Method for stress compensation of crystal frequency temperature characteristic based on temperature sensing material

A technology for sensing materials and temperature characteristics, applied in the direction of electrical components, impedance networks, etc., can solve the problems that it is difficult to adapt to the competition of temperature-compensated crystal oscillators, the structure of crystal oscillators is complicated, and it is difficult to meet, and achieve good pullability and performance The effect of low power consumption and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

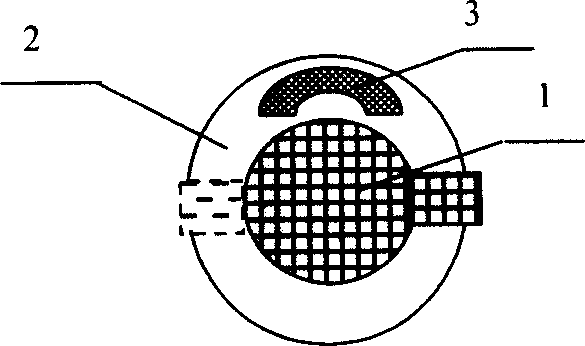

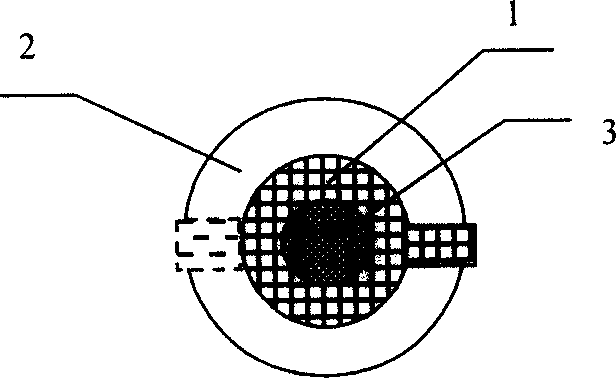

[0013] The present invention will be described in detail below with reference to the accompanying drawings.

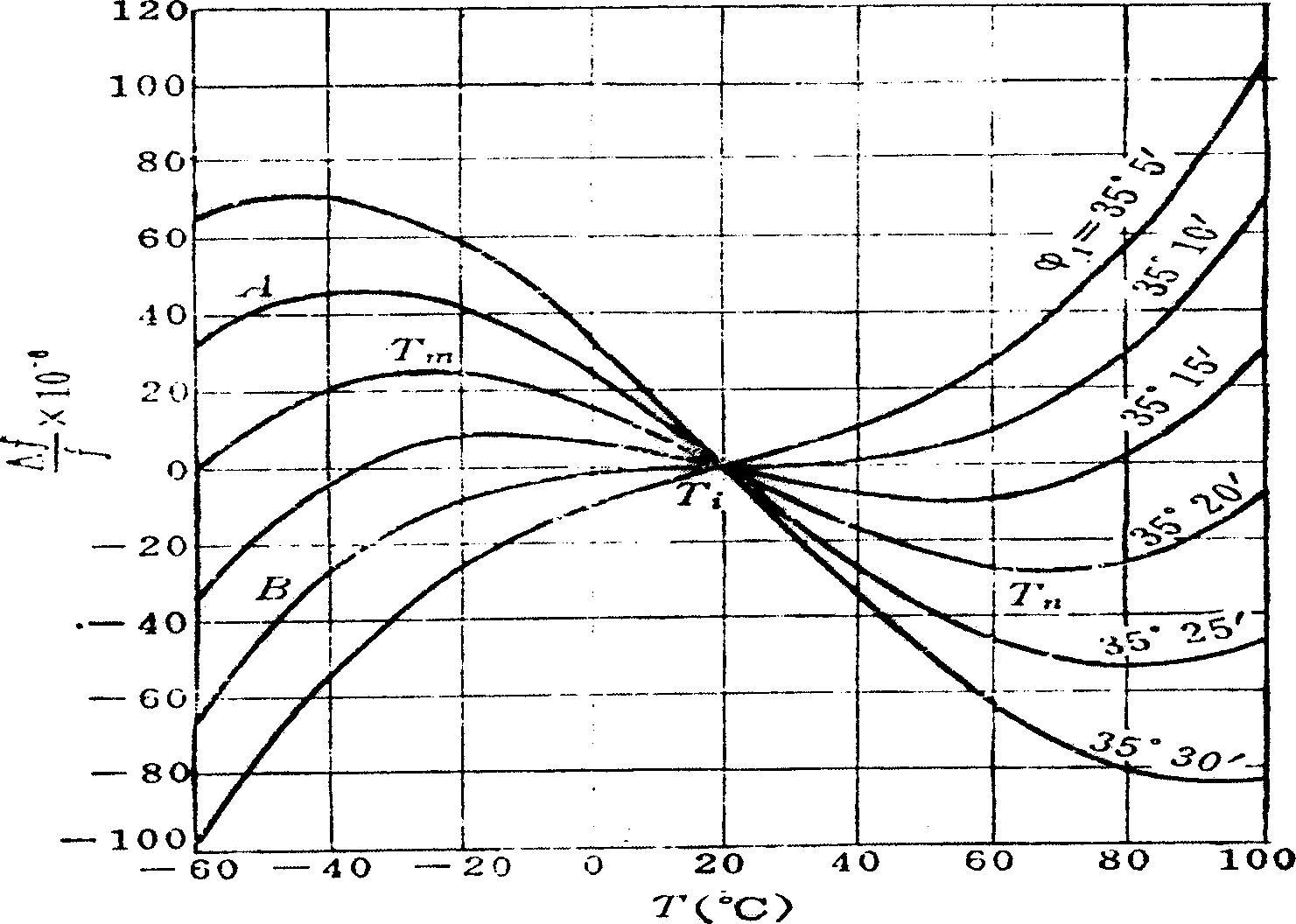

[0014] According to the characteristic that the frequency of the oscillator changes with the change of the stress applied to it, the present invention uses a temperature sensitive device to influence the magnitude of the stress applied to the crystal resonator to compensate the change of the frequency of the crystal oscillator with temperature. The force-frequency effect of crystals and crystal oscillators is that when the resonator is under stress, its resonant frequency will change accordingly. This stress can be caused by external forces, acceleration and vibration, electrode deformation, crystal support, or other factors. As the applied force increases, the change in the oscillation frequency of the crystal also increases, and the change in the force reduction frequency also decreases. The following is the relationship between the specific crystal frequency increment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com