Composite shear wall and steel truss composite beam connection energy dissipation node and its preparation method

A combined shear wall and steel truss technology, applied in the direction of truss beams, truss structures, walls, etc., can solve the problem that the bending moment and shear force of the connecting beam are difficult to effectively transmit the shear wall, and the welding area is prone to bending and tearing , increase the difficulty of construction operations, etc., to solve the problem of reliable connection, easy to guarantee the construction quality, and realize the effect of convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

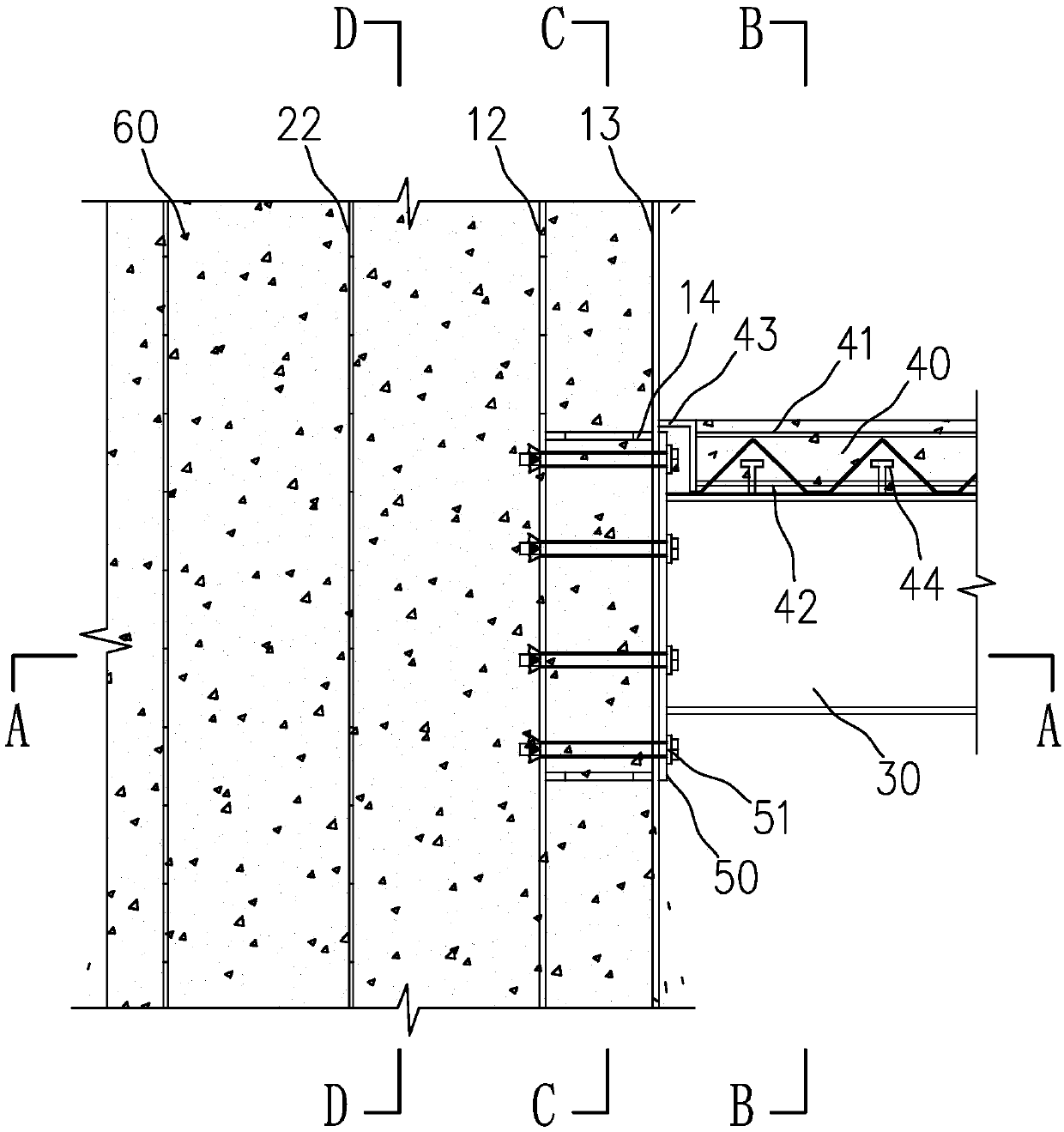

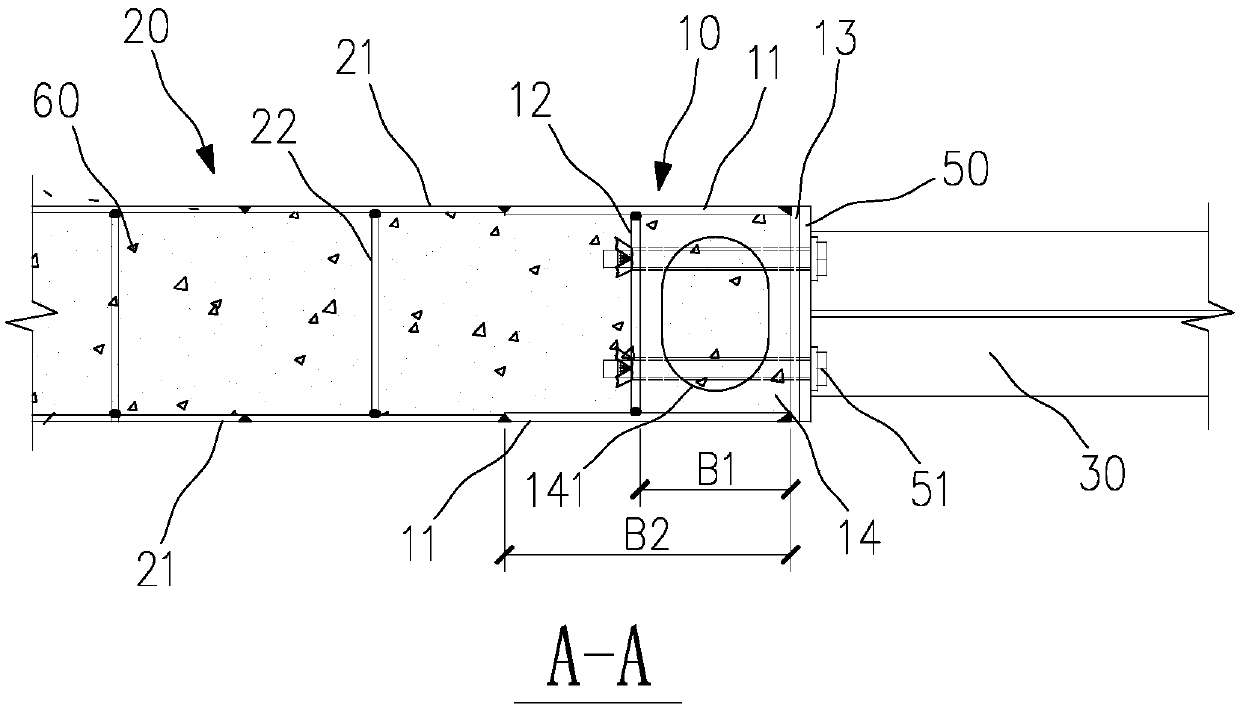

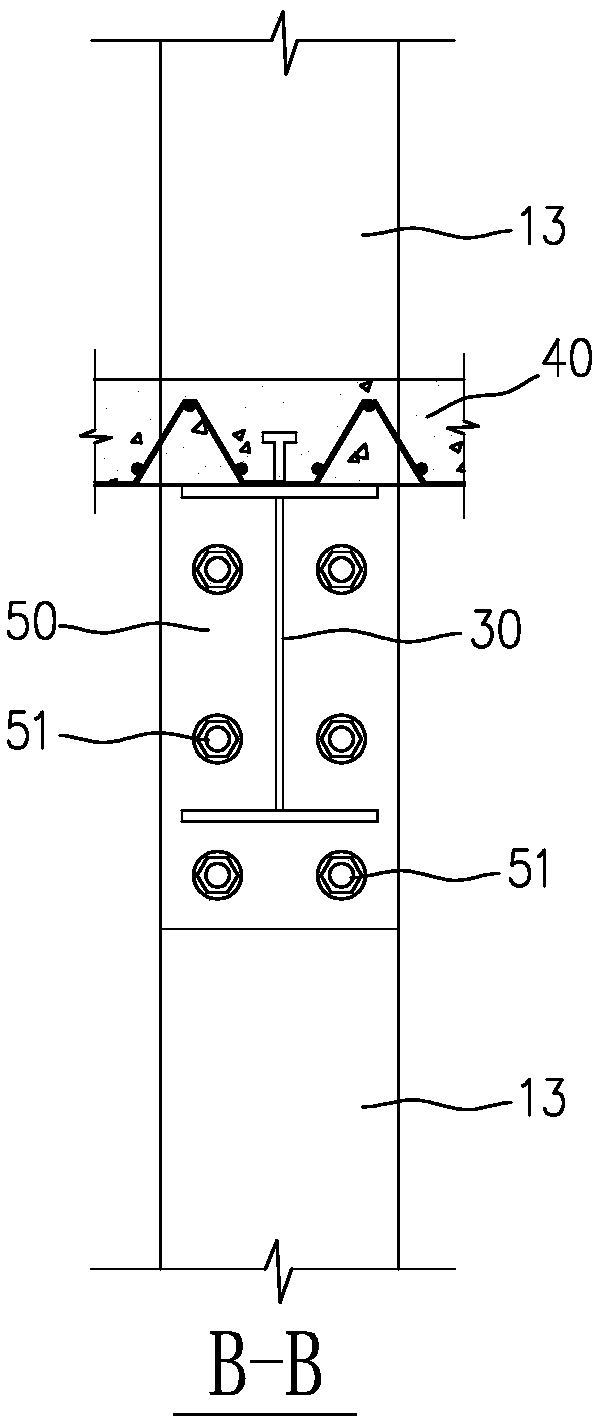

[0048] Such as Figure 1~5 As shown, a composite shear wall is connected to an energy-dissipating node with a steel truss composite beam, the composite shear wall is a steel cavity structure unit filled with concrete 60 inside, and the end of the steel cavity structure unit is provided with The edge reinforced column 10 is conveniently connected with the steel truss composite beam, and the steel truss composite beam is connected with the edge reinforced column 10 through the energy dissipation metal plate 50 and the metal connector 51 to form a hybrid connection energy dissipation node.

[0049] Such as figure 1 As shown, the steel cavity structure unit includes a s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com