Method for preparing film strain sensor

A strain sensor and thin film technology, applied in the direction of using electric/magnetic devices to transmit sensing components, electric/magnetic solid deformation measurement, and measurement of the property and force of piezoresistive materials, can solve problems such as large stress environment and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

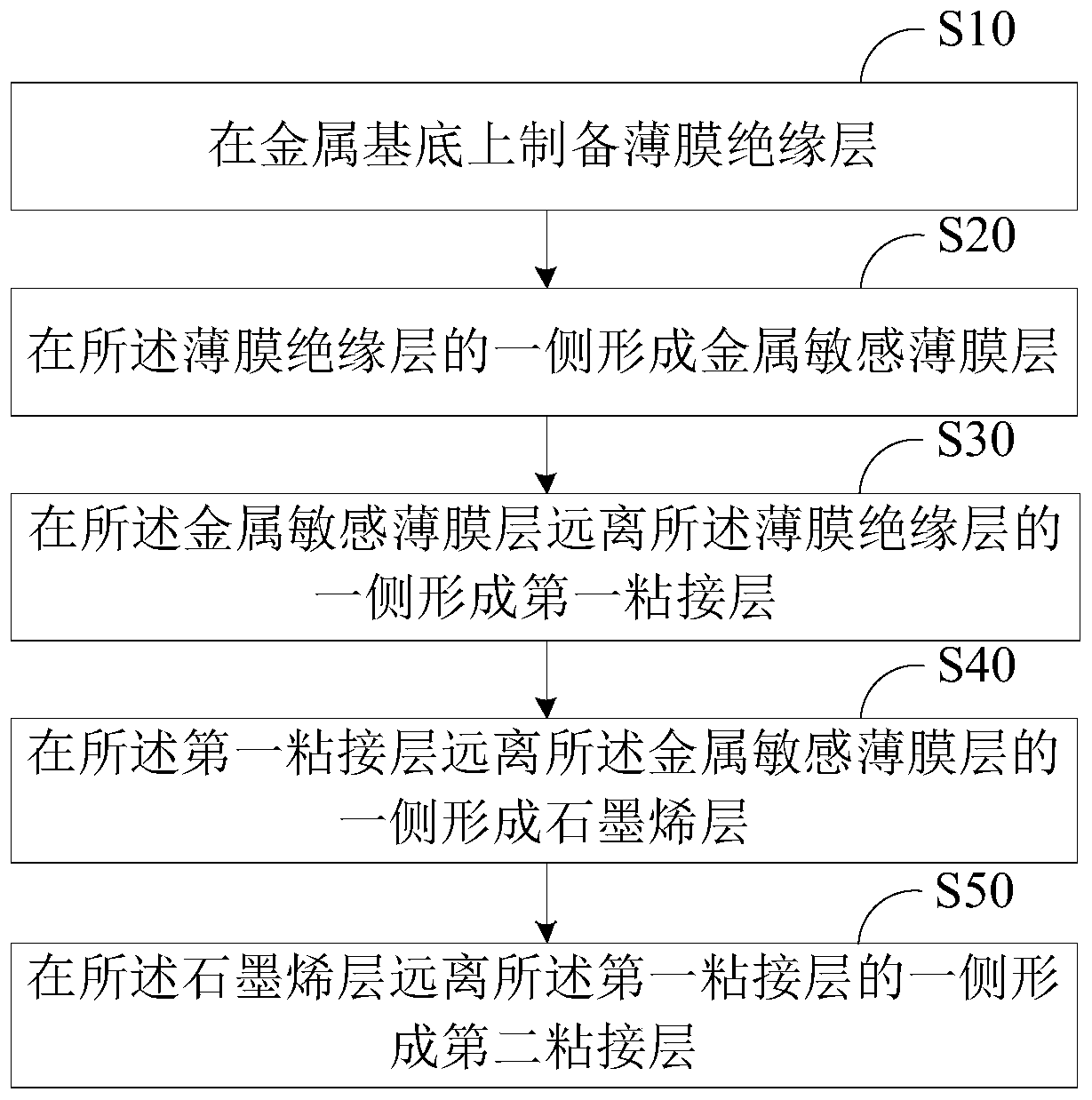

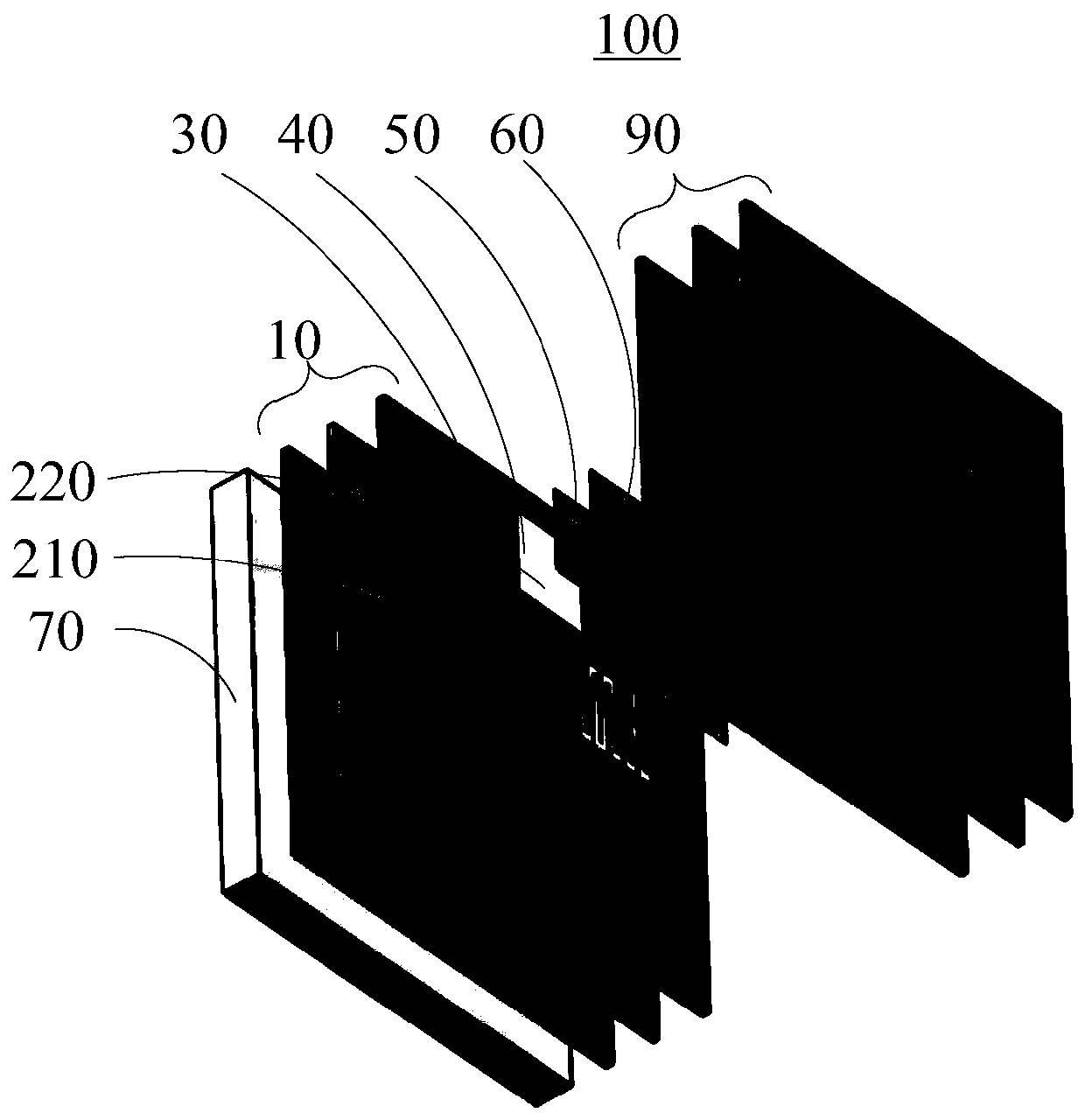

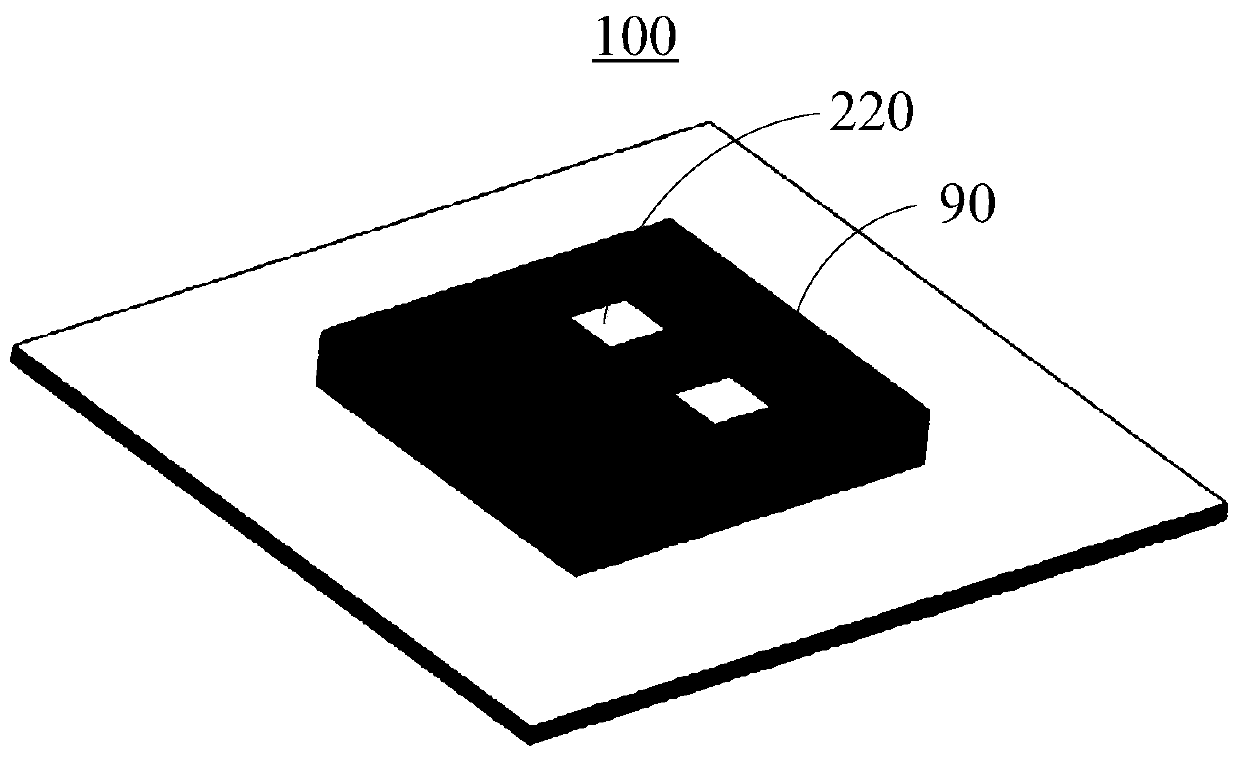

[0045] See Figure 1-Figure 3 , the present application provides a method for preparing a thin film strain sensor. The preparation method of the thin film strain sensor includes: step S10, preparing a thin film insulating layer 10 on the metal substrate. Step S20 , forming a metal-sensitive thin film layer 20 on one side of the thin-film insulating layer 10 . Step S30 , forming the first adhesive layer 30 on the side of the metal sensitive thin film layer 20 away from the thin film insulating layer 10 . Step S40 , forming a graphene layer 40 on the side of the first adhesive layer 30 away from the metal sensitive film layer 20 . Step S50 , forming a second adhesive layer 50 on a side of the graphene layer 40 away from the first adhesive layer 30 . Wherein, the metal-sensitive film layer 20 , the first adhesive layer 30 , the graphene layer 40 and the second adhesive layer 50 have the same shape and are sequentially stacked to form a resistance grid and an electrode connecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com