Preparation method of microalloyed high-strength precision nickel-chromium resistance alloy material

A micro-alloying and resistance alloying technology, applied in the field of metal materials, can solve the problems of mechanical properties, resistivity temperature coefficient of resistivity and foil surface quality that cannot meet the requirements of precision machining, achieve good surface quality, reduce impurity elements and gases Good content and processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

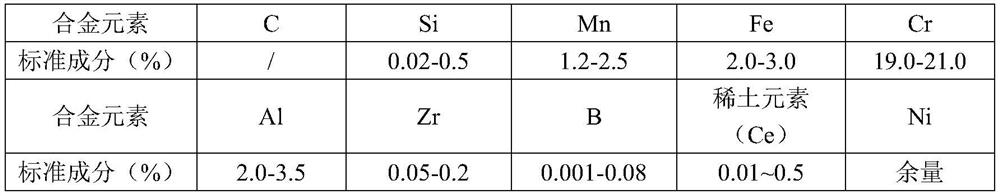

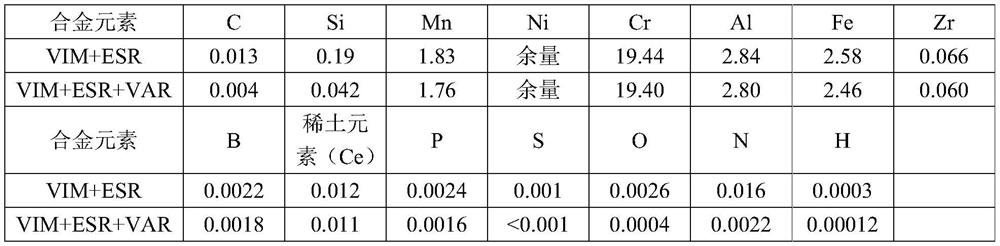

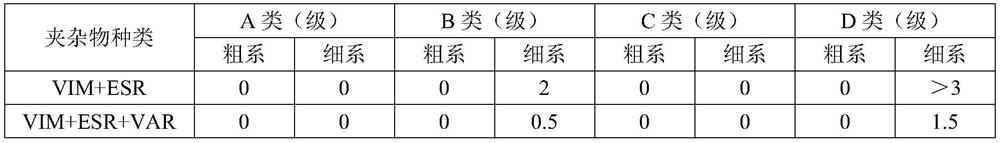

[0034] In the present embodiment, take each component of the microalloyed high-strength precision nickel-chromium resistance alloy material of the present invention according to the proportioning described in Table 1:

[0035] Table 1 chemical composition list (wt%)

[0036]

[0037] 1) Preparation of electrode rod:

[0038] Get each component according to table 1, dry at 200 DEG C for 6 to 8 hours; Ni, Cr, Fe are used as large materials, Si, Mn, Al, Zr, B, rare earth elements are used as small materials, and the rare earth elements are Ce.

[0039] Take the large material and carry out smelting. The smelting is divided into 5 times to raise the temperature. The first three times control the power transmission power to 30kW, 60kW and 100kW respectively, and the holding time is controlled at 5-10 minutes each time; 90 minutes; then control the transmission power to 180kW, keep warm for 60-90 minutes until the large material melts, and ensure that the vacuum degree is <20Pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com