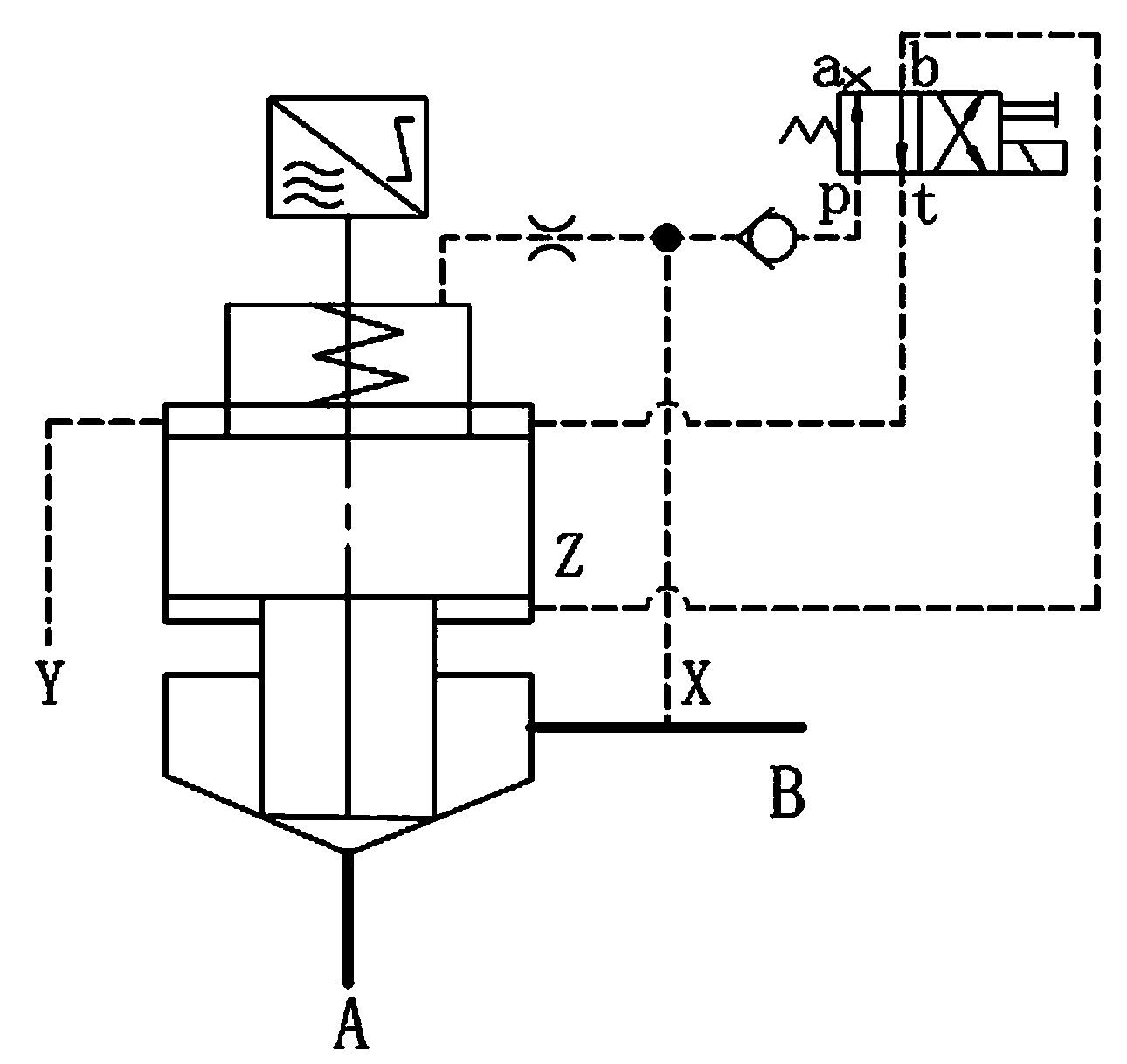

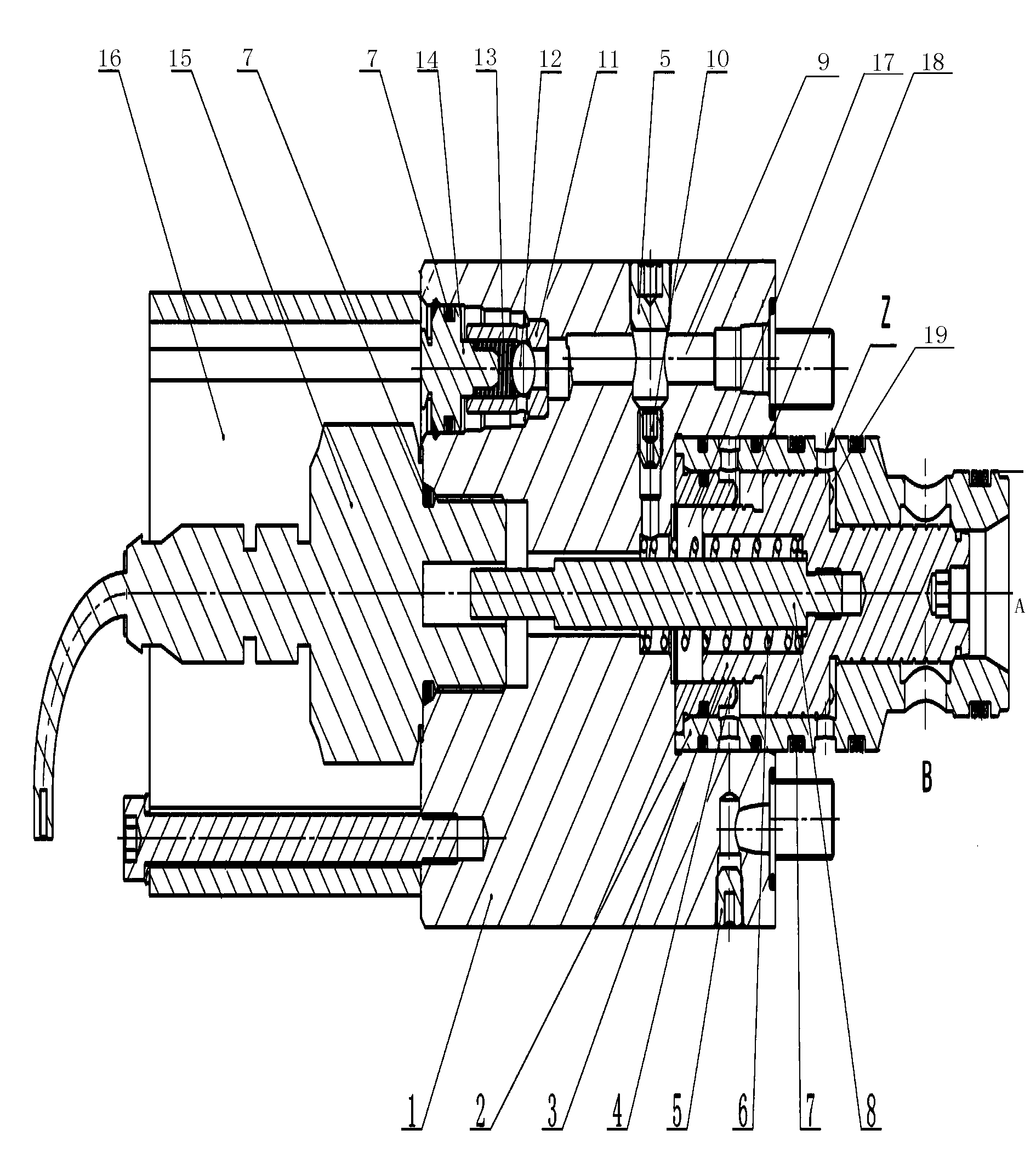

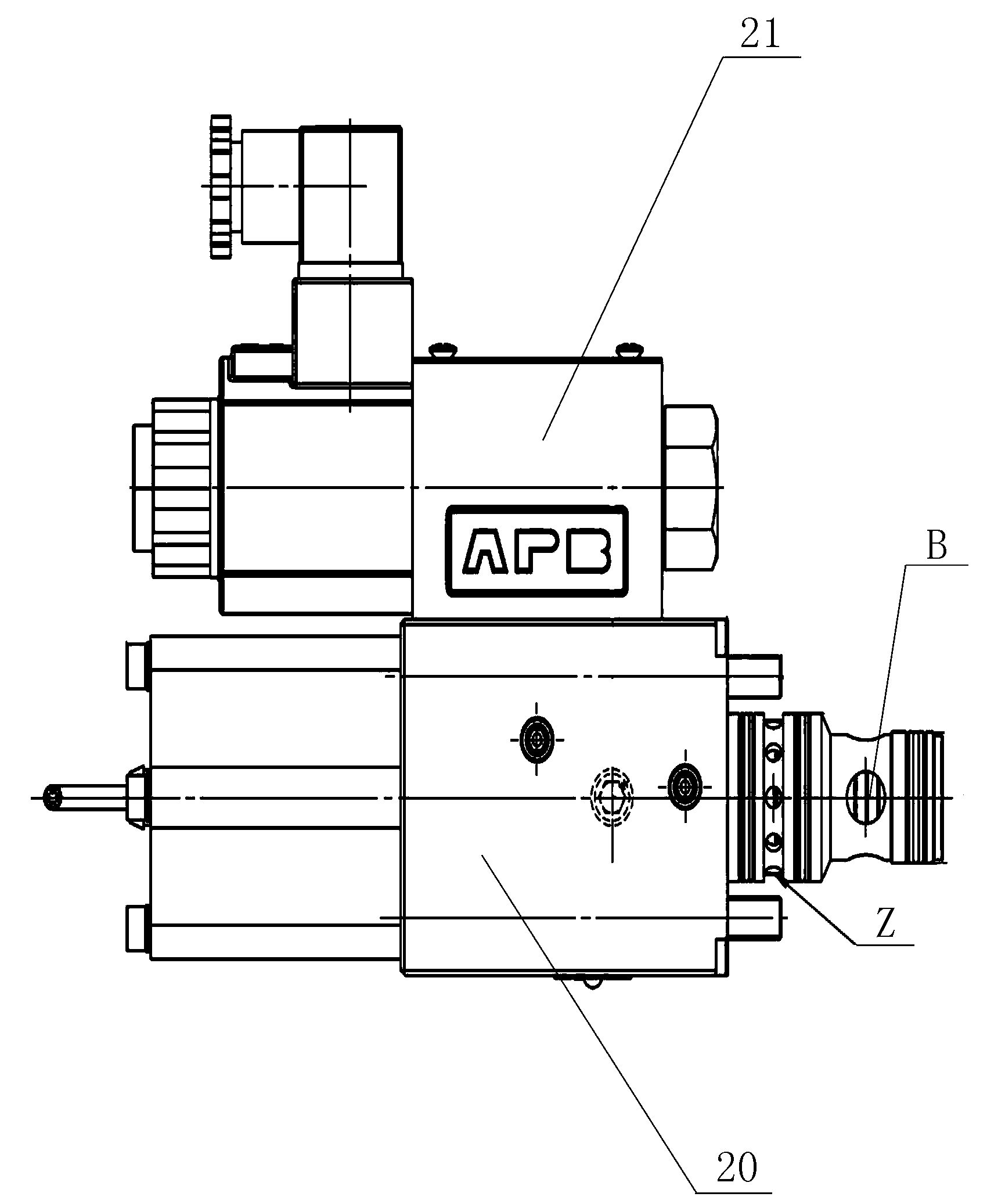

Pilot type active belt position monitoring safety valve

ActiveCN103644336ACorrect monitoring positionAffect openingServomotor componentsEqualizing valvesEngineeringCheck valve

The invention relates to a valve, and in particular relates to a pilot type active belt position monitoring safety valve. The pilot type active belt position monitoring safety valve comprises an electromagnetic directional valve (21), a main valve (20) and a check valve, wherein the main valve (20) comprises a valve sleeve (2) with a stepped hollow inner part, an outlet A is formed in the right end of the valve sleeve (2), a port B communicated with an oil inlet is formed in the circumference of the right end of the valve sleeve (2), and a lantern ring (4) is installed in the left end of the valve sleeve (2); a valve core (3) with a boss in the middle is installed in the valve sleeve (2), linear sealing is formed between the outer conical surface of the right end of the valve core (3) and an inner conical hole in the right end of the valve sleeve (2) to separate a port A from the port B, the right end of the valve core (3) extends into the lantern ring (4) in a matching way, the boss in the middle of the valve core (3) is matched with the inner wall of a large hole in the left end of the valve sleeve (2), and the cylindrical surface on the right side of the boss of the valve core (3) is matched with the inner hole in the middle of the valve sleeve (2) is a sealing way. The pilot type active belt position monitoring safety valve is reasonable to design and simple in structure.

Owner:TAIZHONG GRP YUCI HYDRAULIC IND

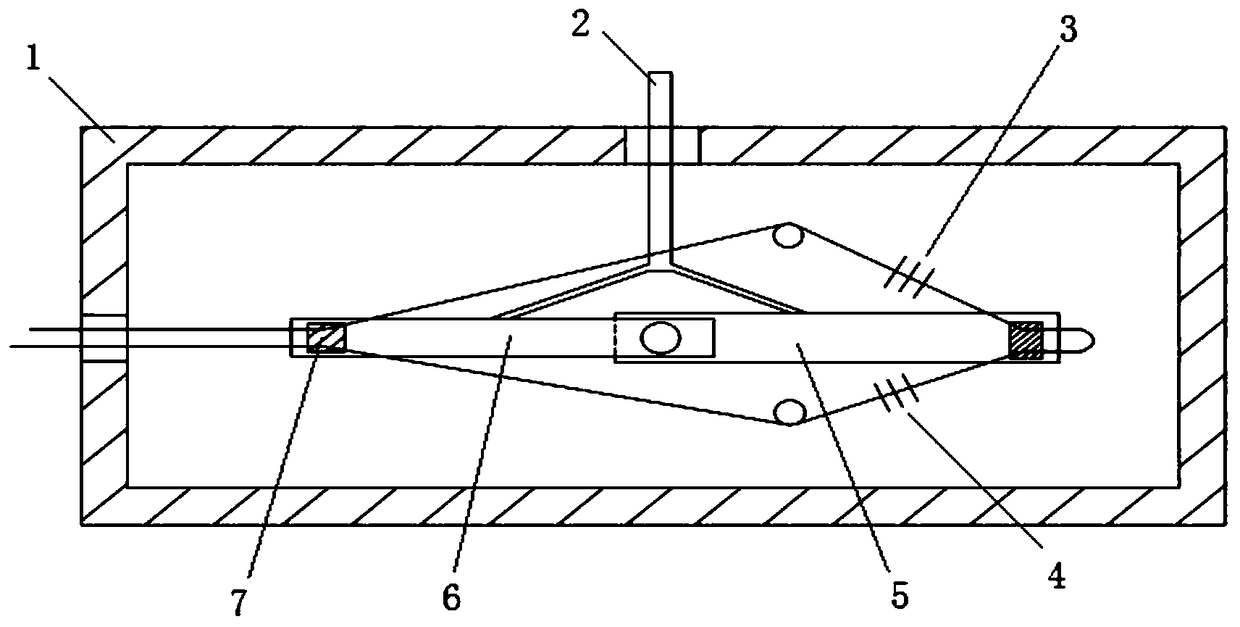

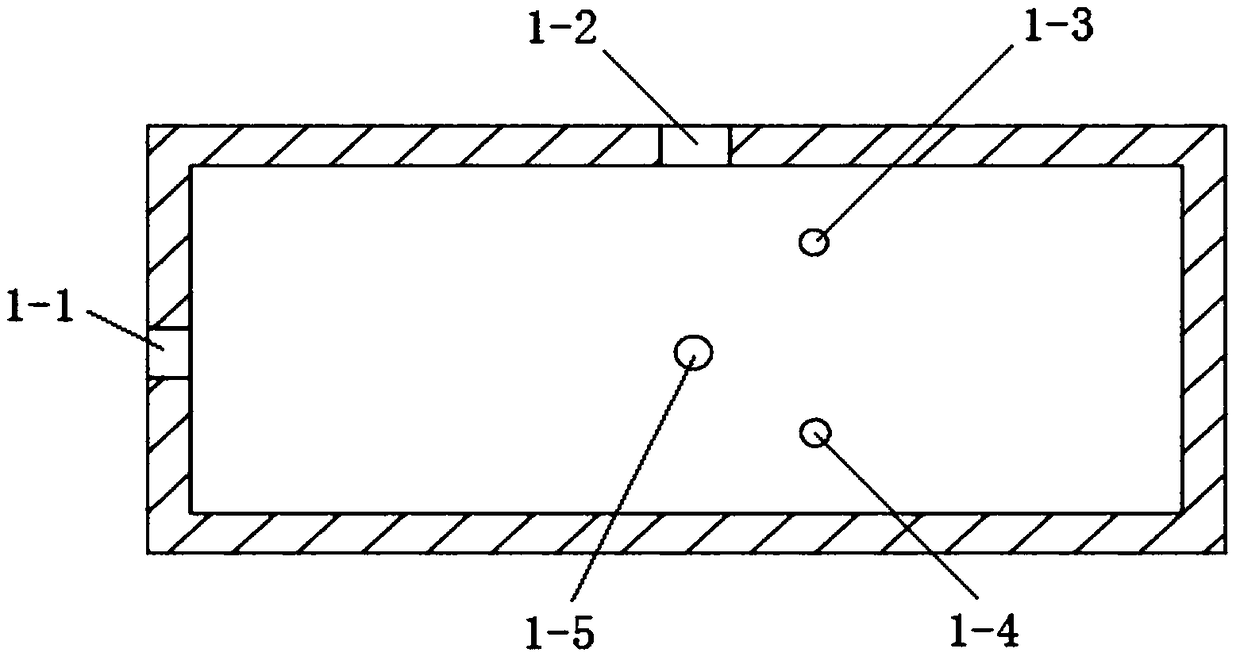

Fiber bragg grating displacement sensor

PendingCN108955540AHigh sensitivityAvoid inaccurate measurementsUsing optical meansFiberFiber Bragg grating

The present invention discloses a fiber bragg grating displacement sensor. The displacement sensor comprises a substrate, a push rod, a first fiber bragg grating, a second fiber bragg grating, a firstrotation rod and a second rotation rod; one side of the substrate is provided with an fiber output hole, the upper side of the substrate is provided with an upper through hole, the middle portion ofthe internal portion of the substrate is provided with a first cylinder, a second cylinder and a third cylinder which is located at the center of the substrate, and the first cylinder and the second cylinder are respectively located at the upper and lower sides of the third cylinder; one ends, connected to each other, of the first rotation rod and the second rotation rod are fixed at the top portion of the third cylinder, and the other ends thereof are hung in the air; the rotation rods freely rotate around the third cylinder under the action of the push rod; and the two ends of the first fiber bragg grating and the second fiber bragg grating bypass the first cylinder and the second cylinder to be fixed at the two ends of the first rotation rod and the second rotation rod; and the pigtailof the optical fiber is led out through the fiber output hole. The fiber bragg grating displacement sensor is high in sensitivity, anti-electromagnetic interference, free of signal distortion, simplein structure and high in stability, can perform long-term real-time online monitoring.

Owner:刘绍波

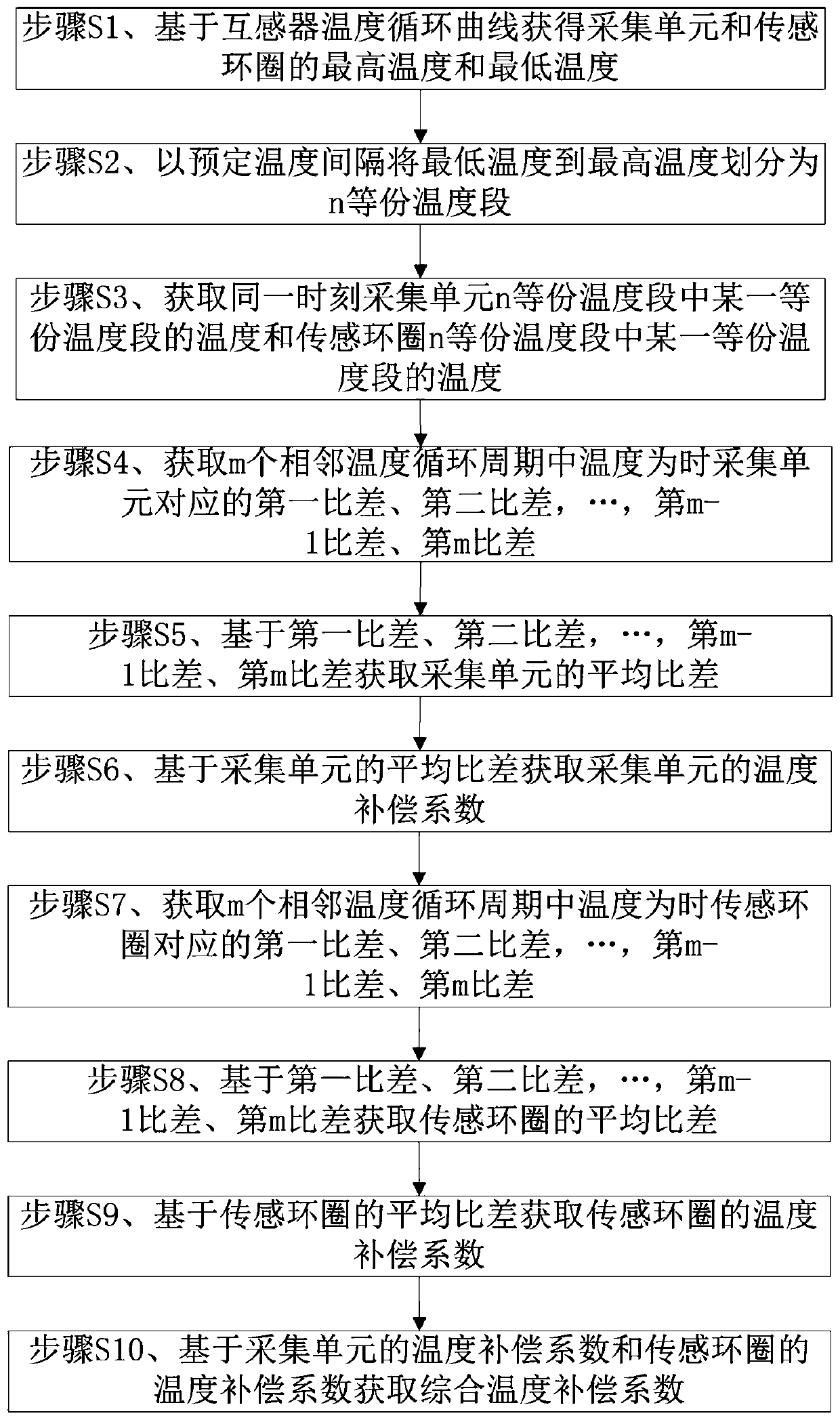

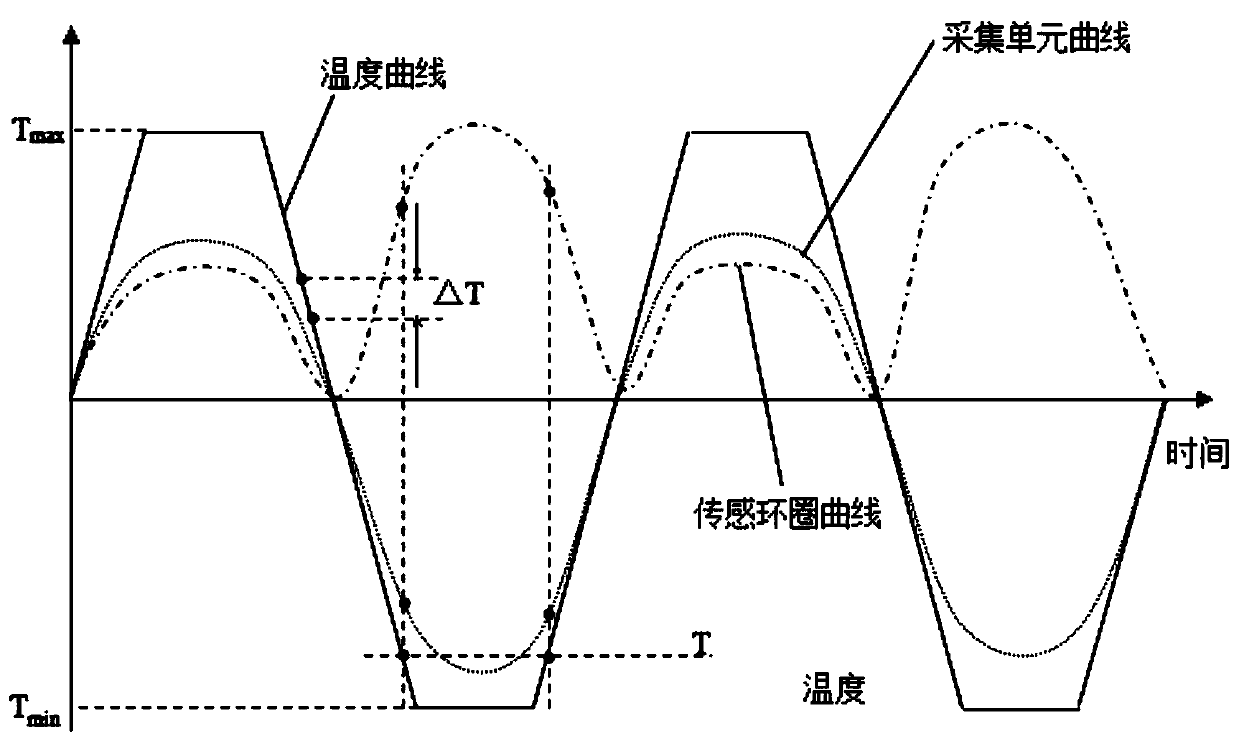

Method for precise temperature compensation of optical fiber current transformer

InactiveCN110988452AOvercoming Compensation Error ProblemsAccurate temperature compensationCurrent/voltage measurementVoltage/current isolationPhysicsEngineering

The invention provides a method for precise temperature compensation of an optical fiber current transformer. The method comprises the following steps: obtaining the highest temperature and the lowesttemperature of an acquisition unit and a sensing ring; dividing the temperature from the lowest temperature to the highest temperature into n equal temperature sections at a preset temperature interval; acquiring the temperature of the acquisition unit and the temperature of the sensing ring at the same moment; acquiring a first ratio difference, a second ratio difference-an (m-1) th ratio difference and an mth ratio difference corresponding to the acquisition unit when the temperature in m adjacent temperature cycle periods is T1; acquiring a temperature compensation coefficient of the acquisition unit; obtaining a first ratio difference, a second ratio difference-an (m-1) th ratio difference and an mth ratio difference corresponding to the sensing ring when the temperature is T2 in m adjacent temperature cycle periods; obtaining a temperature compensation coefficient of the sensing ring; obtaining comprehensive temperature compensation coefficients. According to the technical scheme, the technical problem that in the prior art, the temperature compensation effect is not ideal due to the fact that temperature fields of a sensing ring and an acquisition unit in an optical fiber current transformer are inconsistent is solved.

Owner:BEIJING AUTOMATION CONTROL EQUIP INST

Anesthetic vaporizer and temperature compensation unit

ActiveUS20100180893A1Good temperature compensation effectRespiratorsMedical devicesEngineeringAnesthetic

An anesthetic vaporizer and a temperature compensation unit are disclosed. The temperature compensation unit, which cooperates with a vaporizing chamber having a bottom wall, includes a first device connected to the bottom wall of the vaporizing chamber for contacting with liquid anesthetic agent in the vaporizing chamber and changing in length according to temperature change of the liquid anesthetic agent, and a second device connected to the vaporizing chamber. A gas flow gap through which a gas flow passes is formed between the first and second devices. The gas flow gap becomes larger as temperature of the liquid anesthetic agent rises and smaller as the temperature of the liquid anesthetic agent drops. Since the first device is connected with the bottom wall of the vaporizing chamber, the first device will directly contact with the liquid anesthetic agent regardless of the liquid level of the anesthetic agent, as long as there is liquid agent in the vaporizing chamber; therefore the efficiency of heat exchange is high and the effect of temperature compensation is good.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD

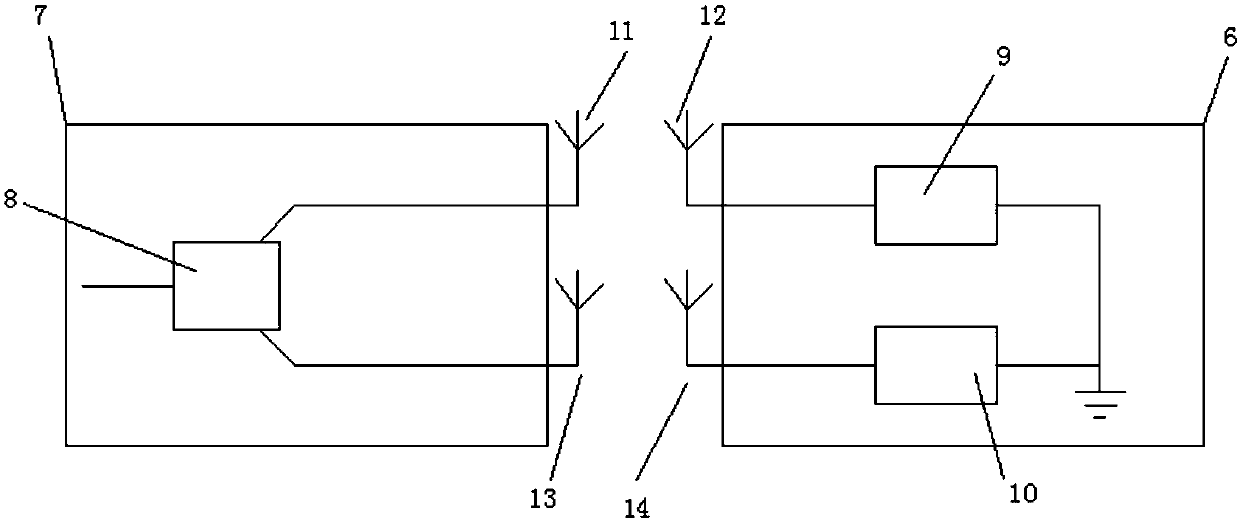

Wireless passive temperature compensation method for film bulk acoustic wave pressure sensor

ActiveCN107941391AEliminate the effects ofEasy to packForce measurementFluid pressure measurement by acoustic meansCapacitive pressure sensorElectromagnetic interference

The invention discloses a wireless passive temperature compensation method for a film bulk acoustic wave pressure sensor. On the one hand, the film bulk acoustic wave sensor of a conventional transmitter is replaced with a pair of parallel sealed and unsealed film bulk acoustic wave devices. On the other hand, a conventional wired active temperature compensation method is replaced with a wirelesspassive temperature compensation method. Compared with traditional piezoresistive pressure sensors and capacitive pressure sensors, the film bulk acoustic wave pressure sensor has high sensitivity andhigh resolution, presents the same in the form of frequency, and is less affected by electromagnetic interference.

Owner:深圳市封神微电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com