High-performance optical-fiber built-in intelligent composite material and preparation method thereof

A fiber composite material and composite material technology, applied in the field of high-performance optical fiber built-in smart composite materials and their preparation, can solve the problems of increasing the degree of fiber damage and slip, spectral distortion, double hyperrefractive spectrum, etc. Effects of Compatibility and Mechanical Matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

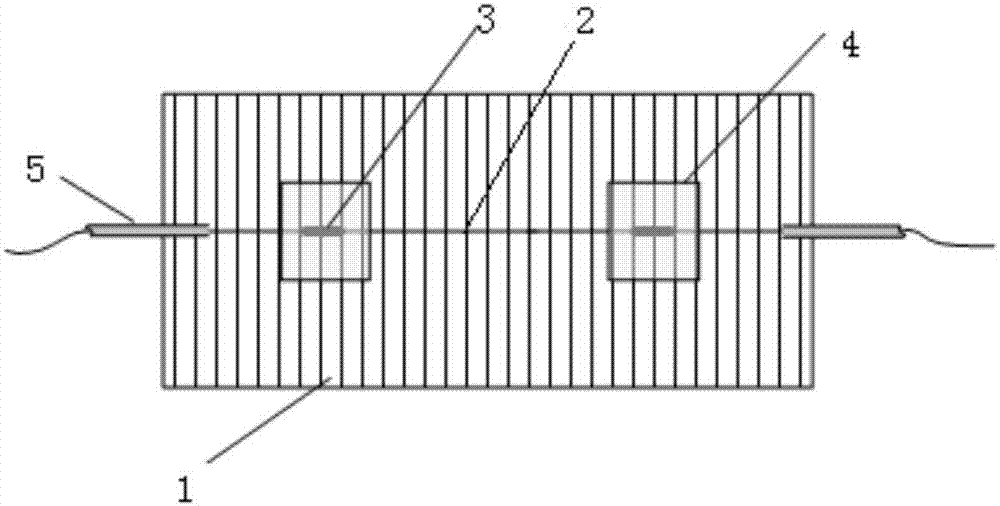

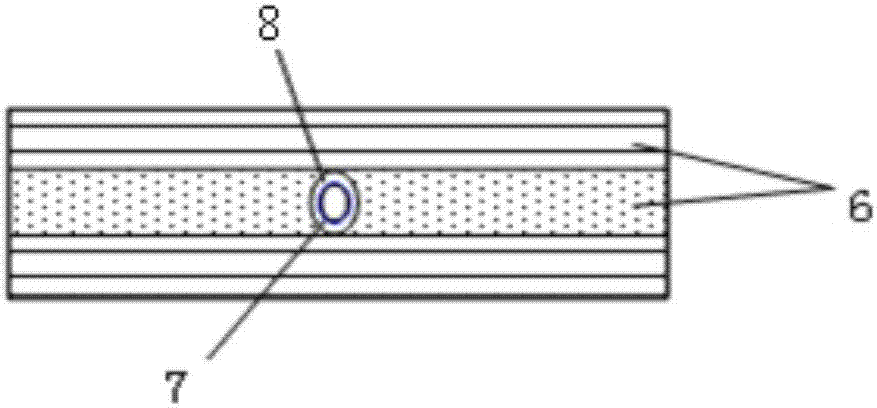

[0054] A high-performance optical fiber built-in carbon fiber smart composite material, including: fiber composite material, sensing fiber grating, pigtail protection sleeve, the sensing fiber grating is built in the middle layer of carbon fiber-epoxy resin composite material, carbon fiber and The direction of the optical fiber is at an angle of 0°, the sensing fiber grating is coated with a 10 μm thick polyimide coating, the outer layer of the fiber grating grating area is coated with epoxy resin adhesive coating, and the fiber grating grating area after coating protection is set outside The epoxy resin film is pre-fixed, and the pigtail part of the optical fiber is provided with a Teflon pigtail protective sleeve, and the outer diameter of the sleeve is 1mm.

Embodiment 2

[0056] A high-performance optical fiber built-in carbon fiber intelligent composite material, including: fiber composite material, sensing fiber grating, pigtail protection sleeve, the sensing fiber grating is built in the middle layer of glass fiber-phenolic resin composite material, carbon fiber and The direction of the optical fiber is at an angle of 90°, the sensing fiber grating is coated with 60μm thick acrylate coating, the outer layer of the fiber grating grating area is coated with phenolic resin adhesive coating, and the outer layer of the fiber grating grating area after coating protection is provided with phenolic resin resin The adhesive film is pre-fixed, and the pigtail part of the optical fiber is provided with a Teflon pigtail protective sleeve, and the outer diameter of the sleeve is 1mm.

Embodiment 3

[0058] A high-performance optical fiber built-in carbon fiber smart composite material, including: fiber composite material, sensing optical fiber grating, pigtail protective sleeve, the sensing optical fiber grating is built in the upper layer of carbon fiber-vinyl resin composite material, carbon fiber and optical fiber The direction is at an angle of 45°. The sensing fiber grating is covered with a 25 μm thick polyimide coating. The outer layer of the fiber grating is coated with vinyl resin adhesive coating. The base resin film is pre-fixed, and the pigtail part of the optical fiber is provided with a Teflon pigtail protective sleeve, and the outer diameter of the sleeve is 1mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com