Pressure column pressure wheel axle structure with built-in pressure sensors

A pressure sensor and pressure wheel shaft technology, which is applied in the direction of material forming presses, presses, instruments, etc., can solve the problems of inability to timely feedback pressure detection values, cumbersome installation of pressure sensors, affecting the accuracy of pressure detection, etc. Mechanical connection structure, avoiding errors, and the effect of small mechanical lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, further illustrate the present invention.

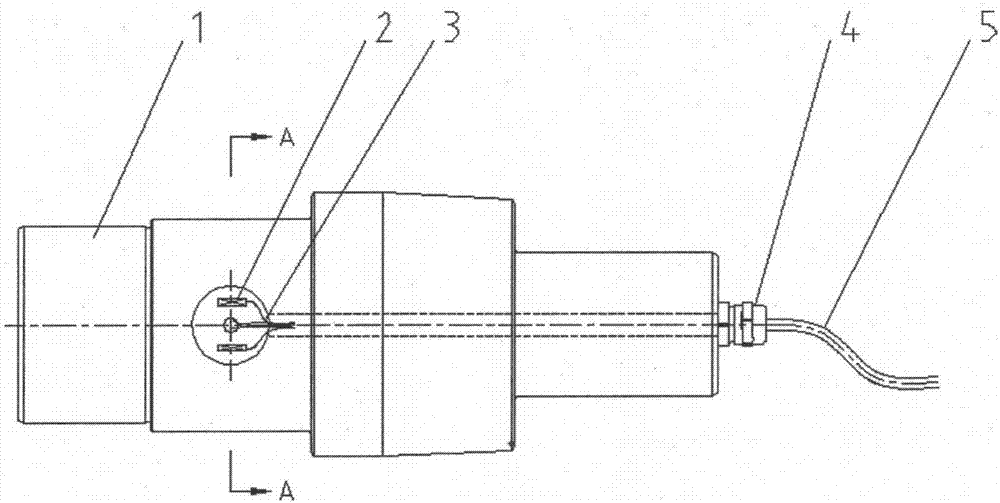

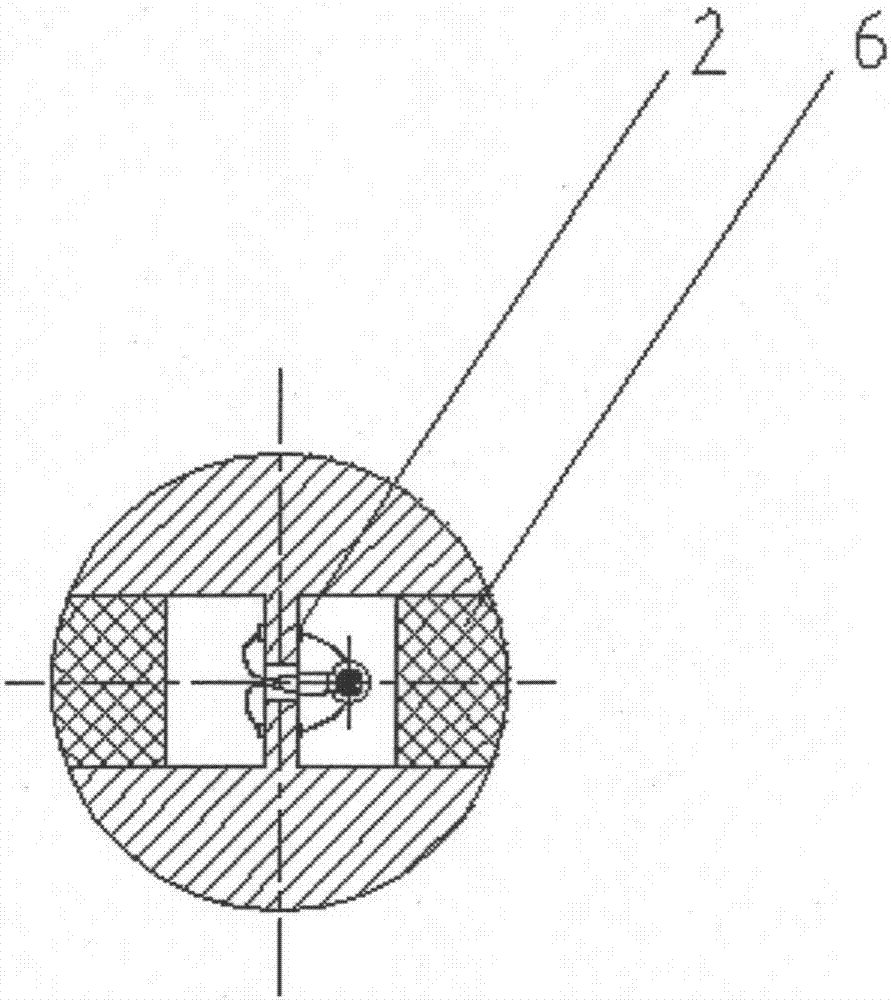

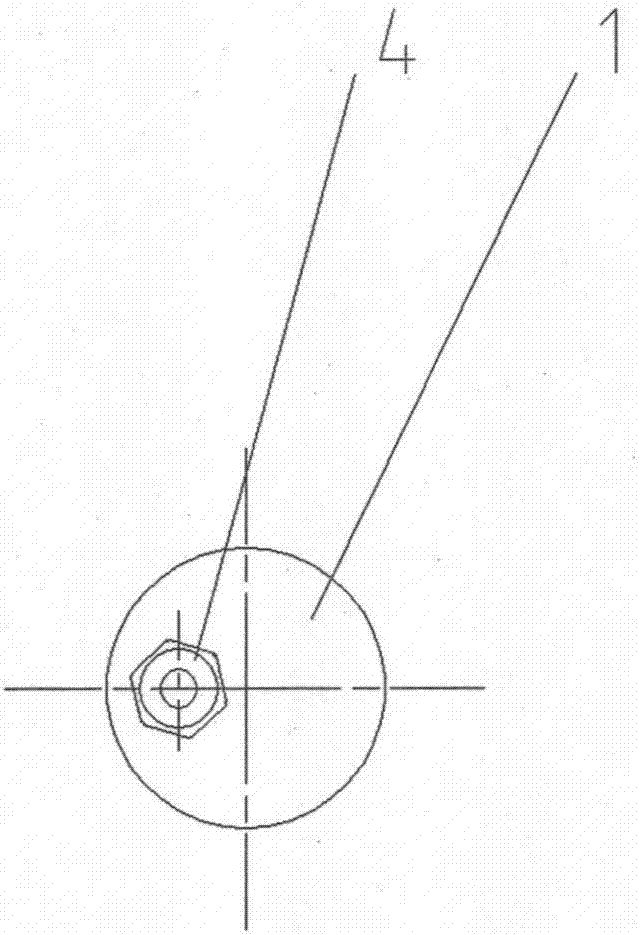

[0023] figure 1 with figure 1 The structure schematic diagram of the pressure column pinch wheel shaft with built-in pressure sensor provided for this embodiment, the structure of the pressure column pinch wheel shaft with built-in pressure sensor is composed of the following parts:

[0024] The pressure roller shaft body 1 is used as a carrier for the installation of the pressure sensor;

[0025] The pressure strain gauge 2 realizes the sensing part of the pressure detection;

[0026] Wire 3, a carrier for signal transmission;

[0027] The cable 5 is used to tighten the wire 3 to form an integral component;

[0028] Cable connector 4, used to fix the cable 5 on the pressure roller shaft body 1;

[0029] The silicone protective cover 6 is used for isolating the pressure strain gauge 2 from the outside world to achieve protection.

[0030] The processing process of the pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com