Preparation method and application of a kind of large strain hyperelastic pva/mcnts hydrogel

A hydrogel and superelastic technology, which is applied in the field of preparation of large strain superelastic PVA/MCNTS hydrogel, can solve the problems of poor conductivity and limitations of polyvinyl alcohol hydrogel, and achieve the solution of uneven distribution of carbon tubes, Effect of large strain and improvement of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

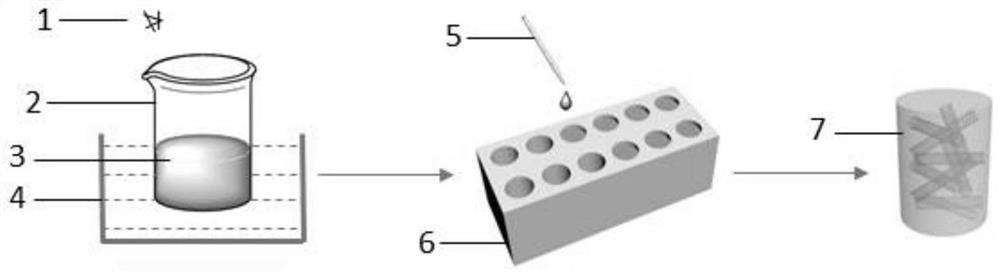

[0026] Such as figure 1 Shown, a kind of preparation method of large strain hyperelastic PVA / MCNTS hydrogel comprises the following steps:

[0027] 01. Adopt CVD tube furnace, use 100ml dichlorobenzene as carbon source, 0.6g ferrocene as catalyst, in the atmosphere of 2000sccm hydrogen and argon mixed gas, the reaction temperature is 850℃, grow disordered on the wall of quartz tube MCNTS powder;

[0028] 02. Soak the MCNTS powder in 20% dilute nitric acid for 12 hours. After acidification, the MCNTS powder is washed to neutrality by a suction filter and then separated from the solid and liquid. The separated MCNTS is dried in a vacuum oven at 60°C for 12 hours. The dried MCNTS powder is ground into finer particles with a mortar;

[0029] 03. Add 10g of PVA powder into 90ml of water, heat and stir in a water bath at 85°C for 3h to prepare a 10wt.% PVA aqueous solution, add the MCNTS powder treated in step 02 into the PVA aqueous solution, and heat in a water bath at 65°C for ...

Embodiment 1

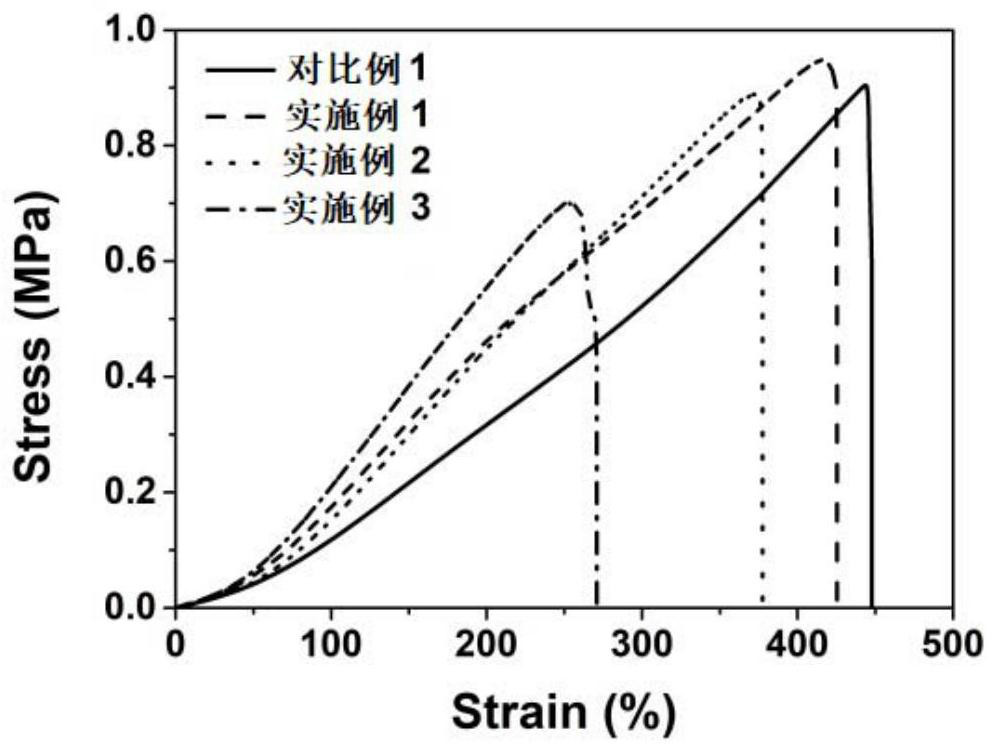

[0034] Add 10g of PVA powder into 90ml of water, heat and stir in a water bath at 85°C for 3h to obtain PVA in water. MCNTS powder was prepared by chemical vapor deposition. After the MCNTS powder was acidified, dried, and ground, 0.2 g of MCNTS powder was added to 30 ml of the PVA solution, heated and stirred in a water bath at 65° C. for 3 h, and the PVA / MCNTS mixed solution obtained was poured into a mold. It was frozen in the refrigerator for 12 hours, and then thawed at room temperature for 12 hours. The freezing and thawing process was repeated several times to obtain the PVA / MCNTS hydrogel.

Embodiment 2

[0036] Add 10g of PVA powder into 90ml of water, heat and stir in a water bath at 85°C for 3h to obtain PVA in water. MCNTS powder was prepared by chemical vapor deposition. After the MCNTS powder was acidified, dried and ground, 0.6g of MCNTS powder was added to 30ml of the PVA solution, heated and stirred in a water bath at 65°C for 3h, and the obtained PVA / MCNTS mixed solution was poured into the mold. It was frozen in the refrigerator for 12 hours, and then thawed at room temperature for 12 hours. The freezing and thawing process was repeated several times to obtain the PVA / MCNTS hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com