Wireless passive temperature compensation method for film bulk acoustic wave pressure sensor

A thin-film bulk acoustic wave and pressure sensor technology, which is applied in the application of acoustic methods for fluid pressure measurement, fluid pressure measurement, instruments, etc., can solve the problems of high circuit requirements, difficult implementation, poor anti-interference ability, etc. The effect of low electromagnetic interference and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

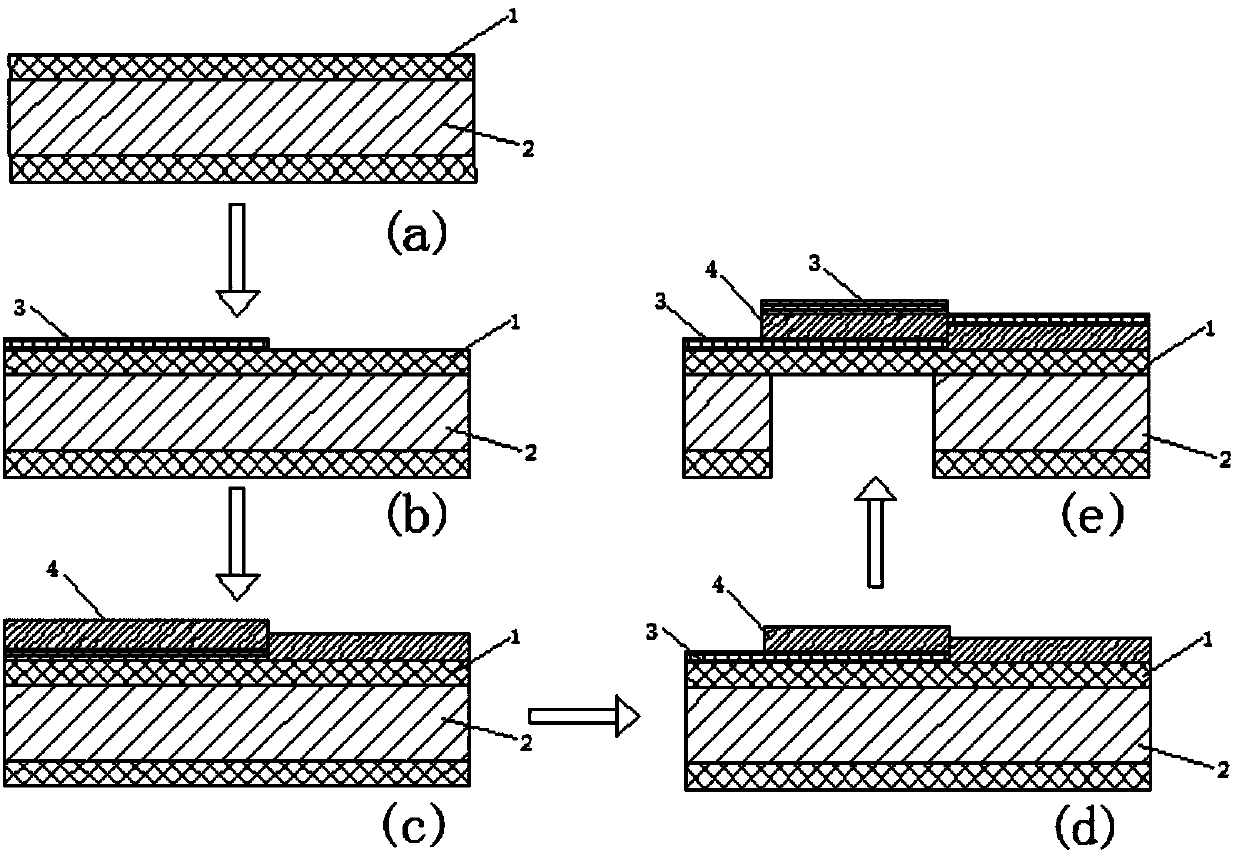

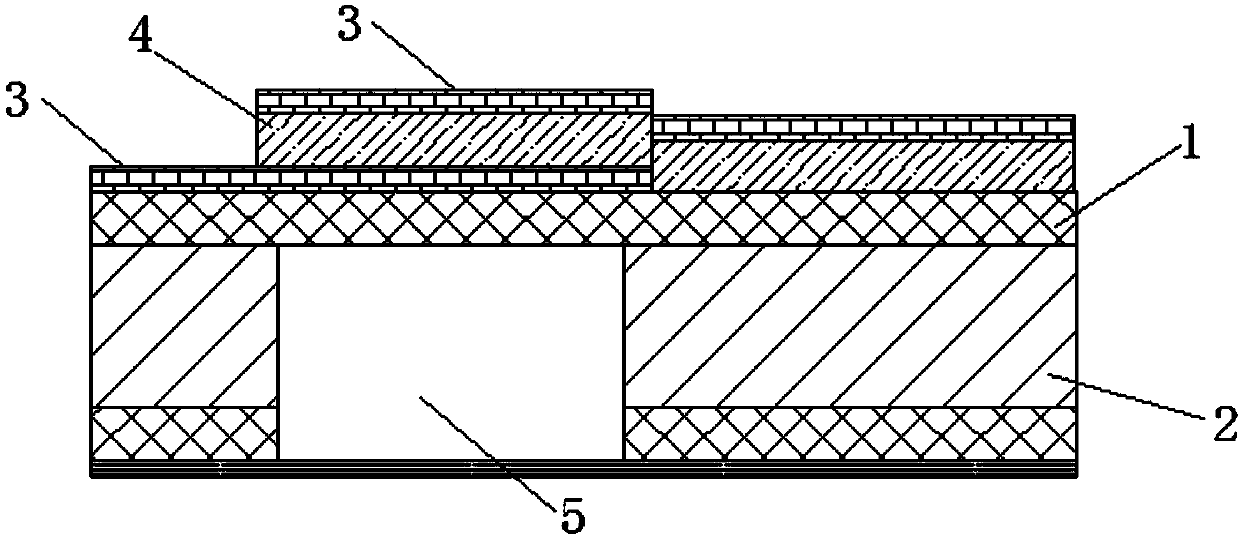

[0037] The preparation method of the non-sealed and sealed film bulk acoustic wave sensor comprises the following steps:

[0038] Step (1), double-sided polished silicon wafer and cleaned, then through the sequence of acetone, ethanol, deionized water, and finally dried by nitrogen, as figure 1 (a) shown.

[0039] Step (2), on the basis of step (1), adopt 60-500 nanometer thick aluminum (also can adopt gold, aluminum, tungsten, molybdenum etc.), utilize photolithography and etching to form the lower electrode of FBAR device, as figure 1 (b) shown.

[0040] Step (3), on the basis of step (2), adopt 50-5000 nanometer thick zinc oxide (also can be aluminum nitride, lithium niobate, lithium zirconate, lithium tantalate, lithium tetraborate, bismuth germanate , bismuth silicate, etc.) to make the piezoelectric layer, and use sputtering to form a deposited film, such as figure 1 (c) shown.

[0041] Step (4), on the basis of step (3), use diluted hydrochloric acid solution to exp...

Embodiment 1

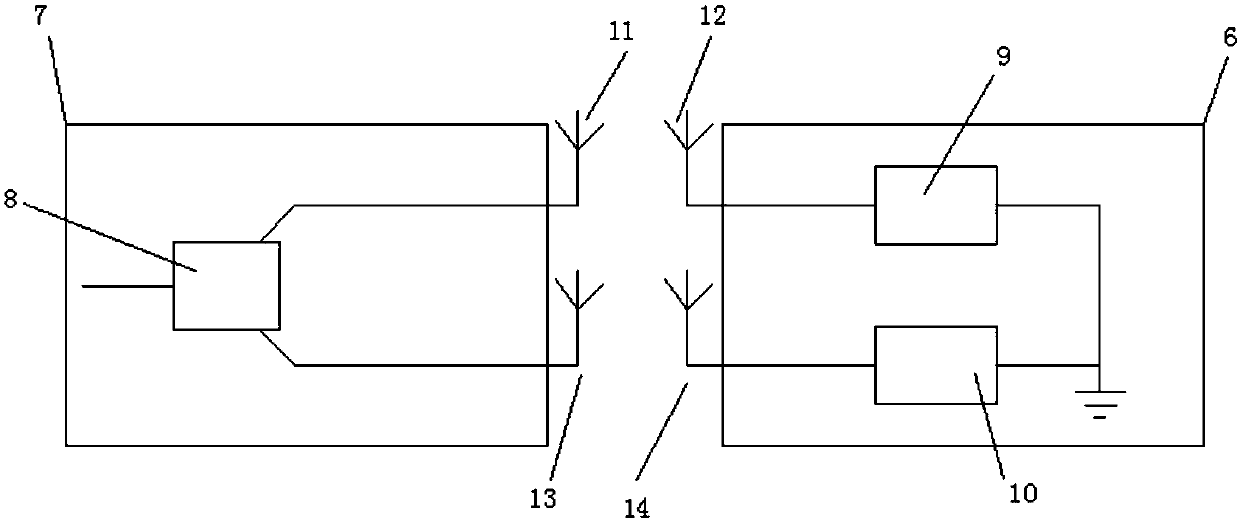

[0045] Example 1, such as image 3 :

[0046] a. The wireless pulse interrogation signal received by the outside through the directional antenna 12 and the directional antenna 14 excites the sealed thin-film bulk acoustic wave sensor 9 and the non-sealed thin-film bulk acoustic wave sensor 10 to work;

[0047] b. The excited sealed thin-film bulk acoustic wave sensor 9 is subjected to frequency deviation due to temperature and pressure in the environment. The frequency deviation occurs when the non-sealed thin-film BAW sensor 10 is subjected to the temperature in the environment. At this time, if the frequency of the external inquiry signal is consistent with the resonant frequency of a certain thin-film bulk acoustic wave sensor, the energy of the thin-film bulk acoustic wave sensor is maximum at this time. Finally, the resonant frequency of the thin film bulk acoustic wave sensor affected by the environment will be transmitted from the directional antenna 11 and the direct...

Embodiment 2

[0052] The two resonance frequencies of the sealed film bulk acoustic wave (FBAR) sensor and the non-sealed film bulk acoustic wave (FBAR) sensor are different, and the frequency deviation of the film bulk acoustic wave (FBAR) sensor with a low resonance frequency in the normal working range should be less than two The resonant frequency of the film bulk acoustic wave (FBAR) sensor is different, so as to avoid interference between frequencies (this example sets the non-sealed film bulk acoustic wave sensor 19 as a sensor with a low resonant frequency to describe the example conveniently, and it should be pointed out that 19 is not limited to one with a low resonant frequency thin film bulk acoustic wave sensor). Combine below Figure 4 The application diagram of the present invention is described:

[0053] a. The wireless pulse interrogation signal received by the outside world through the antenna 21 excites the sealed film BAW sensor 17 and the non-sealed film BAW sensor 19 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| frequency | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com