Method for forming surface acoustic wave resonance device

A resonator device, surface acoustic wave technology, applied in impedance networks, electrical components, etc., can solve the problem that the resonator forming process needs to be improved, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

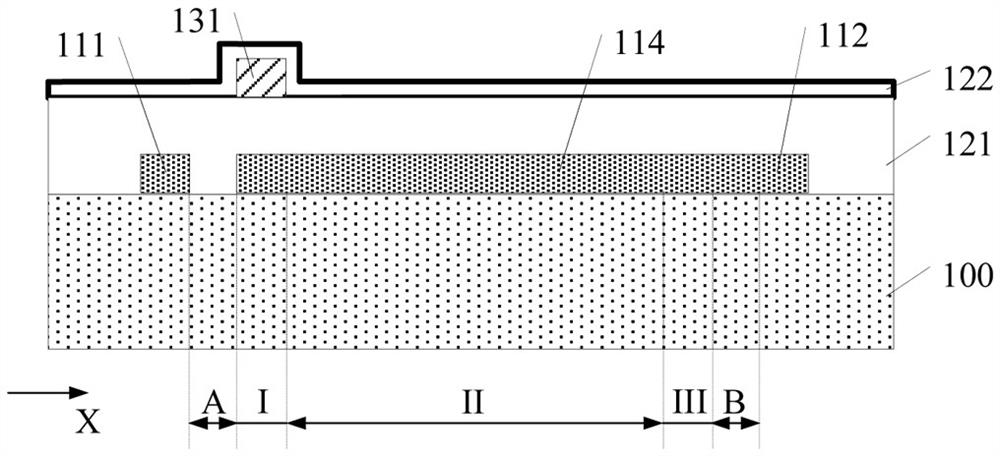

[0026] As described in the background art, the existing resonator formation process still needs to be improved, which will be described in detail below with reference to the accompanying drawings.

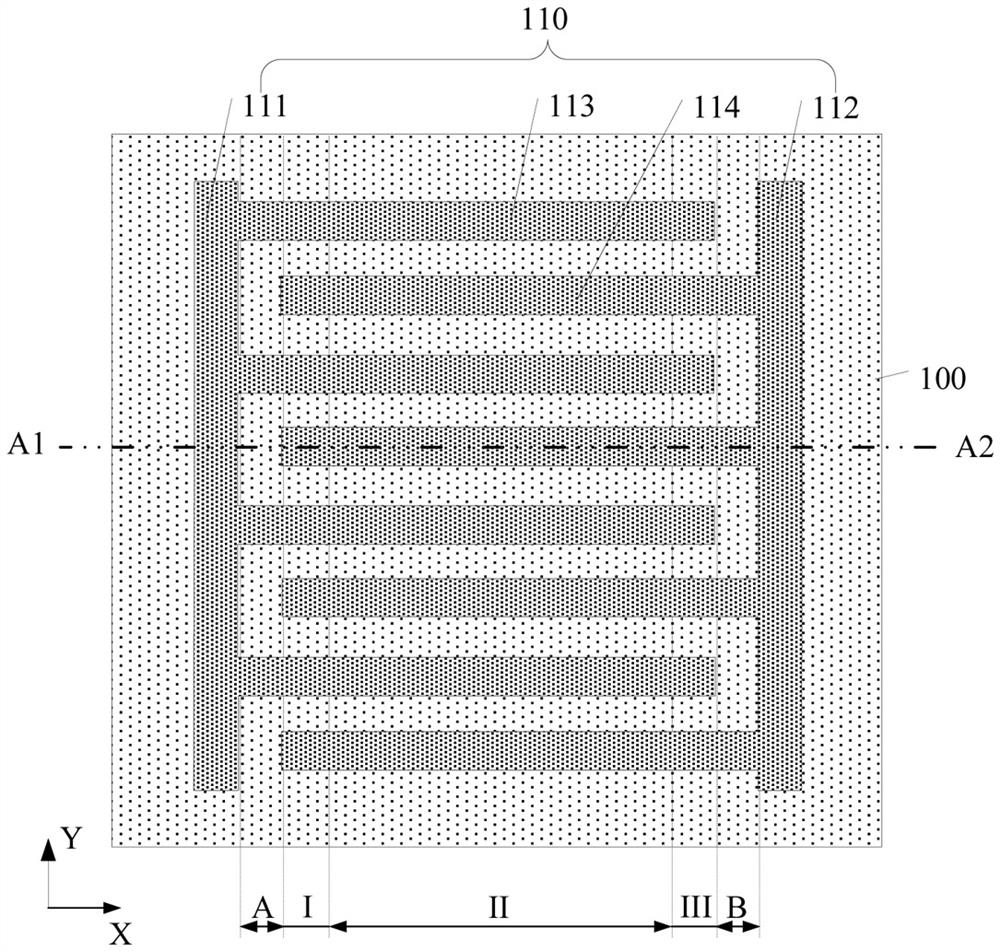

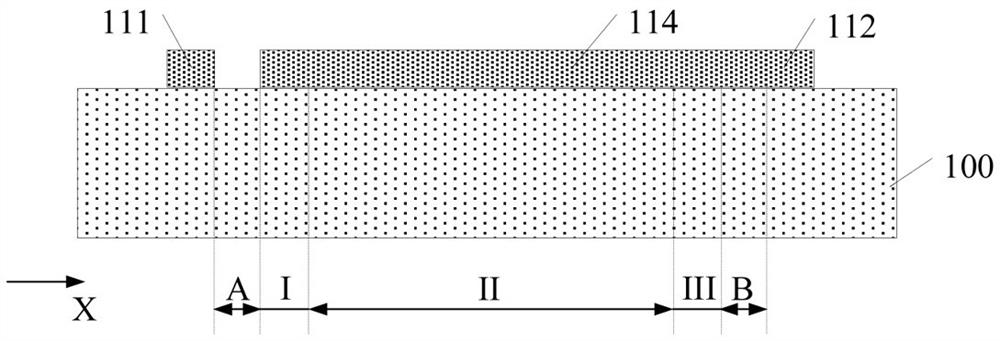

[0027] Figure 1 to Figure 6 It is a structural schematic diagram of each step in the formation process of a SAW resonator.

[0028] Please refer to figure 1 and figure 2 , figure 1 Yes figure 2 Schematic top view of the structure, figure 2 Yes figure 1 A schematic cross-sectional structure diagram along the direction A1-A2 in the middle, a piezoelectric substrate 100 is provided, and the piezoelectric substrate 100 has an electrode layer 110 thereon.

[0029] The piezoelectric substrate 100 includes a first isolation region A, a first region I, a second region II, a third region III and a second isolation region B which are sequentially arranged in the first direction X.

[0030] The electrode layer 110 includes: a first bus line 111 , a second bus line 112 , a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com