Single-chip bridge-type magnetic field sensor

一种磁场传感器、单芯片的技术,应用在磁传感器领域,能够解决降低传感器线性度、温度补偿功能降低、磁场动态范围减小等问题,达到良好线性度和高灵敏度、改善温度补偿性能、增大动态范围的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

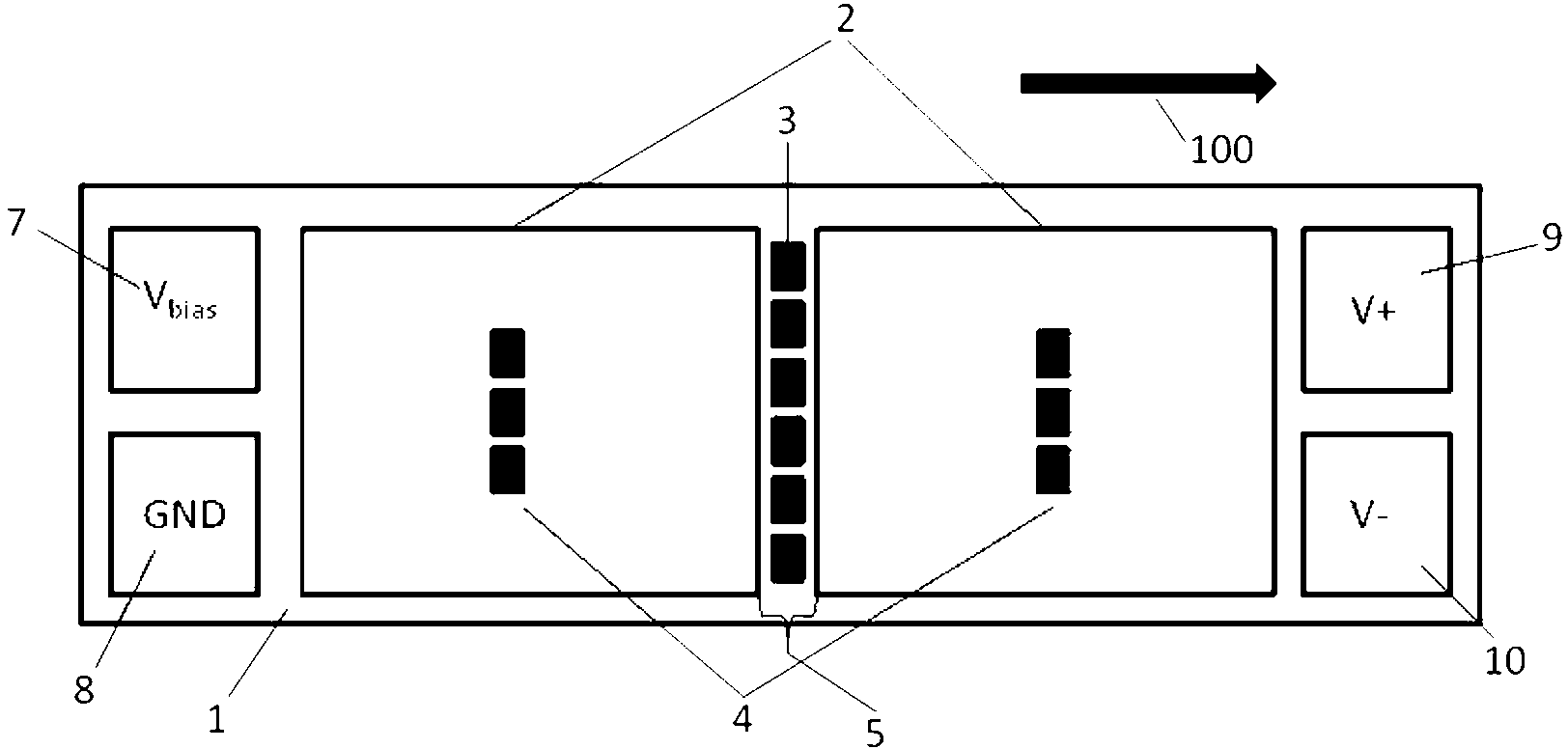

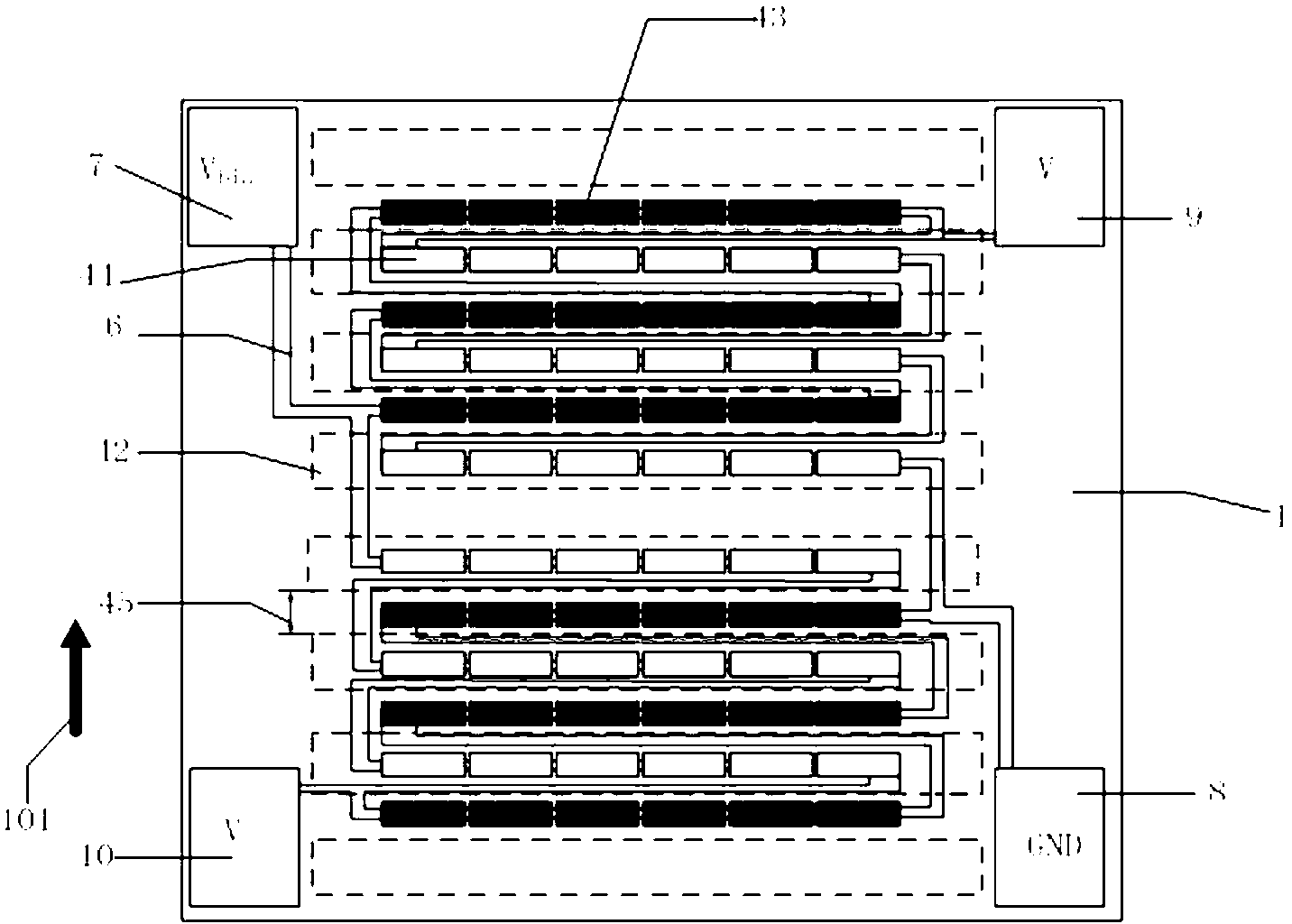

[0072] figure 2 It is a structural schematic diagram of the single-chip full-bridge magnetic field sensor of the present invention. The sensor includes a substrate 1, a Wheatstone full bridge deposited on the substrate 1, eight shielding structures 42 and four pads 7-10. The Wheatstone full bridge includes a first bridge arm and a second bridge arm electrically connected to each other, the first bridge arm includes a reference arm R1 and a sensing arm S1, the second bridge arm includes a reference arm R2 and a sensing arm S2, and the reference arm R1 R2 and R2 respectively include 3 rows of first reference element strings and 3 rows of second reference element strings, sensing arms S1 and S2 respectively include 3 rows of first sensing element strings and 3 rows of second sensing element strings, each reference element string and each Each sensing element string is composed of one or more identical magnetoresistive sensing elements electrically connected. The reference arm R...

Embodiment 2

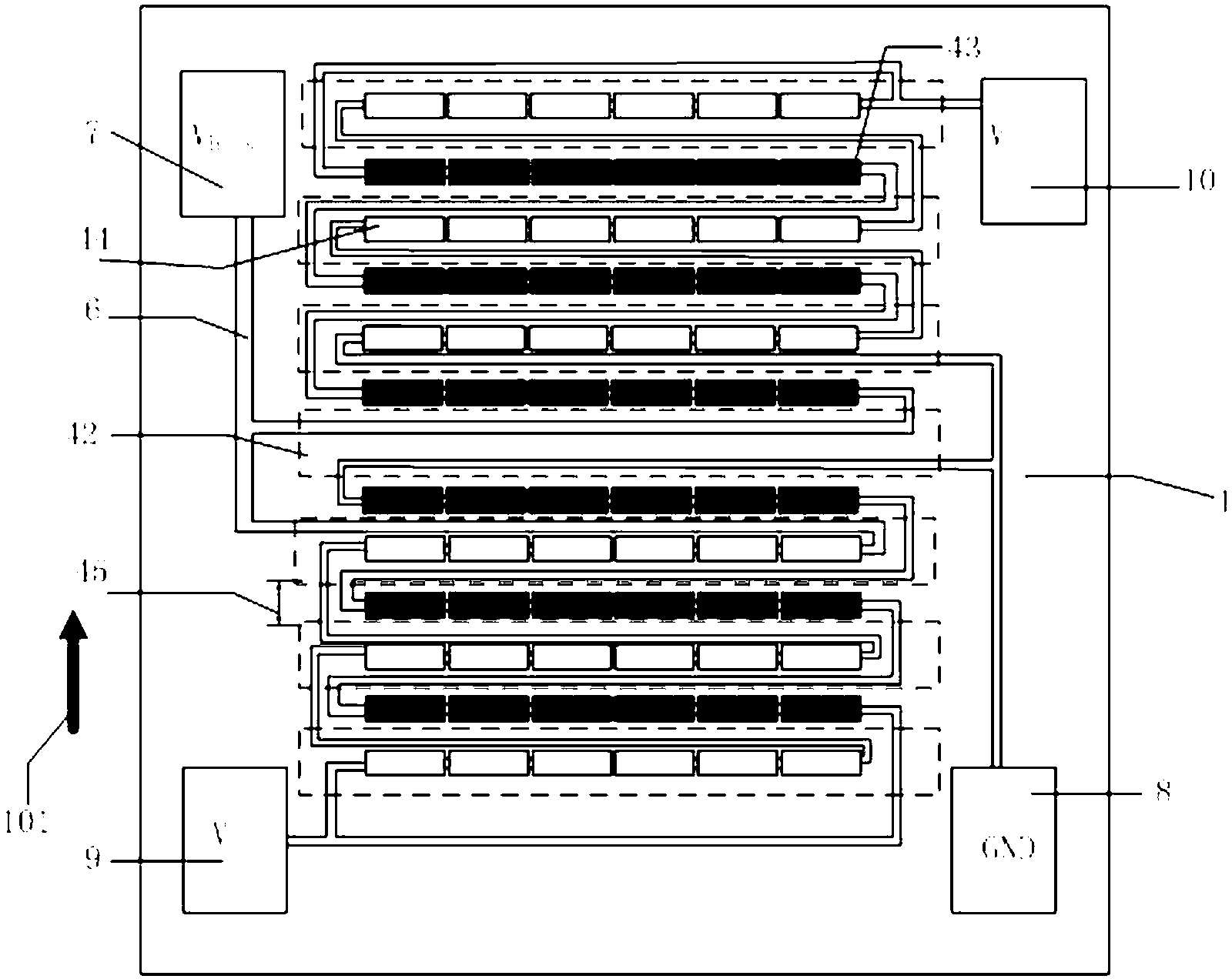

[0085] Figure 12 It is a structural schematic diagram of the single-chip half-bridge magnetic field sensor of the present invention. The sensor includes a substrate 1, a Wheatstone half bridge deposited on the substrate 1, six shielding structures 42 and three pads 7-9. The Wheatstone half-bridge includes a reference arm R1 and a sensing arm S1, each of which includes 3 rows of reference element strings 44 and 3 rows of sensing element strings 43, each reference element string 44 and each sensing element Each of the strings 43 is formed by electrically connecting one or more identical magnetoresistive sensing elements, 6 magnetoresistive sensing elements are shown in the figure. The reference element strings 44 and the sensing element strings 43 are arranged at intervals along the longitudinal direction, and the interval between two adjacent reference element strings 44 and the sensing element strings 43 is the same and is L. A certain gap 45 is provided between two shieldi...

Embodiment 3

[0089] The difference between this embodiment and the second embodiment is that a Wheatstone quasi-bridge circuit is used. The single-chip bridge magnetic field sensor includes three pads, and the three pads are respectively the first pad for ground bias and the first pad for ground bias. Based on the second pad and the third pad of the output, the Wheatstone quasi-bridge also includes two identical current sources (I1, I2), a reference arm R1 and a sensing arm S1, current sources (I1, I2), Each of the reference arm R1 and the sensing arm S1 has a first end and a second end, and the first pad is connected to the first end of the reference arm R1, the first end of the sensing arm S1 and the second end of the current source (I1, I2). One end is electrically connected, the second pad is electrically connected to the second end of the reference arm R1 and the second end of the current source I2, and the third pad is electrically connected to the second end of the sensing arm S1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com