Aluminum alloy surface treatment method

A technology of aluminum alloy surface and treatment method, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, anodic oxidation, etc., which can solve the difficulty in balancing the quality and energy consumption of oxide film, the distribution of energy-consuming metal nanoparticles, and the easy generation of oxide film cracks and other problems to achieve the effect of solving the uneven distribution of metal nanoparticles, improving the distribution and migration of ions, and improving the uneven distribution of current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

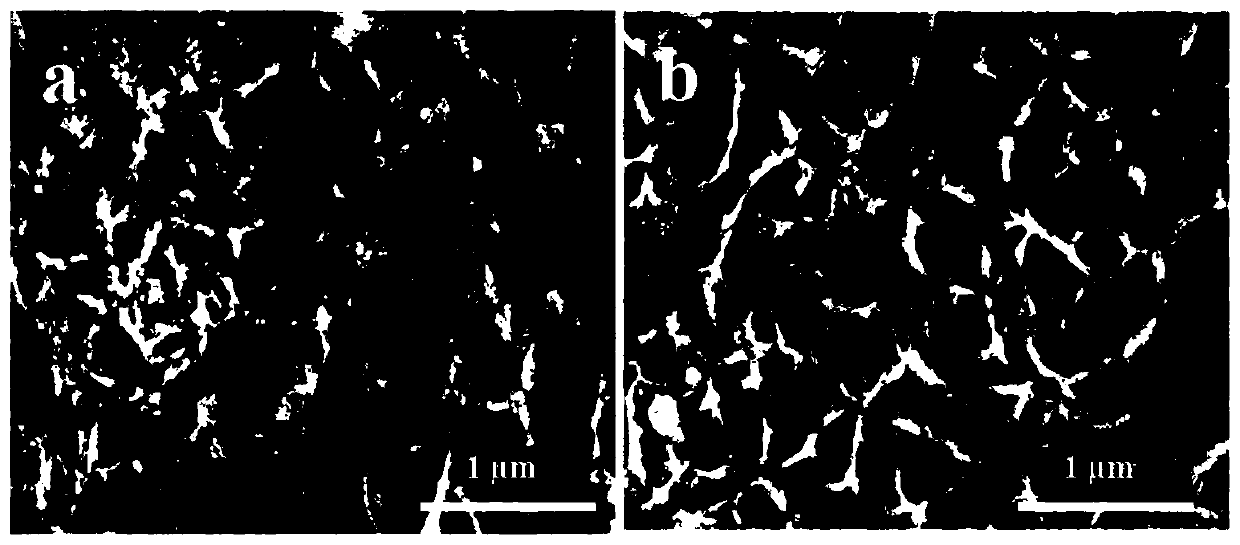

Image

Examples

Embodiment 1

[0026] Pretreatment: put the aluminum alloy sample in 30g / L NaOH, 0.2g / L C 12 h 25 SO 4 Na (sodium lauryl sulfate) and 1g / L C 6 h 11 NaO 7 (sodium gluconate) in the mixed solution of alkali washing for 3min; the sample after alkali washing is rinsed with deionized water, put into 10% H 2 SO 4 and 4% HNO 3 Pickling in the mixed solution for 5 minutes to obtain an aluminum alloy sample with a smooth surface and active chemical properties, which is ready for use.

[0027] S1: Put the pretreated aluminum alloy sample into an anodizing tank filled with sulfuric acid solution (170g / L), and use 1.2A / dm 2 The direct current, and the auxiliary power of 80W ultrasonic wave is anodized for 30min, and the intermediate A is obtained, and the oxidation temperature is 15°C; Adjust the ultrasonic power to 20W for 2 minutes, and then slowly adjust to 80W for the rest of the anodic oxidation;

[0028] S2: Rinse the intermediate A obtained after anodic oxidation with deionized water, pu...

Embodiment 2

[0031] Pretreatment: put the aluminum alloy sample in 30g / L NaOH, 0.2g / L C 12 h 25 SO 4 Na and 1g / LC 6 h 11 NaO 7 Wash with alkali in the mixed solution for 3 minutes; rinse the sample after alkali washing with deionized water, put in 10% H 2 SO 4 and 4% HNO 3 Pickling in the mixed solution for 5 minutes to obtain an aluminum alloy sample with a smooth surface and active chemical properties, which is ready for use.

[0032] S1: Put the pretreated aluminum alloy sample into an anodic oxidation tank filled with sulfuric acid solution (170g / L), using 1.4A / dm 2 The direct current, and the auxiliary power of 80W ultrasonic wave is anodized for 30min, and the intermediate A is obtained, and the oxidation temperature is 20°C; Adjust the ultrasonic power to 20W for 2 minutes, and then slowly adjust to 80W for the rest of the anodic oxidation;

[0033] S2: Rinse the intermediate A obtained after anodic oxidation with deionized water, put it into a 4 Electrolytic coloring solu...

Embodiment 3

[0036] Pretreatment: put the aluminum alloy sample in 30g / L NaOH, 0.2g / L C 12 h 25 SO 4 Na and 1g / LC 6 h 11 NaO 7 Wash with alkali in the mixed solution for 3 minutes; rinse the sample after alkali washing with deionized water, put in 10% H 2 SO 4 and 4% HNO 3 Pickling in the mixed solution for 5 minutes to obtain an aluminum alloy sample with a smooth surface and active chemical properties, which is ready for use.

[0037] S1: Put the pretreated aluminum alloy sample into an anodic oxidation tank filled with sulfuric acid solution (170g / L), and use 1.7A / dm 2 DC, and an auxiliary power of 80W ultrasonic wave was anodized for 30 minutes to obtain intermediate A, and the oxidation temperature was 25°C; Adjust the ultrasonic power to 20W for 2 minutes, and then slowly adjust to 80W for the rest of the anodic oxidation;

[0038] S2: Rinse the intermediate A obtained after anodic oxidation with deionized water, put it into a 4 Electrolytic coloring solution with main salt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com