Pilot type active belt position monitoring safety valve

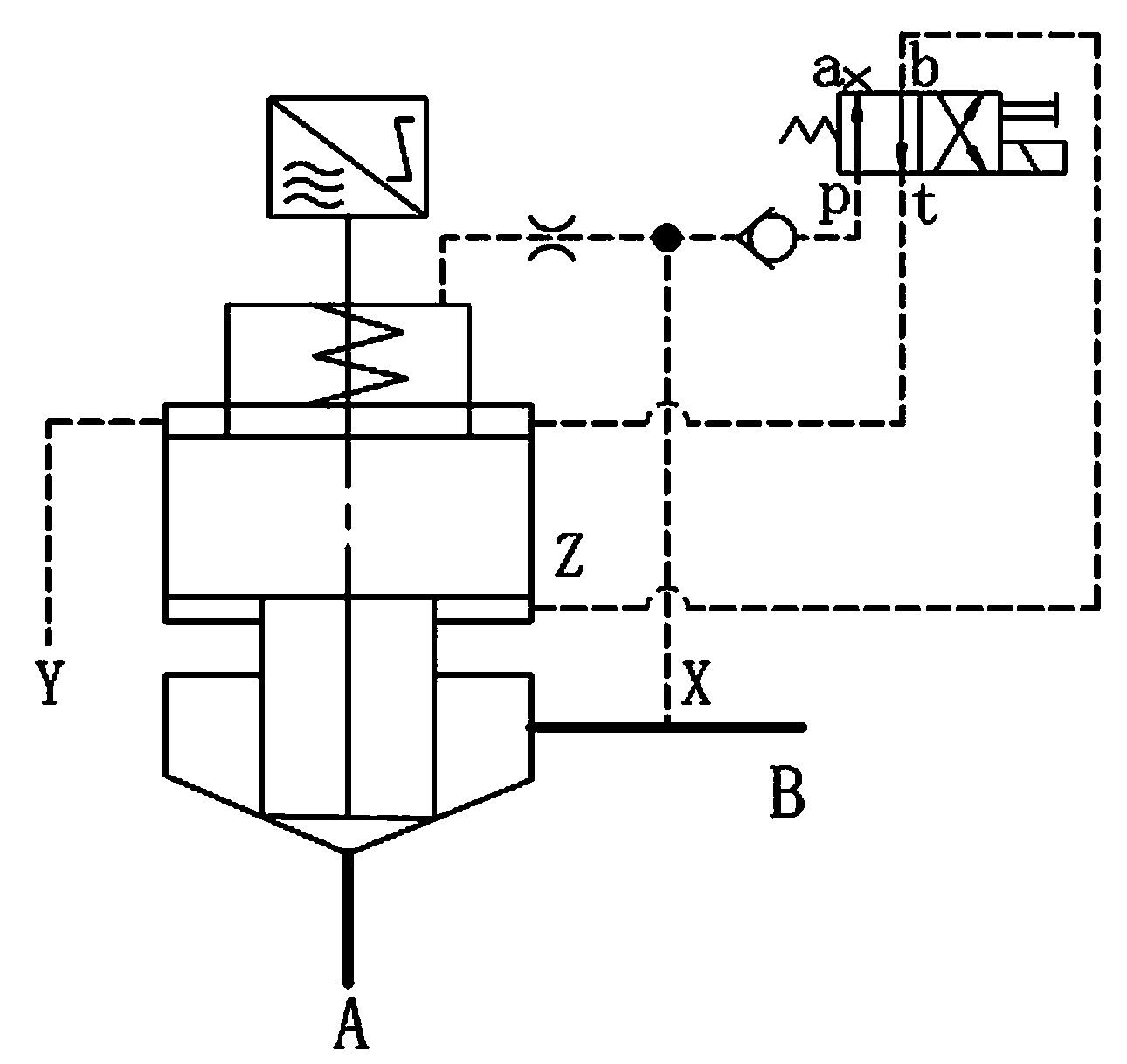

An active and pilot-operated technology, applied in safety valves, fluid pressure actuators, balance valves, etc., can solve problems such as poor safety valve action stability, complex system loop requirements, safety production accidents, etc., to ensure stability, The effect of stable and reliable switching action and good temperature compensation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

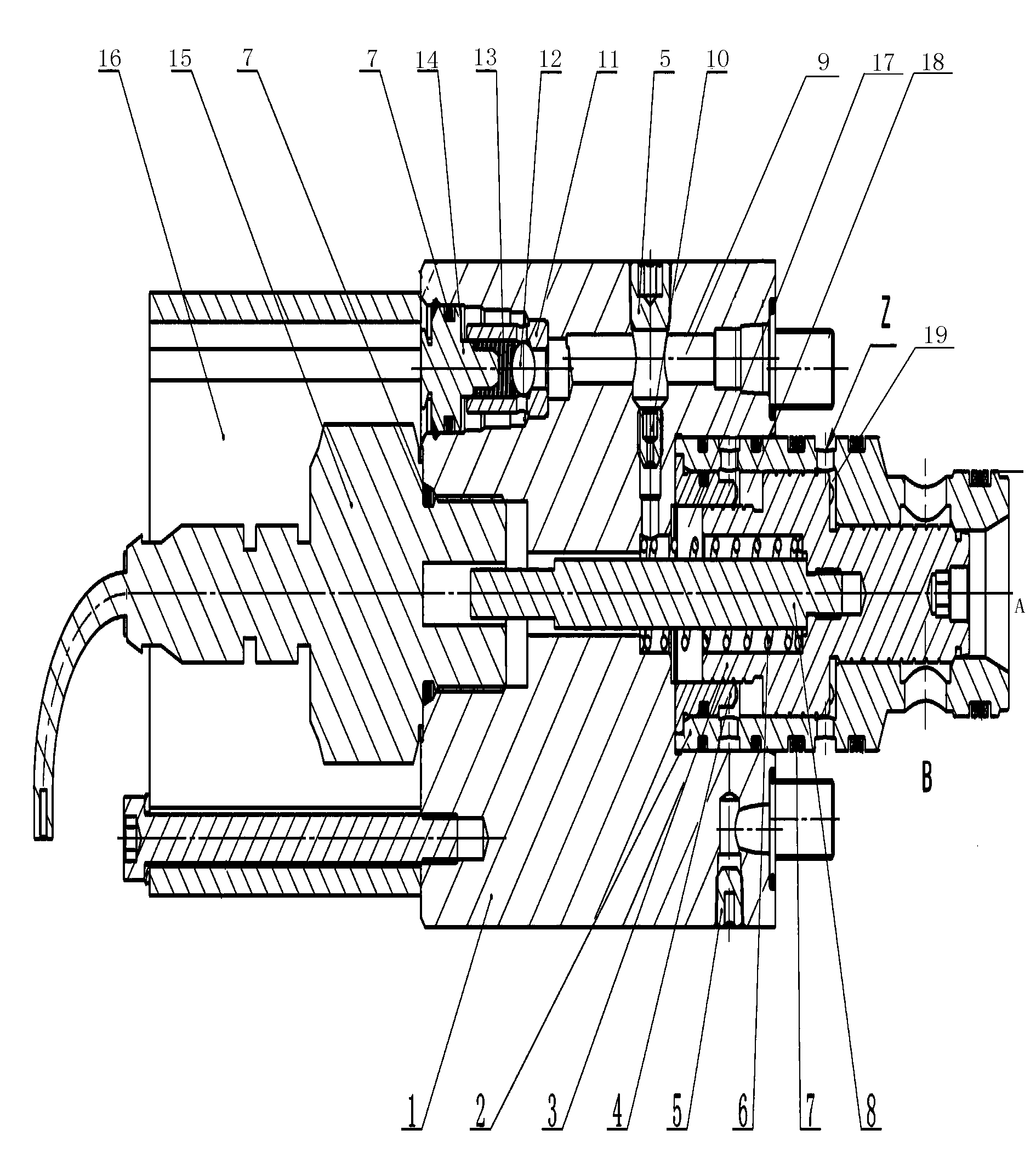

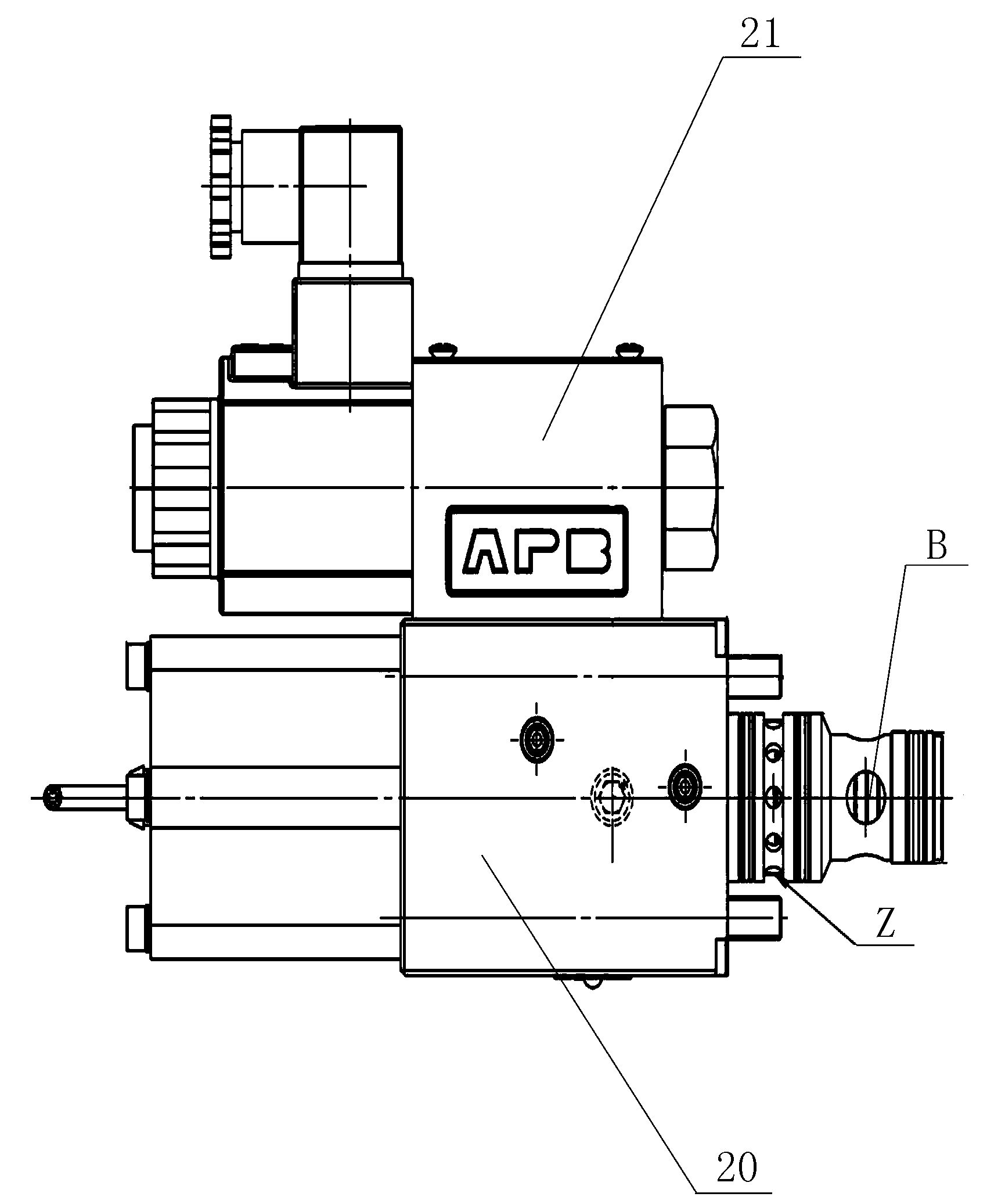

[0034] A pilot-operated active safety valve with position monitoring, including an electromagnetic reversing valve 21, a main valve 20 and a check valve, such as figure 2 , 3 shown.

[0035] The main valve 20 includes a valve sleeve 2 with a stepped hollow inside. The outlet on the right end of the valve sleeve 2 is port A, and the circumference of the right end of the valve sleeve 2 is provided with a port B communicating with the oil inlet.

[0036] A collar 4 is installed in the left end of the valve sleeve 2 .

[0037] The valve sleeve 2 is installed with a spool 3 with a boss in the middle, and the outer cone surface of the right end of the valve core 3 forms a line seal with the inner taper hole of the right end of the valve sleeve 2, and the A port and the B port on the valve sleeve 2 are sealed. The left end of the spool 3 is seale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com