Temperature compensation circuit for laser drive

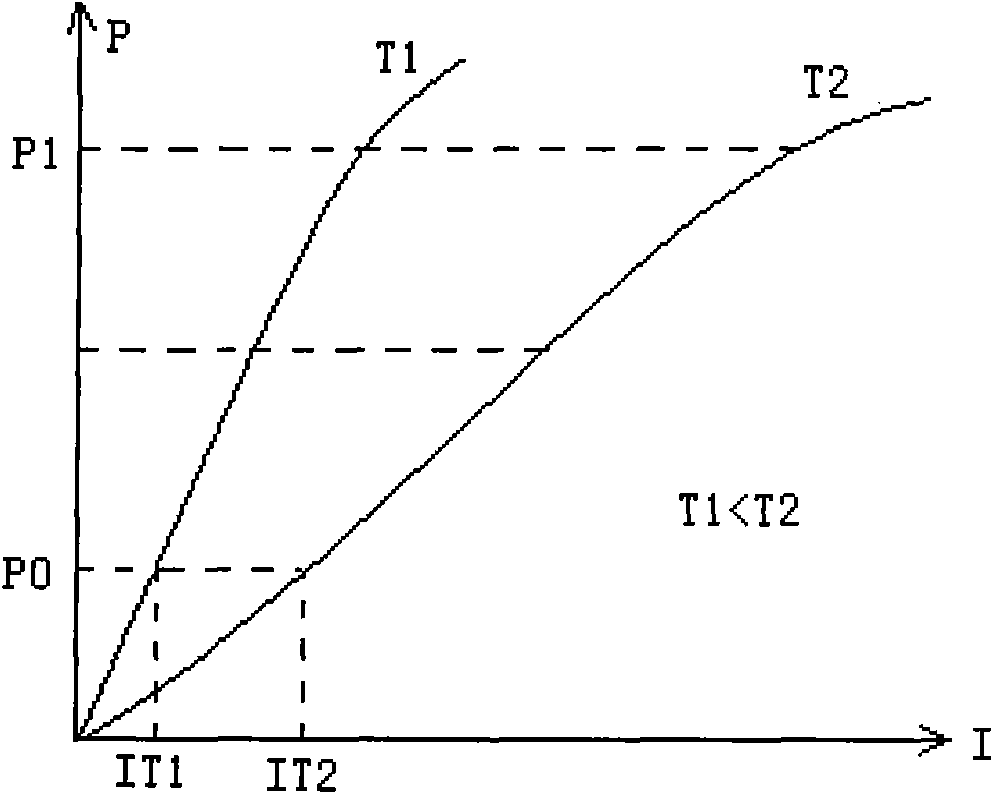

A temperature compensation circuit, laser driver technology, applied in electrical components, power oscillators, etc., can solve the problems of difficult laser compensation proportional laser, difficult to adapt to laser temperature characteristics, fixed temperature compensation, etc., to achieve simple circuit structure, low price, The circuit is stable and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

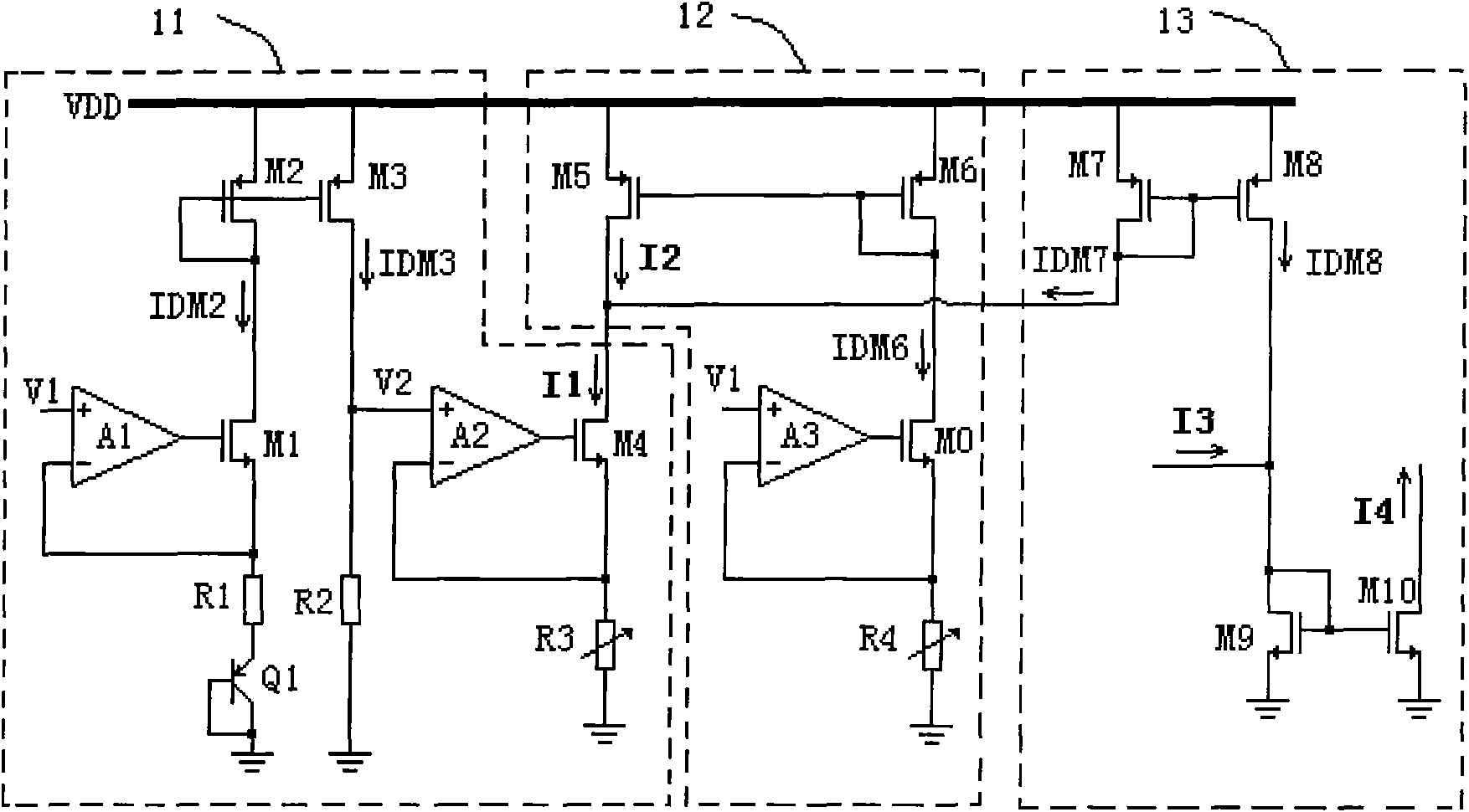

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

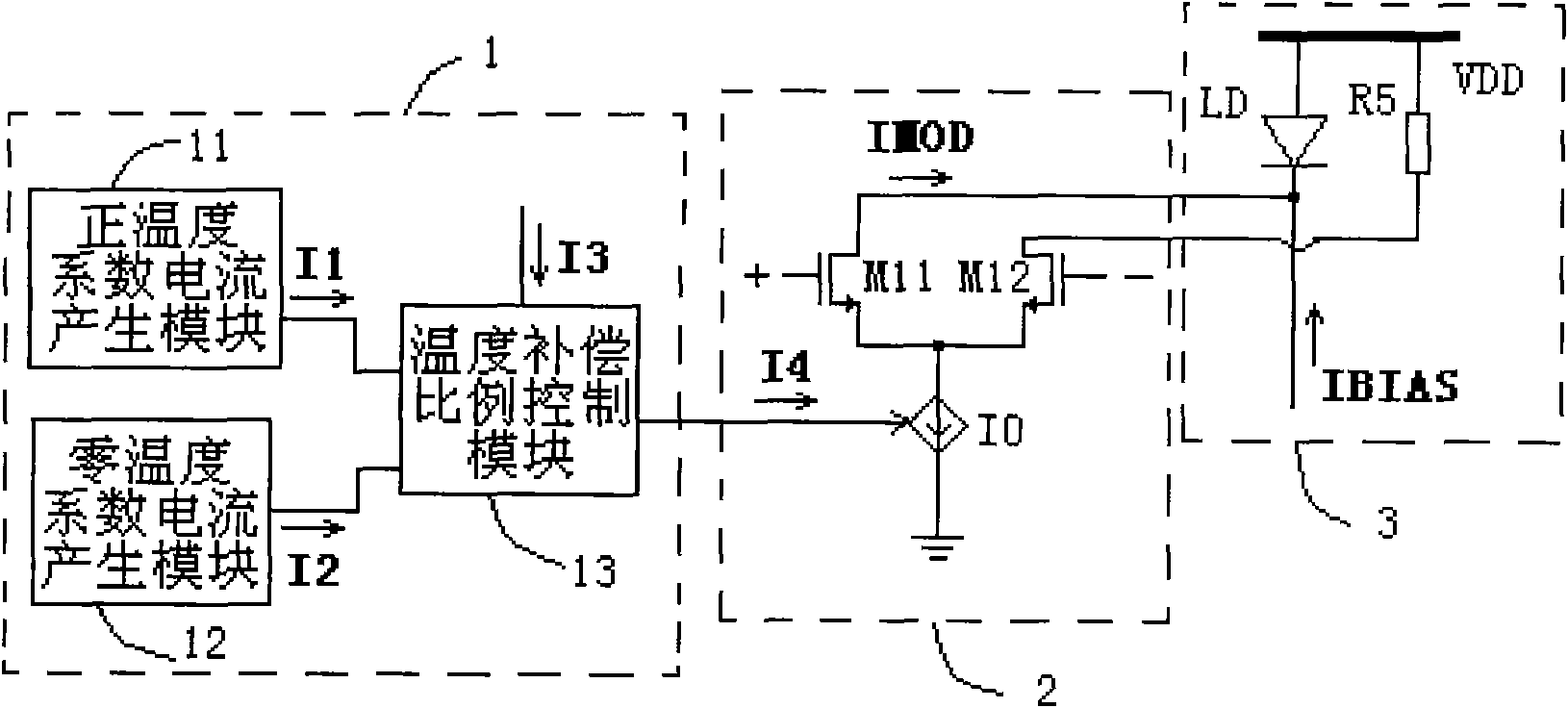

[0024] Embodiments of the present invention are applied to laser drivers, see figure 2 As shown, it includes the temperature compensation circuit 1 applied to the laser driver, the modulation current output module 2 and the laser and its matching network 3, the temperature compensation circuit 1 applied to the laser driver outputs the compensation current I4 to the modulation current output module 2, and the modulation current output Module 2 will have a compensated modulating current I MOD Output to the laser, thereby compensating the temperature characteristics of the laser itself. The modulation current output module 2 is a more general differential output control method. The compensation current I4 directly controls the tail current source I0 of the differential output unit, which will directly affect the modulation current of the laser,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com