Fiber grating sensor insert for detection of plastic thick plate products and manufacturing method thereof

A fiber grating and a manufacturing method technology are applied in the field of fiber grating sensor inserts for detection of plastic thick plate products and their manufacturing fields, which can solve the problem that the optical fiber connector cannot guarantee all the coupling of the light energy of the emitted optical fiber, and achieves a reliable connection problem. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

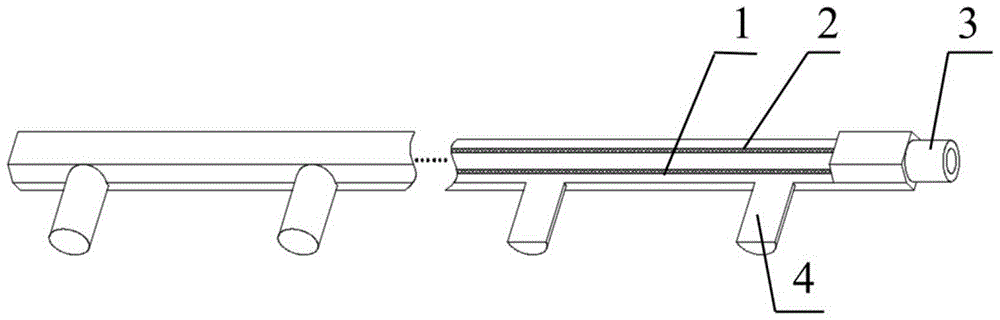

[0055] A fiber grating sensor insert for on-line temperature and strain monitoring of the filter plate of a filter press

[0056] (1) Select two optical fibers that have been engraved with gratings, coat the stainless steel capillary in the grating unit area of one of them, and seal the tube mouth with glue to form a temperature fiber grating sensor, and the other fiber grating without stainless steel capillary is a strain fiber grating sensor.

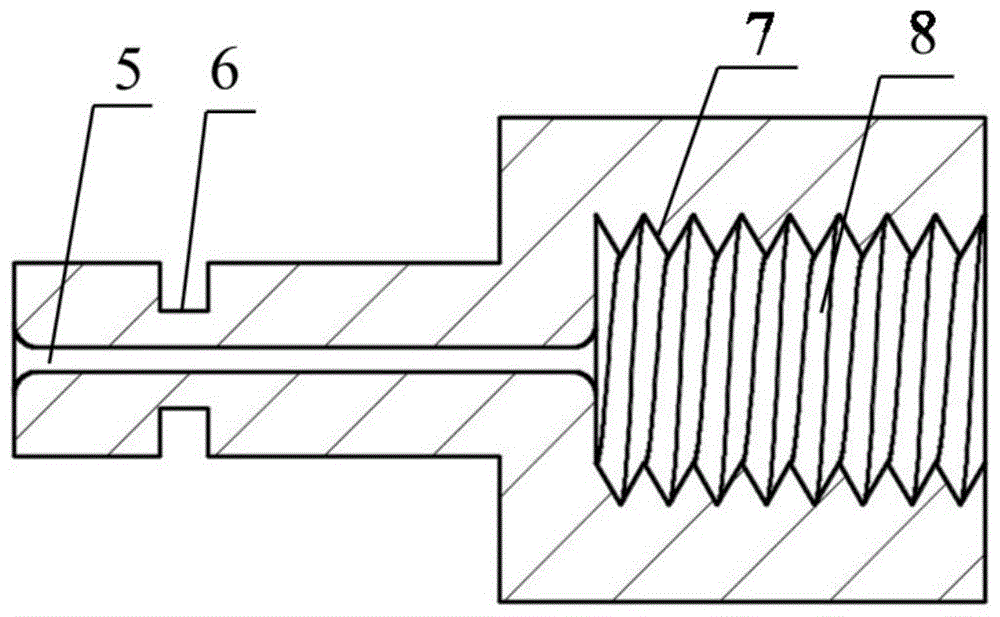

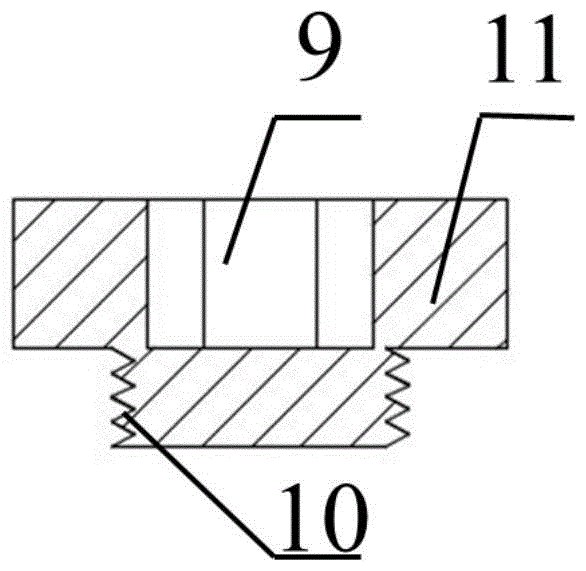

[0057] (2) According to the size requirements of the filter plate, a rod-shaped grating packager is manufactured, and the embedded joint of the optical fiber connector is pre-installed on both ends of the packaging mold through the insert fixing mechanism of the mold.

[0058] (3) Put a temperature fiber grating sensor and a strain fiber grating sensor side by side, put them into the package mold for preparing the rod-shaped fiber grating sensor insert, and the two ends of the optical fiber pass through the embedded fiber optic conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com